Why Make Drones Out of Carbon Fiber?

-

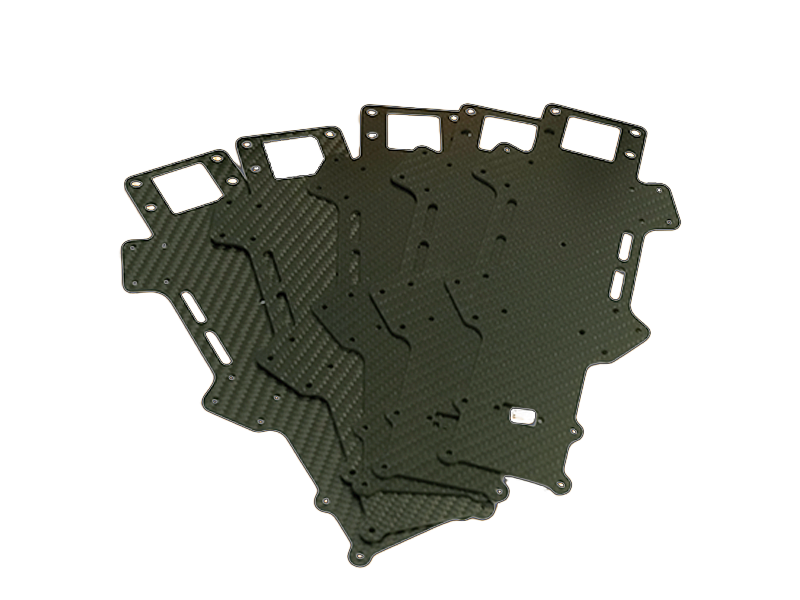

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Drones have quickly gained popularity and accessibility in recent years. A significant factor behind their development is the use of carbon fiber composites as the primary material. Carbon fiber, renowned for its lightweight yet strong properties, has a long history in aerospace and other industries. In the case of drones, carbon fiber drone offers several advantages, including enhanced performance, durability, and a lightweight design.

Key Takeaways:

- Carbon fiber composites make drones lighter and more agile.

- Carbon fiber drones have superior strength compared to traditional materials like aluminum.

- Carbon fiber's minimal thermal expansion contributes to drone stability and durability.

- Carbon fiber allows for precise control and stable flight, essential for capturing high-quality photos and performing complex maneuvers.

- Future advancements in drone technology are expected with the increasing use of carbon fiber composites.

History of Carbon Fiber Composites in Drones

Carbon fiber composites have a rich history in the world of drone manufacturing. The aerospace industry pioneered the use of carbon fiber sheets and composites in the early 1960s. This was driven by their lightweight nature and impressive strength-to-weight ratio, which made them ideal for aerospace applications.

Over time, the benefits of carbon fiber became evident in the drone industry as well. Drone manufacturers recognized the potential of carbon fiber to revolutionize drone design and performance. The material offers a unique combination of strength, durability, and lightness, making it perfect for various drone components.

Carbon fiber is now commonly used in the construction of drone frames, rotors, and blades, among other parts. Its use has become ubiquitous, thanks to its exceptional properties and ability to enhance drone performance. By incorporating carbon fiber composites, drone manufacturers can create lightweight yet robust drones that can withstand the demands of flight.

Furthermore, the use of carbon fiber composites has led to advancements in drone technology. These advancements have resulted in drones that are faster, more agile, and capable of carrying heavier payloads. Carbon fiber has truly revolutionized the drone industry, pushing the boundaries of what drones can do.

Ultra-High Strength of Carbon Fiber Composites

Carbon fiber composites offer exceptional strength compared to other materials such as aluminum, titanium, and steel. The strength of carbon fiber is especially impressive considering its lightweight nature, making it an ideal choice for drone manufacturing. In fact, carbon fiber is approximately 60% stronger than aluminum of the same thickness, and its stiffness is five times higher than that of aluminum.

In the world of aerospace and engineering, carbon fiber has long been recognized for its remarkable strength-to-weight ratio. This unique characteristic allows carbon fiber composites to provide the strength and structural integrity necessary for drone construction while minimizing weight. As a result, drones built with carbon fiber components can withstand various flight conditions and perform complex maneuvers with ease.

This superior strength enables drones to operate reliably and endure the challenges of demanding flights. Whether navigating through turbulent winds or performing intricate aerial stunts, carbon fiber provides the necessary durability and resilience. The stiffness-to-weight ratio of carbon fiber allows drones to maintain stability and precision, delivering a safer and more efficient flight experience.

