Main Differences Between Dry Carbon Fiber And Wet Carbon Fiber

Welcome to our article where we explore the main differences between dry carbon fiber and wet carbon fiber. If you're interested in lightweight and high strength carbon fiber, this is the article for you. We'll discuss the characteristics, manufacturing processes, and applications of both dry and wet carbon fiber.

But first, a quick introduction. Contact us at info@ictfibers.com or via WhatsApp at +86 15057108966 if you have any questions or need further information.

Now, let's dive in!

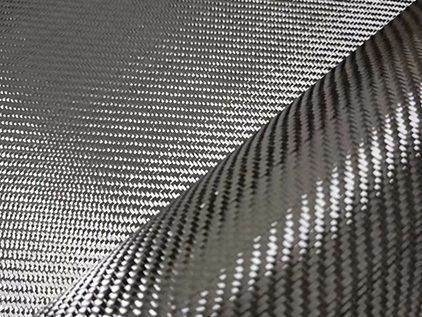

What is Dry Carbon Fiber?

Dry carbon fiber is a type of carbon fiber material that is known for its lightweight nature and high strength. It is commonly used in various industries, including automotive and aerospace, due to its exceptional properties.

Unlike wet carbon fiber, which is impregnated with resin during the manufacturing process, dry carbon fiber is produced without the use of resin. This results in a material that has a higher fiber-to-resin ratio, making it lighter and stronger.

The manufacturing process of dry carbon fiber involves layering carbon fiber sheets and applying pressure and heat. This helps to ensure that the fibers are tightly woven together, improving their strength and rigidity.

Due to its lightweight and high strength characteristics, dry carbon fiber finds applications in a wide range of products and components. It is commonly used in the manufacturing of sports equipment, automotive parts, aerospace components, and even luxury goods.

Some of the key benefits of dry carbon fiber include:

- Lightweight: Dry carbon fiber's low density makes it a preferred choice in industries where weight reduction is crucial.

- High strength: The tightly woven fibers and absence of resin contribute to the exceptional strength of dry carbon fiber.

- Stiffness: Dry carbon fiber exhibits high rigidity, making it ideal for applications that require stiffness and stability.

- Corrosion resistance: Carbon fiber is inherently resistant to corrosion, improving the durability and lifespan of products made from dry carbon fiber.

Overall, dry carbon fiber offers a unique combination of lightness and strength, making it an excellent material choice for industries that require high-performance components.

Contact us: info@ictfibers.com, WhatsApp: +86 15057108966.

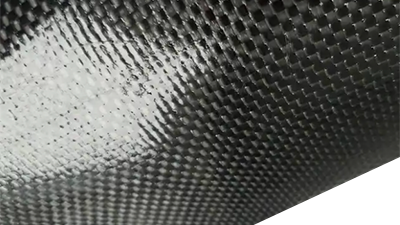

What is Wet Carbon Fiber?

Wet carbon fiber, just like dry carbon fiber, is a material renowned for its exceptional strength and lightweight properties. However, unlike dry carbon fiber, wet carbon fiber is manufactured using a different process that involves impregnating carbon fiber fabric with resin.

During the production of wet carbon fiber, the carbon fiber fabric is soaked or "wetted" with resin, which is typically epoxy. This resin acts as a binding agent, strengthening the carbon fiber and providing it with added durability and impact resistance.

Compared to dry carbon fiber, wet carbon fiber offers several unique advantages. The resin in wet carbon fiber enhances the material's stiffness and toughness, making it ideal for applications requiring greater structural integrity.

Manufacturing Process

The manufacturing process of wet carbon fiber involves several steps:

- Carbon fiber fabric is laid out in the desired pattern or shape.

- The fabric is then infused with resin, ensuring the fibers are fully saturated.

- The excess resin is removed through a process known as "vacuum bagging" to achieve the optimal resin-to-fiber ratio.

- The wet carbon fiber is cured at a specific temperature and pressure, allowing the resin to harden.

- The cured wet carbon fiber can then be further processed or used as-is for various applications.

It's important to note that the manufacturing process of wet carbon fiber can result in a higher volume fraction of resin compared to dry carbon fiber. This higher resin content improves the material's ability to absorb energy and withstand impact, making it ideal for applications in industries such as aerospace, sports equipment, and marine.

