Carbon Fiber 3D Printing Guide: A Comparison with Traditional Materials and Methods

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Carbon fiber composites are characterized by high stiffness, strength, lightweight, high chemical resistance, and high-temperature resistance, making them popular in aerospace, construction, military, racing, and sports products, such as race cars, drone frames, bicycles, and tennis rackets.

On the market, many professional 3D printers use polymer-based materials and a variety of composite materials. Combining the excellent characteristics of carbon fiber composites with the flexibility of 3D printing technology, they can create lightweight, high-strength, personalized, and complex parts, with a wide range of application prospects.

Therefore, many people will ask: How to 3D print carbon fiber?

Currently, there are two ways to build carbon fiber parts:

1. 3D printing of mold entities for use in traditional manufacturing methods

2. Direct 3D printing of carbon fiber composites

Combining 3D printing technology with traditional methods to manufacture carbon fiber parts

Carbon fiber is a composite material that is traditionally manufactured by interweaving long bundles of carbon fibers and fixing them with polymer bonds. These fiber tows can be woven as precisely as needed to provide strength in one direction or to give the final material balanced mechanical properties in all directions, after which the finished product is typically made by one of three main processes: wet lay-up, prepreg lamination, or resin transfer molding (RTM).

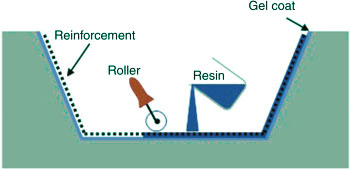

Wet Lay-up

Wet layup is a composite manufacturing process that involves soaking carbon fiber cloth or other reinforcement in resin and then laying it down onto the mold layer by layer. Each layer is carefully compacted to remove air bubbles and ensure the resin fully penetrates the fibers. Once the layers are completed, they usually need to be cured in a vacuum bag to ensure that the material is dense and strong. This process is suitable for beginners and most operations can usually be done by hand. The disadvantage is that it is less precise than other methods.

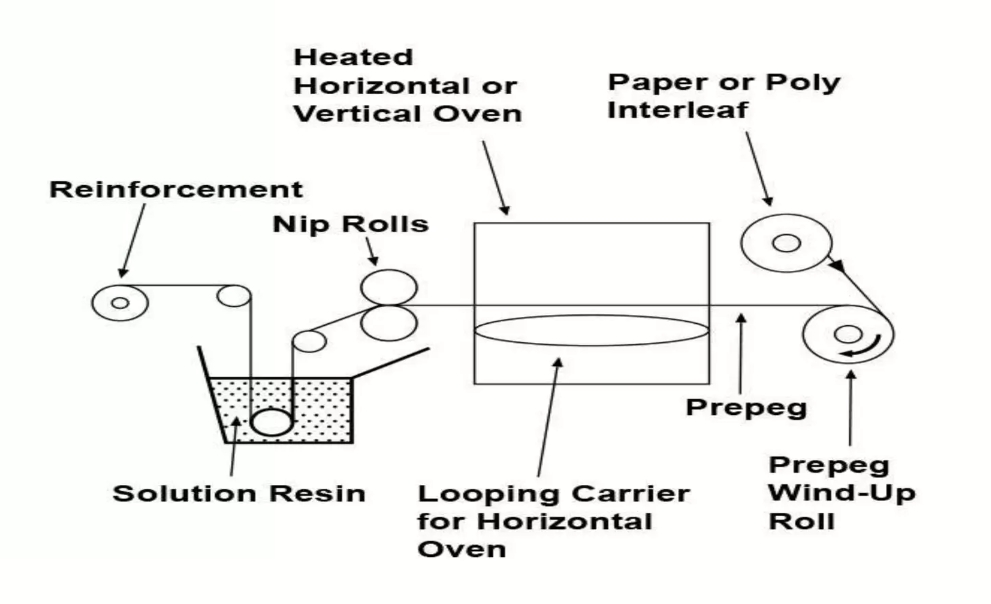

Prepreg Lamination

In this process, carbon fibers that have been prepreg impregnated with resin and semi-cured into sheets are used. During the lamination process, the prepreg is cut and stacked in a mold layer by layer, with each layer aligned in the desired fiber orientation to ensure that the strength characteristics of the final part meet the design requirements. Once stacked, the prepreg is pressed, usually in a vacuum bag, and cured at controlled high temperatures, ensuring that the resin is uniformly distributed and fully impregnated into the fibers, resulting in a dense, high-strength composite.

This method is more expensive because it requires specialized equipment to store and handle the pre-injected sheets, as well as heating and pressurizing the forming machine. The advantage is that it is suitable for mass production of carbon fiber components.

