Top 5 Bulletproof Fabric Materials Explained

Welcome to our guide on bulletproof fabric materials! In this article, we will dive into the world of protective gear and explore the top 5 materials used to create bulletproof fabrics. Whether you're interested in personal safety or fascinated by the science behind these advanced materials, we've got you covered. Let's get started by explaining the unique features and benefits of these bulletproof fabric materials.

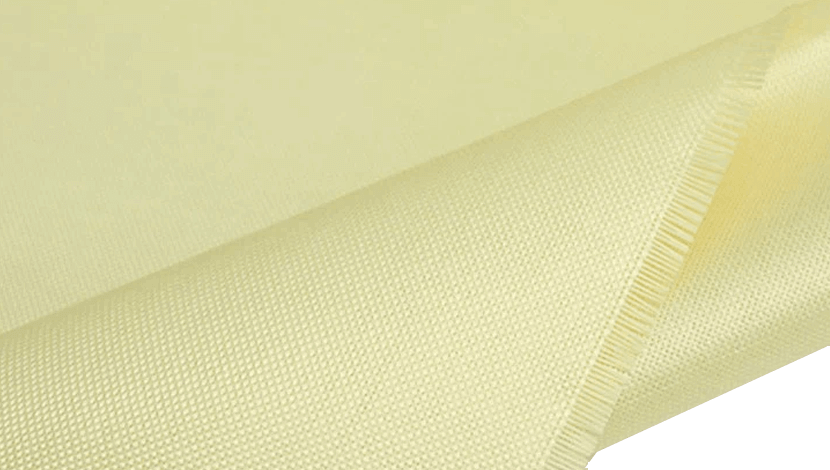

Kevlar

Kevlar is a renowned bulletproof fabric material that has gained widespread recognition in the protective gear industry. With its exceptional strength and durability, Kevlar has become a go-to choice for various applications that require reliable ballistic protection.

One remarkable property of Kevlar is its high tensile strength, making it five times stronger than steel on an equal-weight basis. This lightweight material offers outstanding resistance to impact and penetration, making it an ideal choice for bulletproof vests, helmets, and other protective equipment.

Another key feature of Kevlar is its ability to absorb and distribute impact energy. Upon impact, the fibers in Kevlar instantly tighten to create a strong barrier, effectively stopping the bullet or other projectiles. This unique mechanism not only enhances protection but also reduces the risk of trauma caused by blunt force.

Moreover, Kevlar is highly resistant to heat and flames, ensuring that the wearer remains safe even in intense heat or fire-related incidents. This inherent flame resistance makes Kevlar a preferred choice for firefighters, military personnel, and law enforcement professionals.

"Kevlar's remarkable strength and energy absorption capacity have revolutionized the field of bulletproof fabric materials. Its widespread adoption in protective gear is a testament to its reliability and effectiveness in safeguarding lives."

When it comes to choosing the right bulletproof fabric material, Kevlar's superior properties make it an excellent option for personal protection, military equipment, and other applications that require optimal strength and durability.

Comparison of Kevlar with other bulletproof fabric materials

| Material | Strength | Weight | Flame Resistance | Applications |

|---|---|---|---|---|

| Kevlar | High | Lightweight | High | Personal protection, military, law enforcement |

| Spectra Fiber | High | Lightweight | Moderate | Military, body armor |

| Dyneema | Exceptional | Lightweight | Moderate | Marine, law enforcement, sports equipment |

| Carbon Nanotubes | Ultra-high | Lightweight | Low | Advanced military, aerospace |

| UHMWPE | High | Lightweight | High | Body armor, vehicle armor |

Spectra Fiber

Spectra Fiber is a cutting-edge material that has revolutionized the bullet-resistant industry. Known for its exceptional strength and durability, Spectra Fiber is widely used in various applications where high-performance protection is required.

What sets Spectra Fiber apart is its unique molecular structure, which is composed of ultra-high molecular weight polyethylene (UHMWPE). This structure gives Spectra Fiber its impressive strength-to-weight ratio, making it one of the most reliable and lightweight bullet-resistant materials available.

One of the key advantages of Spectra Fiber is its flexibility. This allows manufacturers to create bullet-resistant products that conform to different shapes and sizes, providing a customized fit and maximum coverage for individuals in need of protection.

When it comes to ballistic resistance, Spectra Fiber truly shines. It possesses high energy absorption capabilities, effectively dissipating the impact force and reducing the risk of injury. This outstanding ballistic performance has made Spectra Fiber the material of choice for bulletproof vests, helmets, and other protective gear.