Overall, wet carbon fiber offers a versatile and durable alternative to dry carbon fiber, providing enhanced mechanical properties and allowing for greater customization in terms of design and performance.

| Properties | Wet Carbon Fiber | Dry Carbon Fiber |

|---|---|---|

| Manufacturing Process | Impregnated with resin during production | Infused with resin after production |

| Resin Content | Higher volume fraction of resin | Lower volume fraction of resin |

| Strength | Enhanced stiffness and toughness | High strength-to-weight ratio |

| Applications | Aerospace, sports equipment, marine | Automotive, construction, renewable energy |

If you're interested in learning more about wet carbon fiber or want to explore its potential applications, feel free to reach out to us at info@ictfibers.com or message us on WhatsApp at +86 15057108966.

Manufacturing Processes of Dry Carbon Fiber

When it comes to producing dry carbon fiber, several manufacturing processes are involved. These processes play a crucial role in creating the lightweight and high-strength material that is widely used in various industries. Understanding the steps involved can provide valuable insights into the production of dry carbon fiber and its unique properties.

Step 1: Preparation of Carbon Fiber Sheets

In the first step, carbon fiber sheets are prepared. These sheets are made by aligning thousands of carbon fiber strands together to form a strong and uniform material. This process involves coating the carbon fibers with a protective layer to ensure their stability and prevent fraying during subsequent manufacturing steps.

Step 2: Resin Application

Once the carbon fiber sheets are prepared, a resin is applied to them. The resin acts as a binding agent, holding the carbon fibers together and providing additional strength and stability to the final product. Resins can be epoxy-based or thermoplastic, depending on the desired characteristics of the dry carbon fiber.

The application of resin is crucial in the manufacturing process of dry carbon fiber. It helps to create a strong bond between the carbon fibers, resulting in a material that is both lightweight and durable.

Step 3: Compression and Curing

After the resin is applied, the carbon fiber sheets are carefully compressed and placed in a mold. The mold ensures that the sheets, along with the applied resin, maintain the desired shape and form. This compression process helps to eliminate any air pockets, ensuring a solid and uniform structure.

Once the sheets are in the mold, they undergo curing, which involves subjecting the material to heat, pressure, or a combination of both. This process allows the resin to harden, forming a rigid and stable matrix that encases the carbon fibers.

Step 4: Finishing and Quality Control

After curing, the dry carbon fiber material is carefully inspected for any imperfections or defects. Any excess material is trimmed and smoothed out, ensuring a clean and precise finish.

Quality control measures are implemented to ensure that the manufactured dry carbon fiber meets the required specifications and standards. This includes checking for dimensional accuracy, structural integrity, and overall quality.

| Benefits of Dry Carbon Fiber Manufacturing | Limitations of Dry Carbon Fiber Manufacturing |

|---|---|

| Lightweight natureHigh strength-to-weight ratioExcellent stiffnessResistance to corrosion and chemicalsDiverse applicability | High manufacturing costsLabor-intensive processRequires specialized equipment and expertiseLimited scalabilityPotential issues with delamination |

Despite its limitations, the manufacturing processes of dry carbon fiber result in a material that offers exceptional performance and versatility. With its unique combination of lightweight and high strength properties, dry carbon fiber continues to revolutionize industries such as automotive, aerospace, sports equipment, and many others.

Contact us at info@ictfibers.com or via WhatsApp at +86 15057108966 to learn more about our dry carbon fiber manufacturing capabilities.

Manufacturing Processes of Wet Carbon Fiber

In this section, we will explore the manufacturing processes used for wet carbon fiber and examine how the resin is impregnated into the carbon fiber fabric. Wet carbon fiber manufacturing involves the infusion of resin into the fibers, allowing for a more controlled and precise application.

This process begins with the laying of carbon fiber fabric, which is then combined with a resin solution in a mold. The resin is spread evenly over the fabric, ensuring proper saturation and impregnation. This method allows for better adherence between the fibers and the resin, resulting in a finished product with enhanced overall strength and structural integrity.

Wet carbon fiber manufacturing offers several advantages over other methods. By impregnating the fabric with resin, it allows for a more uniform distribution of the resin throughout the structure, resulting in consistent mechanical properties. This method also enables easier molding of complex shapes, making it a popular choice in industries such as automotive, aerospace, and sports equipment manufacturing.

However, wet carbon fiber manufacturing does have some limitations. The addition of resin during the manufacturing process can increase the weight of the final product compared to dry carbon fiber composites. This can be a disadvantage in applications where weight reduction is a critical factor, such as in the aerospace industry. Additionally, the wet manufacturing process generally requires longer curing times, which can impact production efficiency.

