How to Prevent Oxidation in Carbon-Carbon Fiber Components?

-

Table of Contents

“Shield Your Strength: Effective Strategies to Prevent Oxidation in Carbon-Carbon Fiber Components.”

Introduction

Oxidation in carbon-carbon fiber components can significantly compromise their structural integrity and performance, particularly in high-temperature applications. To prevent oxidation, it is essential to implement effective strategies that protect these materials from exposure to oxygen and moisture. This introduction outlines key methods for mitigating oxidation, including the use of protective coatings, optimizing processing techniques, and employing inert atmospheres during manufacturing and storage. By understanding and applying these preventive measures, manufacturers can enhance the durability and longevity of carbon-carbon fiber components in demanding environments.

Proper Storage Techniques for Carbon-Carbon Fiber Components

Proper storage techniques for carbon-carbon fiber components are essential in preventing oxidation, which can significantly compromise the integrity and performance of these advanced materials. Carbon-carbon composites, known for their exceptional strength-to-weight ratio and thermal stability, are widely used in aerospace, automotive, and industrial applications. However, their susceptibility to oxidation, particularly at elevated temperatures, necessitates careful consideration of storage conditions to maintain their properties over time.

To begin with, it is crucial to store carbon-carbon fiber components in a controlled environment. Ideally, the storage area should be cool, dry, and well-ventilated. High humidity levels can accelerate oxidation processes, so maintaining a relative humidity below 50% is advisable. Additionally, temperature fluctuations should be minimized, as extreme heat can exacerbate the oxidation of the carbon matrix. Therefore, a climate-controlled storage facility is often the best choice for preserving these materials.

Moreover, the use of protective coverings can further enhance the longevity of carbon-carbon fiber components. Wrapping these components in moisture-resistant materials, such as polyethylene or specialized vacuum-sealed bags, can shield them from environmental contaminants and moisture. This protective layer not only prevents direct exposure to humidity but also reduces the risk of physical damage during handling and storage. It is also beneficial to ensure that the storage containers are clean and free from any substances that could react with the carbon fibers.

In addition to environmental controls and protective coverings, it is important to consider the arrangement of carbon-carbon fiber components during storage. Components should be stored in a manner that prevents physical stress or deformation. Using racks or shelves designed specifically for these materials can help maintain their shape and prevent any potential damage. Furthermore, components should be stored away from direct sunlight, as ultraviolet radiation can degrade the resin matrix and contribute to oxidation.

Another critical aspect of proper storage is the regular inspection of carbon-carbon fiber components. Periodic checks can help identify any signs of oxidation or degradation early on, allowing for timely intervention. During these inspections, it is essential to look for discoloration, surface cracks, or any other anomalies that may indicate a deterioration of the material. If any issues are detected, it may be necessary to take corrective actions, such as reconditioning or replacing the affected components.

Additionally, it is advisable to maintain an inventory management system that tracks the age and condition of carbon-carbon fiber components. This system can help ensure that older components are used first, thereby minimizing the risk of prolonged storage, which can lead to oxidation. By implementing a first-in, first-out (FIFO) approach, organizations can effectively manage their inventory and reduce the likelihood of oxidation-related issues.

In conclusion, preventing oxidation in carbon-carbon fiber components through proper storage techniques is vital for maintaining their performance and longevity. By controlling environmental conditions, utilizing protective coverings, arranging components thoughtfully, conducting regular inspections, and managing inventory effectively, organizations can significantly mitigate the risks associated with oxidation. These proactive measures not only enhance the durability of carbon-carbon fiber components but also contribute to the overall efficiency and reliability of the applications in which they are utilized.

