Understanding UHMWPE Properties: A Quick Guide

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

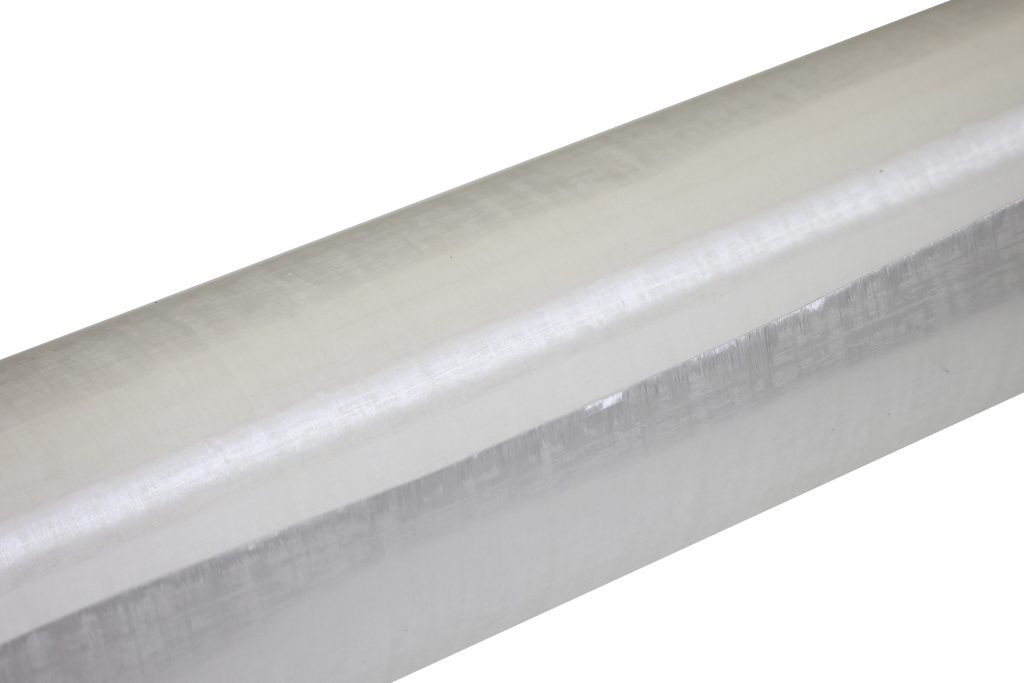

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

In the realm of material science, Ultra-High Molecular Weight Polyethylene (UHMWPE) emerges as a frontrunner distinguished by a spectrum of remarkable qualities. This guide embarks on an exploration of the essential UHMWPE properties, delving into the matrix of advantages that affords versatility across a diverse range of industries. Boasting a plethora of benefits, from extreme durability to high impact resistance, UHMWPE stands as a testament to innovative engineering materials. However, despite the wealth of UHMWPE advantages, it is critical to acknowledge and examine potential UHMWPE disadvantages to ensure a well-rounded understanding. Join us as we journey through the intricacies of UHMWPE, uncovering the nuances that make it an indispensable ally in the technological and development sectors.

The Essentials of UHMWPE

Ultra-High Molecular Weight Polyethylene, or UHMWPE, stands out in the world of polymers due to its exceptional UHMWPE characteristics. Its high molecular weight is a critical factor propelling its physical strength, durability, and versatility. These inherent assets are the cornerstones for the UHMWPE applications that span across an array of industries—from medical devices to heavy-duty industrial parts.

At its core, the molecular structure of UHMWPE sets a strong foundation for its impressive performance attributes. Let's uncover the reasons behind its UHMWPE uses which make it a preferred choice for engineers and designers alike. Here is an outline of its primary characteristics complemented by real-world applications:

- Durable wear resistance endowing longer life span in mechanical parts

- Excellent impact strength vital in protective gear production

- Low coefficient of friction beneficial for creating slide components

- Sound-absorbing properties useful in sound barrier applications

- Chemical and moisture resistance requirement in storage containers

- Food-grade compatibility observed in FDA-approved cutting boards

These characteristics highlight the real-world versatility of UHMWPE, illustrating why it becomes an engineer's material of choice. Let's further delve into its applications with a detailed table:

| Characteristic | Application | Related Industry |

|---|---|---|

| Durability | Conveyor belt components | Material handling |

| Impact Resistance | Body armor | Defense |

| Low Friction | Artificial joints | Medical |

| Sound Absorption | Acoustic panels | Construction |

| Chemical Resistance | Chemical tanks | Chemical Processing |

| Food-grade Safety | Commercial cutting boards | Food Service |

Whether it is for everyday objects or specialized industrial components, UHMWPE proves its worth by offering substantial advantages with its robust characteristics and broad applications. It's clear that UHMWPE isn't just an ordinary material; it is a strategic cornerstone that pushes the boundaries of innovation and efficiency.

What is UHMWPE and Its Common Uses?

Ultra-High Molecular Weight Polyethylene (UHMWPE) is a powerhouse material with a magnitude of uses that penetrate every corner of modern industry and daily life. Noted for its outstanding durability, low friction, and high impact strength, UHMWPE’s definition barely scratches the surface of its potential. Let's demystify UHMWPE's role in our world and explore its diverse applications.

Defining the Material

At its core, UHMWPE is a thermoplastic with an exceptionally high molecular weight, resulting in a low coefficient of friction, excellent abrasion resistance, and superb toughness. It is a linear, non-branching polymer chain which gifts it with its characteristic strength. This material stands up to repeated bending and flexing without failure, a feature that has cemented its position across multiple arenas.

UHMWPE in Everyday Life

From the kitchen cutting board fashioned to resist the daily dicing to the hollow fibers in water filtration systems, UHMWPE graces daily objects with unfaltering reliability. A closer look into our homes exposes its presence in synthetic ropes, often preferred for their lightweight yet strong fibers, and in medical devices like joint replacements where biocompatibility is paramount.

- Durable cutting boards for culinary use

- High-quality synthetic ropes and lines for boating and utility

- Joint replacements that offer increased longevity

- Orthopedic liners that reduce the risk of infection and improve patient outcomes

Industrial Applications of UHMWPE

In industrial arenas, the definition of UHMWPE extends into a portfolio of functions. Its application manifests in the bulletproof vests that safeguard lives to the lining of chutes that ensures smooth, uninterrupted production lines. The material's self-lubricating nature positions it well for intricate machinery components—impacting industries from the depths of mining to the heights of space exploration.

- Protective gear in law enforcement and military sectors

- Non-stick liners for transportation of bulk materials

- High endurance parts within the mining and heavy machinery sector

- Components in the aerospace industry, chosen for their resilience and weight efficiency

In summary, UHMWPE's everyday uses and industrial applications underline its versatility and near-universal adoption. Its excellent material properties assure a future where UHMWPE continues to influence our quality of life and industrial advancements. As we have seen, UHMWPE is not simply defined; it is essential.

Key Characteristics of UHMWPE

Ultra-High Molecular Weight Polyethylene (UHMWPE) stands out in the realm of materials due to its outstanding mechanical and physical properties, which are integral to its performance in various demanding environments. Engineers and designers often prefer UHMWPE for its unique combination of durability and strength, contributing significantly to its success across industries.

Understanding UHMWPE's Unique Traits

When examining the UHMWPE mechanical properties, its molecular structure presents a series of noteworthy qualities. Resistant to abrasion and impact, it is able to endure severe conditions without significant degradation, which is a testament to its robust composition. The UHMWPE physical properties, including low moisture absorption and high resistance to chemicals, make it suitable for a diverse range of applications.

Weight-to-Strength Ratio in UHMWPE

The weight-to-strength ratio in UHMWPE is a critical factor that defines its versatility and efficiency. Despite being remarkably lightweight, UHMWPE exhibits tensile strength that rivals that of much heavier materials, offering a superior alternative for applications that require both durability and minimal weight. This remarkable ratio is what allows UHMWPE to excel in areas where other materials fall short.