To summarize, wet carbon fiber manufacturing involves impregnating the carbon fiber fabric with resin, resulting in a stronger and more structurally sound final product. While it offers advantages such as improved strength and easier molding of complex shapes, it may not be suitable for applications where weight reduction is essential or when shorter production times are required.

| Advantages of Wet Carbon Fiber Manufacturing | Disadvantages of Wet Carbon Fiber Manufacturing |

|---|---|

| - More uniform resin distribution | - Increased weight compared to dry carbon fiber composites |

| - Enhanced overall strength | - Longer curing times |

| - Easier molding of complex shapes |

Contact us:

Email: info@ictfibers.com

WhatsApp: +86 15057108966

Strength and Lightness of Dry Carbon Fiber

Dry carbon fiber is known for its exceptional strength and lightness, making it a highly sought-after material in various industries. Its unique properties contribute to a remarkable strength-to-weight ratio, making it ideal for applications where both strength and lightness are crucial.

The lightweight nature of dry carbon fiber allows for significant weight reduction in various products, leading to improved performance and fuel efficiency. This is especially valuable in industries such as aerospace, automotive, and sporting goods, where reducing weight can have a significant impact on speed, agility, and overall performance.

"Dry carbon fiber offers a winning combination of strength and lightness, making it an excellent choice for high-performance applications."

In addition to its lightweight properties, dry carbon fiber also exhibits exceptional strength. With its high tensile strength and stiffness, it provides excellent structural integrity and enhances the durability of the products it is used in. This strength is crucial in industries where safety and reliability are paramount, such as aerospace, defense, and marine applications.

The unique properties of dry carbon fiber have led to its use in a wide range of industries and applications. From aerospace components like aircraft wings and fuselages to automotive parts like body panels and chassis reinforcements, dry carbon fiber is widely utilized for its combination of high strength and lightness.

Furthermore, dry carbon fiber can be used in the manufacturing of sporting goods like tennis rackets, golf clubs, and bicycles, where its lightness and strength contribute to improved performance.

Performance Comparison: Dry Carbon Fiber vs. Wet Carbon Fiber

When comparing dry carbon fiber to wet carbon fiber, the dry variant often holds the advantage in terms of strength and lightness. The manufacturing process of dry carbon fiber allows for a more controlled and consistent distribution of resin, resulting in a higher fiber-to-resin ratio.

This higher fiber-to-resin ratio translates to increased strength and stiffness, making dry carbon fiber the preferred choice where maximum performance and lightweight design are desired. Wet carbon fiber, on the other hand, typically has a lower fiber-to-resin ratio due to the impregnation process, which can result in slightly reduced strength and increased weight.

| Dry Carbon Fiber | Wet Carbon Fiber |

|---|---|

| High strength | Relative strength |

| Lightweight | Slightly heavier |

| Controlled resin distribution | Impregnation process |

Table: Strength and Lightness Comparison of Dry Carbon Fiber and Wet Carbon Fiber

Overall, dry carbon fiber offers a compelling combination of strength and lightness, making it an excellent choice for high-performance applications where weight reduction and durability are paramount. Its properties make it a prized material in industries such as aerospace, automotive, and sporting goods, where every ounce matters for achieving optimal performance.

For more information about dry carbon fiber, its manufacturing processes, and applications, feel free to contact us at info@ictfibers.com or reach out through WhatsApp at +86 15057108966.

Strength and Lightness of Wet Carbon Fiber

When it comes to strength and lightness, wet carbon fiber holds its ground against its dry carbon fiber counterpart. The manufacturing process of wet carbon fiber plays a crucial role in shaping its properties, allowing it to excel in various applications.

Wet carbon fiber, like its dry counterpart, boasts high strength and a lightweight construction. However, the presence of resin in wet carbon fiber offers additional benefits, enhancing its strength and durability. The resin infusion process used in manufacturing wet carbon fiber ensures a thorough impregnation of resin into the carbon fiber fabric, resulting in a cohesive and robust structure.

"The wet carbon fiber manufacturing process allows for improved resin distribution, resulting in a stronger and more impact-resistant material."

This infusion of resin enables wet carbon fiber to exhibit exceptional stiffness and rigidity, making it ideal for applications that require high strength and structural integrity. Its lightweight nature also contributes to reducing the overall weight of components and structures, enabling enhanced performance and fuel efficiency in industries such as automotive, aerospace, and sports.