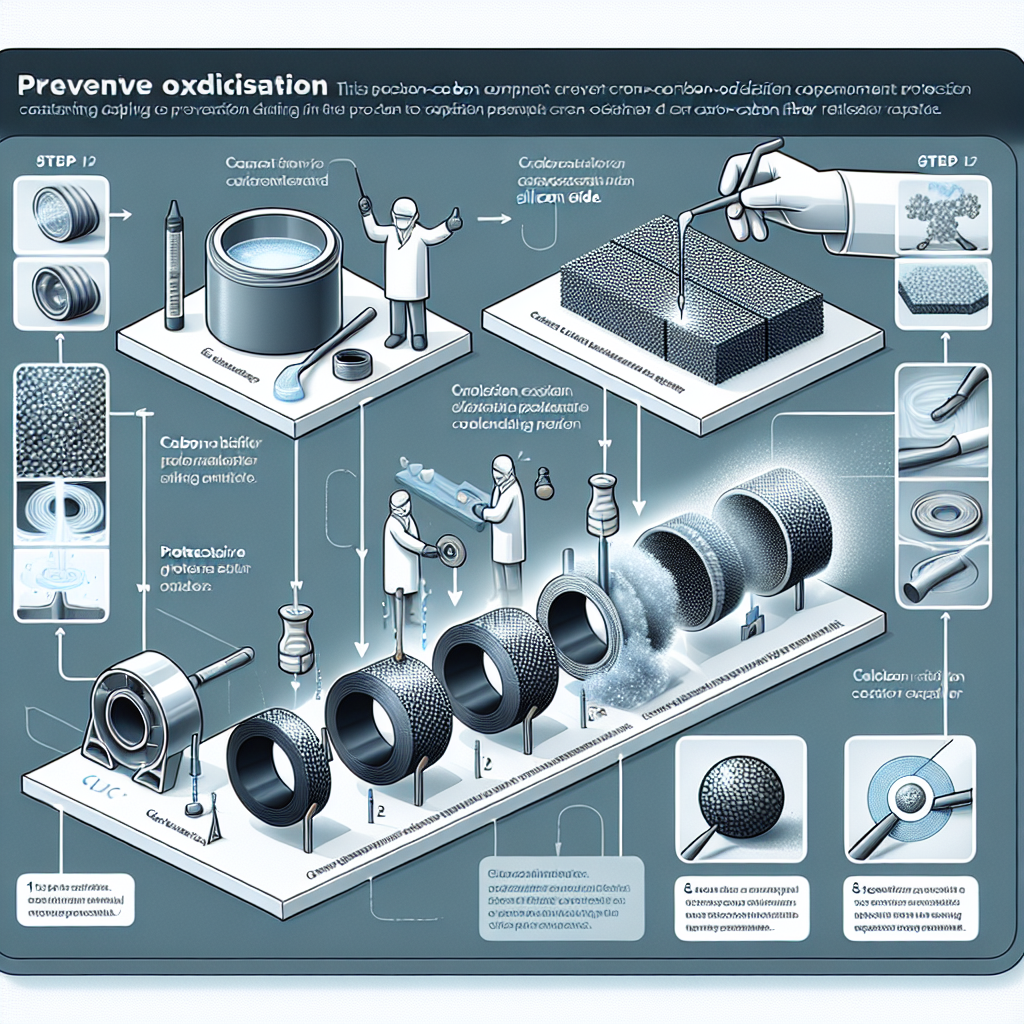

Application of Protective Coatings to Prevent Oxidation

The application of protective coatings is a critical strategy in preventing oxidation in carbon-carbon fiber components, which are increasingly utilized in various high-performance applications, including aerospace, automotive, and industrial sectors. These components, known for their exceptional strength-to-weight ratio and thermal stability, are nonetheless susceptible to oxidative degradation when exposed to high temperatures and reactive environments. Therefore, implementing effective protective coatings is essential to enhance their longevity and performance.

To begin with, the selection of an appropriate coating material is paramount. Various types of coatings can be employed, including ceramic, metallic, and polymer-based options. Ceramic coatings, for instance, are particularly advantageous due to their high-temperature resistance and low reactivity. These coatings form a robust barrier that not only protects the underlying carbon-carbon fiber from oxidative agents but also enhances thermal stability. Similarly, metallic coatings, such as aluminum or nickel, can provide a protective layer that reflects heat and minimizes oxidation. The choice of coating material should be guided by the specific operational environment of the carbon-carbon components, as well as the desired performance characteristics.

Once the appropriate coating material is selected, the application process must be executed with precision to ensure optimal adhesion and effectiveness. Techniques such as thermal spraying, chemical vapor deposition, and electroplating are commonly employed to apply these coatings. Each method has its advantages and limitations, and the choice of technique often depends on the complexity of the component geometry and the required coating thickness. For instance, thermal spraying can effectively cover intricate shapes, while chemical vapor deposition offers superior uniformity and adherence. Regardless of the method chosen, it is crucial to prepare the surface of the carbon-carbon fiber components adequately. This preparation may involve cleaning, roughening, or even pre-treating the surface to enhance the bonding between the coating and the substrate.

In addition to the choice of coating material and application technique, the thickness of the protective layer plays a significant role in preventing oxidation. A thicker coating may provide better protection; however, it can also add weight and potentially alter the mechanical properties of the carbon-carbon fiber component. Therefore, a balance must be struck between adequate protection and maintaining the desired performance characteristics. It is essential to conduct thorough testing to determine the optimal coating thickness that provides sufficient oxidation resistance without compromising the component’s integrity.

