Carbon fiber production process

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

The making of carbon fiber is a top achievement in advanced material production. It combines new ideas with strict standards. This process turns raw materials into something amazing, blending art and science.

The journey of carbon fiber manufacturing is complex. It's not just a series of steps. It's a detailed process that creates materials at the edge of lightweight strength. This journey is fascinating, leading to a material with unique properties important for many industries.

Key Takeaways

- The carbon fiber production is a hallmark of advanced material production in the modern era.

- Understanding the production process is key to appreciating the value and versatility of carbon composite materials.

- In the realm of carbon fiber manufacturing, precision and expertise are paramount to yield high-performance materials.

- Carbon fiber's exceptional strength-to-weight ratio makes it crucial to innovation across various sectors.

- Exploring the methods behind its creation reveals the complex interplay of technology and craftsmanship.

- Every phase, from selecting raw materials to final weaving techniques, requires meticulous detail and quality control.

Understanding Carbon Fiber and Its Unique Properties

Carbon fiber is a top-notch material in tech and industry. It's a lightweight composite key in aerospace engineering and automotive applications. Its wide use and success are clear.

What is Carbon Fiber?

Carbon fiber is made of thin carbon strands in a special structure. These strands are woven and set in resin. This creates a strong, yet light composite, unlike metal.

The Unmatched Strength-to-Weight Ratio

Carbon fiber's strength-to-weight ratio is unmatched. It offers great strength without extra weight. This makes it vital for aerospace engineering and high-performance cars.

Applications Across Industries

Carbon fiber is used in many fields. It boosts sports cars in automotive applications and makes planes more efficient in aerospace engineering. It's also in sports gear, military gear, and wind turbine blades. Its uses are endless.

The Origins of Carbon Fiber: From Concept to Commercialization

The story of carbon fiber is both fascinating and crucial in today's engineering and design. It shows how material innovation and commercial use have evolved. Learning about carbon fiber history helps us understand its versatility and ongoing improvement.

The story of carbon fiber begins in the late 19th century. But it wasn't until the mid-20th century that its true value was seen. The aerospace industry was the first to use it, needing materials that were both light and strong.

- Initial development aimed at improving high-temperature tolerance.

- Advancements to integrate carbon fibers in commercial products.

- Expansion into sports, automotive, and other industrial applications.

| Decade | Innovation | Commercial Impact |

|---|---|---|

| 1960s | Introduction in aerospace | Revolutionized material use in aviation |

| 1970s | Integration in sports equipment | Enhanced performance gears |

| 1980s | Expanding to automotive sectors | Improved fuel efficiency and strength |

| 1990s and beyond | Advancements in production techniques | Broadened accessibility and applications |

Carbon fiber is very important because of its special properties. It has changed how we make things, blending science with real-world uses.

Every decade, carbon fiber history has made material science better. It has also led to new designs and functions. The study of carbon fiber keeps going, promising more benefits for many areas around the world.

Key Raw Materials Used in Carbon Fiber Manufacturing

Exploring the world of carbon fiber shows how important raw materials are. Materials like PAN precursor, textile fibers, and resins are key. They help make high-quality carbon fiber composites for many industries.

Polyacrylonitrile (PAN) as a Precursor

The process of making carbon fiber begins with PAN precursor. This material turns into carbon fiber through several steps. The quality of PAN precursor affects the carbon fiber's strength, heat resistance, and stiffness.

The Role of Textile Fibers

Textile fibers are the foundation of carbon fiber. They help shape and align the carbon filaments. The type and pattern of these fibers are crucial for the composite's mechanical properties. This makes carbon fiber versatile for uses like aerospace and sports equipment.

Resin Types for Carbon Fiber Composites

Resins like thermoset and thermoplastic are used to hold the carbon fibers together. Thermoset resin is durable and heat-resistant, perfect for long-term stability. Thermoplastic resin is recyclable and great for parts needing impact resistance. The choice depends on the application's needs, showing the custom nature of composite manufacturing.

| Material Type | Properties | Applications |

|---|---|---|

| PAN Precursor | High strength, Thermal stability | Aerospace, Sporting goods |

| Textile Fibers | Flexibility, Structural integrity | Automotive, Industrial |

| Thermoset Resin | Durability, Heat resistance | Electronics, Marine |

| Thermoplastic Resin | Recyclability, Impact resistance | Consumer Goods, Medical devices |

