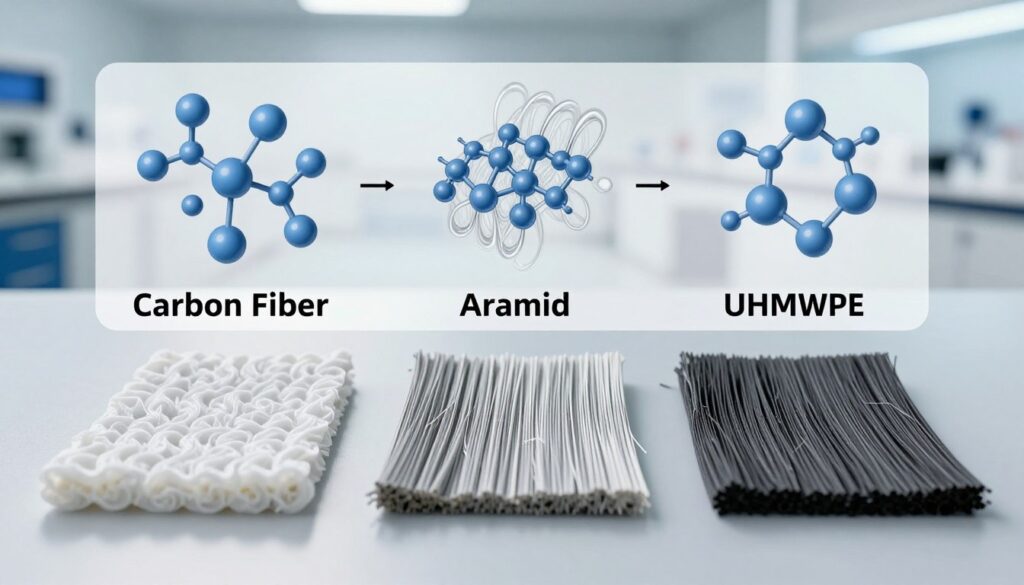

Carbon Fiber vs. Aramid vs. UHMWPE: Which High-Performance Fiber Fits Your Project?

When it comes to selecting the right material for your project, understanding the characteristics of high-performance fibers is crucial. Advanced materials like carbon fiber, aramid, and UHMWPE are revolutionizing various industries due to their exceptional strength, durability, and resistance to extreme conditions.

The choice between these fibers depends on the specific requirements of your project. Whether you’re looking for lightweight reinforcement, ballistic protection, or resistance to abrasion and chemicals, each of these fibers has its unique advantages. By understanding the properties and applications of carbon fiber, aramid, and UHMWPE, you can make an informed decision that meets your project’s needs.

Key Takeaways

- High-performance fibers offer exceptional strength and durability.

- Carbon fiber, aramid, and UHMWPE have unique properties and applications.

- The choice of fiber depends on the specific project requirements.

- Understanding the characteristics of each fiber is crucial for making an informed decision.

- Advanced materials are revolutionizing various industries.

The World of High-Performance Fibers

High-performance fibers have revolutionized various industries with their exceptional properties. These advanced materials are engineered to provide superior performance in demanding applications.

What Defines a High-Performance Fiber

A high-performance fiber is characterized by its outstanding tensile strength, modulus, and resistance to various environmental factors. These fibers are designed to maintain their properties under extreme conditions, making them ideal for critical applications.

The Evolution of Advanced Materials

The development of high-performance fibers has been driven by advancements in material science and technology. Over the years, these fibers have evolved to offer improved density and weight characteristics, along with enhanced thermal and chemical resistance.

Critical Properties for Project Success

When selecting a high-performance fiber for a project, several key properties must be considered. These include tensile strength, modulus, and density. Understanding these properties is crucial for ensuring the success of the project.

By examining the characteristics and evolution of high-performance fibers, we can better understand their role in modern applications and their potential for future innovations.

