Why Carbon Fiber Is So Expensive

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Carbon fiber has gained immense popularity in various industries due to its unique combination of lightweight agility and high strength. From automotive to aerospace applications, carbon fiber has become a game-changer, revolutionizing the way products are designed and manufactured.

But why is carbon fiber so expensive? The answer lies in its exceptional properties and the complex fabrication process it undergoes. Let's dive deeper into the world of carbon fiber to unravel the secrets behind its high cost and understand why it is worth every penny.

Key Takeaways

- Carbon fiber is a lightweight material with high strength, making it an ideal choice for industries seeking performance and efficiency.

- Its cost is justified by the remarkable properties it offers, such as enhanced fuel efficiency in the automotive sector and increased safety in aerospace applications.

- The fabrication process of carbon fiber involves intricate steps and cutting-edge technology, contributing to the overall cost.

- Ongoing advancements in carbon fiber technology hold the potential to reduce costs in the future, making it more accessible for widespread use.

- Contact us at info@ictfibers.com or via WhatsApp at +86 15057108966 for more information on carbon fiber and its applications.

Understanding carbon fiber

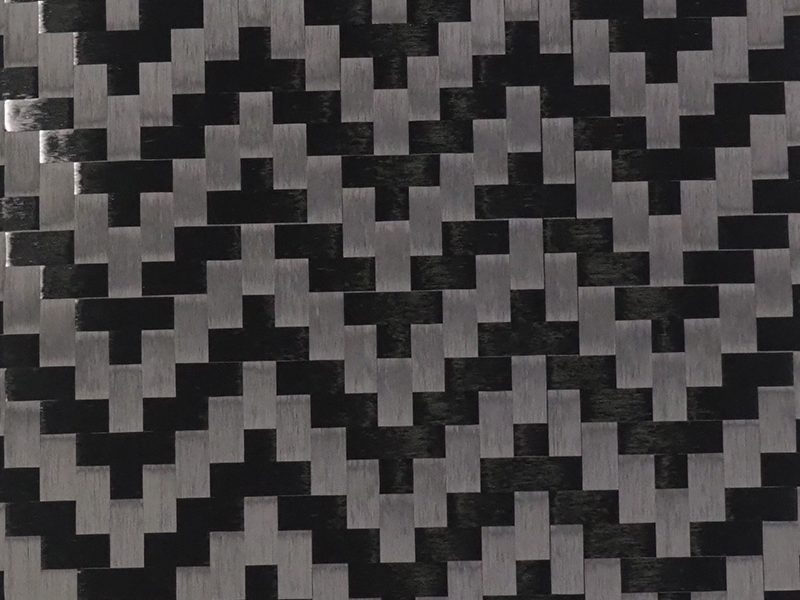

Before diving into the cost aspects, it is essential to understand what carbon fiber is and how it differs from traditional materials. Carbon fiber is a composite material made up of long, thin strands of carbon tightly woven together. These carbon fibers are then combined with a polymer resin to create a strong and lightweight material that is revolutionizing various industries.

Composition of Carbon Fiber

The composition of carbon fiber is what sets it apart from other materials. Each carbon fiber strand is made up of thousands of carbon atoms bonded together in a repeating pattern. This unique structure gives carbon fiber its incredible strength-to-weight ratio, making it stronger than steel while being significantly lighter.

"Carbon fiber is like a superhero in the world of materials. It combines the strength of traditional materials with the lightweight agility of innovative composites, creating endless possibilities for design and performance." - Dr. Rachel Thompson, Materials Scientist

Game-Changing Properties

Carbon fiber's properties make it a game-changer in various industries. Its lightweight nature reduces the overall weight of products, resulting in improved fuel efficiency and maneuverability. The high tensile strength of carbon fiber enables the construction of structures that can withstand immense forces without compromising safety.

- High Strength: Carbon fiber is known for its exceptional strength, making it ideal for applications that require durability and reliability.

- Low Weight: Carbon fiber is significantly lighter than traditional materials such as steel or aluminum, reducing the overall weight of products and enhancing their performance.

- Flexibility: Carbon fiber can be molded into complex shapes, allowing for intricate designs and customization.

- Corrosion Resistance: Unlike metals, carbon fiber is not prone to corrosion, ensuring long-lasting durability even in harsh environments.

