Construction Process of unidirectional carbon fiber cloth

Unidirectional carbon fiber cloth is revolutionizing the construction industry with its advanced properties and versatile applications. As a carbon fiber fabric that finds its roots in aerospace materials, it has become an essential component in composite materials used for construction projects. This lightweight fabric offers high-strength reinforcements, making it an ideal choice for enhancing the durability and structural integrity of buildings and infrastructure.

Unidirectional carbon fiber cloth is a game-changer in industrial textiles, providing exceptional strength and flexibility. Its unique manufacturing process and composition make it an ideal choice for creating advanced composites that deliver superior performance. From improving load-bearing capacity to withstanding harsh environmental conditions, this carbon fiber fabric offers numerous benefits in construction applications.

Key Takeaways:

- Unidirectional carbon fiber cloth is a lightweight fabric that offers high-strength reinforcements.

- This fabric is widely used in composite materials for construction, stemming from its aerospace origins.

- Industrial textiles benefit from the exceptional strength and flexibility of unidirectional carbon fiber cloth.

- Unidirectional carbon fiber cloth enhances the durability and structural integrity of buildings and infrastructure.

- Its unique composition and manufacturing process make it suitable for creating advanced composites.

What is unidirectional carbon fiber cloth?

Unidirectional carbon fiber cloth is a specialized type of carbon fiber fabric that plays a crucial role in the development of advanced composites and industrial textiles. It is composed of high-strength carbon fibers aligned in a single direction, providing exceptional rigidity and tensile strength.

This type of fabric is widely used in the manufacturing of composite materials, where its unidirectional alignment enhances structural integrity and performance. Unidirectional carbon fiber cloth is known for its remarkable properties, including low weight, high strength, and excellent resistance to corrosion and fatigue.

The manufacturing process of unidirectional carbon fiber cloth involves weaving carbon fibers into a matrix, often using a resin system. This precise arrangement creates a fabric with unidirectional strength, allowing it to efficiently transmit load-bearing forces along a designated axis.

Unidirectional carbon fiber cloth finds applications in various industries, with the construction sector being one of its key beneficiaries. The cloth reinforces structures, effectively increasing their load-bearing capacity and durability. Additionally, it offers significant weight savings compared to traditional materials, making it an ideal choice for lightweight construction projects.