The inherent strength and lightweight characteristics of wet carbon fiber make it an excellent choice for applications where the demands for both strength and weight reduction are critical. Some common applications of wet carbon fiber include:

- Automotive body panels and structural components

- Aerospace components, such as aircraft wings and fuselage parts

- Sports equipment, including bicycle frames and tennis rackets

- Marine components, such as boat hulls and masts

By leveraging the strength and lightness of wet carbon fiber, manufacturers can achieve significant performance improvements in their products. Whether it's enhancing the speed and maneuverability of a race car or reducing the weight of an aircraft to increase its payload capacity, wet carbon fiber delivers exceptional results.

To learn more about wet carbon fiber, its properties, and its applications, contact us at info@ictfibers.com or reach out to us on WhatsApp at +86 15057108966.

| Advantages of Wet Carbon Fiber | Disadvantages of Wet Carbon Fiber |

|---|---|

| Enhanced strength and impact resistanceImproved resin distributionExcellent stiffness and rigidityWide range of applications | Longer manufacturing processHigher cost compared to dry carbon fiberRequires skilled labor for proper resin infusion |

Applications of Dry Carbon Fiber

Dry carbon fiber is widely utilized in various industries due to its unique properties and numerous advantages. Here are some of the key applications where dry carbon fiber is commonly used:

- Automotive Components: Dry carbon fiber is extensively used in the automotive industry for manufacturing lightweight and durable components. It is commonly employed in the production of body panels, interior trims, aerodynamic parts, and chassis structures. The exceptional strength-to-weight ratio of dry carbon fiber enhances the overall performance and fuel efficiency of vehicles.

- Aerospace: The aerospace industry relies heavily on dry carbon fiber for its exceptional strength and lightweight characteristics. It is utilized in the construction of aircraft parts such as wings, fuselage sections, tail components, and interior fittings. Dry carbon fiber's high strength properties make it essential for ensuring the structural integrity of aerospace equipment.

- Sports and Recreation: Dry carbon fiber finds extensive applications in the sports and recreation field. It is used in the manufacturing of sporting goods such as bicycles, tennis rackets, golf club shafts, and hockey sticks. The lightweight nature of dry carbon fiber enhances performance and maneuverability for athletes, while its high strength offers durability and reliability.

- Medical Equipment: Dry carbon fiber is increasingly being adopted in the medical industry for various applications. It is used in medical equipment, prosthetics, braces, and orthopedic devices. Dry carbon fiber's lightweight properties and high strength make it an ideal choice for developing functional and comfortable medical solutions.

These are just a few examples of the wide-ranging applications of dry carbon fiber. Its versatile nature and exceptional properties make it a preferred choice in industries that require lightweight, high-strength materials. By utilizing dry carbon fiber, manufacturers can achieve enhanced performance, improved efficiency, and superior durability in their products.

For more information about dry carbon fiber and its applications, contact us at info@ictfibers.com or reach us via WhatsApp at +86 15057108966.

Applications of Wet Carbon Fiber

Wet carbon fiber offers a range of applications in various industries, providing unique advantages over dry carbon fiber in specific scenarios. The wet carbon fiber manufacturing process allows for greater customization and adaptability, making it a preferred choice in certain applications.

1. Automotive Industry

In the automotive industry, wet carbon fiber composites are widely used for body panels, interior components, and structural reinforcements. The wet infusion process enables seamless integration of carbon fiber into complex shapes, improving overall vehicle performance, fuel efficiency, and safety.

2. Aerospace and Aviation

Wet carbon fiber is extensively employed in the aerospace and aviation sectors for manufacturing aircraft components, such as wings, fuselages, and tail sections. Its high strength-to-weight ratio enhances fuel efficiency, reduces overall weight, and increases structural integrity, ensuring safe and reliable air travel.

3. Marine Industry

Wet carbon fiber finds applications in the marine industry for building lightweight and durable watercraft, including boats and yachts. Its exceptional resistance to corrosion and ability to withstand harsh marine environments make it an ideal choice for hulls, mast sections, and other structural components.

4. Sports and Recreation

With its excellent strength and lightweight properties, wet carbon fibers are widely used in sports and recreational equipment production. From tennis rackets and fishing rods to bicycle frames and hockey sticks, wet carbon fiber offers enhanced performance, durability, and maneuverability for athletes and enthusiasts.

5. Construction and Infrastructure

Wet carbon fiber is increasingly being utilized in the construction industry, particularly for reinforcing concrete structures and strengthening bridges. The high tensile strength and corrosion resistance of wet carbon fiber make it an excellent choice for enhancing structural integrity while minimizing weight.

