Can Carbon Fiber Sheets Be Laser-Cut Without Damage?

-

Table of Contents

“Precision Meets Strength: Laser-Cutting Carbon Fiber Sheets Without Compromise.”

Introduction

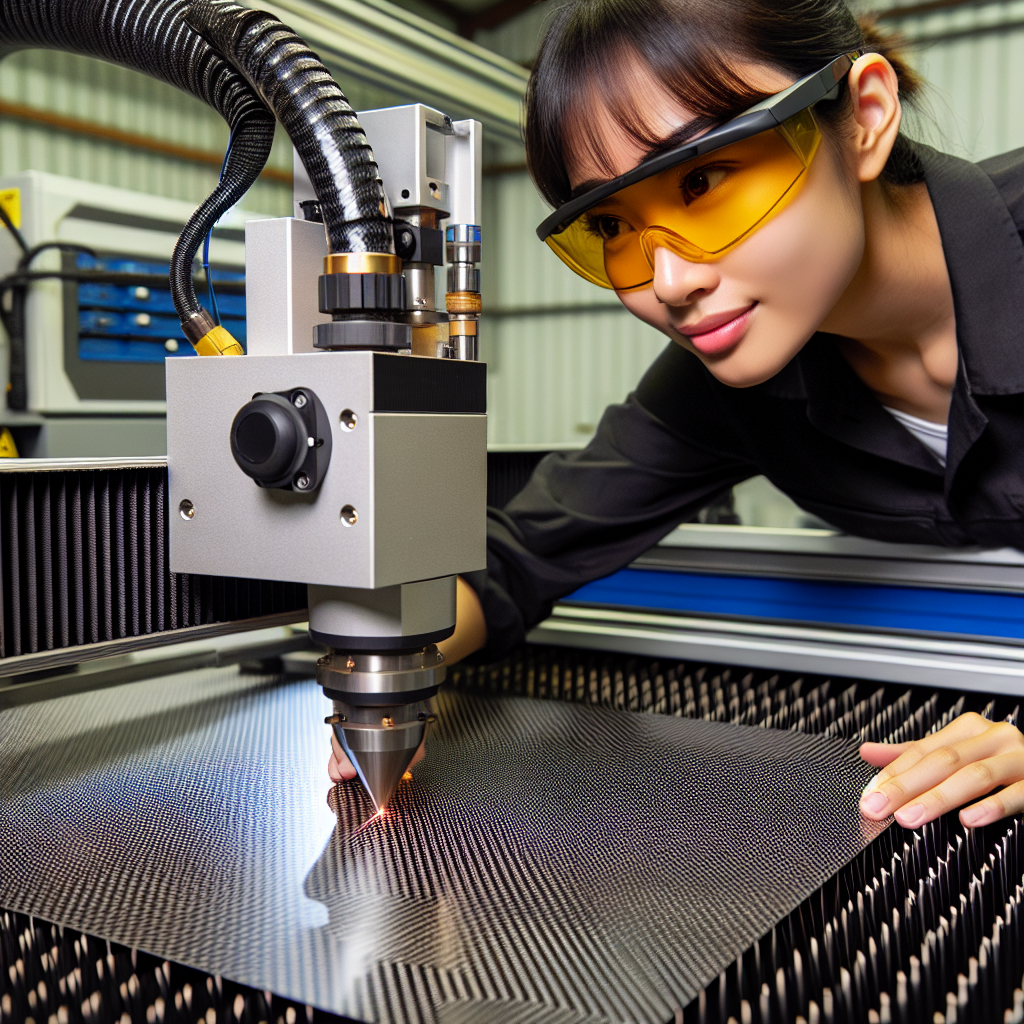

Carbon fiber sheets are renowned for their strength, lightweight properties, and versatility in various applications, from aerospace to automotive industries. However, when it comes to fabrication techniques, particularly laser cutting, concerns about potential damage to the material often arise. This introduction explores the feasibility of laser cutting carbon fiber sheets, examining the advantages and challenges associated with this method, as well as best practices to ensure precision and integrity during the cutting process. Understanding these factors is crucial for manufacturers and designers looking to leverage the benefits of carbon fiber while maintaining the quality of their products.

Advantages of Laser Cutting Carbon Fiber Sheets

Laser cutting has emerged as a highly effective method for processing various materials, and carbon fiber sheets are no exception. The advantages of using laser cutting for carbon fiber sheets are numerous, making it a preferred choice in industries ranging from aerospace to automotive and beyond. One of the primary benefits of laser cutting is its precision. The technology allows for intricate designs and complex shapes to be cut with remarkable accuracy. This precision is particularly important in applications where tight tolerances are required, as even minor deviations can lead to significant issues in performance and safety.