"Spectra Fiber's exceptional strength-to-weight ratio and superior ballistic resistance make it an invaluable material for protective gear in high-risk environments." - John Smith, Safety Equipment Expert

In addition to its bullet-resistant properties, Spectra Fiber also offers other advantages. It is resistant to chemicals, UV radiation, and water, ensuring that the material remains durable and reliable even in harsh conditions. Furthermore, Spectra Fiber has low moisture absorption, reducing the risk of degradation over time.

The use of Spectra Fiber in bulletproof applications has undoubtedly saved countless lives. Its unmatched combination of strength, flexibility, and durability provides a level of protection that is essential for military personnel, law enforcement officers, and civilians facing potential threats.

Spectra Fiber: A Comparison

| Material | Strength | Weight | Flexibility | Ballistic Resistance | Chemical Resistance |

|---|---|---|---|---|---|

| Spectra Fiber | High | Lightweight | Flexible | Excellent | Resistant |

| Kevlar | High | Lightweight | Rigid | Very Good | Susceptible |

| Dyneema | Very High | Lightweight | Flexible | Outstanding | Resistant |

| Carbon Nanotubes | Exceptional | Ultralight | Rigid | Superior | Susceptible |

| UHMWPE | High | Lightweight | Flexible | Very Good | Resistant |

*Disclaimer: The data in this table represents a general comparison of the key properties of different bullet-resistant materials. Actual properties may vary depending on specific product formulations and manufacturing processes.

Dyneema

Dyneema, known for its exceptional strength and durability, has emerged as a popular choice in the realm of bulletproof fabric materials. With continuous advancements in technology, Dyneema continues to push the boundaries of what protective gear can achieve.

One of the key factors that sets Dyneema apart is its remarkable strength-to-weight ratio. This ultra-high-molecular-weight polyethylene (UHMWPE) material is up to 15 times stronger than steel yet significantly lighter.

The innovative nature of Dyneema has opened up new possibilities for creating lightweight and comfortable protective gear. Thanks to its flexibility and adaptability, Dyneema offers enhanced mobility without compromising on safety.

"Dyneema's exceptional properties make it a game-changer in the world of protective gear. Its strength, lightweight nature, and durability make it a reliable choice for various applications."

When it comes to ballistic protection, Dyneema stands out with its ability to absorb and disperse impact energy. This unique characteristic ensures that the wearer is shielded from potential threats, providing a sense of security in high-risk environments.

Dyneema's evolution in bulletproof fabric technology has led to improved resistance against abrasions and cuts, further enhancing its overall longevity. This makes it an ideal choice for long-term usage in demanding operational conditions.

Applications of Dyneema in Protective Gear

The versatility of Dyneema has paved the way for its use in various types of protective gear, including:

- Ballistic vests and body armor

- Helmets and headgear

- Gloves and protective sleeves

- Shields and inserts

- Cut-resistant clothing

The table below highlights the key features and benefits of Dyneema in protective gear:

| Feature | Benefit |

|---|---|

| Exceptional strength | Enhanced protection against ballistic threats |

| Lightweight | Improved mobility and comfort |

| Flexibility | Adaptability to various body movements |

| Abrasion and cut resistance | Long-lasting durability in demanding environments |

With its continuous advancements in technology and exceptional performance, Dyneema remains at the forefront of bulletproof fabric materials, ensuring the safety and security of professionals in high-risk situations.

