How to Test Carbon Fiber Fabric Rolls for Consistency?

-

Table of Contents

“Ensure Quality: Test Carbon Fiber Fabric Rolls for Consistency with Precision.”

Introduction

Testing carbon fiber fabric rolls for consistency is crucial to ensure the quality and performance of composite materials in various applications. Consistency in fiber alignment, weight, thickness, and resin content directly impacts the mechanical properties and durability of the final product. This introduction outlines the essential methods and techniques for evaluating carbon fiber fabric rolls, including visual inspections, mechanical testing, and advanced analytical methods. By implementing these testing protocols, manufacturers can maintain high standards and ensure that their carbon fiber materials meet the required specifications for optimal performance in aerospace, automotive, and other high-performance industries.

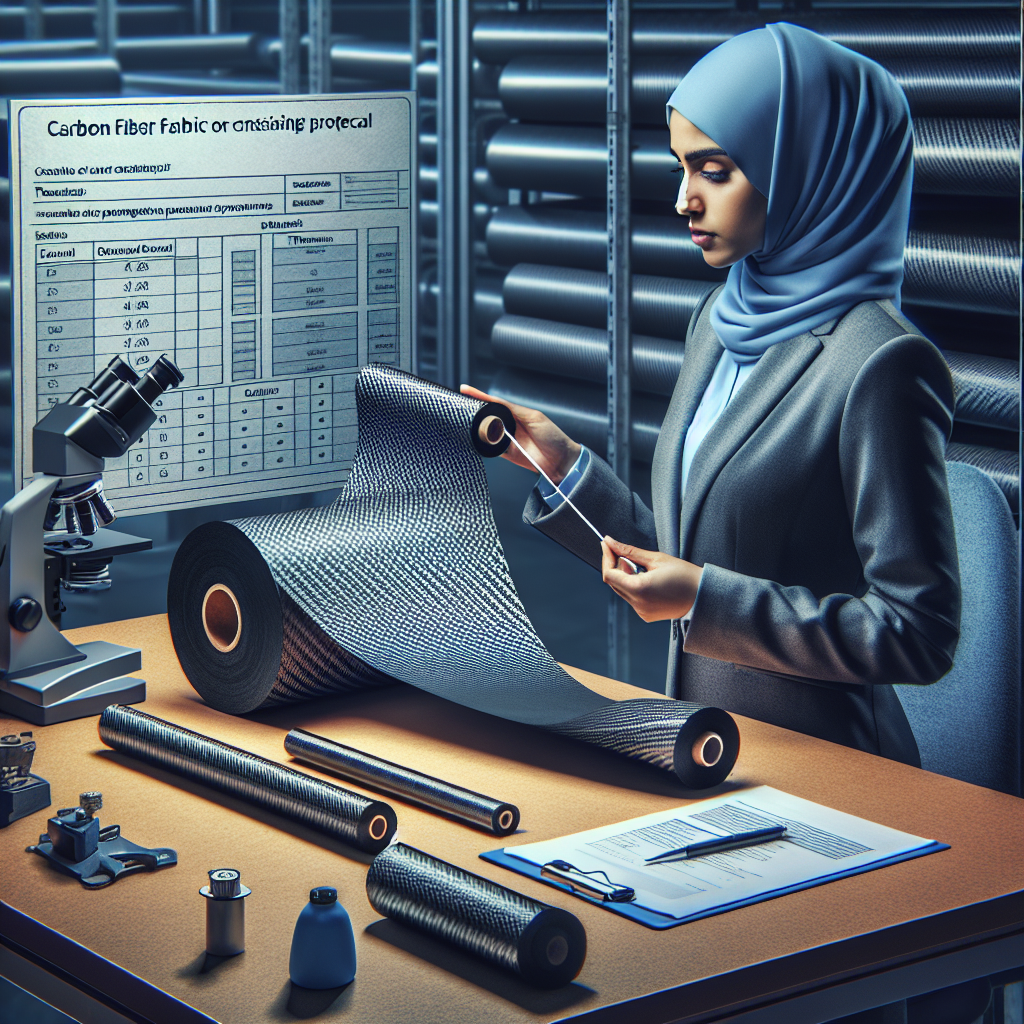

Visual Inspection Techniques for Carbon Fiber Fabric Rolls

When assessing the quality of carbon fiber fabric rolls, visual inspection techniques play a crucial role in ensuring consistency and reliability. The initial step in this process involves a thorough examination of the fabric’s surface. Inspectors should look for any visible defects such as tears, fraying, or irregularities in the weave pattern. These imperfections can significantly affect the performance of the final composite material, making it essential to identify them early in the evaluation process. A consistent weave pattern is indicative of high-quality manufacturing, as it suggests uniformity in the distribution of fibers, which is vital for achieving optimal mechanical properties.

