15 Things You Didn’t Know About Carbon Fiber

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Are you aware of the amazing properties of carbon fiber? This material has taken several industries by storm with its exceptional strength-to-weight ratio, making it highly sought-after. In this article, we will explore fascinating facts and lesser-known aspects of carbon fiber.

1. The Largest Producer of Carbon Fiber Is Not USA!

The largest producer of carbon fiber is Japan. They have been in the carbon fiber market for over 20 years and have been a key player in the development of the carbon fiber industry. They have a large market share and are continuing to invest in the research and development of new applications for carbon fiber.

Japan has been a leader in the production of carbon fiber since the early 1990s. They were the first to commercialize the production of carbon fiber and have been a key player in the development of the carbon fiber industry. The country has a large market share and is continuing to invest in the research and development of new applications for carbon fiber.

One of the leading manufacturer is Toray Industries, Inc.

Founded in 1926, Toray Industries, Inc. is a Japanese multinational corporation that is known for its advanced materials technology. The company produces a wide range of carbon fiber products, including prepreg, tow, and filament.

2. There Are 2 Methods of Manufacturing: Wet Layup And Prepreg

Carbon fiber manufacturing is a process that involves converting raw carbon fiber into a usable product. There are two main methods of carbon fiber manufacturing: wet layup and prepreg. Wet layup is the most common method of carbon fiber manufacturing, and it involves soaking the carbon fiber in a resin before layering it onto a mold. Prepreg is a more complex method of carbon fiber manufacturing that involves impregnating the carbon fiber with a resin before it is laid onto a mold.

Carbon fiber properties are largely determined by the manufacturing process. For example, wet layup carbon fiber will have different properties than prepreg carbon fiber. Carbon fiber composites also have different properties than pure carbon fiber, as the resin used in the manufacturing process can affect the final product. In general, carbon fiber is an extremely strong and lightweight material that is often used in applications where these properties are desired.

3. Carbon Fiber Is More Fire Resistant Than Aramid

-1.png)

In addition to its strength and durability, carbon fiber also has the advantage of being more fire-resistant than other materials like kevlar. The melting point of carbon fiber is around 3500°C, while aramid cloth is only 500 °C. This leads to the question of, why not use carbon fiber as the material for fireproof suits? The answer is simple. While carbon fiber may be more fire-resistant than kevlar, it is not enough to withstand the extreme conditions of a fire.

Firefighters need protective gear that is designed to withstand not only high heat but also the harsh chemicals and toxins present in a fire. Kevlar, on the other hand, is specifically designed to handle these conditions and is the material of choice for fireproof suits.

4. UHM Carbon Fiber Is The Most Expensive Type

The most expensive type of carbon fiber is typically made from ultra-high-modulus (UHM) carbon fibers. These fibers have a tensile strength of over 600 ksi (4,140 MPa) and a modulus of elasticity of over 70 msi (483 GPa). This puts them among the strongest and stiffest materials available. The high cost of these fibers is due to the specialized manufacturing process required to produce them.

Despite the high cost, UHM carbon fiber has many unique properties that make it well-suited for certain applications. For example, its high strength and stiffness make it ideal for use in industries where weight reduction is critical, such as the aerospace industry, where every ounce of weight saved translates into significant fuel savings.