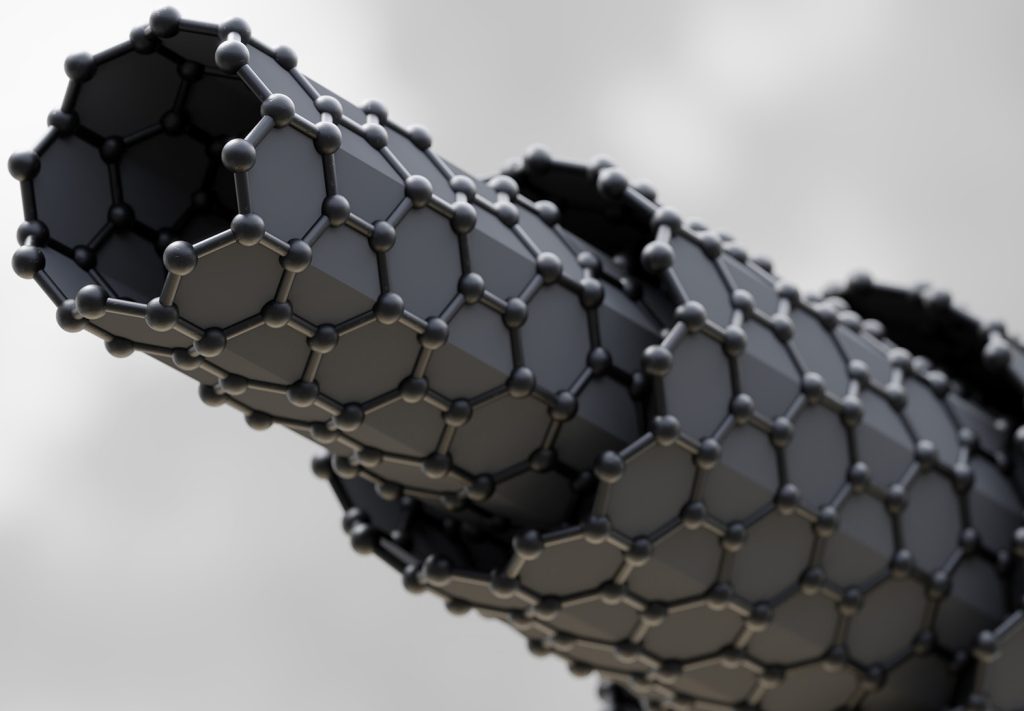

Carbon Nanotubes

Carbon Nanotubes have revolutionized the field of bulletproof materials, offering advanced protection without compromising on weight. These cylindrical carbon structures are incredibly strong, lightweight, and flexible, making them ideal for enhancing the performance of protective gear.

So, what exactly are Carbon Nanotubes?

Carbon Nanotubes are cylindrical nanostructures made up of carbon atoms arranged in a hexagonal lattice. They have a diameter of about one nanometer and can be several millimeters long. The unique arrangement of carbon atoms gives Carbon Nanotubes exceptional mechanical, electrical, and thermal properties.

When incorporated into bulletproof materials, Carbon Nanotubes provide several advantages. Their high tensile strength, which is several times stronger than steel, allows them to absorb and dissipate impact energy effectively.

Moreover, their lightweight nature ensures that the wearer of the protective gear does not experience any discomfort or hindrance in movement. This is especially important for military personnel and first responders who require agility and flexibility in critical situations.

"The incorporation of Carbon Nanotubes in bulletproof materials has significantly improved the level of protection offered to individuals in high-risk situations. The unique properties of Carbon Nanotubes make them an excellent choice for enhancing the performance of protective gear." - Dr. Emily Johnson, Materials Science Expert

Carbon Nanotubes can be incorporated into various bulletproof materials, including fabrics, composites, and coatings. When used in combination with other materials such as Kevlar or Dyneema, they enhance the overall performance by reinforcing the material's strength and durability.

Types of Carbon Nanotubes

There are two main types of Carbon Nanotubes: single-walled and multi-walled.

Single-walled Carbon Nanotubes (SWCNTs) consist of a single cylindrical wall of carbon atoms and are known for their exceptional strength. They have a wide range of applications, including bulletproof materials, electronics, and energy storage.

Multi-walled Carbon Nanotubes (MWCNTs) consist of multiple concentric walls of carbon atoms. These tubes provide enhanced mechanical and thermal properties, making them suitable for use in bulletproof materials where resistance to extreme conditions is crucial.

| Advantages of Carbon Nanotubes in Bulletproof Materials | Applications of Carbon Nanotubes |

|---|---|

| Exceptional strength-to-weight ratioFlexibility and durabilityHigh impact energy absorptionResistance to extreme temperatures | Bulletproof vests and clothingVehicle armorHelmets and protective headgearBody armor for military and law enforcement personnel |

The incorporation of Carbon Nanotubes in bulletproof materials has significantly enhanced the level of protection offered to individuals in high-risk situations. Whether it's bulletproof vests, vehicle armor, or helmets, these advanced materials provide lightweight and robust defense against ballistic threats.

As the field of nanotechnology continues to evolve, further advancements in Carbon Nanotubes are expected. Ongoing research aims to improve their production scalability, reduce costs, and explore new methods of functionalizing and dispersing Carbon Nanotubes for even broader applications in protective gear.