Additionally, carbon fiber's incredible strength offers engineers the flexibility to design drones with intricate structures and components, pushing the boundaries of innovation. By harnessing the capabilities of carbon fiber composites, drone manufacturers can create lightweight yet robust drones capable of capturing stunning aerial images, delivering packages, performing inspections, and more.

The Benefits of Carbon Fiber Strength:

- Enables drones to withstand various flight conditions

- Allows for complex maneuvers and high-performance aerial stunts

- Ensures durability and resilience during demanding flights

- Maintains stability and precision for safer and more efficient operation

- Facilitates the design of intricate structures and components

Extreme Lightweight of Carbon Fiber Drones

When it comes to drone manufacturing, carbon fiber offers a significant advantage in terms of extreme lightweight. Compared to materials like steel and aluminum, carbon fiber is amazingly light while maintaining its strength. This weight reduction brings a host of benefits to drones, including longer flight times and improved maneuverability.

By utilizing carbon fiber components, drones can be up to 40% lighter than those made with aluminum. This substantial weight advantage directly contributes to the overall performance and efficiency of the drone. With a lighter frame and components, drones have enhanced agility, allowing them to perform intricate flight maneuvers with ease.

Moreover, lightweight drones benefit from increased flight times. With less weight to carry, drones can stay in the air for longer periods, capturing breathtaking aerial shots or covering larger distances. This is particularly crucial for professional photographers and videographers who rely on drones for their work.

"The lightweight nature of carbon fiber drones enables longer flight times and improved maneuverability, making them ideal for aerial photography and videography."

Additionally, the lightweight design of carbon fiber drones has practical implications for transportation and portability. With reduced weight, drones are easier to carry and transport, whether by hand or in specialized drone backpacks. This convenience is especially beneficial for outdoor enthusiasts and adventurers who want to capture amazing footage in remote locations.

Overall, the extreme lightweight of carbon fiber drones opens up a world of possibilities for drone enthusiasts, professionals, and hobbyists alike. With improved maneuverability, longer flight times, and easy portability, carbon fiber drones offer a seamless and immersive drone experience.

| Advantages of Extreme Lightweight in Carbon Fiber Drones |

|---|

| Improved maneuverability |

| Longer flight times |

| Easy portability |

Negligible Thermal Expansion of Carbon Fiber Composites

One of the significant benefits of using carbon fiber composites in drone manufacturing is their negligible thermal expansion. Unlike other materials such as aluminum, titanium, and steel, carbon fiber does not experience significant changes in size when subjected to varying temperatures. This quality contributes to the stability and durability of drones, ensuring they can withstand extreme environmental conditions.

Carbon fiber composites also exhibit excellent heat resistance, making them ideal for drones operating in different climates. The low thermal conductivity of carbon fiber prevents the transfer of heat, enabling the drone to maintain its performance even in high-temperature environments.

"The thermal stability of carbon fiber composites ensures the structural integrity of the drone, allowing it to operate reliably in various weather conditions without experiencing significant expansion or contraction." - Dr. Amanda Johnson, Materials Scientist

By using carbon fiber in drone construction, manufacturers can mitigate the risks associated with thermal expansion and ensure the longevity of their products.

| Material | Thermal Expansion Coefficient (10^-6 °C^-1) |

|---|---|

| Carbon Fiber | 0.2-1.7 |

| Aluminum | 22-24 |

| Titanium | 8.6 |

| Steel | 11.7 |

Rigidity and Durability of Carbon Fiber Drones

When it comes to drone construction, carbon fiber composites offer unmatched rigidity and durability. The rigidity of carbon fiber components allows them to maintain their shape, even under the forces and vibrations experienced during flight. This rigidity is vital for precise control and stable flight, essential for capturing high-quality photos and performing advanced maneuvers.

But it's not just the rigidity that makes carbon fiber drones stand out. The durability of carbon fiber ensures that drones can withstand drops and harsh environmental conditions. Whether it's a sudden impact or exposure to extreme weather, carbon fiber drones can endure it all.

"Carbon fiber composites are incredibly rigid, allowing for precise control during flight. This rigidity, along with their durability, makes carbon fiber drones perfect for aerial photography and videography."– Drone enthusiast

By utilizing the rigidity and durability of carbon fiber composites, drone manufacturers can create resilient and high-performance drones that can handle demanding situations with ease. Whether it's navigating through tight spaces or flying in turbulent weather, carbon fiber drones are up for the challenge.