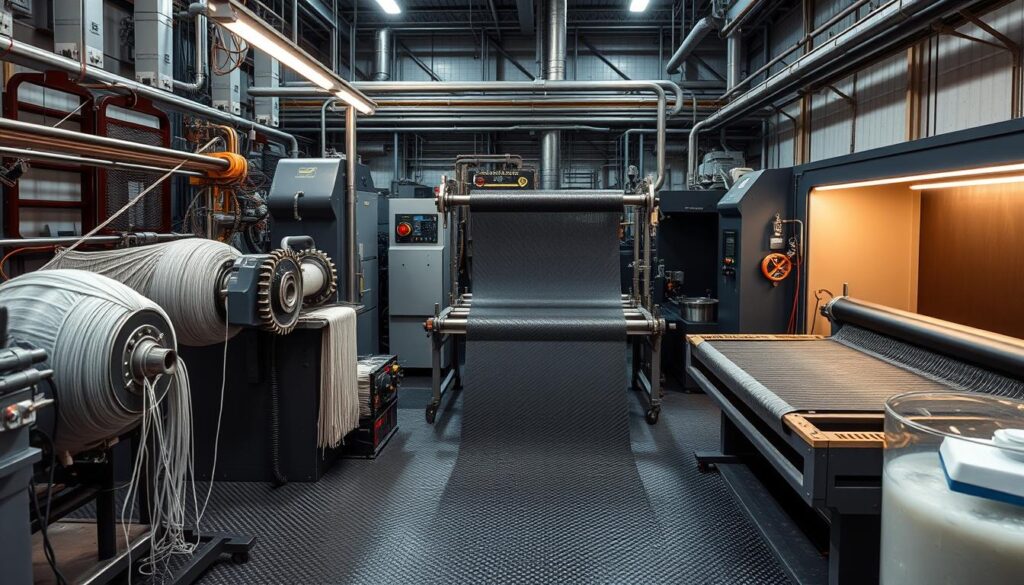

Step-by-Step Breakdown of the Carbon Fiber Manufacturing Process

The making of carbon fiber is a detailed process. It uses precise fiber processing and advanced techniques. Each step is key to turning raw materials into a strong, light composite material.

The process starts with getting the precursor, usually polyacrylonitrile (PAN). It goes through several stages to become carbon fiber. These stages are spinning, stabilizing, carbonizing, and surface treatment.

- Spinning of the Precursor: First, the PAN is spun into fibers. This step is crucial for the fibers' alignment and uniformity. It's important for the final product's consistency.

- Stabilization: Then, the fibers are oxidized at high temperatures. This step increases their strength and prepares them for carbonization.

- Carbonization: The fibers are heated to very high temperatures in an inert atmosphere. This removes non-carbon atoms, making the fibers almost all carbon. This is when they get their strength.

- Surface Treatment: To improve bonding with resins, the fibers' surface is treated. This step makes the final product stronger and more durable.

- Sizing: Last, a protective coating is applied to the fibers. This coating helps during weaving and other tasks. It also makes handling easier.

Knowing the details of each step shows the technology behind making carbon fiber.

| Stage | Process Detail | Importance |

|---|---|---|

| 1. Spinning | Conversion of PAN to fiber form | Establishes fiber alignment and strength |

| 2. Stabilization | Oxidization at controlled temperatures | Prepares fibers for carbonization |

| 3. Carbonization | Heating to remove non-carbon elements | Increases tensile strength |

| 4. SurfaceTreatment | Chemical or physical etching | Enhances resin bonding ability |

| 5. Sizing | Application of protective coating | Protects during handling and weaving |

This detailed look at carbon fiber production stages and manufacturing techniques is enlightening. It shows how each step in fiber processing makes the final product superior.

