Carbon Fiber Industry Analysis 2023

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Abstract

◆ Carbon fiber, ultra-high molecular weight polyethylene fiber and aramid fiber are the three high-performance fibers that our country is focused on developing. These materials are the cornerstone of high-performance new materials that boast a plethora of excellent properties. They offer ultra-high strength, ultra-high modulus, low density, and resistance to chemical corrosion. These fibers are a testament to our dedication to innovation and continued progress in advanced materials.

◆ It is expected that global carbon fiber demand will grow to 150,000 tons and 200,000 tons by 2023 and 2025, with growth mainly driven by demand in the wind power blade field. In addition, the demand for high-pressure hydrogen storage bottles in aerospace, new energy vehicles, and hydrogen fuel cell vehicles is expected to explode.

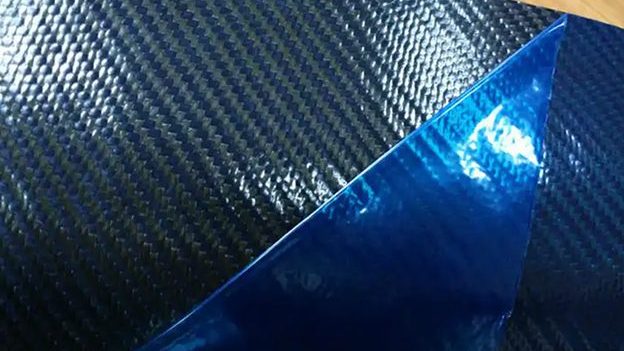

Carbon Fiber

Carbon fiber is widely regarded as a ‘black gold’ due to its superior mechanical properties and remarkable chemical stability. These fibers can be categorized as either small tows or large tows, based on the number of fibers they contain. Small tows, which typically have a tow number less than 24K, are referred to as such (where 1K represents 1,000 filaments in a bundle of carbon fibers).

Those are above 24K are considered as large tows. They may have relatively lower performance and may be harder to control, yet they are highly effective in basic and civil industries. On the other hand, small tows made of carbon fiber boast exceptional performance but have high prices and low output. Ultimately, carbon fibers are a vital and essential material for many industries, contributing to the advancement of technology and progress.

| High strength | The tensile strength is above 3500MPa, which is 7-9 times that of steel. |

| High modulus | The elastic modulus is above 230GPa. |

| Low density; high specific strength | The density is 1/4 of steel and 1/2 of aluminum alloy; Specific strength is 16 times greater than steel and 12 times greater than aluminum alloy. |

| Resistant to ultra-high temperatures | Under reducing atmosphere conditions, it can be used at 2000°C and can be partially melted and softened at high temperatures of 3000°C. |

| Resistant to low temperature | At low temperatures of -180°C, steel becomes brittle than glass, while carbon fiber remains elastic. |

| Resistant to acid, oil and corrosion | It can withstand the erosion of concentrated hydrochloric acid, phosphoric acid and other media. Its corrosion resistance exceeds that of gold and platinum, and it also has good oil resistance. |

| Small thermal expansion coefficient and large thermal conductivity | It can withstand rapid cooling and heating, and will not explode even if it suddenly drops from a high temperature of 3000°C to room temperature. |

Our product classification is primarily based on Toray from Japan. By utilizing this information, we are able to determine the most suitable brands and levels for our products. We strive to constantly improve and optimize our product classification in a positive manner.

| Product model | Tensile strength (MPa) | Modulus(GPA) | Elongation at break(%) | Density(g/cm³) |

| T300 | 3,530 | 230 | 1.5 | 1.76 |

| T700S | 4,900 | 230 | 2.1 | 1.8 |

| T800S | 5,880 | 294 | 2 | 1.8 |

| T1000G | 6,370 | 294 | 2.2 | 1.8 |

| T1100G | 7,000 | 324 | 2 | 1.79 |

| M35J | 4,510/4,700 | 343 | 1.3 | 1.75 |

| M40J | 4,400 | 377 | 1.2 | 1.77 |

| M50J | 4,120 | 475 | 0.9 | 1.88 |

| M55J | 4,020 | 540 | 0.8 | 1.91 |

| M60J | 3,820 | 588 | 0.7 | 1.93 |

The Process of Carbon Fiber Production

- The upstream companies in the industrial chain begin by producing propylene from fossil fuels such as petroleum, coal, and natural gas. This propylene is then used to obtain acrylonitrile through ammonia oxidation.