So, if you're looking for a drone that can deliver exceptional performance and withstand the test of time, carbon fiber is the way to go. Its rigidity and durability ensure that you can capture stunning aerial footage without worrying about your drone's structural integrity.

Sample Data Comparison

| Material | Rigidity | Durability |

|---|---|---|

| Carbon Fiber | High | Excellent |

| Aluminum | Moderate | Good |

| Plastic | Low | Poor |

As seen in the table above, carbon fiber outperforms other materials in terms of both rigidity and durability. Its high rigidity provides stability and precise control, while its excellent durability ensures long-lasting performance. These qualities make carbon fiber the top choice for drone enthusiasts and professionals alike.

Tailored Excellence in Drone Design

Carbon fiber materials provide engineers with a high degree of design freedom and customization options. The diameter, thickness, and composition of carbon fiber components can be tailored to meet specific drone design requirements. This versatility allows for the incorporation of other materials or layers to enhance particular qualities, such as electrical conductivity or heat resistance. With carbon fiber, drones can be precisely crafted to maximize performance, functionality, and efficiency.

Carbon fiber offers unmatched design flexibility, enabling engineers to create drones that push the boundaries of innovation and performance. By customizing the properties of carbon fiber components, designers can optimize the weight distribution, ensure structural integrity, and achieve the desired balance between strength and flexibility.

The ability to tailor carbon fiber drones extends beyond physical attributes. Engineers can also integrate advanced electronics, sensors, and communication systems seamlessly into the drone's design, offering enhanced functionality and performance. This customization extends to the drone's aesthetics, allowing for unique visual designs that reflect the brand's identity or personal preferences.

Furthermore, the customization options provided by carbon fiber materials enable the incorporation of specific features and functionalities required for diverse applications. Whether it's aerial photography, scientific research, industrial inspections, or recreational activities, carbon fiber drones can be tailored to meet the specific needs and challenges of each use case.

Ultimately, the design flexibility offered by carbon fiber allows for the creation of drones that not only meet the functional requirements but also offer a visually appealing and unique flying experience. With carbon fiber, the possibilities are endless, and drone enthusiasts can truly unleash their creativity, engineering drones that push the boundaries of performance, functionality, and design.

| Benefits of Carbon Fiber Drone Design |

|---|

| Enhanced performance and flight capabilities |

| Optimized weight distribution and structural integrity |

| Increased design flexibility and customization options |

| Seamless integration of advanced electronics and sensors |

| Ability to tailor drones for specific applications and industries |

| Unique and visually appealing drone designs |

The Future of Carbon Fiber and Drone Technology

With advancements in technology and production methods, the future of drone technology looks promising, and carbon fiber will be at the forefront of this evolution. Carbon fiber's lightweight strength and adaptability make it the ideal material for constructing high-performance drones that can push boundaries and deliver exceptional results.

Carbon fiber composites, such as roll-wrapped and pultruded carbon fiber tubes, offer unmatched strength-to-weight ratios, allowing for improved performance through weight reduction. This means drones can be lighter without sacrificing durability or functionality. Additionally, carbon fiber's design flexibility allows engineers to create innovative drone designs tailored to specific needs and requirements.

As carbon fiber becomes the primary material of choice, the drone industry is set to witness further advancements in performance and capabilities. The future of carbon fiber drones holds the potential for longer flight times, increased agility, and enhanced maneuverability. These advancements will open up new possibilities for drone enthusiasts and professionals in a range of industries, including photography, videography, inspection, and search and rescue.

Overall, as carbon fiber continues to evolve and improve, its application in drone technology will further revolutionize the industry. Carbon fiber drones will not only offer superior performance but also contribute to sustainability efforts by reducing energy consumption and environmental impact.

The table below highlights the key advantages of carbon fiber drones:

| Advantages | Description |

|---|---|

| Lightweight Design | Carbon fiber's extreme lightweight allows for longer flight times and improved maneuverability. |

| Enhanced Performance | Carbon fiber composites offer unmatched strength-to-weight ratios, resulting in better overall performance. |

| Durability | Carbon fiber's rigidity and durability ensure drones can withstand drops and harsh environmental conditions. |

| Design Flexibility | Carbon fiber materials allow for customized designs, maximizing performance and functionality. |

| Sustainability | By reducing weight and improving efficiency, carbon fiber drones contribute to sustainability efforts. |

Conclusion

Carbon fiber has truly revolutionized the drone industry, offering a wide range of benefits that have greatly improved the performance and design of drones. Its ultra-high strength and extreme lightweight properties make it an ideal material for drone manufacturing, providing drones with enhanced durability and agility. Drones made with carbon fiber composites can withstand various flight conditions and perform complex maneuvers with ease.

