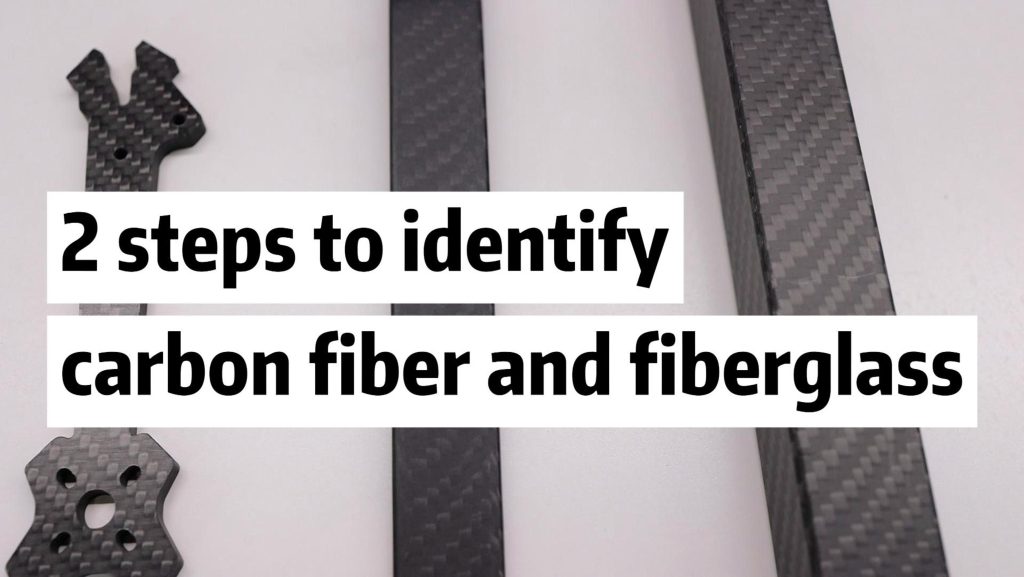

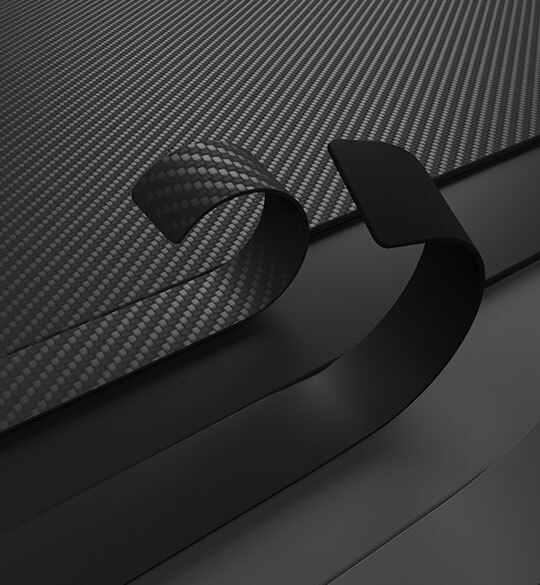

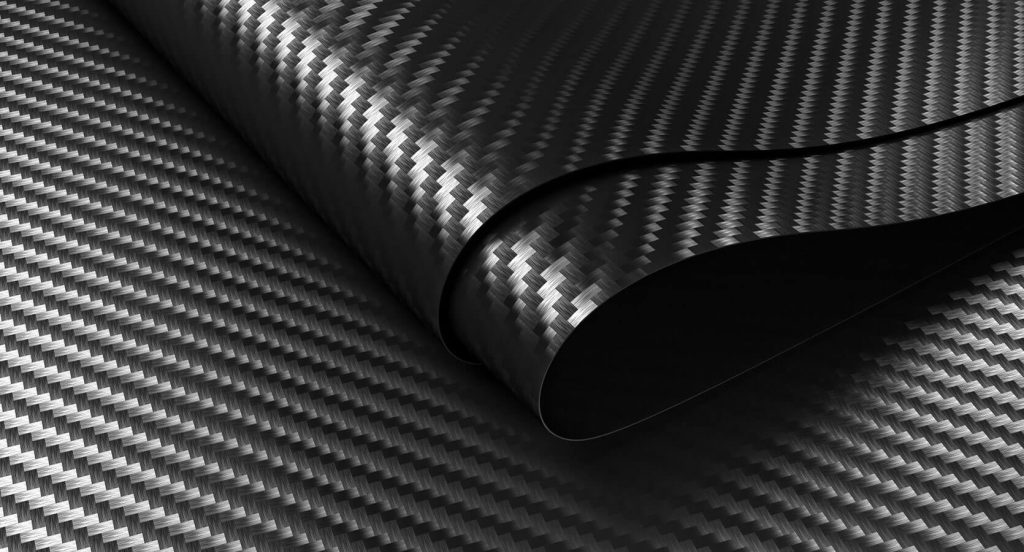

Carbon Fiber

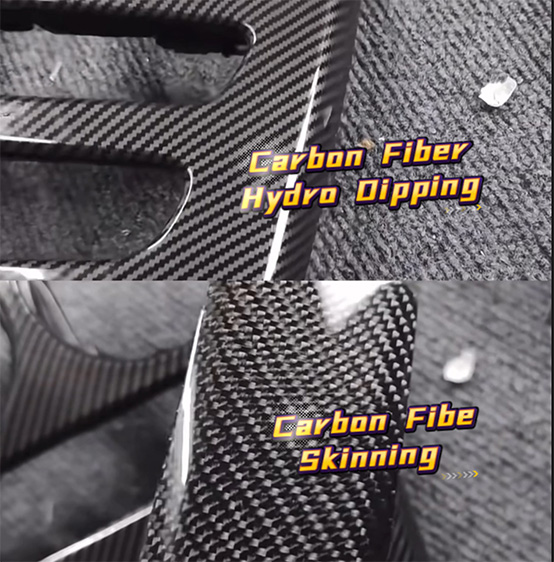

Carbon Fiber Finishes

Carbon fiber finished products are designed with various processes such as compression molding, CNC, or injection molding, using carbon fiber as raw materials. One of the significant advantages of these products is their lightweight, high strength, and customizability, making them highly sought after in several industries.

Get A Quote

-1.png)