Carbon Fiber: Strength Meets Lightweight Design

In the realm of advanced materials, carbon fiber stands out for its exceptional mechanical properties and lightweight design. This unique combination has made it a cornerstone in various high-performance applications, from aerospace to sports equipment.

Composition and Manufacturing Process

Carbon fiber is composed of carbon atoms bonded together in crystals, aligned in a parallel manner along the fiber axis. This alignment is crucial for its strength and stiffness. The manufacturing process involves the pyrolysis of a precursor material, typically polyacrylonitrile (PAN), under high temperatures in an inert atmosphere. This process removes non-carbon atoms, resulting in a material that is over 90% carbon.

The production process is complex and requires precise control over temperature, tension, and processing time to achieve the desired properties. Manufacturers often use various techniques, including chemical vapor deposition (CVD) and graphitization, to enhance the material’s characteristics.

Key Mechanical Properties

Carbon fiber is renowned for its high tensile strength, stiffness, and low density. These properties make it an ideal material for applications where weight reduction is critical without compromising on strength. For instance, in the aerospace industry, carbon fiber is used to manufacture aircraft components that are not only lighter but also stronger than their metal counterparts.

The mechanical properties of carbon fiber can be tailored by adjusting the manufacturing process and the type of precursor used. This versatility allows engineers to design materials that meet specific project requirements.

Thermal and Electrical Characteristics

Carbon fiber also exhibits interesting thermal and electrical properties. It has a high thermal conductivity, which can be beneficial in applications requiring heat dissipation. Additionally, carbon fiber is electrically conductive, making it suitable for use in applications such as electromagnetic interference (EMI) shielding.

“The unique combination of mechanical, thermal, and electrical properties in carbon fiber opens up new possibilities for innovative product design.”

Strengths and Limitations in Application

The strengths of carbon fiber include its high strength-to-weight ratio, resistance to fatigue, and dimensional stability. However, it also has limitations, such as relatively low impact resistance and potential for degradation under certain environmental conditions.

Understanding these strengths and limitations is crucial for selecting carbon fiber for specific applications and ensuring its optimal performance.

Aramid Fibers: Exceptional Toughness and Heat Resistance

The versatility of aramid fibers makes them a preferred choice for a wide range of applications. Aramid fibers are synthetic fibers known for their exceptional toughness and heat resistance, making them ideal for use in demanding environments.

Chemical Structure and Varieties

Aramid fibers are characterized by their aromatic polyamide structure, which provides them with high strength and thermal stability. There are two main types of aramid fibers: para-aramid and meta-aramid. Para-aramid fibers, such as Kevlar, are known for their high tensile strength and are often used in ballistic protection and composites. Meta-aramid fibers, like Nomex, offer excellent thermal resistance and are commonly used in protective clothing and insulation.

Manufacturing Techniques

The production of aramid fibers involves a complex process known as dry-jet wet spinning. This technique allows for the creation of fibers with highly aligned molecular structures, contributing to their exceptional mechanical properties. The manufacturing process can be tailored to produce fibers with specific characteristics, such as varying levels of tensile strength and thermal resistance.

Performance Characteristics

Aramid fibers exhibit a range of performance characteristics that make them suitable for various applications. They have high tensile strength, excellent resistance to heat and flames, and good chemical resistance. The following table summarizes some key properties of aramid fibers:

| Property | Para-Aramid | Meta-Aramid |

|---|---|---|

| Tensile Strength | High | Moderate |

| Thermal Resistance | High | Very High |

| Chemical Resistance | Good | Excellent |

Advantages and Disadvantages in Use

Aramid fibers offer several advantages, including their high strength-to-weight ratio, thermal stability, and resistance to chemicals. However, they also have some limitations, such as sensitivity to UV light and difficulty in processing due to their high crystallinity. Understanding these advantages and disadvantages is crucial for selecting the appropriate aramid fiber for a specific application.

UHMWPE: The Ultra-Strong Contender

The emergence of UHMWPE has marked a significant milestone in the development of ultra-strong fibers. UHMWPE is renowned for its exceptional mechanical properties, making it a critical material in various high-performance applications.

