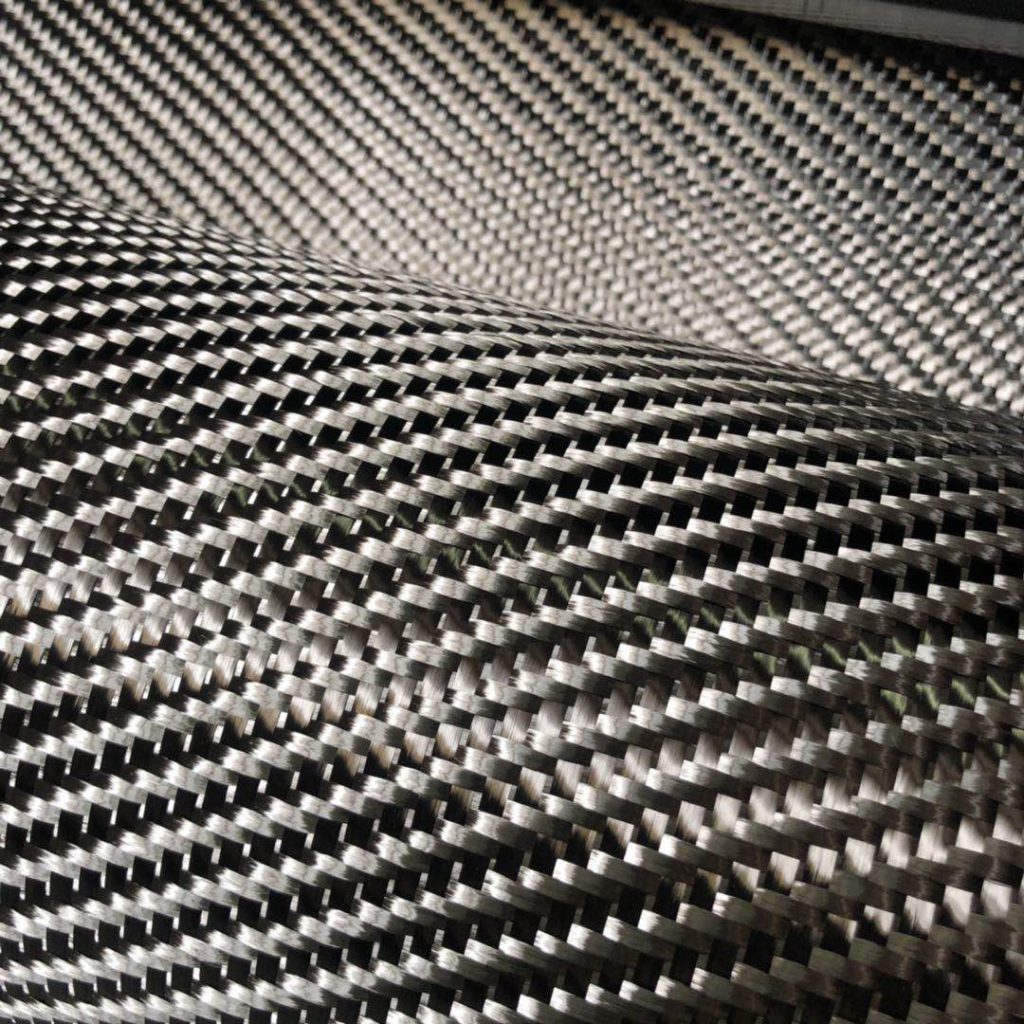

Bidirectional Carbon Fiber Cloth

Carbon fiber cloth is a strong and lightweight material that has numerous applications across various industries. Whether it's in aerospace, sporting goods or automotive manufacturing, carbon fiber cloth has revolutionized the way products are built and designed. In today's article, we will introduce the most popular type of carbon fiber cloth, to help you gain a better understanding of how this amazing material can be used. From woven to unidirectional, this article will provide you with all the information you need to know about carbon fiber cloth, its benefits, and its various applications. Whether you are a design engineer, a manufacturer, or simply fascinated by innovative materials, this article will surely leave you inspired. So, let's dive in and explore the exciting world of carbon fiber cloth!