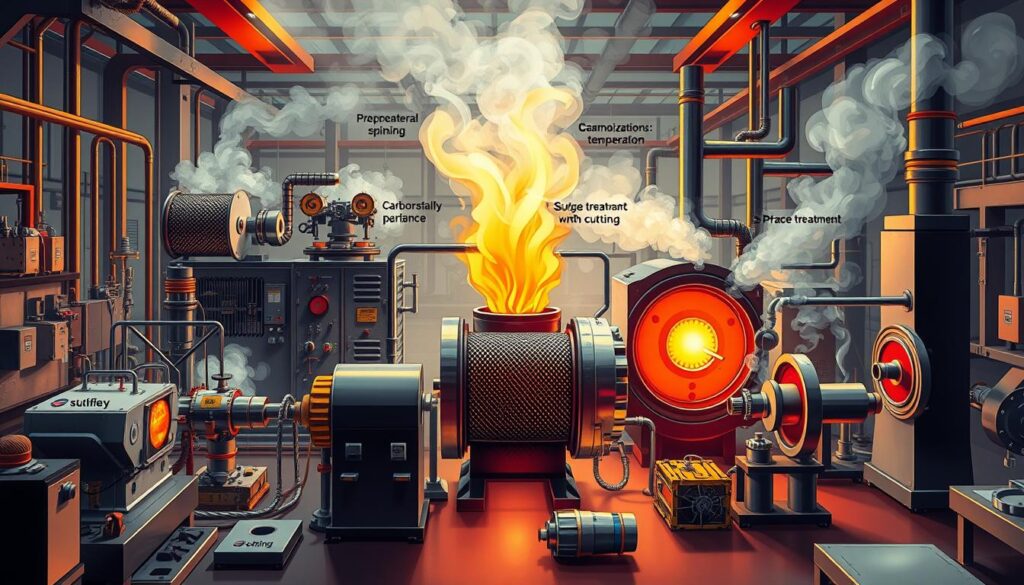

The Role of Stabilization in Carbon Fiber Strength

The process of stabilizing carbon fibers is key to making materials strong and consistent. It's important to understand how temperature regulation and chemical treatment play a role. These steps are crucial for achieving the right material properties.

Temperature Control During Stabilization

The stabilization process of carbon fiber heavily relies on temperature regulation. This stage involves heating the fibers carefully. It ensures that polyacrylonitrile (PAN) fibers are stabilized without melting.

The specific temperature range is key. It allows the fibers to undergo oxidative stabilization. This prepares them for the carbonization phase without losing their form or desired characteristics.

Chemical Adjustments for Optimal Performance

The stabilization process also involves chemical treatment. Chemical agents are used to help stabilize the fibers. They introduce functional groups that improve bonding and mechanical strength.

These treatments are customized for different uses. This means the chemical composition can vary greatly. It's tailored to optimize performance in various applications.

| Aspect | Role in Stabilization Process | Importance |

|---|---|---|

| Temperature Control | Prevents fiber degradation and prepares fibers for carbonization. | Critical for maintaining integrity of fibers. |

| Chemical Treatment | Enhances fiber characteristics such as bonding and strength. | Vital for tailoring fibers to specific applications and performance needs. |

Carbonization: Creating the Signature Strength of Carbon Fiber

The carbonization process is key in making carbon fiber strong and durable. It involves heating stabilized fibers at high temperatures. This process refines the carbon lattice structure, boosting performance.

When carbonizing, fibers are heated from 1,000°C to 3,000°C. This heat removes hydrogen, nitrogen, and oxygen from the fibers. The remaining carbon atoms then form a tighter, more ordered lattice. This change is crucial for carbon fiber's high tensile strength.

The realignment and packing of carbon atoms are crucial in defining the mechanical strength and the thermal and electrical conductivity of the final carbon fiber product.

This high-temperature treatment also makes the fiber stiffer and stronger. It's why carbon fiber is used in aerospace, cars, and sports equipment.

| Temperature Range (°C) | Effect on Fiber |

|---|---|

| 1,000 - 1,500 | Initial carbonization, removal of non-carbon atoms |

| 1,500 - 2,000 | Enhanced carbon lattice formation |

| 2,000 - 3,000 | Optimization of structural alignment for maximum strength |

The carbonization process improves carbon fiber's mechanical, electrical, and thermal properties. This makes it a versatile material for many engineering needs.

Surface Treatment and Sizing: Enhancing Fiber Bonding

Improving bond strength and composite material quality relies on surface treatments and sizing agents. This part looks at how these steps boost bond strength and enhance composite material performance.

Importance of Surface Treatment

Surface treatments are key to bettering carbon fiber surfaces for stronger adhesion with polymer resins. Treating the fibers increases bond strength, crucial for durable and high-performance composites. Chemical treatments are used to improve bonding between fibers and resin.

Choosing the Right Sizing for End-Use Applications

Choosing the right sizing agents is vital for carbon fibers' final use. The correct sizing ensures fibers work well with the resin, improving compatibility and function in the composite. Sizing agents add mechanical and thermal properties, tailored for specific uses.

| Surface Treatment Method | Benefits | Common Applications |

|---|---|---|

| Anodic Oxidation | Improves corrosion resistance, surface conductivity | Aerospace components, sporting goods |

| Plasma Treatment | Enhances surface energy for better adhesion | Automotive, marine industries |

| Chemical Treatment | Increases surface roughness, promotes bond strength | Building and construction materials |

Effective surface treatments and sizing agent choices boost bond strength and composite material performance. These improvements are key for creating advanced materials that meet various industrial needs.