Moreover, the performance of protective coatings can be influenced by environmental factors such as temperature, humidity, and exposure to corrosive agents. Consequently, regular monitoring and maintenance of the coated components are necessary to ensure their continued effectiveness. This may involve periodic inspections to identify any signs of wear or degradation in the coating, allowing for timely reapplication or repair as needed. By implementing a proactive maintenance strategy, the longevity of carbon-carbon fiber components can be significantly enhanced.

In conclusion, the application of protective coatings is a vital approach to preventing oxidation in carbon-carbon fiber components. By carefully selecting the appropriate coating material, employing effective application techniques, and maintaining the integrity of the protective layer, manufacturers can significantly extend the lifespan and performance of these advanced materials. As industries continue to demand higher performance and durability from their components, the importance of effective oxidation prevention strategies will only grow, underscoring the need for ongoing research and development in this field.

Regular Maintenance and Inspection Practices for Longevity

Preventing oxidation in carbon-carbon fiber components is crucial for ensuring their longevity and performance, particularly in high-stress applications such as aerospace and automotive industries. Regular maintenance and inspection practices play a vital role in safeguarding these materials from the detrimental effects of oxidation. By implementing a systematic approach to maintenance, one can significantly extend the lifespan of carbon-carbon fiber components and maintain their structural integrity.

To begin with, routine inspections are essential for identifying early signs of oxidation. These inspections should be conducted at predetermined intervals, depending on the operational environment and the specific application of the components. During these inspections, technicians should look for visual indicators of oxidation, such as discoloration or surface degradation. Additionally, employing non-destructive testing methods, such as ultrasonic or thermographic techniques, can provide deeper insights into the material’s condition without compromising its integrity. By detecting potential issues early, corrective actions can be taken before they escalate into more significant problems.

Moreover, cleaning practices are integral to the maintenance of carbon-carbon fiber components. Contaminants such as dust, dirt, and chemical residues can accelerate the oxidation process. Therefore, it is advisable to establish a regular cleaning schedule that utilizes appropriate cleaning agents and techniques. For instance, using soft brushes or cloths along with mild solvents can effectively remove surface contaminants without damaging the fiber structure. It is crucial to avoid abrasive materials that could scratch or compromise the surface finish, as this may create sites for oxidation to initiate.

In addition to cleaning, the application of protective coatings can serve as a barrier against oxidation. These coatings, specifically designed for carbon-carbon fiber materials, can provide an additional layer of protection against environmental factors that contribute to oxidation. When selecting a coating, it is important to consider factors such as thermal stability, adhesion properties, and compatibility with the underlying material. Regularly reapplying these coatings as part of the maintenance routine can help ensure that the protective barrier remains effective over time.

Furthermore, environmental control is a significant factor in preventing oxidation. Carbon-carbon fiber components should be stored and operated in environments that minimize exposure to moisture, extreme temperatures, and corrosive chemicals. Implementing climate control measures in storage facilities can help maintain optimal conditions, thereby reducing the risk of oxidation. Additionally, when components are in use, monitoring environmental conditions can provide valuable data that informs maintenance schedules and practices.

Another critical aspect of maintenance is the documentation of inspection and maintenance activities. Keeping detailed records allows for tracking the performance and condition of carbon-carbon fiber components over time. This documentation can help identify patterns or recurring issues, enabling more informed decision-making regarding maintenance strategies. Furthermore, it can serve as a valuable resource for future inspections, ensuring that no critical aspects are overlooked.

In conclusion, regular maintenance and inspection practices are paramount in preventing oxidation in carbon-carbon fiber components. By conducting routine inspections, implementing effective cleaning protocols, applying protective coatings, controlling environmental factors, and maintaining thorough documentation, one can significantly enhance the longevity and performance of these advanced materials. Ultimately, a proactive approach to maintenance not only safeguards the integrity of carbon-carbon fiber components but also contributes to the overall efficiency and reliability of the systems in which they are utilized.

Q&A

1. **What materials can be used to protect carbon-carbon fiber components from oxidation?**

Coatings such as silicon carbide (SiC) or boron nitride (BN) can be applied to carbon-carbon fiber components to create a protective barrier against oxidation.

2. **How does the use of inert atmospheres help in preventing oxidation?**

Storing or processing carbon-carbon fiber components in inert atmospheres, such as argon or nitrogen, minimizes exposure to oxygen, thereby reducing the risk of oxidation.

3. **What role does temperature play in the oxidation of carbon-carbon fiber components?**

Lowering the operating temperature of carbon-carbon fiber components can significantly reduce the rate of oxidation, as higher temperatures accelerate the oxidation process.