Features

Popularity: 🌟🌟🌟🌟🌟

Strength: 🌟🌟🌟🌟

Lightweight: 🌟🌟🌟🌟🌟

Specification: 1K/3K/6K/12K/24K/48K

Pattern: Plain/Twill

Advantages:

- Exceptional Strength

- High Durability

- Lightweight

- Versatile

- Corrosion Resistant

- Fireproof

Common Applications:

- Automotive

Many people think that a full carbon fiber car costs more than a house. Don't think this is a rumor, it's true!Carbon fiber cloth is a high-performance material with high strength, lightweight and upgraded appearance. It is one of the most popular materials in car modification. The most common specifications are 3K200G and 3K240G plain/twill. Unlike traditional materials like steel or aluminum, carbon fiber is incredibly tough and resistant to impacts. This means that a car made of carbon fiber can handle higher speeds, sharper turns, and more extreme conditions without breaking down or sustaining damage. That's why carbon fiber modifications can be so expensive. Of course, it’s also worth trying if you’re looking for a high-performance driving experience.

2. Medical

Alright everyone, it's time to get excited about something that many of us may not have thought about before…carbon fiber tubes! Yes, you heard me right. And no, I'm not kidding.

Believe it or not, these sleek and lightweight tubes are actually used to make prosthetic limbs. Why, you ask? Well, let's think about it. When you're walking around with a prosthetic leg or arm, the last thing you want is something heavy and bulky weighing you down. And you don't want someone walking around with a heavy metal leg, do you? Plus, you can't forget about the added benefit of looking like a futuristic cyborg. Who wouldn't want that kind of attention? Plus, the durability of carbon fiber means these prosthetic legs can handle some serious wear and tear. So, if you ever find yourself in need of a new leg, don't worry, just look for the one made out of carbon fiber. Trust me, it's the ultimate upgrade.

That's where carbon fiber comes in. With its super strong and lightweight properties, it's the perfect material to use in creating prosthetic limbs. Plus, who wouldn't want to walk around with a limb that looks like it belongs on a high-tech robot? I know I would.

So, next time you see someone walking around with a carbon fiber prosthetic, you can now impress them with your knowledge of just how cool and practical their limb truly is. Trust me, they'll appreciate it.

3. Aerospace

Gone are the days when materials like aluminum and steel ruled the skies. Carbon fiber has taken over and given a new meaning to the phrase "light as a feather." Its incredible strength to weight ratio has made it possible for planes to fly longer distances without refueling, carry heavier loads, and improve overall performance.

It's like having a personal trainer for your aircraft. Carbon fiber helps planes get in shape and stay in shape. No more flabby, heavy wings or fuselages. With carbon fiber, everything is sleek, compact, and efficient. Who needs a gym when you have carbon fiber?

And let's not forget the aesthetic appeal of carbon fiber. Its distinctive pattern has become a symbol of modern aviation. It's like the superhero costume for planes. Who needs a fashion designer when you have carbon fiber?

In conclusion, carbon fiber is the superhero of the aerospace industry. It has transformed the way planes are designed and built. Its incredible properties have made air travel safer, more efficient, and more stylish. So, next time you're flying, take a moment to appreciate the real hero of the skies - carbon fiber.

How Many Colors Do Bidirectional Carbon Fiber Cloth Have?

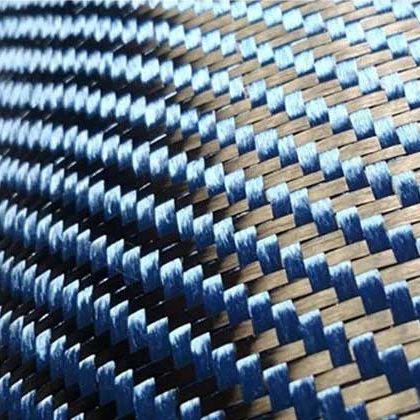

While black is the most common color of carbon fiber fabric, there are options available for those looking to add some color to their projects. One option is to use colored resin during the manufacturing process. This can result in carbon fiber fabric with a range of colors such as blue, red, and green. Another option is to apply a colored film or vinyl wrap to the surface of the fabric. This offers a wider range of colors and designs to choose from, as well as the ability to customize the appearance for a specific project or application.

At the same time, there are many hybrid carbon fiber cloths mixed with metal wires or kevlar fiber on the market, which are very popular among young people. It’s very cool to show different lusters and colors under different lights.