Molecular Structure and Properties

UHMWPE’s molecular structure is characterized by its extremely long chains of polyethylene, which provide exceptional strength and durability. This unique structure contributes to its high tensile strength, resistance to abrasion, and low friction coefficient.

Production Methods and Innovations

The production of UHMWPE involves advanced manufacturing techniques, including gel spinning and compression molding. These methods enable the creation of fibers with consistent quality and performance. Innovations in production have further enhanced the material’s properties, expanding its potential applications.

Performance Metrics and Testing

UHMWPE’s performance is evaluated through various metrics, including tensile strength, modulus, and impact resistance. Rigorous testing protocols ensure that UHMWPE materials meet the stringent requirements of different industries. Key performance metrics include:

- High tensile strength

- Excellent abrasion resistance

- Low friction coefficient

- Chemical resistance

Benefits and Limitations in Projects

The benefits of using UHMWPE include its outstanding strength-to-weight ratio, resistance to chemicals, and durability. However, UHMWPE also has limitations, such as its relatively low operating temperature range and potential for creep under constant load. Understanding these factors is crucial for effectively integrating UHMWPE into various projects.

Carbon Fiber vs. Aramid vs. UHMWPE: Comprehensive Comparison

To determine the most appropriate high-performance fiber for your specific needs, a comprehensive comparison of carbon fiber, aramid, and UHMWPE is necessary. This comparison will help you understand the strengths and weaknesses of each material across various critical parameters.

Tensile Strength and Modulus

Tensile strength and modulus are crucial indicators of a material’s performance. Carbon fiber is renowned for its high tensile strength and modulus, making it ideal for applications requiring stiffness and strength. In contrast, UHMWPE offers exceptional tensile strength but with a lower modulus compared to carbon fiber. Aramid fibers fall somewhere in between, with a balance of tensile strength and modulus.

| Fiber Type | Tensile Strength (GPa) | Modulus (GPa) |

|---|---|---|

| Carbon Fiber | 4.0-6.0 | 300-400 |

| Aramid Fiber | 3.0-4.0 | 70-130 |

| UHMWPE | 3.0-4.0 | 100-150 |

Density and Weight Considerations

Density is a critical factor in material selection, especially for weight-sensitive applications. Carbon fiber and aramid fibers have relatively low densities, making them suitable for lightweight applications. UHMWPE has a slightly higher density but still offers a good strength-to-weight ratio.

Temperature Performance Range

The temperature performance range varies significantly among these fibers. Aramid fibers are known for their excellent thermal stability, maintaining properties over a wide temperature range. Carbon fiber also performs well at high temperatures, while UHMWPE has a more limited temperature range due to its lower melting point.

Impact and Abrasion Resistance

UHMWPE stands out for its exceptional impact and abrasion resistance, making it ideal for applications subject to wear and tear. Aramid fibers also offer good impact resistance, while carbon fiber is more prone to damage from impact.

Chemical and Environmental Durability

Carbon fiber is generally resistant to chemicals, but its durability can be affected by certain environments. Aramid fibers are susceptible to degradation from UV light and some chemicals. UHMWPE is resistant to many chemicals but can be affected by certain organic solvents.

Processability and Fabrication Requirements

The processability of these fibers varies. Carbon fiber can be challenging to work with due to its brittleness and the need for specialized fabrication techniques. Aramid fibers are relatively easier to process, while UHMWPE can be processed using various methods, including molding and extrusion.

Industry-Specific Applications and Case Studies

The versatility of advanced fibers like carbon fiber, aramid, and UHMWPE is evident in their widespread adoption across multiple sectors. These high-performance materials are not only enhancing product performance but also enabling innovations that were previously unimaginable.

Aerospace and Aviation Implementations

In the aerospace industry, carbon fiber is widely used for aircraft structures due to its high strength-to-weight ratio, significantly improving fuel efficiency. For instance, Boeing’s 787 Dreamliner incorporates extensive use of carbon fiber composites.