- Polyacrylonitrile (PAN) raw yarn is obtained after polymerization and spinning of acrylonitrile;

- Enterprises in the middle and lower tiers of the industrial chain can acquire high-quality carbon fibers with a carbon content of over 99% and temperature resistance of 2000-3000℃.

- After surface treatment, carbon fiber can be made into carbon fiber fabric and carbon fiber prepreg;

- Carbon fiber is combined with resin, ceramics and other materials to form carbon fiber composite materials. Finally, various molding processes are used to obtain the final products required for downstream applications.

Application Areas of Carbon Fiber

- Wind power blade

The future looks bright for large-tow carbon fiber as the demand for this superior material is on the rise. With the increasing popularity of large-scale wind turbines and the expiration of Vesta's patent, the demand for this lightweight, high-performance material is set to surge. Not only does large-tow carbon fiber offer superior performance, but it can also reduce blade weight by 30%. As we look to a cleaner and more efficient future, large-tow carbon fiber will play an essential role in propelling us forward. To ensure optimal performance, wind turbines larger than 3MW and blades exceeding 50 meters require the use of large-tow carbon fiber.

To facilitate wider adoption, Vestas is finding ways to manufacture these blades at reduced costs. As the patent expiration draws near, domestic wind power plants are actively exploring this technology, resulting in a significant increase in demand for large tow carbon fiber. This presents an exciting opportunity for the growth of renewable energy.

With the trend of developing more powerful wind turbines and longer rotor blades, reducing blade mass while ensuring adequate strength and stiffness is critical. To meet these challenges, incorporating high-performance carbon fiber composite materials is vital.

The global demand for carbon fiber is predicted to flourish, reaching 150,000 tons and 200,000 tons by 2023 and 2025. This growth is primarily attributed to the increasing demand for wind power blade applications, indicating a bright future for the carbon fiber industry.

- Hydrogen storage

Carbon fiber-wound composite hydrogen storage bottles use carbon fiber tows soaked in epoxy resin, wrapped with aluminum alloy or polymer liner, and then solidified and molded to demould, thus having the characteristics of light weight, fatigue resistance, and high and low temperature resistance. Impact, good stability and other characteristics.

At the same time, compared with type three bottles, although the amount of carbon fiber used in type four bottles is increased, the total cost is reduced. Under the same working pressure, the cost of type four bottles is 7%-11% lower than that of type three bottles. Therefore, the demand for large tow carbon fiber for hydrogen storage bottles will grow rapidly.

In natural gas vehicles (NGV) and fuel cell vehicles (FCV), type IV high-pressure gas storage bottles can effectively reduce weight, store more fuel, effectively extend the vehicle's cruising range, and have obvious economic benefits. In the next few years, natural gas vehicles and fuel Battery vehicles will be the main application direction of type III and IV high-pressure hydrogen storage bottles. The demand for carbon fiber in the pressure vessel field may reach 15,000 tons-21,900 tons in 2023 and 2025.

- Aerospace

Carbon fiber composites have become an indispensable material in the construction of lightweight structures, especially in aviation. Their exceptional physical properties have led to widespread use and rapid development. It is worth noting that carbon fiber usage in U.S. fighter aircraft has steadily increased since 1969, reaching an impressive 36%.

Carbon fiber composite materials make up over half of the U.S. B2 stealth strategic aircraft, demonstrating their strength and reliability. In recent years, the civil aviation industry has seen a surge in the use of carbon fiber composite materials. This can be seen in the B787, A350, and COMAC's C919. Aviation field utilizes a range of carbon fibers, including 3K, 6K, and 12K.

- Sports and leisure

In the sports and leisure market, carbon fiber is mainly used in high-end sports and leisure markets such as golf clubs, hockey sticks, tennis rackets, fishing rods, bicycle frames, skis, and rowing boats. This application is mainly based on the lightweight, high strength, high modulus, corrosion resistance and other characteristics of carbon fiber.