These are just a few examples of the diverse applications of wet carbon fiber. From transportation to sports, and even in architectural advancements, wet carbon fiber continues to push the boundaries of what is possible with its unique characteristics and manufacturing process.

Conclusion

In summary, the main differences between dry carbon fiber and wet carbon fiber lie in their manufacturing processes and resulting properties. Dry carbon fiber is produced by layering carbon fiber sheets and applying resin, while wet carbon fiber involves impregnating the carbon fiber fabric with resin. This distinction affects the final product's characteristics.

Dry carbon fiber is known for its lightweight nature and high strength, making it ideal for applications where weight reduction and durability are paramount, such as in the automotive and aerospace industries. On the other hand, wet carbon fiber offers a more cost-effective manufacturing process and can be suitable for applications that prioritize cost-efficiency over the highest strength-to-weight ratio.

When choosing between dry carbon fiber and wet carbon fiber, it is important to consider specific requirements and application needs. If lightweight and high strength are crucial, dry carbon fiber may be the optimal choice. However, if cost-effectiveness is a priority without compromising performance, wet carbon fiber can be a viable alternative.

For more information on dry carbon fiber, wet carbon fiber, carbon fiber properties, and carbon fiber manufacturing, please contact us at info@ictfibers.com or via WhatsApp at +86 15057108966.

FAQ

What are the main differences between dry carbon fiber and wet carbon fiber?

Dry carbon fiber refers to carbon fiber sheets that are pre-impregnated with resin and do not require additional resin application during the manufacturing process. Wet carbon fiber, on the other hand, involves the resin being applied to the carbon fiber fabric during the manufacturing process. The choice between dry and wet carbon fiber depends on factors such as manufacturing requirements, desired properties, and application needs.

What is dry carbon fiber?

Dry carbon fiber refers to carbon fiber sheets that are pre-impregnated with resin before the manufacturing process. It is known for its lightweight nature and high strength. Dry carbon fiber is commonly used in various industries, including automotive and aerospace, where its properties contribute to improved performance and fuel efficiency.

What is wet carbon fiber?

Wet carbon fiber involves the resin being applied to the carbon fiber fabric during the manufacturing process. This method allows for more flexibility in shaping the final product. Wet carbon fiber differs from dry carbon fiber in terms of its manufacturing process and the properties it exhibits.

What are the manufacturing processes of dry carbon fiber?

The manufacturing processes of dry carbon fiber involve the use of pre-impregnated carbon fiber sheets. These sheets are typically layered and cured under pressure to create the desired shape and form. The application of resin occurs prior to the curing process. The benefits of this method include better control over resin distribution and reduced waste.

What are the manufacturing processes of wet carbon fiber?

Wet carbon fiber manufacturing involves impregnating carbon fiber fabric with resin during the manufacturing process. The resin is applied to the dry fabric, saturating it to create a composite material. This method allows for more flexibility in shaping the final product. However, it requires careful attention to resin distribution and curing to ensure optimal strength and performance.

How does dry carbon fiber compare to wet carbon fiber in terms of strength and lightness?

Dry carbon fiber is known for its high strength-to-weight ratio, making it incredibly strong and lightweight. This is achieved through the precise application of resin during the manufacturing process. Wet carbon fiber, while also exhibiting strength and lightness, may have slightly different properties due to the resin impregnation process. The choice between the two depends on specific application needs and requirements.

What are the applications of dry carbon fiber?

Dry carbon fiber finds applications in various industries, including automotive components, aerospace structures, sporting goods, and high-performance equipment. The lightweight and high strength properties of dry carbon fiber make it suitable for applications where weight reduction, durability, and performance are crucial.

What are the applications of wet carbon fiber?

Wet carbon fiber is commonly used in industries such as marine, architecture, and medical, where the flexibility of shaping the final product is essential. It is often preferred for applications that require complex geometries and custom designs. Wet carbon fiber can be molded into intricate shapes, allowing for greater design freedom.

What are the key differences between dry carbon fiber and wet carbon fiber?

In summary, dry carbon fiber is pre-impregnated with resin before the manufacturing process, while wet carbon fiber involves the resin being applied during the process. Dry carbon fiber is characterized by its lightweight nature and high strength, making it suitable for various applications. Wet carbon fiber offers more flexibility in shaping the final product and is commonly used in industries that require complex geometries and custom designs.