- Thermal Stability: Carbon fiber can withstand extreme temperatures, making it suitable for use in applications exposed to heat or cold.

| Properties | Carbon Fiber | Steel | Aluminum |

|---|---|---|---|

| Tensile Strength (MPa) | 5900 | 3400 | 276 |

| Density (g/cm3) | 1.75 | 7.85 | 2.70 |

| Young's Modulus (GPa) | 230 | 200 | 70 |

The table above illustrates the significant differences in properties between carbon fiber, steel, and aluminum. Carbon fiber showcases higher tensile strength and a significantly lower density, making it an appealing choice for lightweight yet strong applications.

Now that we have explored the composition and incredible properties of carbon fiber, we can delve deeper into the cost aspects in the next section.

Lightweight agility for automotive industry

The automotive industry has undergone a significant transformation in recent years, with a strong focus on sustainability and efficiency. As manufacturers strive to create vehicles that are lighter, more fuel-efficient, and environmentally friendly, carbon fiber has emerged as a game-changing material that is revolutionizing the industry.

Carbon fiber, with its exceptional strength and lightweight nature, has become highly sought after in the automotive sector. It offers a unique combination of properties that traditional materials like steel and aluminum simply cannot match.

Carbon fiber's high strength-to-weight ratio allows manufacturers to reduce the weight of vehicle components without compromising on performance or safety. This not only results in improved fuel efficiency but also enhances acceleration and handling, providing a thrilling driving experience.

Automakers are utilizing carbon fiber in various automotive applications, such as body panels, chassis, interiors, and even wheels. By incorporating carbon fiber into these components, vehicles can achieve significant weight reduction, contributing to better overall performance and lower emissions.

Furthermore, carbon fiber's exceptional stiffness allows for greater design freedom. Automakers can explore more aerodynamic shapes and innovative structural designs, optimizing vehicle performance and safety.

In terms of manufacturing, carbon fiber offers several advantages. It can be molded into complex shapes, enabling the production of streamlined components with minimal material wastage. This not only enhances efficiency but also reduces the environmental impact of the manufacturing process.

Carbon fiber's ability to dampen vibrations and reduce noise makes it an ideal choice for high-performance vehicles. The superior ride quality and quiet interiors provide an added level of comfort and luxury for drivers and passengers alike.

Realizing the Full Potential of Carbon Fiber

While carbon fiber's adoption within the automotive industry is growing steadily, there are still challenges that need to be overcome to unlock its full potential. One major barrier is the cost of production, as carbon fiber remains an expensive material compared to traditional options.

However, as technology advances and economies of scale are achieved in the production process, the cost of carbon fiber is expected to decrease. This would pave the way for wider adoption and integration of carbon fiber in mainstream vehicles, further propelling the automotive industry towards a more sustainable and efficient future.

Future Outlook for Carbon Fiber in the Automotive Industry

The future of carbon fiber in the automotive industry looks promising. As consumers demand greener and more advanced vehicles, automakers continue to explore ways to integrate carbon fiber technology into their product lines.

Improved manufacturing techniques, innovative composites, and ongoing research and development efforts are driving advancements in carbon fiber technology. These efforts aim to enhance affordability, increase production efficiency, and further optimize the performance benefits offered by carbon fiber.

As carbon fiber becomes more accessible and cost-effective, we can expect to see a wider range of vehicles featuring carbon fiber components, from high-performance sports cars to everyday sedans.

| Benefits of Carbon Fiber in the Automotive Industry | Examples |

|---|---|

| Lightweight construction | Carbon fiber body panels reduce weight and improve fuel efficiency |

| Enhanced performance | Carbon fiber components contribute to improved acceleration and handling |

| Aerodynamic design | Streamlined carbon fiber structures optimize vehicle performance |

| Reduced emissions | Lightweight carbon fiber reduces vehicle weight, leading to lower emissions |

| Superior ride quality | Carbon fiber's vibration-damping properties provide a smoother driving experience |

With its lightweight agility and exceptional performance benefits, carbon fiber is reshaping the automotive industry. As advancements continue and costs decrease, the integration of carbon fiber in vehicles will become increasingly common, helping to create a greener, more efficient, and thrilling driving experience for car enthusiasts worldwide.

