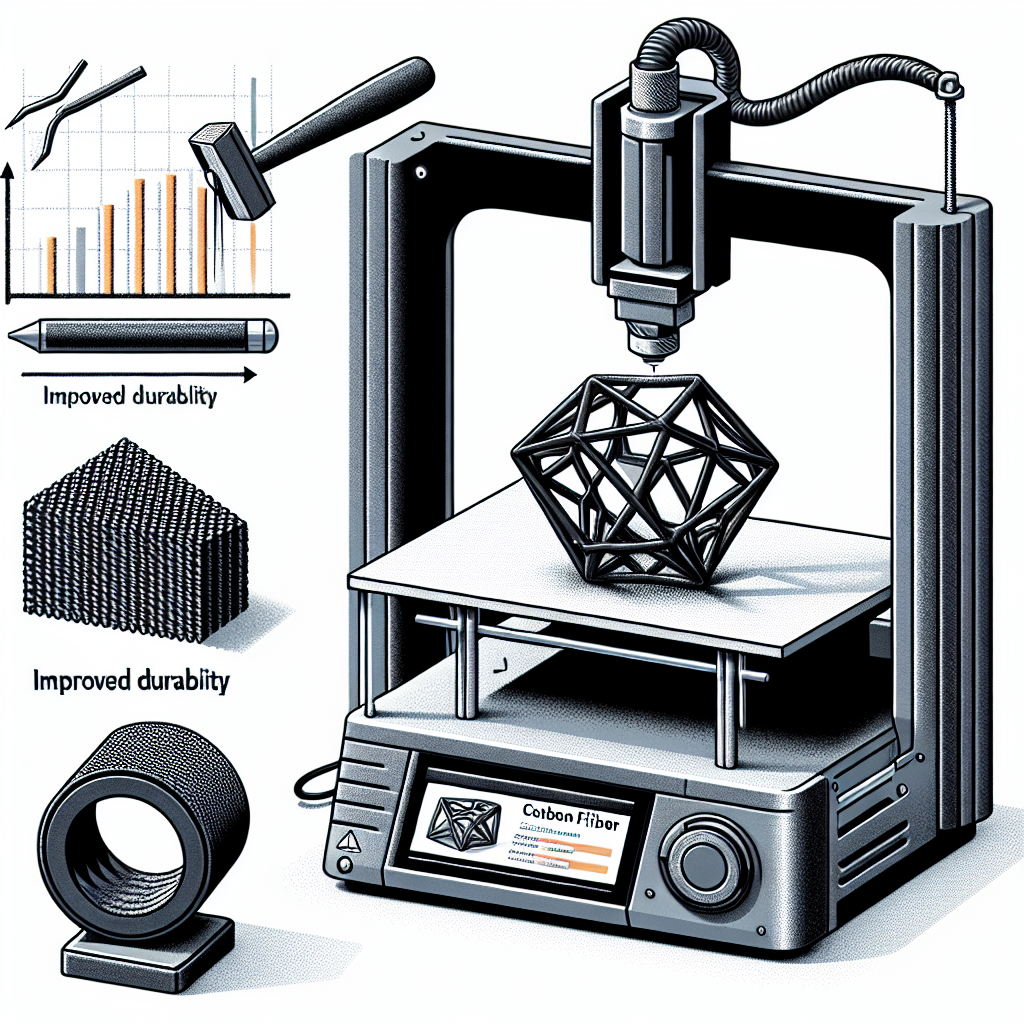

Can Chopped Carbon Fiber Improve 3D-Printed Parts’ Durability?

-

Table of Contents

“Reinforce Your Prints: Chopped Carbon Fiber for Unmatched Durability in 3D-Printed Parts!”

Introduction

Chopped carbon fiber has emerged as a promising additive in the realm of 3D printing, particularly for enhancing the durability and mechanical properties of printed parts. By incorporating short strands of carbon fiber into thermoplastic matrices, manufacturers aim to create composite materials that exhibit superior strength, stiffness, and impact resistance compared to traditional 3D printing materials. This introduction explores the potential benefits of using chopped carbon fiber in 3D-printed components, examining how it can improve performance in various applications, from automotive to aerospace, while also addressing challenges such as printability and cost-effectiveness. As the demand for high-performance parts continues to grow, understanding the role of chopped carbon fiber in additive manufacturing becomes increasingly important for engineers and designers seeking to push the boundaries of 3D printing technology.

Benefits of Chopped Carbon Fiber in 3D Printing

The integration of chopped carbon fiber into 3D printing processes has emerged as a significant advancement in the quest for enhanced material properties. As industries increasingly turn to additive manufacturing for producing complex geometries and lightweight components, the need for improved durability and strength in 3D-printed parts becomes paramount. Chopped carbon fiber, known for its exceptional mechanical properties, offers a compelling solution to these challenges. By incorporating this material into the 3D printing process, manufacturers can achieve parts that not only exhibit superior strength but also enhanced stiffness and reduced weight.