Carbon Fiber Weaving Techniques and Patterns

Looking into weaving methods for carbon fiber textiles shows how fabric design and reinforcement patterns affect the material. These methods are key for making advanced composites for many industries.

Plain Weave and Its Properties

The plain weave is simple, with warp and weft threads crossing over each other in a pattern. It's stable and even, great for many carbon fiber uses. Its even tension makes it good for looks and function in fabric design.

Twill Weave for Enhanced Drapeability

Twill weave has diagonal ribs, making it flexible and drapable. It's better than plain weave for complex shapes that need to fit different curves without losing strength. Its beauty also makes it popular in luxury items.

Unidirectional Fabric for Maximum Strength

Unidirectional fabric is made for strength in one direction. All fibers run parallel, boosting tensile strength along one axis. It's perfect for parts under stress in one direction, like in planes and cars.

Choosing the right weaving method is crucial for carbon fiber textiles. Whether it's twill weave for balance or unidirectional for strength, new patterns are always being explored. This innovation is changing what we can do with fabric design.

Conclusion

Exploring carbon fiber manufacturing shows us a key material in today's engineering and design. We've looked at how it's made, from picking raw materials like Polyacrylonitrile (PAN) to weaving techniques. This shows the future of carbon fiber is bright, with more innovation on the way.

The industry has made big strides in making carbon fiber lighter, stronger, and more durable. This is true for many fields, from aerospace to sports gear. These advancements are exciting and show the potential of carbon fiber.

There's also a push for making carbon fiber production more eco-friendly. Efforts are underway to cut down on waste and make it easier to recycle. This is important as we look to the future and want materials that are good for the planet.

Carbon fiber's growth is marked by important scientific breakthroughs. These breakthroughs show its potential to change many industries. With new tech coming out, carbon fiber is a symbol of human creativity and innovation.

Looking ahead, the story of carbon fiber is just beginning. It's a story of progress and new possibilities in material science and product development. We're all excited to see what's next for carbon fiber.

FAQ

What is Carbon Fiber?

Carbon fiber is a material made from thin strands of carbon atoms. These strands are bound together with a plastic polymer resin. This creates a composite that is very strong, yet very light. It also has high chemical resistance and can handle high temperatures well.

What Industries Benefit Most from Carbon Fiber?

Many industries use carbon fiber, like aerospace and automotive. It's also used in sports equipment and any field needing strong, light parts. Its high-performance properties make it very valuable.

What is the History of Carbon Fiber?

Carbon fiber's history started in the late 1800s. But it really took off in the mid-20th century. Now, it's a key material in many fields, thanks to its advancements over the years.

What Raw Materials are Used in Making Carbon Fiber?

Most carbon fiber is made from Polyacrylonitrile (PAN), a type of polymer. Other materials include textile fibers and resin systems. These bind the fibers together in the manufacturing process.

How is Carbon Fiber Manufactured?

Making carbon fiber involves several steps. First, the precursor fibers are spun. Then, they are stabilized, carbonized, and treated. Each step is crucial for achieving the fiber's strength and properties.

Why is Stabilization Important in Carbon Fiber Production?

Stabilization controls the temperature of PAN fibers. This prevents them from melting during high-temperature treatment. It also enhances the fibers' performance and stability before carbonization.

What Happens During Carbonization in Carbon Fiber Production?

In carbonization, fibers are heated to very high temperatures. This removes non-carbon elements. The heat rearranges the carbon atoms, making the fiber very strong and rigid.

What is Surface Treatment in Carbon Fiber Manufacturing?

Surface treatment prepares the fiber surface for bonding with resin. It involves coating the fibers with sizing agents. This improves adhesion, ensuring the fibers work well in the composite material.

What are the Different Weaving Techniques for Carbon Fiber?

There are several weaving techniques for carbon fiber. Plain weave offers balanced properties. Twill weave is better for complex shapes. Unidirectional fabric weave is ideal for parts under unidirectional stress.

How is Carbon Fiber Expected to Evolve in the Future?

The future of carbon fiber involves innovation and sustainable production. We'll see more efficient processes and new applications. New types of carbon composites will also emerge, pushing engineering boundaries.