For example, golf clubs made of carbon fiber composite materials are nearly 50% lighter than metal clubs, and carbon fiber bicycles are 40% lighter than aluminum materials and achieve higher frame accuracy. Carbon fiber for fishing rods, rackets, skis, golf clubs and other sporting goods mostly use large tow carbon fiber (≥24K).

It is expected that the demand for carbon fiber in the sports and leisure field will reach approximately 18,000 tons-20,000 tons in 2023 and 2025.

- Automobile lightweight

The most important application of carbon fiber in automobiles is to reduce weight. The international community is becoming stricter in terms of energy conservation, emission reduction, and fuel consumption standards. Lightweight technology is one of the most effective engineering ways to reduce automobile fuel consumption, reduce emissions, and increase the cruising range of new energy vehicles.

Using high-performance fiber-reinforced composite materials to partially replace traditional metal materials is the most effective way to achieve lightweighting in automobiles. Due to its high height, high modulus and low density, carbon fiber composite materials can lose more weight than steel and magnesium-aluminum alloys under equal stiffness or equal strength. At the same time, they have better safety performance and better fatigue resistance. The structure is integrally formed and can be used. More design.

Demand for carbon fiber in the automotive field: It is expected that the demand for carbon fiber will reach approximately 17,000 tons-18,000 tons in 2023 and 2025. With the trend of lightweighting in the automotive field, carbon fiber will also see more and more applications in automobiles. At the same time, energy saving and cost reduction due to lightweighting, as well as green and environmental protection value will further promote this application trend.

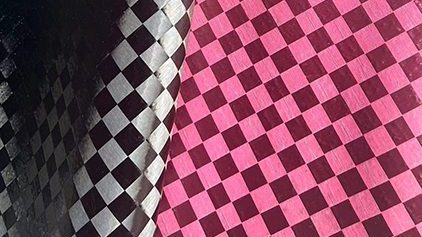

- Prepreg

Prepreg is a prepreg sheet product made by impregnating the matrix in reinforcing fibers. It is the intermediate material of composite materials. Carbon fiber prepreg is a composite material made of reinforcements, such as carbon fiber yarn, resin matrix, release paper and other materials, which are processed through coating, hot pressing, cooling, laminating, coiling and other processes. It is also called carbon fiber prepreg cloth.

Advantages of carbon fiber prepreg:

1) High strength and low density: the strength of carbon fiber prepreg can reach 6-12 times that of steel, and the density is only one-quarter of steel;

2) Good plasticity: it can be made into any shape according to the shape of the mold Shape, easy to form and process;

3) Corrosion-resistant, long shelf life

Types of carbon fiber prepreg:

1) unidirectional carbon fiber: it has the greatest strength in the fiber direction and is usually used for laminated boards with different combinations of directions;

2)Woven carbon fiber prepreg: it has different weaving methods, its strength is approximately equal in both directions, and can be applied to different structures.

There are two main methods of production process for carbon fiber prepreg: one is to directly heat the resin to reduce its viscosity and facilitate even distribution among the fibers, which is called the hot melt method. The other method is to dissolve the resin in a solvent to reduce the viscosity. After the resin is impregnated into the fiber, it is heated to evaporate the solvent, which is called the solution impregnation method.

In the hot melt adhesive process, the resin content is easy to control, the drying step can be omitted, and there is no residual solvent. However, the resin viscosity is high, and it is easy to cause fiber deformation when impregnating fiber braiding. The solvent method has low investment cost and simple manufacturing process, but the use of solvents can easily remain in the prepreg, affecting the strength of the final composite material and causing environmental pollution problems.

| Hot melt method | Solution dipping method | |

| Advantages | Easy to control resin content, no solution residue. | When the resin viscosity is high, the fiber is easily deformed. |

| Disadvantages | Easy to make and low cost. | The solution can easily cause environmental pollution, may affect fiber strength. |

- Composite Materials

When carbon fiber is used to make products, it is generally not easy to use independently due to the difficulty of the production and processing technology and the great damage to the equipment. Instead, it is combined with conventional raw materials such as epoxy resin to form carbon fiber composite materials.