One of the primary benefits of using chopped carbon fiber in 3D printing is the substantial increase in tensile strength. When blended with thermoplastic materials, such as nylon or PLA, chopped carbon fiber reinforces the matrix, resulting in a composite that can withstand greater loads without deforming. This characteristic is particularly advantageous in applications where mechanical stress is a critical factor, such as in automotive or aerospace components. The ability to produce parts that can endure higher stress levels without compromising structural integrity is a game-changer for engineers and designers alike.

In addition to increased tensile strength, chopped carbon fiber contributes to improved stiffness in 3D-printed parts. The incorporation of carbon fibers into the polymer matrix enhances the rigidity of the final product, making it less prone to bending or flexing under load. This property is especially beneficial in applications requiring precise tolerances and dimensional stability. For instance, in the production of brackets or supports, the added stiffness ensures that the components maintain their shape and functionality over time, thereby reducing the likelihood of failure.

Moreover, the lightweight nature of chopped carbon fiber composites cannot be overlooked. In industries where weight reduction is critical, such as aerospace and automotive, the use of carbon fiber can lead to significant improvements in overall performance. By replacing heavier materials with lightweight composites, manufacturers can enhance fuel efficiency and reduce energy consumption. This aspect not only contributes to cost savings but also aligns with the growing emphasis on sustainability and environmental responsibility in manufacturing practices.

Another noteworthy advantage of incorporating chopped carbon fiber into 3D printing is the potential for improved thermal stability. Carbon fibers exhibit excellent thermal conductivity, which can help dissipate heat more effectively than traditional materials. This property is particularly beneficial in applications where heat buildup could lead to material degradation or failure. By utilizing chopped carbon fiber, manufacturers can produce parts that maintain their performance characteristics even under elevated temperatures, thereby extending the lifespan of the components.

Furthermore, the versatility of chopped carbon fiber allows for a wide range of applications across various industries. From consumer products to industrial machinery, the adaptability of this material makes it suitable for diverse manufacturing needs. As 3D printing technology continues to evolve, the ability to customize and tailor the properties of chopped carbon fiber composites opens up new possibilities for innovation.

In conclusion, the incorporation of chopped carbon fiber into 3D printing processes presents numerous benefits that significantly enhance the durability and performance of printed parts. With increased tensile strength, improved stiffness, reduced weight, enhanced thermal stability, and versatility across applications, chopped carbon fiber stands out as a transformative material in the realm of additive manufacturing. As industries continue to explore the potential of this innovative approach, the future of 3D-printed components looks promising, paving the way for more robust and efficient designs.

Comparing Durability: Standard Filaments vs. Chopped Carbon Fiber-Infused Filaments

The quest for enhanced durability in 3D-printed parts has led to the exploration of various materials, with filaments infused with chopped carbon fiber emerging as a promising alternative to standard filaments. To understand the potential benefits of using chopped carbon fiber, it is essential to compare the durability of standard filaments, such as PLA and ABS, with that of carbon fiber-infused variants. Standard filaments have long been the go-to choice for 3D printing due to their ease of use, availability, and relatively low cost. However, these materials often fall short in terms of mechanical strength and impact resistance, particularly in applications that demand high performance.

In contrast, chopped carbon fiber-infused filaments are engineered to address these shortcomings. By incorporating short strands of carbon fiber into the base polymer, these filaments significantly enhance the mechanical properties of the printed parts. The addition of carbon fiber not only increases tensile strength but also improves stiffness, making the resulting components more resistant to deformation under load. This is particularly advantageous in applications where parts are subjected to stress or impact, as the enhanced durability can lead to longer service life and reduced failure rates.

Moreover, the infusion of chopped carbon fiber can also improve the thermal stability of 3D-printed parts. Standard filaments, while suitable for many applications, often exhibit limited thermal resistance, which can lead to warping or deformation when exposed to elevated temperatures. In contrast, carbon fiber-infused filaments tend to maintain their structural integrity under higher thermal loads, making them suitable for applications in automotive, aerospace, and industrial settings where temperature fluctuations are common.

Transitioning from standard filaments to carbon fiber-infused options does come with certain considerations. For instance, the printing process may require adjustments to accommodate the unique properties of the carbon fiber material. The abrasive nature of chopped carbon fiber can lead to increased wear on standard nozzles, necessitating the use of hardened or specialized nozzles designed to withstand such wear. Additionally, the printing parameters, such as temperature and speed, may need to be fine-tuned to achieve optimal layer adhesion and surface finish.