- Reduced weight

- Increased fuel efficiency

- Enhanced durability

Automotive and Transportation Solutions

The automotive sector benefits from aramid fibers in tire reinforcement and brake pads, enhancing safety and performance. Carbon fiber is also used in high-performance vehicles for body panels, reducing weight and improving acceleration.

Sports Equipment and Performance Gear

Carbon fiber and UHMWPE are popular in sports equipment for their lightweight and high-strength properties. Examples include bicycle frames, golf clubs, and fishing rods.

Defense, Ballistics, and Safety Equipment

Aramid fibers are crucial in ballistic protection gear, such as bulletproof vests, due to their exceptional toughness and resistance to penetration. UHMWPE is also used in ballistic helmets and armor.

- Enhanced ballistic protection

- Lightweight solutions

- Improved wearer comfort

Marine and Offshore Applications

In marine applications, carbon fiber and UHMWPE are used for their resistance to corrosion and high strength. They are used in boat hulls, masts, and offshore oil rig components.

Medical Devices and Healthcare Innovations

Advanced fibers are also finding applications in medical devices, such as prosthetics and implants, where biocompatibility and strength are critical.

These case studies illustrate the diverse and innovative applications of high-performance fibers across various industries, highlighting their potential to drive technological advancements and improve product performance.

Cost Analysis and Economic Considerations

The economic aspects of high-performance fibers, including cost and supply chain factors, are vital in decision-making. When evaluating carbon fiber, aramid, and UHMWPE for your project, it’s essential to consider not just the raw material costs but also the broader economic implications.

Raw Material Cost Comparison

The initial cost of raw materials varies significantly among the three fibers. Carbon fiber tends to be the most expensive due to its complex production process. In contrast, UHMWPE can offer a more economical option, depending on the specific application. Aramid fibers fall somewhere in between. A detailed comparison is necessary to determine the most cost-effective choice for your specific needs.

- Carbon Fiber: High raw material cost

- Aramid Fibers: Moderate raw material cost

- UHMWPE: Potentially lower raw material cost

Processing and Manufacturing Expenses

Beyond raw material costs, the expenses associated with processing and manufacturing must be considered. Carbon fiber, for instance, requires specialized equipment and techniques, increasing its overall cost. Aramid and UHMWPE may offer more straightforward manufacturing processes, potentially reducing expenses.

Lifecycle Cost Analysis and ROI

Conducting a lifecycle cost analysis helps in understanding the long-term economic implications of your material choice. This includes assessing the return on investment (ROI) by considering factors like durability, maintenance, and potential for recycling or reuse. A comprehensive analysis can reveal that while one material may have a higher upfront cost, its long-term benefits could provide a better ROI.

Supply Chain Factors and Availability

The availability of these high-performance fibers and the reliability of their supply chains can significantly impact project timelines and costs. Understanding the global market dynamics and potential supply chain disruptions is crucial for making informed decisions.

Cost Optimization Strategies

To optimize costs, consider strategies such as material hybridization, where combining different fibers can achieve a balance between performance and cost. Additionally, advancements in manufacturing technologies and processes can help reduce expenses without compromising on the material properties.

By carefully evaluating these economic considerations, you can make a more informed decision that aligns with your project’s budgetary and performance requirements.

Project-Based Selection Guide

To ensure project success, it’s crucial to match the high-performance fiber to the specific needs and conditions of the application. This guide will walk you through the key considerations for selecting between carbon fiber, aramid, and UHMWPE.

Matching Fiber Properties to Project Requirements

The first step in selecting a high-performance fiber is understanding the project’s requirements. Different fibers excel in different areas: carbon fiber offers exceptional stiffness and strength-to-weight ratio, aramid fibers provide outstanding impact resistance and toughness, and UHMWPE boasts high tensile strength and resistance to abrasion.

| Fiber Type | Tensile Strength | Impact Resistance | Abrasion Resistance |

|---|---|---|---|

| Carbon Fiber | High | Moderate | Low |

| Aramid Fiber | High | High | Moderate |

| UHMWPE | Very High | High | High |

Environmental and Operating Conditions Assessment

The operating environment plays a significant role in fiber selection. For instance, high-temperature applications may favor carbon fiber or aramid due to their thermal stability.