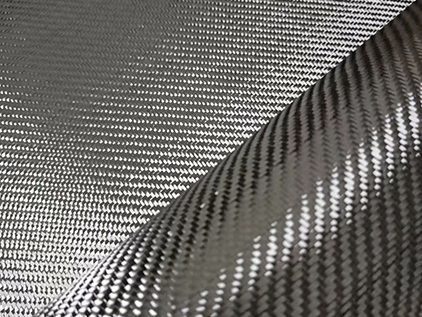

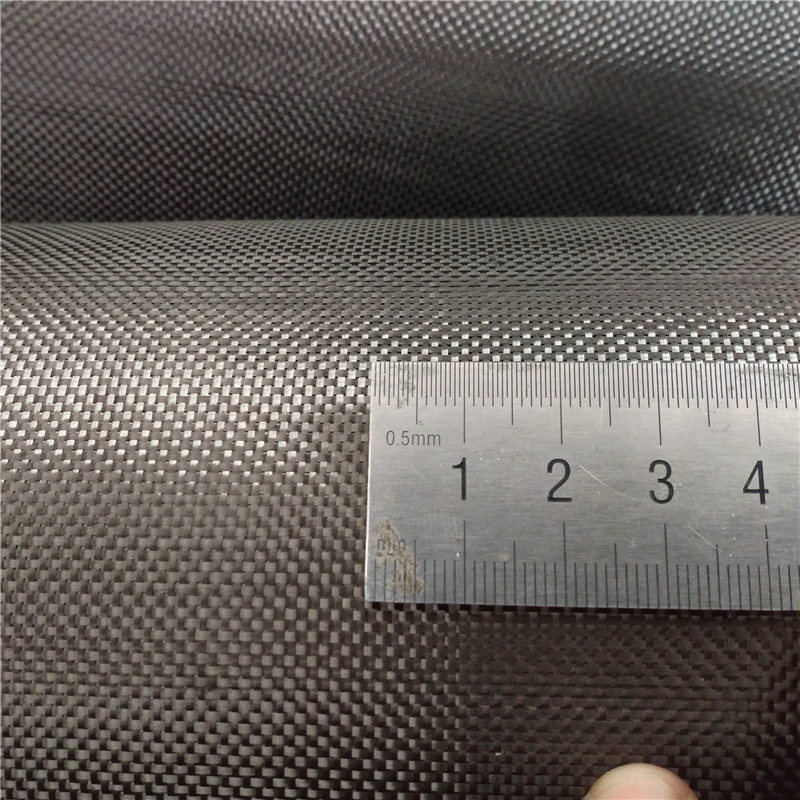

5. Twill Pattern Is Stronger Than Plain Pattern

Twill carbon fiber is widely considered to be stronger than plain carbon fiber due to its unique weaving pattern. This pattern creates a diagonal configuration of fibers, which allows twill carbon fiber to maintain its shape and stiffness when placed under stress or tension.

In contrast, plain carbon fiber is woven in a simple over-under pattern, which allows it to be more flexible but less resistant to deformation under stress. This can make plain carbon fiber less effective in applications where stiffness and stability are crucial, such as in aerospace and high-performance sports equipment.