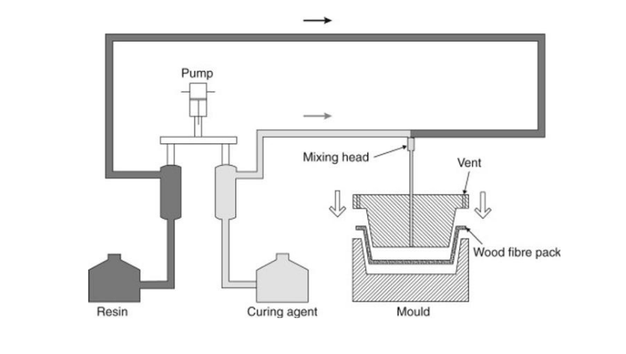

Resin Transfer Molding (RTM)

In the process, two mold halves (upper and lower molds) are used to form the shape of the part, then carbon fibers are laid on the inner surface of the mold, the mold is closed under vacuum and liquid resin is injected into the mold cavity through a pipe, and finally, the mold is heated to a specific curing temperature to harden the resin to a solid state.

The RTM process produces parts with a glossy surface finish without the need for subsequent surface treatments and is often automated for high-volume production. Attachment 4 (RTM hand-drawing process)

3D Printing Makes Molds to Create Carbon Fiber Parts

All three of these processes use molds. In traditional processes, making molds is relatively very time-consuming and expensive, such as in the automotive and aerospace industries, where the iterative process can require hundreds of different molds, while 3D printed molds not only shorten lead times but also are suitable for small batch production and customization, greatly improving efficiency and saving costs.

Direct 3D Printed Carbon Fiber Composites

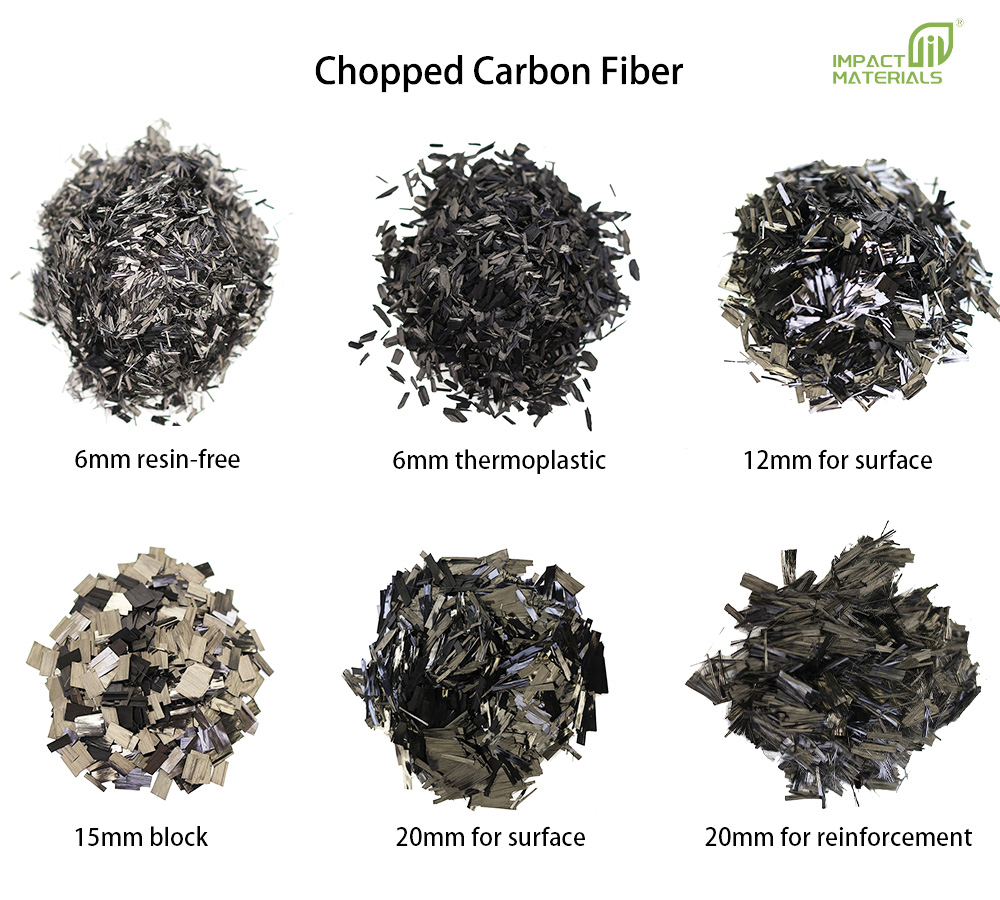

In the direct 3D printing process, carbon fibers, usually in the form of chopped or continuous fibers, are blended with thermoplastics such as PLA, nylon, or PEEK to form printed wires or pellets of composites. These composites are processed through specially designed 3D printers.

Want to know the difference between chopped carbon fiber 3D printing and continuous carbon fiber 3D printing?

Chopped carbon fiber 3D printing

The process involves combining chopped carbon fibers with thermoplastics to create high-performance composite parts via 3D printing technology. These chopped carbon fibers, which are typically cut into pieces ranging from 6-25mm, provide additional strength to the composite and can be used as carbon fiber filaments for fused deposition molding (FDM) or nylon powder for selective laser sintering (SLS) 3D printing.