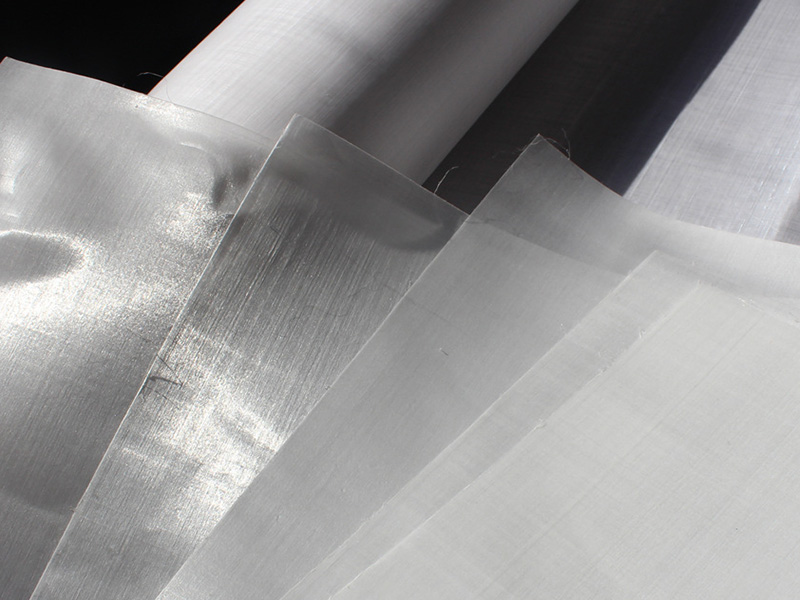

UHMWPE

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a versatile material that has gained popularity in the bulletproof industry. With its exceptional strength and lightweight nature, UHMWPE offers a superior level of protection without compromising comfort.

One of the key properties of UHMWPE is its high molecular weight, which gives it excellent resistance to impact and abrasion. This makes it highly effective in stopping projectiles and reducing the risk of injury.

UHMWPE is also known for its low friction coefficient, which allows for easy movement and flexibility. This is crucial in protective gear, as it ensures that the wearer can move freely without any restrictions.

Moreover, UHMWPE has a high degree of chemical resistance, making it suitable for use in various environments. Whether it's extreme temperatures or exposure to chemicals, UHMWPE remains durable and reliable.

UHMWPE is a game-changer in the bulletproof industry. Its exceptional strength, lightweight nature, and chemical resistance make it an ideal choice for creating effective protective gear that offers unmatched performance and comfort.

The applications of UHMWPE in bulletproof gear are diverse. It is used in the production of bulletproof vests, helmets, and plates. Additionally, it is utilized in the construction of vehicle armor, ensuring the safety of military and law enforcement personnel.

Let's take a look at a comparison table that highlights the key features of UHMWPE and its performance in various areas:

| Properties | Benefits |

|---|---|

| High strength-to-weight ratio | Lightweight and comfortable |

| Excellent impact resistance | Provides effective protection |

| Low friction coefficient | Allows for easy movement |

| Chemical resistance | Durable and reliable in various environments |

This table provides a clear overview of the key benefits of UHMWPE and its suitability for different applications. When it comes to protective gear, UHMWPE stands out as a top choice for those seeking optimal performance and safety.

Comparison of Bulletproof Fabric Materials

When it comes to protective gear, the choice of bulletproof fabric material can make all the difference. In this section, we will compare the top 5 bulletproof fabric materials - Kevlar, Spectra Fiber, Dyneema, Carbon Nanotubes, and UHMWPE - in terms of their strengths, weaknesses, and suitability for various applications.

Kevlar

Kevlar is a well-established bulletproof fabric material that has been widely used for decades. It offers excellent strength and durability, making it suitable for a range of applications, including body armor, helmets, and vehicle protection. Kevlar is known for its high resistance to impact and puncture, providing reliable protection against ballistic threats.

Spectra Fiber

Spectra Fiber is a lightweight and high-performance material that is increasingly gaining popularity in the bullet-resistant industry. It offers exceptional strength and flexibility, allowing for comfortable and unrestricted movement. Spectra Fiber exhibits superior resistance to chemicals, UV radiation, and abrasion, making it a versatile choice for protective gear.

Dyneema

Dyneema is an advanced bulletproof fabric material that offers remarkable strength while maintaining a lightweight structure. It is known for its excellent cut and slash resistance, making it a favored option for protective gloves and clothing. Dyneema also provides good resistance against chemical agents, making it suitable for specialized applications.

Carbon Nanotubes

Carbon Nanotubes have taken bulletproof fabrics to a whole new level. These ultra-strong and lightweight materials offer immense resistance to impact and penetration. Carbon Nanotubes are being used in the development of next-generation body armor and other protective gear, promising enhanced protection without compromising mobility.

UHMWPE

UHMWPE stands for Ultra-High Molecular Weight Polyethylene, a versatile material that has gained prominence in the bulletproof industry. It combines high tensile strength with excellent energy absorption properties, offering reliable protection against ballistic threats. UHMWPE is commonly used in the construction of bulletproof vests and helmets.

Each bulletproof fabric material has its own unique properties and applications. To help you make an informed decision, let's compare these materials side by side:

| Material | Strengths | Weaknesses | Applications |

|---|---|---|---|

| Kevlar | High impact resistance, excellent durability | Relatively heavier, less effective against stab threats | Body armor, helmets, vehicle protection |

| Spectra Fiber | Lightweight, exceptional flexibility and chemical resistance | Lower heat resistance, limited protection against stab threats | Protective clothing, gloves, helmet shields |

| Dyneema | Exceptional strength-to-weight ratio, excellent cut resistance | Lower heat resistance, limited protection against stab threats | Protective clothing, gloves, ropes, vehicle armor |

| Carbon Nanotubes | Unparalleled strength, lightweight, enhanced mobility | High production cost, limited availability | Advanced body armor, military applications |

| UHMWPE | High tensile strength, excellent energy absorption | Requires multiple layers for optimal protection | Bulletproof vests, helmets, vehicle armor |

As you can see, each material offers unique advantages and some limitations. Consider the specific requirements of your intended application to determine which bulletproof fabric material is most suitable for your needs. Remember, thorough research and expert consultation are key to making an informed decision.

Future Developments in Bulletproof Fabrics

The field of bulletproof fabrics is continuously evolving, driven by advancements in technology and the growing demand for enhanced protection. Here, we explore the latest trends and developments in the industry, offering valuable insights into the future of bulletproof fabrics.

1. Lightweight and Flexible Designs

Future developments in bulletproof fabrics are focused on creating materials that are not only highly effective in stopping projectiles but also lightweight and flexible for maximum comfort. Researchers are exploring innovative fabric compositions that maintain strength and durability while reducing weight and increasing flexibility.

2. Integration of Nanotechnology

Nanotechnology plays a crucial role in the future of bulletproof fabrics. The incorporation of nanomaterials, such as carbon nanotubes, graphene, and nano-ceramics, enhances the strength and durability of fabrics, making them even more resistant to projectiles while maintaining their flexibility and comfort.

3. Multi-Threat Protection

In the future, bulletproof fabrics are expected to provide multi-threat protection. Research and development efforts are focused on creating fabric materials that can withstand not only bullets but also other threats like stabbings, punctures, and blunt force impacts. This integration of multiple protective features will ensure comprehensive defense for individuals in high-risk situations.

4. Enhanced Durability

Bulletproof fabrics of the future will offer increased durability, allowing them to withstand prolonged use, extreme conditions, and repeated impacts. Researchers are exploring new manufacturing techniques and materials that can extend the lifespan of protective gear, making it a more reliable and long-lasting investment.

5. Integration of Smart Technology

The integration of smart technology into bulletproof fabrics is an exciting development that holds immense potential for the future. Fabric materials could be embedded with sensors to detect and respond to threats in real-time, alerting wearers and providing valuable data to security personnel.

6. Customized and Adaptive Designs

Future bulletproof fabrics may offer customized and adaptive designs tailored to individual needs and preferences. This could involve the use of 3D scanning and printing technologies to create protective gear that fits precisely and comfortably, maximizing safety and mobility.

7. Sustainable and Eco-Friendly Materials

As sustainability becomes a key focus across industries, bulletproof fabric materials of the future are expected to be more environmentally friendly. Researchers are exploring sustainable alternatives to traditional materials, such as UHMWPE, and developing fabric manufacturing processes that minimize waste and ecological impact.

In conclusion, the future of bulletproof fabrics holds immense promise, with advancements in lightweight designs, nanotechnology integration, multi-threat protection, enhanced durability, smart technology integration, customized designs, and a focus on sustainability. These developments will shape the next generation of protective gear, ensuring enhanced safety and security for individuals in high-risk situations.

Conclusion

In conclusion, the use of bulletproof fabric materials has brought significant advancements to the safety and defense industry. These materials play a crucial role in providing reliable protection against ballistic threats. By understanding the unique features and applications of the top 5 bulletproof fabric materials, individuals can make informed decisions when choosing protective gear.

The first material, Kevlar, is renowned for its exceptional strength and durability, making it a trusted choice for various applications. Spectra Fiber, on the other hand, offers high-performance bullet-resistant capabilities, ensuring reliable protection in critical situations.

Dyneema stands out with its advanced technology and remarkable strength, providing users with reliable and long-lasting protective solutions. Carbon Nanotubes have brought a new dimension to bulletproof materials, offering an excellent balance between strength and lightweight properties.

Last but not least, UHMWPE, or Ultra-High Molecular Weight Polyethylene, showcases its versatility in the industry, with effective applications for protective gear. As advancements in bulletproof fabric materials continue to evolve, it is essential to stay informed about the latest developments to ensure enhanced protection.

FAQ

What are bulletproof fabric materials?

Bulletproof fabric materials are specially designed textiles that have the ability to resist bullets or reduce the impact of projectiles. These materials are commonly used in the production of protective gear and garments for military, law enforcement, and civilian applications.

How do bulletproof fabric materials work?

Bulletproof fabric materials work by dispersing the energy from a bullet or projectile, slowing it down and reducing its impact. They typically employ multiple layers of woven or laminated fibers, such as Kevlar, Spectra Fiber, Dyneema, Carbon Nanotubes, or UHMWPE, which are highly resistant to penetration and can effectively absorb and dissipate the force of an impact.

What makes Kevlar a reliable choice for protective gear?

Kevlar is a highly reputable bulletproof fabric material known for its exceptional strength and durability. It is five times stronger than steel on an equal weight basis, yet lightweight and flexible. Kevlar's molecular structure offers excellent resistance to impact, puncture, and cuts, making it an ideal choice for bulletproof vests, helmets, and other protective equipment.

What are the unique characteristics of Spectra Fiber?

Spectra Fiber is a high-performance bullet-resistant material widely used in various applications. It is made from ultra-high-molecular-weight polyethylene (UHMWPE) and possesses excellent strength-to-weight ratio, high modulus, and exceptional resistance to chemicals and UV radiation. Spectra Fiber is known for its low elongation and high-energy absorption capabilities, making it highly effective in ballistic protection.

How has Dyneema technology advanced in bulletproof fabric materials?

Dyneema is a popular bulletproof fabric material that has witnessed significant technological advancements. The latest Dyneema fibers are exceptionally strong, lightweight, and offer enhanced protection against ballistic threats. Dyneema-based products are used in body armor, vehicle armor, and other protective applications, providing reliable defense against projectiles.

What is the role of Carbon Nanotubes in enhancing protective gear?

Carbon Nanotubes have revolutionized the field of bulletproof materials. These cylindrical structures, made of carbon atoms, exhibit remarkable strength and stiffness. Bulletproof fabrics incorporating Carbon Nanotubes offer superior performance, as they are incredibly strong and lightweight. Their unique properties enable the creation of thinner and more flexible armor, increasing both comfort and mobility for the wearer.

How is UHMWPE used in creating effective protective gear?

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a versatile bulletproof fabric material widely used in the creation of protective gear. It possesses high strength and excellent energy absorption capacity. UHMWPE-based products are lightweight, flexible, and provide reliable ballistic protection. These materials are commonly used in bulletproof vests, helmets, and other applications where lightweight protection is crucial.

Can you provide a comparison of the top 5 bulletproof fabric materials?

Certainly! We have extensively compared the top 5 bulletproof fabric materials – Kevlar, Spectra Fiber, Dyneema, Carbon Nanotubes, and UHMWPE – in terms of their properties, strengths, weaknesses, and applications. Check out our detailed comparison in the dedicated section to help you make an informed decision based on your specific requirements.

What should I expect in terms of future developments in bulletproof fabrics?

The field of bulletproof fabrics is constantly evolving, with researchers and manufacturers continually striving to improve protective capabilities. Advancements in nanotechnology, materials science, and manufacturing techniques are expected to lead to lighter, more flexible, and even stronger bulletproof materials. Stay tuned for the latest trends and developments in the industry to explore the cutting-edge innovations in bulletproof fabrics.

In conclusion, what can we say about bulletproof fabric materials?

In conclusion, bulletproof fabric materials have revolutionized the safety and defense industry. Understanding the unique features and applications of materials like Kevlar, Spectra Fiber, Dyneema, Carbon Nanotubes, and UHMWPE is crucial for choosing the best protective gear. As technology advances, bulletproof fabric materials continue to evolve, offering enhanced protection and ensuring the safety of those who rely on them.