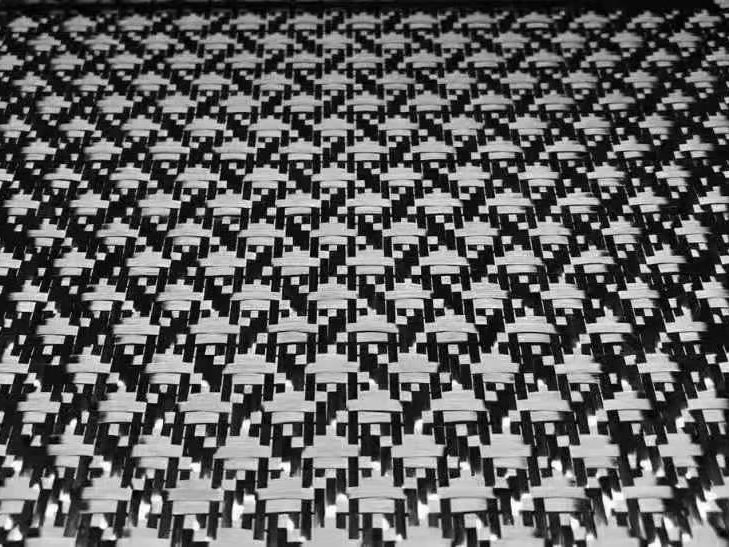

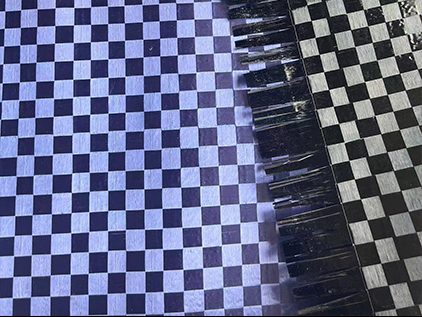

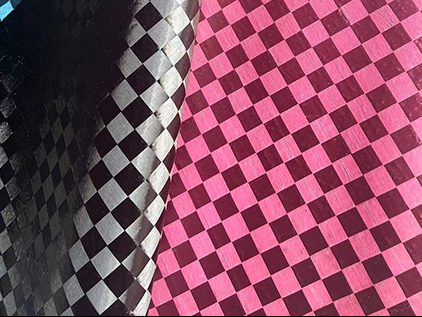

6. The Pattern of Carbon Fiber Cloth Can Be Customized

Customization of carbon fiber cloth patterns can be achieved through a variety of techniques such as weaving, printing, or even laser engraving. Each of these methods provides a unique way to create patterns that can be tailored to suit the requirements of each specific application. For instance, sports equipment manufacturers might want to create carbon fiber cloth with specific designs that reflect their brand or that appeal to their target market.

This customization improves the adaptability of carbon fiber cloth for different applications, which in turns increases its popularity among manufacturers and end-users alike. Overall, it provides a fantastic opportunity for creative exploration, making it an excellent choice for designers and manufacturers who strive for uniqueness and individuality in their products.

7. The Industry That Uses The Most of This Material Is Not Automotive

Carbon fiber is one of the strongest and lightweight materials in the world. Due to its unique properties, it has become increasingly popular in many industries in recent years. So, which industry uses the most carbon fiber?

The aerospace industry is the largest user of carbon fiber in the world. Carbon fiber composites are used to manufacture aircraft parts, including wings, fuselage, tail sections, and engine components. The use of carbon fiber in aircraft helps to reduce the weight of the aircraft, leading to better fuel efficiency and reduced CO2 emissions.

8. Carbon Fiber Can Be Repaired

One way to repair carbon fiber is through applying epoxy. Epoxy is a combination of a resin and a hardening agent. It can be used to fill in cracks or holes in carbon fiber and restored to its original strength. The epoxy is applied to the damaged area, and then the repair is sanded down to smooth it out.

Another method for repair is using patches. Carbon fiber patches can be applied to the surface of a damaged area, and then glued into place with epoxy. The patch and epoxy mixture then bond with the original carbon fiber, resulting in a strong, seamless repair.

Therefore, carbon fiber can be repaired with various methods and techniques. Whether you need to fill in a crack, apply a patch, or seek a complete replacement, there are solutions available to restore the strength and beauty of carbon fiber. So, don't worry if your carbon fiber object is damaged, because with the right repair, it can look and function as great as new.

9. Don’t You Know That The Most Cost-effective Origin Is China?

China's carbon fiber is known for its high cost performance, which is a result of several factors.

- China has a rich resource of low-cost raw materials, such as coal and petroleum, which are essential in the production of carbon fiber. This advantage has enabled Chinese manufacturers to produce carbon fiber at a much lower cost compared to other countries.

- China has continuously invested in research and development, resulting in the establishment of advanced production technologies for carbon fiber. This has enabled Chinese manufacturers to improve the quality of their products while still maintaining competitive prices.

- China's carbon fiber industry is well-integrated, with a complete industry chain that includes raw material supply, processing, and product development. This integration has enabled Chinese manufacturers to achieve economies of scale, making their products accessible to a wider market.

- China's government policies have supported the growth of the carbon fiber industry, providing incentives to manufacturers to invest in R&D, production, and exports.

All these factors have contributed to China's leading position in the global carbon fiber market, with high-performance products that are affordable compared to those of other countries. As China continues to make advancements in technology and invest in the industry, the cost performance of its carbon fiber is expected to remain high in the years to come.