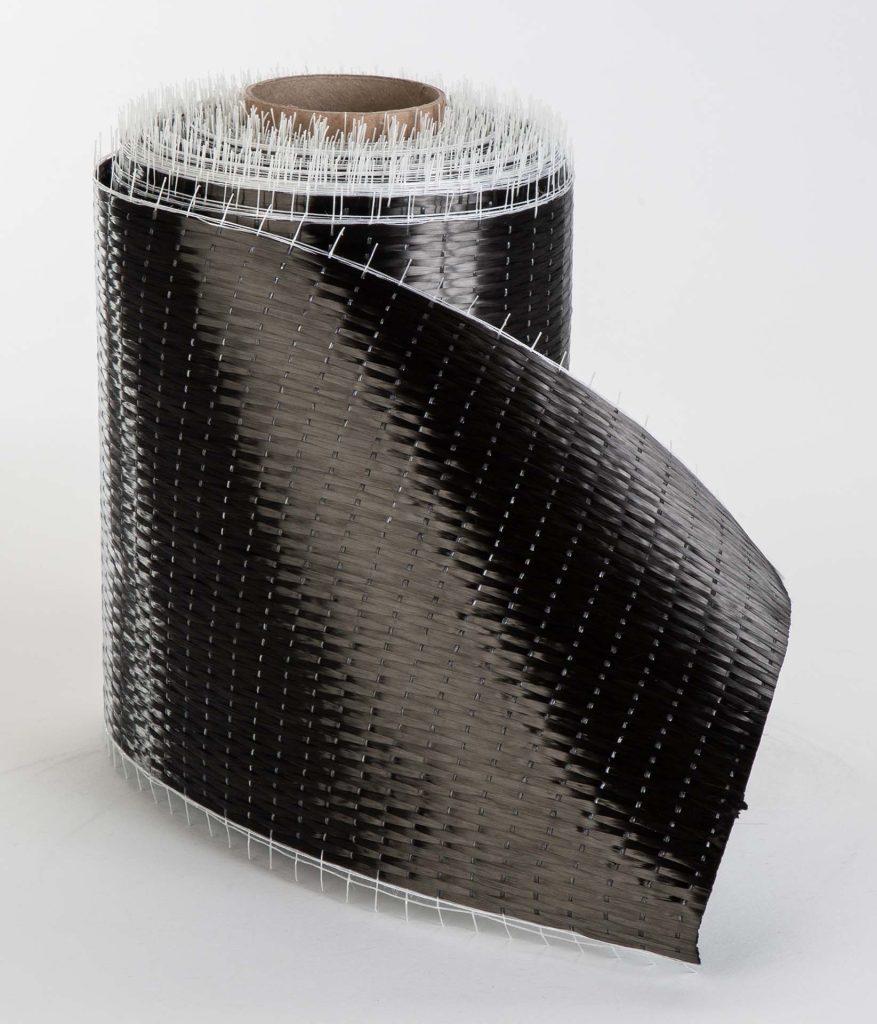

This image illustrates the unidirectional carbon fiber cloth used in construction, exemplifying its alignment of carbon fibers for enhanced strength and performance.

Benefits of using unidirectional carbon fiber cloth in construction

Unidirectional carbon fiber cloth offers a wide range of benefits when used in construction projects. Its unique properties make it an ideal choice for enhancing the strength, durability, and overall performance of buildings and infrastructure.

High Strength Properties

Unidirectional carbon fiber cloth is known for its exceptional strength-to-weight ratio. It provides high tensile strength, allowing structures to withstand heavy loads and stresses. This high strength fabric reinforces concrete and other materials, improving their structural integrity.

Lightweight Nature

One of the major advantages of unidirectional carbon fiber cloth is its lightweight nature. Compared to traditional construction materials, it significantly reduces the weight of structures without compromising their strength. This lightweight fabric enables the construction of lighter and more efficient buildings, reducing the overall load on the foundation and supporting structures.

Enhanced Structural Integrity

The use of unidirectional carbon fiber cloth enhances the overall structural integrity of buildings and infrastructure. Its unidirectional fibers provide excellent stiffness and resistance to deformation, ensuring long-term stability. This high strength fabric reinforces weak areas and prevents cracks, extending the lifespan of structures.

Durability and Environmental Resistance

Unidirectional carbon fiber cloth is highly durable and resistant to environmental conditions. It withstands extreme temperatures, moisture, and chemicals, ensuring long-lasting performance. This makes it suitable for various construction environments and applications, including coastal areas or structures exposed to corrosive elements.

Using unidirectional carbon fiber cloth in construction projects offers numerous benefits, including high strength properties, lightweight fabric, enhanced structural integrity, and durability. It not only improves the performance and longevity of structures but also enables the construction of sustainable and efficient buildings.

Application process of unidirectional carbon fiber cloth in construction

Incorporating unidirectional carbon fiber cloth into construction projects involves a systematic application process that maximizes its benefits. This section will outline the steps and techniques utilized to effectively utilize this advanced material in various construction scenarios, demonstrating its versatility and compatibility with other materials.

- Surface preparation: Before applying the unidirectional carbon fiber cloth, ensuring proper surface preparation is crucial. This involves cleaning the surface, removing any contaminants or loose particles, and creating a suitable bonding surface.

- Adhesive application: The next step is applying the appropriate adhesive to bond the carbon fiber fabric to the substrate. The choice of adhesive depends on factors such as the construction material, environmental conditions, and expected loads. It is important to follow the manufacturer's recommendations and industry standards for adhesive selection and application.

- Curing techniques: After the adhesive application, the curing process begins. This typically involves applying pressure to the carbon fiber fabric to ensure proper bonding and removing any potential air pockets. The curing time and temperature may vary depending on the adhesive and project specifications.

Unidirectional carbon fiber cloth demonstrates exceptional adaptability in different construction scenarios. It can be applied to flat or curved surfaces, making it suitable for various structural elements, such as beams, columns, walls, and ceilings. Additionally, it seamlessly integrates with other construction materials, including concrete, steel, and timber, enhancing their strength and performance.

When utilizing unidirectional carbon fiber cloth, it is essential to follow industry best practices, adhere to relevant regulations, and ensure proper training and expertise. This guarantees the effective application of the material, maximizing its potential benefits in strengthening structures and improving overall construction quality.