In addition to surface defects, the color and texture of the carbon fiber fabric should also be scrutinized. Variations in color can indicate inconsistencies in the resin content or the curing process, which may compromise the integrity of the fabric. Inspectors should ensure that the fabric exhibits a uniform appearance, as any discoloration could signal underlying issues that may not be immediately apparent. Furthermore, the texture of the fabric should be smooth and even, as rough patches or bumps can interfere with the bonding process when the fabric is combined with resin.

Another important aspect of visual inspection is the evaluation of the fabric’s edges. The edges should be cleanly cut and free from any fraying or delamination. Jagged or uneven edges can complicate the fabrication process and may lead to weak points in the final product. Therefore, it is essential to ensure that the edges of the carbon fiber rolls are well-defined and consistent throughout the entire length of the roll.

Moreover, the roll itself should be examined for any signs of damage or deformation. Inspectors should check for kinks, creases, or other distortions that could affect the fabric’s performance. A well-maintained roll will have a uniform diameter and should unwind smoothly without any resistance. Any irregularities in the roll’s shape can lead to complications during the cutting and application processes, ultimately impacting the quality of the finished composite.

In addition to these visual checks, it is beneficial to utilize magnification tools, such as a loupe or microscope, to inspect the fabric at a closer range. This allows for the detection of finer details that may not be visible to the naked eye. For instance, examining the fiber alignment and density can provide insights into the overall quality of the fabric. A consistent fiber alignment is crucial for ensuring that the mechanical properties of the composite are uniform, while a dense arrangement of fibers typically indicates a higher strength-to-weight ratio.

Furthermore, documenting the findings from the visual inspection is essential for maintaining quality control. Inspectors should take detailed notes and photographs of any defects or inconsistencies observed during the evaluation process. This documentation not only serves as a reference for future inspections but also helps in identifying trends or recurring issues that may need to be addressed by the manufacturer.

In conclusion, visual inspection techniques are vital for assessing the consistency of carbon fiber fabric rolls. By carefully examining the surface, color, texture, edges, and overall condition of the rolls, inspectors can identify potential issues that may affect the performance of the final composite material. Utilizing magnification tools and maintaining thorough documentation further enhances the reliability of the inspection process, ultimately contributing to the production of high-quality carbon fiber composites.

Mechanical Testing Methods for Assessing Fabric Consistency

When it comes to ensuring the quality and reliability of carbon fiber fabric rolls, mechanical testing methods play a crucial role in assessing fabric consistency. These methods are essential for manufacturers and engineers who rely on the performance characteristics of carbon fiber composites in various applications, from aerospace to automotive industries. To begin with, tensile testing is one of the most fundamental mechanical tests used to evaluate the strength and elasticity of carbon fiber fabrics. This process involves applying a uniaxial load to a sample until it fractures, allowing for the measurement of key parameters such as tensile strength, elongation at break, and modulus of elasticity. By comparing these values against established standards or specifications, manufacturers can determine whether the fabric meets the required performance criteria.

In addition to tensile testing, shear testing is another important method for assessing the consistency of carbon fiber fabrics. Shear strength is critical in applications where fabrics are subjected to forces that can cause them to slide or deform. During shear testing, a sample is subjected to a controlled shear force, and the resulting data provides insights into the fabric’s ability to withstand such stresses. This information is vital for ensuring that the fabric will perform reliably in real-world applications, where it may encounter various loading conditions.

Moreover, flexural testing is also employed to evaluate the bending properties of carbon fiber fabrics. This test involves applying a load to a sample while it is supported at both ends, measuring the deflection and the force required to achieve that deflection. The results yield valuable information about the fabric’s stiffness and resistance to bending, which are critical factors in applications where the material will be subjected to dynamic loads or flexural stresses. By conducting flexural tests, manufacturers can ensure that their carbon fiber fabrics maintain structural integrity under various conditions.

Another significant aspect of mechanical testing is the assessment of impact resistance. Impact testing evaluates how well a carbon fiber fabric can absorb energy when subjected to sudden forces, which is particularly important in applications where the material may experience collisions or other high-energy events. By using standardized impact testing methods, such as the Charpy or Izod tests, manufacturers can quantify the energy absorption capacity of their fabrics, providing further assurance of their performance and durability.