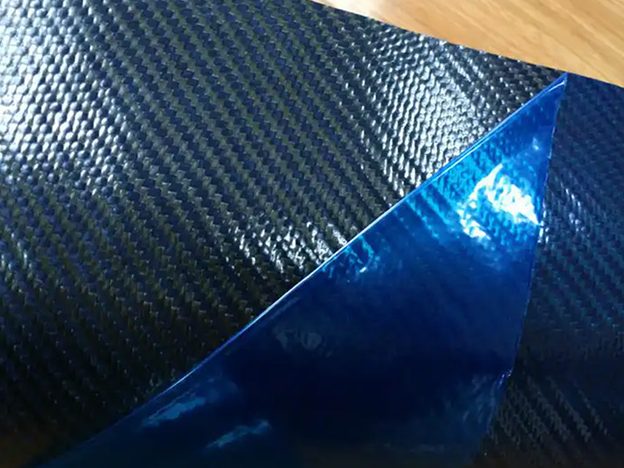

10. Carbon Fiber Isn’t Just Black

One of the common misconceptions about carbon fiber is that it is only available in black. However, this is not true. Carbon fiber can be produced in various colors, including white, blue, red, yellow, and more.

Manufacturers can use different processes to create colored carbon fiber materials. For example, some manufacturers use a colored resin to impregnate the carbon fiber, resulting in a coloration of the carbon weave that is visible on the surface of the material. Other manufacturers may use a technique known as color coating, which involves applying a colored coat over the top of the carbon fiber material.

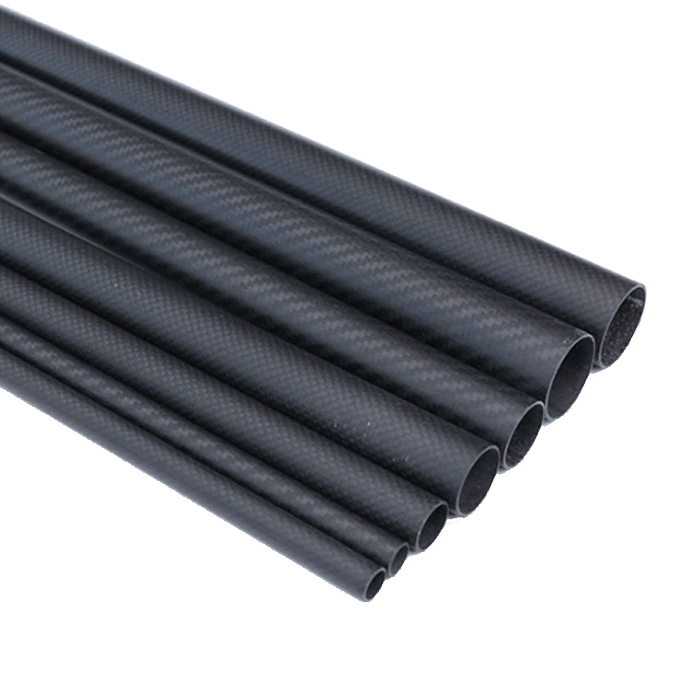

11. Carbon Fiber Can Be DIYed at Home

One of the easiest ways to get started with carbon fiber is to make small parts such as phone cases, keychains, or even bike accessories. These items can be made using carbon fiber sheets, which are readily available online and at some hobby stores. Simply cut the sheet to the desired shape, sand down any rough edges, and apply a clear coat to give it a glossy finish.

Another option is to use carbon fiber fabric, which can be laid up in a mold to create custom-shaped parts. This method requires a bit more expertise and equipment, but it is still achievable for the motivated DIYer. A vacuum bagging setup is needed to compress the fabric and resin together, and the process of curing the resin can take several hours. While working with carbon fiber may seem daunting at first, with some basic knowledge and equipment, it is possible to create impressive and useful items at home. Give it a try and see for yourself the endless possibilities that carbon fiber offers!

12. Carbon Can Be Mixed with Metal Wire to Weave

One example of this is the use of carbon fiber and titanium wire for weaving bicycle frames. The carbon fiber provides the stiffness and strength needed for the frame, while the titanium wire adds flexibility and durability. This composite material results in a lightweight yet strong frame that can withstand the rigors of cycling.