For more information on carbon fiber and its applications in the automotive industry, please contact us at info@ictfibers.com or via WhatsApp at +86 15057108966.

Unparalleled strength in aerospace applications

Carbon fiber has revolutionized the aerospace industry with its exceptional strength-to-weight ratio. Aircraft and space vehicles are now being built using carbon fiber materials, leading to significant advancements in safety and fuel-efficiency. This lightweight yet robust material is transforming the way we design and manufacture aerospace components, allowing for enhanced performance and reliability.

The aerospace applications of carbon fiber are diverse and far-reaching. The material is used to construct aircraft wings, fuselages, tail sections, and even rocket components. Its high strength allows for the creation of lighter structures without compromising on durability, enabling aircraft to achieve higher speeds and better maneuverability.

Additionally, carbon fiber's resistance to corrosion and fatigue makes it ideal for use in aerospace environments where reliability is paramount. By utilizing carbon fiber in critical components, aerospace manufacturers are able to reduce maintenance and replacement costs, resulting in more efficient operations.

Carbon fiber is truly a game-changer in the aerospace industry. Its unparalleled strength and lightweight properties are driving innovation and enabling the development of next-generation aircraft and space vehicles.

The use of carbon fiber in aerospace applications is also contributing to environmental sustainability. The lightweight nature of carbon fiber reduces fuel consumption, leading to lower carbon emissions. This not only benefits the environment but also helps aerospace companies meet increasingly stringent regulatory standards.

The Future of Aerospace with Carbon Fiber

As advancements in carbon fiber technology continue, we can expect even greater integration of this remarkable material in aerospace applications. Ongoing research and development efforts are focused on further improving the strength and performance of carbon fiber composites, ultimately leading to lighter, more fuel-efficient aircraft and space vehicles.

Furthermore, the cost-effectiveness of carbon fiber is being addressed through improved manufacturing processes and economies of scale. This will make carbon fiber more accessible to a wider range of aerospace manufacturers and enable its adoption on a larger scale.

The aerospace industry is embracing carbon fiber and all its possibilities. From commercial airlines to space exploration, carbon fiber is poised to play a vital role in shaping the future of aerospace.

Carbon fiber fabrication process

The process of creating carbon fiber composites involves a series of intricate steps and cutting-edge technology. From raw materials to the final product, each stage plays a vital role in producing high-quality carbon fiber materials.

1. Raw Material Selection

The first step in carbon fiber fabrication is selecting the appropriate raw materials. Carbon fibers are made from a polymer called polyacrylonitrile (PAN) or petroleum pitch. PAN-based carbon fibers are widely used due to their high performance and cost-effectiveness.

2. Stabilization

During the stabilization process, the raw carbon fibers are heated in an oxygen-free environment to remove any volatile components. This process ensures that the carbon atoms are arranged in a stable molecular structure.

3. Carbonization

Next, the stabilized fibers are heated to high temperatures, typically above 1000°C, to convert them into carbon fibers. This carbonization process eliminates non-carbon elements, leaving behind a carbon-rich material with exceptional strength and stiffness.

