Ultra-high Molecular Weight Polyethylene in Defense Industry

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Ultra-high molecular weight polyethylene (UHMWPE) fiber, commonly known as high-strength and high-module polyethylene fiber, represents the latest breakthrough in high-performance fibers, following the development of carbon fiber and aramid fiber. UHMWPE fiber boasts incredible strength and durability, making it a top choice for various industries. UHMWPE is an exceptional high-performance fiber material that boasts the highest specific strength and specific modulus of any commercially available fiber. This incredible fiber is spun from polyethylene resin with a molecular weight exceeding 1 million (compared to ordinary polyethylene with a molecular weight of generally 4-12 million).

This material boasts a higher elongation at break compared to carbon fiber and aramid. Its flexibility is excellent, and it maintains strong mechanical properties even at high strain rates and low temperatures. Furthermore, it showcases superior impact resistance when compared to carbon fiber, aramid, and other materials. As a result, it is an exceptional choice for bulletproof and stab-resistant safety gear.

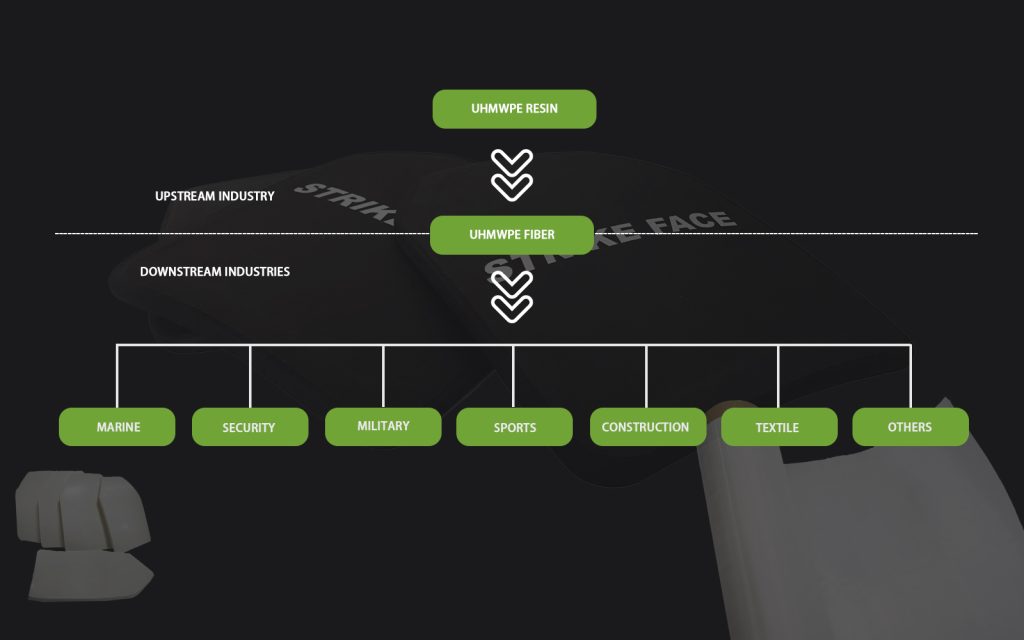

UHMWPE has many excellent properties such as ultra-high strength, ultra-high modulus, low density, and wear resistance. It is widely used in military equipment, marine industry, safety protection, sports equipment and other fields. my country's ultra-high molecular weight polyethylene fiber production capacity has exceeded 50% of the world's total production capacity. However, domestic ultra-high molecular weight polyethylene fiber overall shows a surplus of mid- and low-end production capacity and a shortage of high-end production capacity. This situation is gradually improving. The traditional demand for UHMWPE fiber has not decreased, and in recent years, the increase in investment in defense equipment worldwide is expected to take the lead in driving the demand for UHMWPE fiber.

Because ultra-high molecular weight polyethylene fiber has the advantages of good impact resistance, high specific energy absorption, light weight, and a wide operating temperature range, it can be used in armor protection (bulletproof) panels of helicopters/tanks/ships, and radars. Protective shell covers, missile covers, shields, parachutes, bulletproof helmets, body armor and other different products. The proportion of military expenditures in GDP of many countries, including the United States, the European Union, Russia, and China, has increased in recent years, driving a slight increase in the proportion of global military expenditures in GDP. The increase in defense expenditures will greatly promote the production of ultra-high molecular weight polyethylene fiber needs.