In fact, the combination of the two materials is becoming increasingly popular in the world of textiles and manufacturing. As technology continues to advance, we can only expect to see more exciting uses for this composite material in the future.

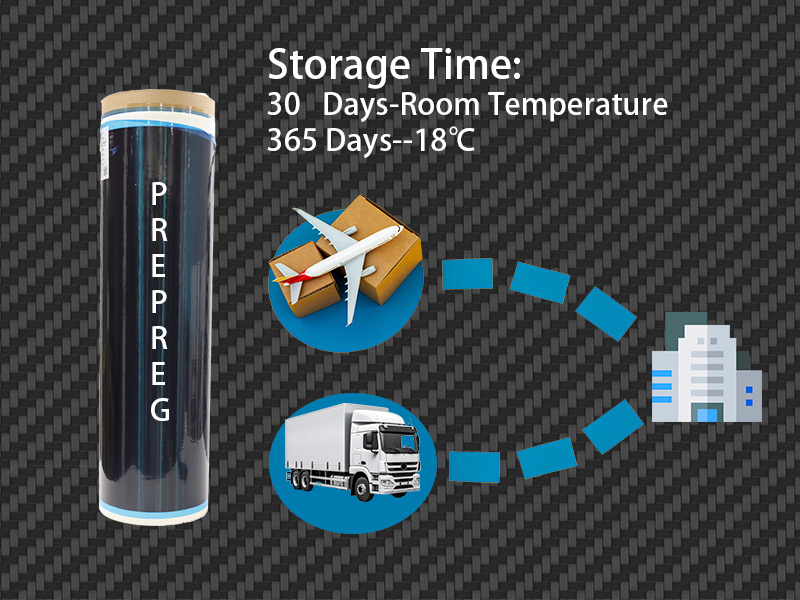

13. Carbon Fiber Also Has A Shelf Life

The shelf life of carbon fiber depends on various factors such as the type of resin used, the manufacturing process, and the storage conditions. Generally, carbon fiber can last for years if stored properly and not exposed to extreme temperatures or humidity. However, over time, carbon fiber can lose its strength and stiffness due to environmental factors, such as ultraviolet radiation, chemical exposure, and moisture absorption.

While, Prepreg is a special material with a very limited storage time. Prepreg is short for "pre-impregnated," which refers to the carbon fibers being pre-impregnated with resin before being used in production. It can only be stored for up to 30 days at room temperature and can be kept for up to a year at -18℃. To ensure that it remains usable for as long as possible, it's best to transport it using either freezer land transportation or air transportation.

14. High Module Doesn't Mean High Quality

High module carbon fiber refers to carbon fiber that has a high stiffness or rigidity, which makes it appealing for use in applications where strength and lightness are essential. However, it is essential to note that high module carbon fiber does not necessarily equate to high-quality carbon fiber.

To understand this better, one must consider that carbon fiber is made up of individual fibers twisted together to form a yarn. The quality of these fibers and how they are processed into the final product determine the overall quality of the carbon fiber.

The manufacturing process of carbon fiber involves a complex series of steps that can significantly impact its overall quality. These include selecting high-quality precursor materials, controlling the manufacturing conditions, and using precise cutting equipment to ensure uniform fiber length.

15. Cold Environments Makes Carbon Fiber Brittle

The reason for this is that the properties of carbon fiber are affected by temperature. When carbon fiber is exposed to cold temperatures, it becomes less flexible and more brittle. This is because the resin that holds the fibers together can become more rigid and brittle when it gets cold. As a result, the fibers in carbon fiber can become more prone to cracking and breaking.

However, it is important to note that this does not mean that carbon fiber is unusable in cold environments. The key is to ensure that the carbon fiber is properly designed and manufactured for the intended use. For example, if carbon fiber is going to be used in a cold environment, it may be necessary to use a different type of resin that is more resistant to cold temperatures.