Despite these challenges, the benefits of using chopped carbon fiber-infused filaments are compelling. The enhanced durability translates not only to improved performance but also to cost savings in the long run. Parts that can withstand greater stress and environmental factors reduce the need for frequent replacements, thereby lowering overall production costs. Furthermore, the ability to produce lightweight yet strong components is particularly appealing in industries where weight reduction is critical, such as aerospace and automotive manufacturing.

In conclusion, the comparison between standard filaments and chopped carbon fiber-infused filaments reveals a significant advantage in terms of durability. While standard filaments serve well for basic applications, the infusion of chopped carbon fiber offers a transformative approach to 3D printing, resulting in parts that are not only stronger and more resilient but also better suited for demanding environments. As the technology continues to evolve, the adoption of carbon fiber-infused filaments is likely to increase, paving the way for innovations in design and functionality across various industries. Ultimately, the integration of chopped carbon fiber into 3D printing represents a significant step forward in the pursuit of durable, high-performance components.

Best Practices for Incorporating Chopped Carbon Fiber in 3D-Printed Parts

Incorporating chopped carbon fiber into 3D-printed parts has emerged as a promising method to enhance the mechanical properties and durability of these components. However, to achieve optimal results, it is essential to follow best practices that ensure effective integration of this advanced material. First and foremost, selecting the right type of chopped carbon fiber is crucial. Various grades and lengths of carbon fiber are available, and the choice should align with the specific application requirements. For instance, shorter fibers may be more suitable for applications requiring improved flowability during the printing process, while longer fibers can provide enhanced strength and stiffness.

Once the appropriate carbon fiber is selected, the next step involves determining the correct fiber loading percentage. This is a critical factor, as too little fiber may not yield significant improvements in mechanical properties, while too much can lead to processing difficulties and compromised print quality. Generally, a loading percentage between 5% and 30% is recommended, depending on the base material and the desired characteristics of the final part. It is advisable to conduct preliminary tests to find the optimal balance that maximizes performance without adversely affecting the printability of the material.

In addition to fiber selection and loading, the choice of the base polymer is also vital. Certain thermoplastics, such as nylon or polycarbonate, exhibit better compatibility with chopped carbon fiber, leading to improved adhesion and overall performance. Moreover, the thermal properties of the base material should be considered, as they can influence the final part’s strength and durability. For instance, materials with higher melting points may allow for better fiber dispersion and bonding during the printing process, ultimately enhancing the mechanical properties of the finished product.

Another important aspect to consider is the printing parameters. Adjusting the nozzle temperature, print speed, and layer height can significantly impact the quality of the final part. Higher temperatures may be necessary to ensure proper melting and bonding of the chopped carbon fiber with the base material. However, it is essential to strike a balance, as excessively high temperatures can lead to degradation of the fibers, negating their reinforcing effects. Additionally, slower print speeds can improve layer adhesion and allow for better fiber distribution, which is crucial for achieving the desired mechanical properties.

Post-processing techniques also play a significant role in enhancing the durability of 3D-printed parts containing chopped carbon fiber. Techniques such as annealing can improve the crystallinity of the polymer matrix, leading to enhanced strength and thermal stability. Furthermore, surface treatments, such as sanding or coating, can help mitigate any surface imperfections that may arise during the printing process, thereby improving the overall aesthetics and performance of the part.

Finally, thorough testing and validation of the 3D-printed parts are essential to ensure that they meet the required performance standards. Conducting mechanical tests, such as tensile and impact tests, can provide valuable insights into the effectiveness of the chopped carbon fiber integration. By adhering to these best practices, manufacturers can significantly enhance the durability and performance of 3D-printed parts, paving the way for their use in demanding applications across various industries. As the technology continues to evolve, the potential for chopped carbon fiber in 3D printing remains vast, promising exciting advancements in material science and engineering.

Q&A

1. **Question:** How does chopped carbon fiber enhance the durability of 3D-printed parts?

**Answer:** Chopped carbon fiber improves the durability of 3D-printed parts by increasing their tensile strength and impact resistance, leading to enhanced mechanical properties compared to standard materials.

2. **Question:** What are the potential drawbacks of using chopped carbon fiber in 3D printing?

**Answer:** Potential drawbacks include increased brittleness, difficulty in processing due to the abrasive nature of carbon fibers, and potential issues with layer adhesion in the printed parts.

3. **Question:** In which applications is chopped carbon fiber particularly beneficial for 3D-printed parts?

**Answer:** Chopped carbon fiber is particularly beneficial in applications requiring high strength-to-weight ratios, such as aerospace components, automotive parts, and high-performance sporting goods.