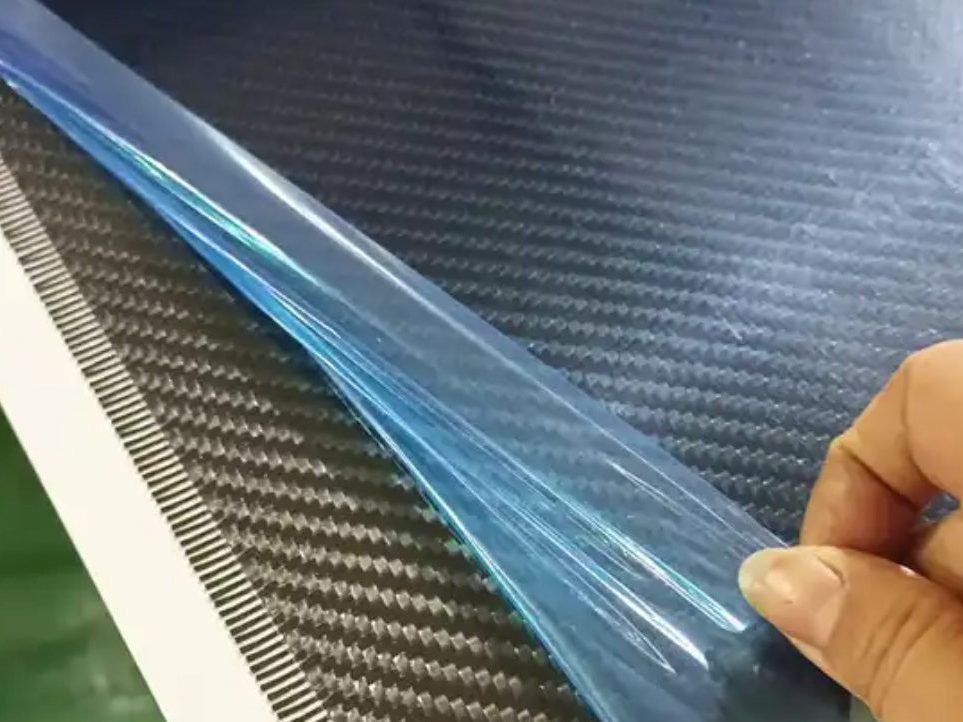

4. Surface Treatment

Carbon fibers have a smooth surface that can hinder proper bonding with other materials. To enhance adhesion, the carbon fibers undergo surface treatment, which involves applying a coating or sizing agent. This treatment improves the interfacial bond between the carbon fibers and the matrix material.

5. Composite Formation

In the final step of carbon fiber fabrication, the carbon fibers are combined with a matrix material, such as epoxy resin, to create a composite structure. The fibers are arranged in a specific orientation and impregnated with the resin, forming a solid and durable material with enhanced mechanical properties.

"The fabrication process of carbon fiber is a precise and intricate endeavor that requires advanced technology and expertise. Each step, from raw material selection to composite formation, contributes to the exceptional strength and lightweight nature of carbon fiber composites."

| Carbon Fiber Fabrication Process: | Advantages: |

|---|---|

| Raw Material Selection | Determines the quality and performance of carbon fibers |

| Stabilization | Removes volatile components for stability |

| Carbonization | Transforms stabilized fibers into carbon fibers |

| Surface Treatment | Enhances adhesion between fibers and matrix material |

| Composite Formation | Combines carbon fibers with a matrix material to create a strong composite |

The intricate process of carbon fiber fabrication ensures the production of lightweight and high-strength materials. This advanced manufacturing technique enables carbon fiber to be utilized in various industries, such as automotive, aerospace, and sports equipment, revolutionizing their performance and capabilities.

To learn more about carbon fiber fabrication or to explore our range of carbon fiber products, contact us at info@ictfibers.com or via WhatsApp at +86 15057108966.

The market for carbon fiber products

In recent years, the demand for carbon fiber products has experienced exponential growth across various industries. This lightweight and high-strength material has become a game-changer in sectors such as automotive, aerospace, sports equipment, and even fashion. The market for carbon fiber products is expanding rapidly, with new applications and innovations continually emerging.

One of the reasons behind this surge in demand is the unique properties that carbon fiber offers. Its exceptional strength-to-weight ratio makes it an ideal choice for applications that require both durability and lightness. Carbon fiber technology has paved the way for the development of products that outperform traditional materials while maintaining structural integrity.

Innovative Applications of Carbon Fiber Technology

The versatility of carbon fiber has resulted in its widespread use in various industries. In the automotive sector, carbon fiber is being employed to manufacture lightweight components, reducing the overall weight of vehicles and improving fuel efficiency. Furthermore, carbon fiber composites provide increased safety and crash resistance, making them essential in the construction of race cars and high-performance vehicles.

Aerospace is another industry where carbon fiber products are revolutionizing the way aircraft are built. The lightweight nature of carbon fiber allows for greater fuel efficiency and increased payload capacity. Additionally, the exceptional strength of carbon fiber composites ensures the structural integrity of aircraft, enhancing safety and reliability.

Carbon fiber technology is also making waves in the world of sports and recreation equipment. From bicycles to tennis rackets, carbon fiber components offer athletes improved performance due to their lightweight nature and high strength. The use of carbon fiber has also extended to fashion, with designers incorporating carbon fiber fabrics into their creations for a futuristic and avant-garde look.