The characteristics of carbon fiber composite materials are mainly reflected in three aspects: mechanical properties, thermophysical properties and thermal ablation properties.

1) Low density (about 1.7g/cm3), it is the lightest among structures that can withstand high temperatures

Material; has good strength at high temperatures and can retain room temperature strength at 2200°C; has high fracture toughness, fatigue resistance and creep resistance.

2) The thermal expansion coefficient is small, the specific heat capacity is high, it can store a large amount of thermal energy, the thermal conductivity is low, and it has excellent resistance to thermal shock and thermal friction.

3) It has good resistance to heat ablation. C-C material is a sublimation-radiation material. It takes away a large amount of heat through the ablation of surface materials and prevents heat from flowing into the interior of the material.

The excellent mechanical properties and thermophysical properties of carbon fiber reinforced composite materials make it widely used in nuclear reactors, solid rocket nozzles, heat exchangers and brake discs etc.

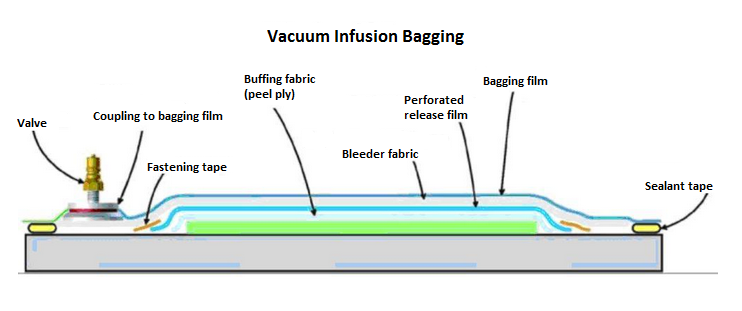

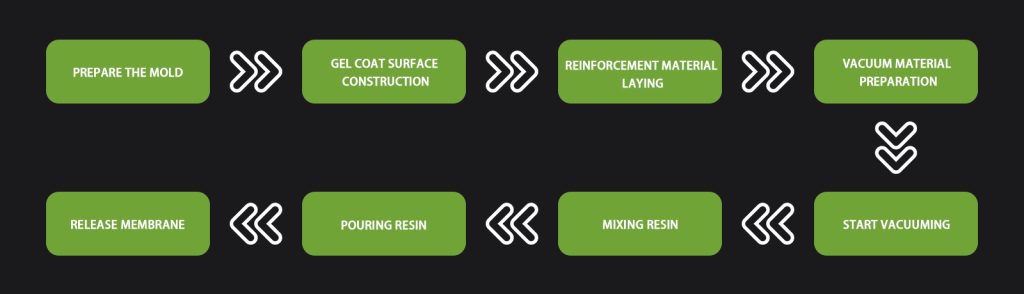

- Vacuum infusion

Carbon fiber vacuum infusion (or "resin infusion") is a process that combines fibers and resin that uses atmospheric pressure to drive the resin through a stack of dry reinforcements under vacuum. The resin simply flows into and through the fiber pile, and the carbon fibers wet out as the resin goes by. The carbon fiber is under a vacuum bag, so it's nicely compacted and pressed against the mold.

When the resin has completely filled the part, the feed line can be clamped to allow it to cure. Parts produced through the infusion process are compacted, have very low void content, and have good surface gloss and hardness.

Vacuum infusion is an ideal way to build composite parts. It has many of the advantages of prepreg in terms of detailed layup and thick laminates, but it's cheaper, faster, and doesn't require an oven or autoclave. After decades of steady development, vacuum infusion has developed into a mature technology with complete technology, supporting products and equipment.

| Advantages | Disadvantages |

| 1. The layup is done with dry fibers, and the cut and layup layout are not limited by the gel time of the resin; 2. High quality laminate with low void content and excellent core bonding; 3. Consistent part-to-part quality and repeatable weight; 4. One-time laminated skin and core, as well as potential stringers and other structures; 5. Suitable for medium-volume production, easy to train, and can be continuously improved. | 1. Requires some tedious bagging, with lots of detail; 2. Not suitable for mass production; Large waste of materials |

Our Solution for Carbon Fiber

For more interesting knowledge and industrial report about composite: