Defense

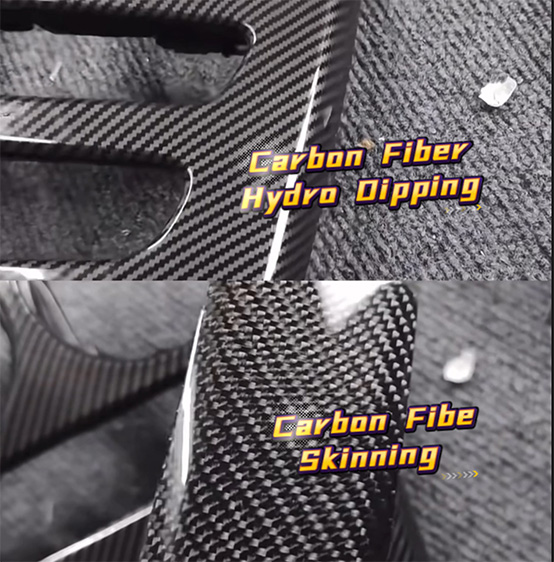

Carbon fiber, aramid, and UHMWPE are widely used in the defense industry due to their exceptional strength and lightweight properties. Carbon fiber is used in the fabrication of aircraft parts, missile components, and military vehicles. Aramid is used in body armor, helmets, and gloves for protection against ballistic and fragmentation threats. UHMWPE is used in the fabrication of helmets and body armor for protection against projectiles.