"The demand for carbon fiber products is driven by a need for lightweight, strong, and durable materials. Industries across the board are recognizing the immense potential that carbon fiber offers, resulting in an expanding market with exciting possibilities." - Industry Expert

Future Growth and Development

As carbon fiber technology continues to advance, we can expect further expansion in the market for carbon fiber products. Ongoing research and development efforts are focused on improving production processes, reducing costs, and expanding the range of applications. These advancements will make carbon fiber more accessible to industries that have yet to fully embrace its potential.

"The future of carbon fiber technology is full of promise. Technological advancements will likely lead to increased affordability, making carbon fiber products a viable choice for a broader range of industries. This will undoubtedly drive further growth and innovation." - Industry Analyst

In conclusion, the market for carbon fiber products is thriving due to its exceptional properties and the numerous applications it offers. As industries recognize the benefits of carbon fiber technology, the demand continues to rise, resulting in an expanding market with boundless potential. To stay ahead in this dynamic market, it is crucial for businesses to embrace the possibilities that carbon fiber brings to the table.

Contact us for more information at info@ictfibers.com or via WhatsApp at +86 15057108966.

The cost factor

Carbon fiber is renowned for its exceptional properties, and one of the main reasons for its high cost lies in its unique characteristic of high strength. The strength-to-weight ratio of carbon fiber is unmatched by other materials, making it highly sought after in various industries.

When it comes to manufacturing carbon fiber, the cost structure is influenced by several factors. Firstly, the production process itself involves complex techniques and requires specialized equipment, resulting in increased manufacturing expenses.

Furthermore, the raw materials used in carbon fiber production also contribute to its high cost. Carbon fiber is derived from a precursor material, typically a polymer fiber, which undergoes an elaborate conversion process to become carbonized and then graphitized. The quality and purity of these precursor materials play a significant role in determining the final strength and performance of the carbon fiber.

Additionally, the limited availability of carbon fiber production facilities and expertise adds to the cost factor. The carbon fiber industry requires substantial investments in research and development, as well as maintaining advanced manufacturing facilities to meet the stringent quality standards demanded by industries like aerospace, automotive, and sports equipment.

High-strength carbon fiber is crucial in demanding applications where weight reduction and durability are paramount.

These factors, combined with the labor-intensive and energy-intensive nature of carbon fiber production, contribute to the high price tag of carbon fiber products.

Breaking Down the Cost Structure

When considering the cost of carbon fiber, it's essential to understand that it varies depending on several factors such as fiber type, fiber density, fiber properties, and manufacturing volume. Carbon fiber can be categorized into different grades, with each grade designed for specific applications and possessing different performance characteristics.

Here is a breakdown of the cost structure for carbon fiber production:

| Cost Component | Percentage of Total Cost |

|---|---|

| Fiber Precursor Material | 30% |

| Manufacturing Process | 25% |

| Labor and Energy | 20% |

| Quality Control and Testing | 15% |

| Research and Development | 10% |

These percentages are approximate and can vary depending on the specific carbon fiber product and manufacturing facility.

Despite its high cost, the exceptional properties of carbon fiber, including its high strength, low weight, and corrosion resistance, make it a valuable investment in various industries. As advancements in production technology continue and economies of scale are achieved, it is expected that the cost of carbon fiber will decrease, making it more accessible to a broader range of applications.

Contact us for more information atinfo@ictfibers.com

or via WhatsApp at+86 15057108966

.

Advancements in carbon fiber technology

Ongoing research and development efforts are continuously pushing the boundaries of carbon fiber technology, resulting in remarkable advancements with the potential to revolutionize various industries. These ongoing innovations not only enhance the performance of carbon fiber but also hold the promise of reducing its costs in the future.

Enhancing Lightweight Material Properties

One area of focus in carbon fiber technology advancements is the quest to further improve its lightweight characteristics. Engineers and scientists are developing new manufacturing techniques and composite formulations to create carbon fiber materials that are even lighter while maintaining their exceptional strength.

These advancements in lightweight material properties have significant implications for industries such as automotive and aerospace. By utilizing lighter carbon fiber components, vehicles and aircraft can achieve improved fuel efficiency, reduced emissions, and enhanced overall performance.

Increased Manufacturing Efficiency

Efforts are also being made to streamline the manufacturing process of carbon fiber. These advancements aim to reduce production time and costs while maintaining the high-quality standards that carbon fiber is known for.

