Aerospace Industry

Aramid short-cut fiber is used in aircraft components, such as landing gear, engine covers, and structural parts, due to its high strength-to-weight ratio and resistance against heat, abrasion, and impact.

Composite materials have played a crucial role in the aerospace and aviation industry, providing lightweight and strong components for aircraft. With their high strength-to-weight ratio and durability, composites have enabled the development of more efficient and cost-effective aircraft, leading to significant advancements in air travel. This relationship between composite material and the aerospace and aviation industry has led to numerous innovations and breakthroughs in aircraft design and engineering.

One of the most significant benefits of composite materials is that they are lightweight. This feature is crucial in the aerospace and aviation industry, where the weight of the aircraft affects the amount of fuel consumed during flight. The lighter the material, the less fuel the aircraft will consume, and this has a positive impact on the aircraft's performance.

Composite materials are also highly durable and resilient. This feature is vital in the aerospace and aviation industry, where aircraft components are exposed to different temperatures, pressure, and other environmental factors. Composite materials are designed to withstand all these conditions, meaning that aircraft built with them can withstand high-speed impacts and vibrations, both on the ground and in the air.

Composite materials are also more cost-effective compared to other materials used in the aerospace and aviation industry. Although composite materials are initially more expensive, they last longer and require less maintenance than other materials. This makes them a more cost-effective option in the long run and can help companies save on operational costs.

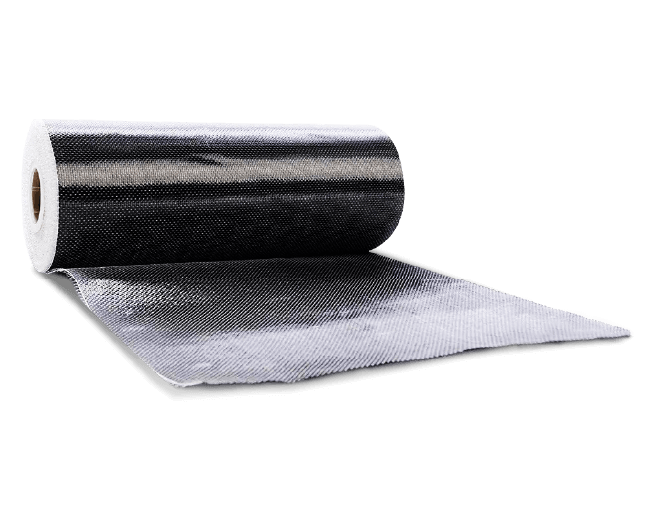

Carbon fiber has revolutionized the Aerospace and Aviation industry, offering exceptional strength and durability while being lightweight. This remarkable material is used in the manufacturing of aircraft and rocket components, including wings, fuselages, and propulsion systems. Its remarkable properties have significantly improved the performance of these aerospace products, making them more fuel-efficient and safer for passengers.

Heat Shields

Electrical Wiring

Engine Components

Protective Gear

Aircraft Structures

Composite materials such as ceramic fibers are used in the manufacture of heat shields that protect critical components of the aircraft from heat damage. These fibers are known for their excellent thermal stability and resistance to high temperatures.

Composite materials such as aramid fibers are used in the manufacture of electrical wiring and cables in aircraft. These fibers are lightweight and have excellent electrical insulation properties that make them ideal for use in aviation.

Composite materials are also used in the manufacture of engine components such as turbine blades, fan blades, and exhaust systems. These fibers help to improve the efficiency of the engine by reducing its weight and increasing its strength.

Composite materials such as aramid fibers are used in the manufacture of protective gear for pilots and ground crew members. These fibers are lightweight and provide excellent protection against impacts, cuts, and abrasion.

Composite materials such as carbon fibers are used in the manufacture of aircraft structures such as wings, fuselages, and empennages. These fibers help to reduce the overall weight of the aircraft, increase its strength, and improve its fuel efficiency.

Experienced service team and strong production support team provide client worry-free order service.

Get our catalog in just 30 seconds! Simply fill in your information and we'll send the file directly to your email address.

Send Email

info@ictfibers.com

Send Email

info@ictfibers.com

Have any Questions?

+86 571 8609 8806 (Office)

+86 150 5710 8966 (Whatsapp)

Have any Questions?

+86 571 8609 8806 (Office)

+86 150 5710 8966 (Whatsapp)