Chopped carbon fiber-reinforced 3D printing materials offer significant advantages over other polymer-based 3D printing materials in that they are strong, lightweight, heat-resistant, and resistant to creep. In addition, the material offers greater geometric flexibility in part design than traditionally molded carbon fiber parts.

Continuous Carbon Fiber 3D Printing

The process enhances the mechanical properties of the part by embedding a continuous bundle of carbon fibers during the printing process. This technique combines the high strength and rigidity of carbon fiber with the design flexibility of 3D printing. Continuous carbon fiber 3D printers are typically equipped with a dual nozzle system, with one nozzle used to extrude a thermoplastic matrix material and the other nozzle used to precisely place the carbon fiber tows. The matrix material provides the basic shape for the printed part, while the carbon fibers are embedded in areas where reinforcement is needed to provide additional strength. Certain specialized FDM 3D printers are capable of continuous carbon fiber 3D printing, generating parts that are nearly comparable in strength to traditional carbon fiber parts. However, similar to chopped fiber FDM printers, this strength is primarily concentrated in the XY plane.

Comparison: Traditional Carbon Fiber Manufacturing Processes VS. 3D Printed Carbon Fiber Processes

| WET LAY-UP | PRE-PREG LAMINATION | RESIN TRANSFER MOLDING | CHOPPED FIBERS FDM 3D PRINTING | CHOPPED FIBERS SLS 3D PRINTING | CONTINUOUS FIBERS FDM 3D PRINTING | |

| Accuracy | 60 | 100 | 100 | 60 | 100 | 60 |

| Surface Finish | 60 | 100 | 100 | 60 | 80 | 60 |

| Design Freedom | 60 | 60 | 60 | 80 | 100 | 80 |

| Lightweight | 100 | 100 | 100 | 80 | 80 | 80 |

| Strength | 100 | 100 | 100 | 60 | 60 | 100 |

| Strength in Which Directions | XYZ | XYZ | XYZ | XY | X(Y) | XY |

| Cost | Variable, starting at <$100 | Variable, starting at <$3000 | Variable, generally $100,000+ | Desktop solutions start at $5,000, industrial solutions around $40,000 | Complete industrial solution starting at $39,000 | Desktop solutions start at $20,000, industrial solutions around $70,000 |

| Advantages | High strength Low equipment cost | High strength | strength High strength Precision and repeatability Automation possibilities | Inexpensive No tooling required | Precision and repeatability Design freedom No tooling required | High strength No tooling required |

| Disvantages | Labor intensive Difficult to maintain high quality | Labor intensive | Expensive tooling and machinery | Anisotropic strength Lower strength Hard to print | Anisotropic strength Lower strength | Anisotropic strength |

Do you know the strength of carbon fiber 3D printed composites?

Carbon fibers have extremely high tensile strength and stiffness, and act as a backbone in composites, taking on most of the load, significantly improving the overall strength of the material, and outperforming virtually all other 3D-printed plastics in terms of temperature resistance.

The following is a comparison of the apparent properties between the different materials:

| MANUFACTURING PROCESS | SLS - CHOPPED FIBERS | FDM - CHOPPED FIBERS | FDM - CONTINUOUS FIBERS | FDM - CONTINUOUS FIBERS | INJECTION MOLDING | CASTING OR MACHINING |

| Material | Formlabs Nylon 11 CF Powder | Carbon Fiber-Filled Nylon Filament | Nylon 6 Filament + Carbon Fiber | PEEK Filament + Carbon Fiber | ABS | Aluminum |

| Tensile Modulus (GPa) | 1.6 - 5.3 | 2.4 | 60 - 100 | 145 | 2.3 | 70 |

| Ultimate Tensile Strength (MPa) | 38 - 69 | 40 | 800 - 1000 | 2400 | 39 | 310 |

| Flexural Modulus (GPa) | 4.2 | 3.0 | 51 - 71 | 124 | 2.4 | 70 |

| Flexural Strength (MPa) | 110 | 71 | 540 - 800 | 1300 | 74 | 310 |

| Elongation at Break | 5 - 15% | 25% | 1.5% | N/A | 6 - 15% | N/A |

| Heat Deflection Temp. @ 0.45 MPa (°C) | 188 | 145 | 105 | N/A | 70 - 107 | N/A |

Application of carbon fiber 3D printed composite parts

The strength of carbon fiber 3D printed composites depends on the fiber type, printing direction, and process control. With proper design and optimization, these materials can provide excellent mechanical properties while remaining lightweight and are used in a wide range of applications that require high-strength, lightweight components, including aerospace, automotive industry, medical devices, consumer electronics, and industrial manufacturing.

Request a free sample of chopped carbon fiber from Impact Materials today or speak with one of our experts to find the right solution.