Example Table:

| Construction Step | Details |

|---|---|

| Surface preparation | Thoroughly clean the surface and remove any contaminants or loose particles to create a suitable bonding surface for the carbon fiber cloth. |

| Adhesive application | Select and apply the appropriate adhesive based on project specifications and industry standards, ensuring proper bonding of the carbon fiber fabric to the substrate. |

| Curing techniques | Utilize suitable curing techniques, applying pressure to remove air pockets and promoting optimal adhesive bonding. Follow recommended curing time and temperature. |

Strengthening structures with unidirectional carbon fiber cloth

Unidirectional carbon fiber cloth plays a vital role in enhancing the strength and durability of structures in the construction industry. By utilizing the unique properties of this advanced material, construction professionals can significantly improve the load-bearing capacity and overall structural integrity of buildings, bridges, and other infrastructure.

One of the key factors contributing to the strengthening capabilities of unidirectional carbon fiber cloth is its high strength fabric composition. This fabric is made up of tightly woven carbon fibers, which provide exceptional tensile strength and stiffness. When applied strategically to reinforce specific areas of a structure, such as beams or columns, it effectively redistributes stress and increases the overall load-bearing capacity.

In addition to its high strength properties, unidirectional carbon fiber cloth offers several advantages when used as a reinforcement material in composite structures. Its lightweight nature reduces the overall weight of the structure, making it an ideal choice for applications where weight reduction is essential, such as aerospace or automotive industries. Furthermore, its corrosion-resistant properties ensure long-lasting durability, minimizing the need for frequent maintenance and replacement.

"Unidirectional carbon fiber cloth enhances the strength and durability of structures, providing increased load-bearing capacity and improved structural integrity."

When applied as carbon fiber reinforcements, unidirectional carbon fiber cloth strengthens structural components by providing additional support and preventing further damage. These reinforcements can be strategically placed in areas prone to high stress or where structural weaknesses exist. The carbon fiber reinforcements act as a protective layer, distributing the load and reducing the risk of structural failure.

Potential Applications

The application of unidirectional carbon fiber cloth in construction is diverse, encompassing various structural elements and projects. Here are a few potential use cases:

- Reinforcing bridges and highways to withstand heavy traffic and extreme weather conditions.

- Strengthening building facades and supporting beams for increased resistance against earthquakes or other natural disasters.

- Repairing damaged structures by adding carbon fiber reinforcements to restore their original load-bearing capacity.

The versatility of unidirectional carbon fiber cloth allows it to be tailored to specific construction requirements, providing effective solutions for a wide range of structural strengthening needs.

Case Study: Implementing Unidirectional Carbon Fiber Cloth in Bridge Construction

To further illustrate the benefits of unidirectional carbon fiber cloth in strengthening structures, let's consider the case of the Golden Gate Bridge in San Francisco, California. During a seismic retrofitting project, carbon fiber reinforcements were strategically placed along critical sections of the bridge to enhance its strength and resilience against earthquakes.

The addition of unidirectional carbon fiber cloth provided significant improvements to the bridge's load-bearing capacity and structural stability. The lightweight nature of the fabric minimized the additional weight load on the existing structure, while its high strength properties effectively redistributed stress across the reinforced areas.

The utilization of unidirectional carbon fiber cloth in this bridge construction project demonstrates its effectiveness in strengthening large-scale structures, ensuring their longevity and safety under demanding conditions.

Key considerations for using unidirectional carbon fiber cloth

When using unidirectional carbon fiber cloth in construction, it is crucial to take into account a number of key considerations to ensure optimal results. From proper installation techniques to compatibility with other construction materials, here are the important factors to keep in mind:

1. Proper Installation Techniques

Installing unidirectional carbon fiber cloth requires precision and attention to detail. The fabric should be applied according to manufacturer guidelines, considering factors such as surface preparation, adhesive selection, and curing methods. Following the recommended installation techniques will help maximize the fabric's effectiveness in strengthening structures.

2. Compatibility with Construction Materials

Unidirectional carbon fiber cloth should be compatible with other construction materials used in the project. It is essential to assess the compatibility of the fabric with adhesives, fillers, and other components to ensure a seamless integration and optimal performance. Conducting compatibility tests and seeking expert advice can help mitigate any potential issues.

3. Adherence to Industry Standards and Regulations

Complying with industry standards and regulations is vital when using unidirectional carbon fiber cloth in construction. It is important to stay updated with building codes, safety regulations, and design specifications to ensure compliance. Adhering to these standards not only ensures the structural integrity of the project but also minimizes liability and enhances safety.

4. Training and Expertise

Working with unidirectional carbon fiber cloth requires specialized training and expertise. Proper knowledge of handling, cutting, and applying the fabric is essential to achieve desired results. Engaging professionals with experience in working with advanced composites and industrial textiles can ensure the proper installation of the carbon fiber cloth.

"Proper installation techniques, compatibility with construction materials, adherence to industry standards, and expertise are crucial considerations when using unidirectional carbon fiber cloth in construction projects."

By considering these key factors, construction professionals can effectively utilize the benefits of unidirectional carbon fiber cloth and enhance the strength and durability of structures.

| Key Consideration | Details |

|---|---|

| Proper Installation Techniques | Follow manufacturer guidelines for surface preparation, adhesive selection, and curing methods. |

| Compatibility with Construction Materials | Assess compatibility with adhesives, fillers, and other components to ensure seamless integration. |

| Adherence to Industry Standards and Regulations | Stay updated with building codes, safety regulations, and design specifications. |

| Training and Expertise | Engage professionals with experience in working with carbon fiber cloth and advanced composites. |

Case studies of successful applications

In this section, we present real-life case studies that demonstrate the successful applications of unidirectional carbon fiber cloth in construction. These examples showcase how this innovative material has been effectively used to strengthen various structures, including buildings, bridges, and tunnels.

Case Study 1: Strengthening a High-Rise Building

In this case study, a high-rise building in a seismic-prone area was reinforced using unidirectional carbon fiber cloth. The fabric was strategically applied to key structural elements, enhancing their load-bearing capacity and improving the overall stability of the building. The use of unidirectional carbon fiber cloth not only prevented structural deformation but also minimized the need for costly and disruptive structural modifications.

Case Study 2: Bridge Rehabilitation

A deteriorating bridge in need of rehabilitation found its solution with unidirectional carbon fiber cloth. By wrapping the bridge's support piers and beams with the carbon fiber fabric, engineers effectively restored the bridge's load-bearing capacity and extended its service life. This cost-effective solution not only saved time but also allowed the bridge to remain open to traffic during the rehabilitation process.

Case Study 3: Tunnel Strengthening

Unidirectional carbon fiber cloth played a crucial role in strengthening a tunnel located in a highly corrosive environment. The fabric was applied to the tunnel's walls, providing exceptional resistance to chemicals and abrasion. The carbon fiber reinforcement significantly improved the tunnel's structural integrity and reduced the need for frequent maintenance, resulting in long-term cost savings.

"The use of unidirectional carbon fiber cloth in these construction projects has proven to be highly successful. The fabric's high strength and durability properties have effectively enhanced the structural integrity of the buildings, bridges, and tunnels, ensuring their long-term performance."

These case studies exemplify the wide-ranging applications of unidirectional carbon fiber cloth in the construction industry. The success of these projects highlights the numerous benefits of using this advanced material, including increased structural strength, enhanced durability, and cost-effective solutions.

Future prospects of unidirectional carbon fiber cloth in construction

As the construction industry continues to seek innovative materials and technologies, the future prospects for unidirectional carbon fiber cloth are promising. Ongoing research and development efforts are focused on enhancing the capabilities of this remarkable material for construction applications.

Unidirectional carbon fiber cloth, also known as carbon fiber fabric, has already revolutionized industries such as aerospace and automotive by providing unmatched strength and lightweight characteristics. It is now gaining traction in the construction sector due to its ability to reinforce structures and enhance their performance.

One area of development in the future of unidirectional carbon fiber cloth lies in the advancement of lightweight fabric technology. Lightweight fabrics offer the potential to reduce the overall weight of structures without compromising strength, resulting in more efficient and sustainable construction practices.

Additionally, unidirectional carbon fiber cloth is expected to find increasing use in industrial textiles. Its robustness, flexibility, and durability make it suitable for a variety of applications, such as reinforcing concrete, protecting against corrosion, and improving structural integrity in challenging environments.

"Unidirectional carbon fiber cloth has the potential to revolutionize the construction industry by offering a lightweight, high-strength alternative to traditional materials. With ongoing advancements in technology and an expanding range of applications, the future of this remarkable fabric looks bright."- Industry Expert

With a growing emphasis on sustainability and the need for more resilient structures, unidirectional carbon fiber cloth is poised to play a significant role in future construction projects. Its unique properties, including high strength-to-weight ratio and corrosion resistance, make it an ideal choice for enhancing the safety and durability of buildings and infrastructure.

The potential benefits of unidirectional carbon fiber cloth extend beyond its application as a reinforcement material. Innovations in manufacturing processes and the development of advanced composites hold the promise of expanding its range of uses in construction, further solidifying its position as a material of the future.

Conclusion

Unidirectional carbon fiber cloth and carbon fiber fabric have emerged as game-changers in the construction industry. Throughout this article, we have explored the application process, benefits, and future prospects of these advanced composites in strengthening structures and improving overall performance.

By incorporating unidirectional carbon fiber cloth, construction professionals can harness its exceptional properties to enhance the load-bearing capacity and durability of buildings, bridges, and other infrastructure. The high strength and lightweight nature of this fabric make it a reliable choice for reinforcing composite materials and aerospace structures.

Looking ahead, the future of unidirectional carbon fiber cloth in construction appears promising. Ongoing research and development efforts aim to capitalize on its potential and further optimize its capabilities. As technology advances, we can expect to see more innovative applications of carbon fiber fabric and the expansion of its use in various industrial textiles.

In conclusion, the use of unidirectional carbon fiber cloth has revolutionized the construction industry, presenting new possibilities for creating stronger, more resilient structures. By embracing this advanced material, we can forge a path towards safer, more sustainable construction practices, setting the stage for a future where composite materials and aerospace materials go hand in hand.

FAQ

What is unidirectional carbon fiber cloth?

Unidirectional carbon fiber cloth is a type of fabric that is made up of tightly woven carbon fiber strands aligned in a single direction. It is commonly used in composite materials and industrial textiles due to its high strength and lightweight properties. This fabric plays a crucial role in strengthening structures during the construction process.

What are the benefits of using unidirectional carbon fiber cloth in construction?

There are several benefits of using unidirectional carbon fiber cloth in construction. Firstly, it has excellent strength-to-weight ratio, making it an ideal choice for reinforcing structures without adding significant weight. Additionally, it enhances the durability and resistance of buildings and infrastructure. Its compatibility with other materials and ease of application also make it a popular option in the construction industry.

How is unidirectional carbon fiber cloth applied in construction?

The application process of unidirectional carbon fiber cloth in construction involves surface preparation, adhesive application, and curing techniques. The fabric is typically applied to the surface using adhesives, and then the adhesive is cured to ensure a strong bond. The adaptability of unidirectional carbon fiber cloth allows it to be used in various construction scenarios, including bridges, buildings, and tunnels.

How does unidirectional carbon fiber cloth strengthen structures in construction?

Unidirectional carbon fiber cloth strengthens structures in construction by providing increased load-bearing capacity and improving overall structural integrity. It effectively distributes stress and enhances the strength of the structure. The use of carbon fiber reinforcements further adds to the strength and durability of the construction elements, making them more resistant to various external forces.

What are the key considerations for using unidirectional carbon fiber cloth in construction?

When using unidirectional carbon fiber cloth in construction, it is important to consider factors such as proper installation techniques, compatibility with other construction materials, and adherence to industry standards and regulations. Proper training and expertise are also essential to ensure the correct handling and application of this advanced material.

Can you provide examples of successful applications of unidirectional carbon fiber cloth in construction?

Yes, there have been numerous successful applications of unidirectional carbon fiber cloth in construction. For instance, it has been used to reinforce bridges, strengthen building structures, and repair damaged infrastructure. These real-life case studies highlight the positive outcomes achieved and the significant benefits of using unidirectional carbon fiber cloth in various construction projects.

What are the future prospects of unidirectional carbon fiber cloth in construction?

The future prospects of unidirectional carbon fiber cloth in construction are promising. Ongoing research and development efforts are focused on further enhancing the capabilities of this material for construction applications. Advancements in lightweight fabric technology and its increased use in industrial textiles are also expected to expand the applications of unidirectional carbon fiber cloth in the construction industry, offering new opportunities for improvement and innovation.