Moreover, laser cutting minimizes the risk of damage to the material itself. Traditional cutting methods, such as saws or blades, can introduce mechanical stress and lead to fraying or delamination of the carbon fiber layers. In contrast, laser cutting operates through a non-contact process, which means that the laser beam does not physically touch the material. This characteristic significantly reduces the likelihood of introducing defects, ensuring that the integrity of the carbon fiber sheet is maintained throughout the cutting process.

In addition to precision and reduced risk of damage, laser cutting offers a clean and smooth edge finish. The high temperatures generated by the laser effectively melt and vaporize the material at the cutting edge, resulting in a polished finish that often requires little to no post-processing. This is particularly advantageous in applications where aesthetics are important, as well as in situations where a clean edge can enhance the bonding or assembly of components.

Another significant advantage of laser cutting carbon fiber sheets is its efficiency. The speed at which a laser cutter can operate allows for rapid production times, which is essential in industries that demand quick turnaround times. This efficiency not only accelerates the manufacturing process but also reduces labor costs, as fewer personnel are required to oversee the cutting operation. Furthermore, the automation capabilities of laser cutting systems enable consistent results, reducing variability and ensuring that each cut meets the specified requirements.

Additionally, laser cutting is highly versatile, accommodating a wide range of thicknesses and types of carbon fiber sheets. Whether dealing with standard or specialty grades, laser cutting technology can be adapted to suit various material properties, making it an ideal solution for diverse applications. This versatility extends to the ability to cut multiple sheets simultaneously, further enhancing productivity and material utilization.

Furthermore, the environmental impact of laser cutting is often more favorable compared to traditional cutting methods. The process generates minimal waste, as the precision of the laser allows for optimal material usage. This is particularly important in industries where sustainability is a growing concern. By reducing waste and energy consumption, laser cutting aligns with the principles of lean manufacturing and environmentally responsible practices.

In conclusion, the advantages of laser cutting carbon fiber sheets are compelling. From its precision and reduced risk of damage to the clean edge finishes and efficiency it offers, laser cutting stands out as a superior method for processing this advanced material. As industries continue to seek innovative solutions that enhance performance while minimizing waste, the adoption of laser cutting technology for carbon fiber sheets is likely to grow, solidifying its role as a cornerstone in modern manufacturing processes.

Best Practices for Laser Cutting Carbon Fiber

Laser cutting carbon fiber sheets is a process that requires careful consideration and adherence to best practices to ensure optimal results without damaging the material. Carbon fiber, known for its high strength-to-weight ratio and rigidity, is increasingly used in various industries, including aerospace, automotive, and sporting goods. However, the unique properties of carbon fiber also present challenges during the cutting process. Therefore, understanding the best practices for laser cutting this material is essential for achieving precision and maintaining the integrity of the sheets.

To begin with, selecting the appropriate laser cutting equipment is crucial. CO2 lasers are commonly used for cutting carbon fiber due to their ability to produce a focused beam that can effectively penetrate the material. However, it is important to ensure that the laser’s power settings are correctly calibrated. A power level that is too high can lead to excessive heat generation, resulting in delamination or burning of the fibers. Conversely, insufficient power may not cut through the material effectively, leading to incomplete cuts and rough edges. Therefore, conducting test cuts on scrap pieces of carbon fiber can help determine the optimal settings before proceeding with the final workpiece.

In addition to power settings, the speed of the laser cutting process plays a significant role in the quality of the cut. A slower cutting speed allows for a cleaner cut, as it gives the laser more time to effectively vaporize the material without causing thermal damage. However, if the speed is too slow, it can lead to excessive heat buildup, which may compromise the structural integrity of the carbon fiber. Thus, finding a balance between speed and power is essential for achieving high-quality results.

Moreover, the type of lens used in the laser cutting machine can also impact the outcome. A lens with a shorter focal length can provide a more concentrated beam, which is beneficial for cutting thicker sheets of carbon fiber. On the other hand, a longer focal length lens may be more suitable for thinner sheets, as it can help reduce the risk of burning and ensure a smoother edge. Therefore, selecting the right lens based on the thickness of the material is another important consideration.