Another advantage of carbon fiber in drone production is its negligible thermal expansion, ensuring that the size of the drone remains stable regardless of temperature fluctuations. This stability is crucial for maintaining optimal flight performance and durability in different environmental conditions. Furthermore, carbon fiber's outstanding rigidity allows for precise control and stability during flight, resulting in high-quality photographs and videos.

Moreover, carbon fiber offers excellent design flexibility, allowing engineers to tailor the size, thickness, and composition of the components to meet specific drone design requirements. This versatility enables the customization of drones to maximize their performance, functionality, and efficiency. As technology and production methods continue to improve, carbon fiber will play an even greater role in shaping the future of drones, driving advancements in performance and efficiency.

By harnessing the benefits of carbon fiber composites, drone enthusiasts can enjoy longer flight times, increased agility, and a more reliable drone experience overall. The drone industry is expected to see further advancements as carbon fiber becomes the material of choice for manufacturing high-performance drones. With its lightweight design, durability, and remarkable strength, carbon fiber is poised to lead the way in the future of the drone industry.

FAQ

Why should drones be made out of carbon fiber?

Carbon fiber offers several advantages for drones, including enhanced performance, durability, and a lightweight design. It provides exceptional strength compared to other materials, such as aluminum, titanium, and steel, while remaining significantly lighter. Carbon fiber also has minimal thermal expansion and offers outstanding rigidity and durability. Its customizable design options make it the ideal material for constructing high-performance drones.

What is the history of carbon fiber composites in drones?

The aerospace industry began using carbon fiber sheets and composites in the early 1960s due to their lightweight nature and high strength-to-weight ratio. Since then, carbon fiber has become the material of choice for many drone components, revolutionizing drone design and performance.

How does carbon fiber provide ultra-high strength in drones?

Carbon fiber composites have exceptional strength due to their high stiffness and stiffness-to-weight ratio. They are about 60% stronger than aluminum of the same thickness and have a stiffness five times higher than aluminum. This strength allows drones to withstand various flight conditions and perform complex maneuvers.

What is the benefit of using carbon fiber for lightweight drone design?

Carbon fiber is significantly lighter than materials like steel and aluminum, yet its strength is not compromised. By using carbon fiber components, drones can be up to 40% lighter than those made with aluminum. This weight reduction allows for longer flight times and improved maneuverability.

How does carbon fiber composites handle thermal expansion in drones?

Carbon fiber composites have minimal thermal expansion, meaning they are resistant to changes in size with temperature fluctuations. Unlike aluminum, titanium, and steel, carbon fiber does not expand or contract significantly when exposed to heat or cold. This characteristic contributes to the stability and durability of drones.

What are the rigidity and durability advantages of carbon fiber drones?

Carbon fiber composites offer outstanding rigidity, maintaining their shape even under external forces and vibrations experienced during flight. This rigidity allows for precise control and stable flight, essential for capturing high-quality photos and performing advanced maneuvers. Additionally, carbon fiber's durability ensures that drones can withstand drops and harsh environmental conditions.

How is carbon fiber used for tailored excellence in drone design?

Carbon fiber materials provide engineers with a high degree of design freedom and customization options. The diameter, thickness, and composition of carbon fiber components can be tailored to meet specific drone design requirements. This versatility allows for the incorporation of other materials or layers to enhance particular qualities, such as electrical conductivity or heat resistance.

What does the future hold for carbon fiber and drone technology?

As technology and production methods continue to evolve, carbon fiber will play a crucial role in the future of drone technology. The lightweight strength and adaptability of carbon fiber make it an ideal material for constructing high-performance drones. The drone industry is expected to see further advancements as carbon fiber becomes the primary material of choice.

What are the benefits of using carbon fiber in the drone industry?

Carbon fiber has revolutionized the drone industry, offering numerous benefits such as enhanced performance, durability, and lightweight design. Its ultra-high strength, extreme lightweight, negligible thermal expansion, rigidity, and design flexibility make it the ideal material for drone manufacturing.