Researchers are exploring automated manufacturing methods, such as robotics and additive manufacturing, to enhance production efficiency. These techniques enable precise and consistent fabrication of complex carbon fiber structures, paving the way for increased adoption across industries.

Expanding Applications

As carbon fiber technology continues to advance, the range of applications for this lightweight material is expanding. Industries beyond automotive and aerospace, such as sports equipment, construction, and renewable energy, are recognizing the value of carbon fiber and incorporating it into their products and systems.

By leveraging the unique properties of carbon fiber, manufacturers can create products that are not only lightweight but also exhibit superior strength, durability, and performance. This opens up new possibilities for innovation and creates opportunities for companies to differentiate themselves in the market.

Carbon fiber technology advancements hold the potential to revolutionize industries across the board. Lightweight, yet incredibly strong, carbon fiber is poised to transform the way we design and manufacture products in the future.

In conclusion, ongoing advancements in carbon fiber technology are driving the material towards a more accessible future. As research and development efforts continue, we anticipate further breakthroughs that will enhance the properties of lightweight carbon fiber and reduce its costs, enabling widespread adoption across industries.

For more information and inquiries, please contact us at info@ictfibers.com or reach out via WhatsApp at +86 15057108966.

Conclusion

In conclusion, carbon fiber is an exceptional material that combines lightweight agility with unparalleled strength. Its high cost is justified by the remarkable properties it offers to industries such as automotive and aerospace. Carbon fiber's application in the automotive sector has led to enhanced fuel efficiency and improved performance, while its use in aerospace applications has revolutionized the way aircraft and space vehicles are built, ensuring safety and fuel efficiency.

The market for carbon fiber products is rapidly expanding, driven by the growing demand for innovative solutions. Advancements in carbon fiber technology continue to push the boundaries, potentially reducing costs in the future and making carbon fiber more accessible to a wider range of industries.

To learn more about carbon fiber and its applications, contact us at info@ictfibers.com or reach out to us via WhatsApp at +86 15057108966. We are dedicated to exploring the full potential of carbon fiber and assisting you with any inquiries or requirements you may have.

FAQ

Why is carbon fiber so expensive?

Carbon fiber is an expensive material due to its unique properties, such as being lightweight and high strength. The manufacturing process involves intricate steps and cutting-edge technology, which contribute to its high cost.

What is carbon fiber?

Carbon fiber is a composite material made of thin strands of carbon atoms that are woven together to create a high-strength material. It is known for its exceptional strength-to-weight ratio and is used in various industries.

How is carbon fiber used in the automotive industry?

Carbon fiber is used in the automotive industry to reduce the weight of vehicles, which improves fuel efficiency and enhances performance. It is used in components such as body panels, chassis, and interior parts.

How is carbon fiber used in aerospace applications?

Carbon fiber is widely used in aerospace applications due to its high strength and lightweight nature. It is used in the construction of aircraft and space vehicles, contributing to increased safety and fuel efficiency.

What is the process of carbon fiber fabrication?

The fabrication process of carbon fiber involves several steps, including the selection of raw materials, pre-processing, creating the carbon fiber composite through weaving or molding, curing, and finishing. It requires advanced machinery and expertise.

What is the market for carbon fiber products?

The market for carbon fiber products is expanding rapidly, driven by demand from various industries such as automotive, aerospace, sports equipment, and renewable energy. It offers innovative solutions in terms of weight reduction and improved performance.

What factors contribute to the high cost of carbon fiber?

The high cost of carbon fiber is primarily due to its unique properties, such as high strength and lightweight nature. Additionally, the complex manufacturing process, research and development costs, and limited production capacity contribute to its expense.

What are the advancements in carbon fiber technology?

Ongoing research and development efforts are continuously improving carbon fiber technology. Advancements include the development of new manufacturing techniques, recycling methods, and the exploration of alternative raw materials, which could potentially reduce costs in the future.

How does carbon fiber justify its high cost?

Carbon fiber justifies its high cost through its exceptional properties, including lightweight agility and unparalleled strength. It offers significant advantages in industries such as automotive and aerospace, contributing to improved performance, fuel efficiency, and safety.

Where can I find more information about carbon fiber?

For more information about carbon fiber and its applications, please contact us at info@ictfibers.com or reach out via WhatsApp at +86 15057108966.