Budget-Conscious Decision Making

Cost is a critical factor in material selection. While UHMWPE may offer superior performance in certain aspects, its cost can be prohibitive for some projects.

Fabrication Method Compatibility

The chosen fiber must be compatible with the intended fabrication method. For example, carbon fiber can be challenging to work with due to its brittleness and the need for precise manufacturing techniques.

Hybrid and Composite Solutions

Sometimes, a single material isn’t enough. Hybrid and composite solutions can offer a balance of properties.

Multi-Material Design Approaches

Combining different materials can lead to enhanced performance. For instance, combining carbon fiber with aramid can improve impact resistance while maintaining high stiffness.

Synergistic Property Enhancement

The synergy between different materials can result in properties that are greater than the sum of their parts.

Conclusion: Making the Optimal Choice for Your Specific Needs

Selecting the right high-performance fiber for your project requires a thorough understanding of the properties and applications of carbon fiber, aramid, and UHMWPE. By considering factors such as tensile strength, density, temperature performance, and chemical resistance, you can make an informed decision that meets your specific needs.

When evaluating high-performance fibers, it’s essential to assess your project requirements and match them with the characteristics of each material. For instance, if your project demands exceptional toughness and heat resistance, aramid fibers may be the optimal choice. On the other hand, if you’re looking for a lightweight and rigid material, carbon fiber could be the best fit.

UHMWPE offers ultra-high molecular weight properties, making it suitable for applications requiring high impact resistance and low friction. By understanding the strengths and limitations of each high-performance fiber, you can optimize your project’s performance, cost, and overall success.

Ultimately, the optimal choice depends on a careful analysis of your project’s specific needs and the properties of the available high-performance fibers. By choosing the right material, you can ensure that your project meets its performance, safety, and economic goals.

FAQ

What are the main differences between carbon fiber, aramid, and UHMWPE?

Carbon fiber is known for its high stiffness and strength, aramid fibers are recognized for their exceptional toughness and heat resistance, and UHMWPE is valued for its ultra-high molecular weight and impact resistance.

How do I choose the right high-performance fiber for my project?

To choose the right fiber, consider factors such as tensile strength, density, temperature performance, impact and abrasion resistance, and processability. Assess your project’s specific requirements and match them with the properties of each fiber.

What are the advantages of using carbon fiber in aerospace applications?

Carbon fiber’s high strength-to-weight ratio, stiffness, and resistance to fatigue make it an ideal material for aerospace applications, enabling the creation of lightweight, fuel-efficient aircraft and spacecraft.

Can aramid fibers be used in high-temperature applications?

Yes, aramid fibers are known for their exceptional heat resistance and can be used in high-temperature applications, such as in protective clothing, composites, and brake pads.

How does UHMWPE compare to other high-performance fibers in terms of impact resistance?

UHMWPE is highly regarded for its exceptional impact resistance, outperforming many other high-performance fibers in this regard, making it suitable for applications such as ballistic protection and impact-resistant composites.

What are the cost implications of using high-performance fibers?

The cost of high-performance fibers can vary significantly, with factors such as raw material costs, processing expenses, and supply chain considerations influencing the overall cost. A thorough cost analysis is essential to determine the most economical choice for your project.

Can hybrid and composite solutions be used to enhance the properties of high-performance fibers?

Yes, combining different high-performance fibers or incorporating them into composite materials can lead to synergistic property enhancement, enabling the creation of materials with tailored properties for specific applications.

What are some common fabrication methods used for high-performance fibers?

Common fabrication methods include hand layup, vacuum bagging, resin transfer molding, and filament winding, among others. The choice of fabrication method depends on the specific fiber, the desired product, and the production volume.