Furthermore, it is essential to consider the consistency of the fabric’s properties across different rolls. Variability in mechanical properties can arise from factors such as manufacturing processes, raw material quality, and environmental conditions. To address this, it is advisable to conduct batch testing, where samples from different rolls are tested to ensure uniformity in performance characteristics. This approach not only helps in identifying any discrepancies but also aids in maintaining quality control throughout the production process.

In conclusion, mechanical testing methods are indispensable for assessing the consistency of carbon fiber fabric rolls. Through tensile, shear, flexural, and impact testing, manufacturers can gain a comprehensive understanding of the fabric’s mechanical properties and performance capabilities. By implementing these testing protocols, they can ensure that their products meet the stringent requirements of various applications, ultimately leading to enhanced reliability and customer satisfaction. As the demand for high-performance materials continues to grow, the importance of rigorous testing and quality assurance in the carbon fiber industry cannot be overstated.

Moisture Content Analysis in Carbon Fiber Fabric Rolls

Moisture content analysis is a critical aspect of evaluating carbon fiber fabric rolls, as it directly influences the material’s performance and longevity. Carbon fiber, known for its exceptional strength-to-weight ratio and rigidity, is often used in high-performance applications such as aerospace, automotive, and sporting goods. However, the presence of moisture within the fabric can lead to a range of issues, including compromised mechanical properties, reduced adhesion during the curing process, and potential degradation over time. Therefore, understanding how to accurately assess moisture content is essential for manufacturers and end-users alike.

To begin with, it is important to recognize that moisture can be absorbed by carbon fiber fabrics during storage, handling, or even manufacturing processes. Consequently, the first step in moisture content analysis involves establishing a baseline for acceptable moisture levels specific to the type of carbon fiber being tested. This baseline is typically determined through industry standards or manufacturer specifications, which provide guidelines on the maximum allowable moisture content for optimal performance.

Once the acceptable moisture levels are established, various methods can be employed to measure the moisture content in carbon fiber fabric rolls. One of the most common techniques is the oven-drying method, which involves weighing a sample of the fabric, drying it in an oven at a specified temperature for a predetermined period, and then reweighing it. The difference in weight before and after drying provides a direct measurement of the moisture content. This method is widely regarded for its accuracy; however, it can be time-consuming and may not be suitable for all production environments.

In addition to the oven-drying method, other techniques such as moisture meters and infrared spectroscopy can also be utilized. Moisture meters, which use electrical resistance or capacitance to estimate moisture levels, offer a quicker alternative to the oven-drying method. While they may not provide the same level of precision, they are particularly useful for on-site testing and can help identify fabrics that exceed acceptable moisture thresholds. Infrared spectroscopy, on the other hand, leverages the interaction of infrared light with the material to determine moisture content. This method is non-destructive and can be performed rapidly, making it an attractive option for quality control in manufacturing settings.

Regardless of the method chosen, it is crucial to ensure that the testing process is consistent and repeatable. This can be achieved by standardizing sample sizes, testing conditions, and equipment calibration. Additionally, conducting multiple tests on different samples from the same roll can help account for variability and provide a more comprehensive understanding of the moisture content throughout the fabric.

Furthermore, it is essential to consider the implications of moisture content on the overall quality of the carbon fiber fabric. High moisture levels can lead to issues such as delamination, reduced tensile strength, and compromised bonding with resins during the composite manufacturing process. Therefore, maintaining moisture levels within acceptable limits is not only a matter of compliance but also a critical factor in ensuring the reliability and performance of the final product.

In conclusion, moisture content analysis is a vital component of testing carbon fiber fabric rolls for consistency. By employing appropriate measurement techniques and adhering to established standards, manufacturers can effectively monitor moisture levels, thereby safeguarding the integrity and performance of carbon fiber materials. Ultimately, a thorough understanding of moisture content will contribute to the production of high-quality carbon fiber composites that meet the demanding requirements of various applications.

Q&A

1. **Question:** What is the first step in testing carbon fiber fabric rolls for consistency?

**Answer:** The first step is to visually inspect the fabric for any defects, such as uneven weave patterns, discoloration, or foreign materials.

2. **Question:** How can you measure the weight of the carbon fiber fabric to ensure consistency?

**Answer:** Use a precise scale to weigh a known area of the fabric (e.g., a square meter) and compare it to the manufacturer’s specifications to check for consistency in weight.

3. **Question:** What method can be used to test the tensile strength of the carbon fiber fabric?

**Answer:** Conduct a tensile test using a universal testing machine to measure the fabric’s strength and elongation properties, comparing the results to established standards for consistency.