Furthermore, proper ventilation and exhaust systems are vital during the laser cutting process. Carbon fiber can produce harmful fumes when cut, which can pose health risks to operators and damage the equipment. Implementing an effective fume extraction system not only protects the workspace but also enhances the quality of the cut by preventing the accumulation of debris and smoke that can interfere with the laser beam.

Finally, post-processing is an essential step that should not be overlooked. After laser cutting, the edges of the carbon fiber sheets may require finishing to remove any roughness or charred material. Techniques such as sanding or using a water jet can help achieve a smooth finish, ensuring that the final product meets the desired specifications.

In conclusion, laser cutting carbon fiber sheets can be accomplished without damage by following best practices that encompass equipment selection, power and speed calibration, lens choice, ventilation, and post-processing. By paying attention to these factors, manufacturers can harness the advantages of carbon fiber while minimizing the risks associated with its unique properties. Ultimately, a thorough understanding of these best practices will lead to successful outcomes in laser cutting applications involving carbon fiber.

Common Challenges and Solutions in Laser Cutting Carbon Fiber

Laser cutting carbon fiber sheets presents a unique set of challenges that require careful consideration and expertise. While carbon fiber is renowned for its strength and lightweight properties, its composition can complicate the cutting process. The primary challenge lies in the material’s structure, which consists of tightly woven fibers embedded in a resin matrix. This composition can lead to issues such as delamination, fraying, and heat damage during the cutting process. Therefore, understanding these challenges and implementing effective solutions is crucial for achieving precise and clean cuts.

One of the most significant challenges in laser cutting carbon fiber is the risk of delamination. As the laser beam interacts with the material, the heat generated can cause the resin to soften, potentially leading to the separation of the fibers from the matrix. This delamination not only affects the integrity of the cut but can also compromise the overall strength of the finished part. To mitigate this issue, it is essential to use a laser cutting system that is specifically designed for composite materials. These systems often feature advanced cooling mechanisms that help dissipate heat and maintain a stable cutting temperature, thereby reducing the risk of delamination.

Another common challenge is the tendency of carbon fiber to fray at the edges when cut with a laser. This fraying can result in an unsightly finish and may require additional post-processing to achieve a clean edge. To address this problem, operators can adjust the laser settings, such as power and speed, to optimize the cutting process. Lowering the power while increasing the speed can help minimize the heat input, which in turn reduces the likelihood of fraying. Additionally, using a focused laser beam can enhance precision, allowing for cleaner cuts with minimal edge damage.

Moreover, the type of carbon fiber sheet being cut plays a crucial role in the laser cutting process. Different grades and weaves of carbon fiber can respond differently to laser cutting, making it essential to conduct preliminary tests before proceeding with full-scale production. By experimenting with various settings on sample pieces, operators can determine the optimal parameters for each specific type of carbon fiber, ensuring consistent results across all cuts.

Furthermore, the choice of laser technology can significantly impact the quality of the cut. CO2 lasers are commonly used for cutting carbon fiber due to their ability to produce a high-quality beam that can effectively penetrate the material. However, fiber lasers are also gaining popularity for their efficiency and precision. Each type of laser has its advantages and disadvantages, and selecting the appropriate technology based on the specific requirements of the project is vital for achieving the desired outcome.

In addition to these technical considerations, proper ventilation and dust extraction systems are essential when laser cutting carbon fiber. The cutting process generates fine particles and fumes that can be harmful if inhaled. Implementing effective ventilation not only ensures a safe working environment but also helps maintain the quality of the cut by preventing the accumulation of debris on the cutting surface.

In conclusion, while laser cutting carbon fiber sheets poses several challenges, understanding these issues and employing targeted solutions can lead to successful outcomes. By utilizing specialized laser systems, optimizing cutting parameters, and ensuring proper safety measures, manufacturers can achieve precise cuts without damaging the material. As technology continues to advance, the capabilities of laser cutting carbon fiber will only improve, opening new avenues for innovation in various industries.

Q&A

1. **Question:** Can carbon fiber sheets be laser-cut without causing damage?

**Answer:** Yes, carbon fiber sheets can be laser-cut without damage if the appropriate settings and equipment are used.

2. **Question:** What factors influence the quality of laser cutting on carbon fiber sheets?

**Answer:** Factors include the type of laser used, power settings, speed of cutting, and the thickness of the carbon fiber sheet.

3. **Question:** Are there any precautions to take when laser-cutting carbon fiber?

**Answer:** Yes, proper ventilation is necessary to avoid inhaling harmful fumes, and using a laser with a suitable wavelength is important to minimize damage to the material.