Durability and Lifespan Attributes

Longevity is a key advantage of UHMWPE, with its ability to resist wearing and retain its elemental properties over time, even under constant friction and exposure to UV light. The combination of UHMWPE's mechanical and physical properties ensures that it remains a cost-effective solution with a long service life, reducing the need for frequent replacements and minimizing maintenance costs.

| Property | Value | Impact on Performance |

|---|---|---|

| Tensile Strength | High | Permits use in high-load applications |

| Abrasion Resistance | Exceptional | Enhances product lifespan in abrasive environments |

| Density | Low | Facilitates applications requiring light materials |

| Chemical Resistance | High | Allows for contact with corrosive media without deterioration |

| Impact Strength | Superior | Ideal for protective gear and components subject to impacts |

UHMWPE Mechanical Properties Uncovered

The mechanical properties of Ultra-High Molecular Weight Polyethylene (UHMWPE) are at the heart of its exceptional performance in a wide array of applications. Among these properties, three standouts—the tensile strength, impact resistance, and fatigue endurance—present UHMWPE as a material of choice for engineering challenges demanding high durability and reliability. In the following overview, we delve into how each of these properties defines UHMWPE performance, making it a superior choice in performance-critical environments.

| Property | Description | Performance Benefit |

|---|---|---|

| Tensile Strength | Ability to withstand pulling forces without breaking. | Handles heavy loads and resists stretching under tension. |

| Impact Resistance | Capacity to absorb energy from sudden impacts without fracturing. | Withstands harsh contact in demanding environments. |

| Fatigue Endurance | Resistance to weakening over repeated stress cycles. | Maintains integrity and performance over a long service life. |

UHMWPE stands above other polymers largely because of its stellar tensile strength, a measure of how much stress the material can withstand while being stretched or pulled. The material's impact resistance is crucial in scenarios where it is subject to sudden and forceful blows—a property particularly valued in industries like automotive and defense. Lastly, UHMWPE's fatigue endurance signifies its ability to endure repetitive loading and unloading, which translates to longevity and sustainability in applications such as mechanical gears and medical implants. Through unrivaled resilience and toughness, UHMWPE continues to set the benchmark for high-performance polymers.

Digging Into UHMWPE Chemical Properties

As we delve deeper into the remarkable attributes of Ultra-High Molecular Weight Polyethylene (UHMWPE), it's imperative to take a closer look at its chemical composition, which bestows the material with an outstanding chemical resistance. This unparalleled resistance not only contributes to its robustness but also to its remarkable stability, allowing UHMWPE to function exceptionally well across a diverse array of industrial environments.

Chemical Resistance and Stability

The chemical properties of UHMWPE include an impressive resistance to a wide range of corrosive agents, from acidic and alkaline environments to organic solvents. This polymer is virtually unaffected by the harsh chemical reagents that can quickly degrade other materials. Below is an exploration of UHMWPE's chemical defiance, which stands as a testament to its stability and longevity in chemically strenuous applications.

- Acidic and Alkaline Solutions: UHMWPE exhibits excellent resistance to both strong acids and bases, maintaining its integrity even upon prolonged exposure.

- Organic Solvents: Hydrocarbon solvents pose little threat to UHMWPE, as its molecular structure is resilient against such organic compounds.

- Oxidizing Agents: Strong oxidizers are known to attack most polymers, yet UHMWPE remains steadfast, preserving its molecular integrity even in oxidative settings.

Behavior in Various Environments

The versatility of UHMWPE is palpable when observing its stable behavior in different environmental contexts. Whether subjected to extreme temperatures or exposed to the rigors of outdoor elements, UHMWPE stands as a bulwark against environmental aggressors, ensuring consistent performance.

UHMWPE's chemical properties and chemical resistance translate into numerous industrial advantages:

- With its imperviousness to a broad spectrum of destructive agents, it is the material of choice in chemical handling and storage facilities.

- Medical applications benefit from its biocompatibility and resistance to sterilization agents, thus underscoring its value in healthcare settings.

- In the food and beverage industry, UHMWPE’s inert nature means it doesn't react with food products, guaranteeing safety and contamination-free processing.

This exceptional chemical resistance provides peace of mind for engineers and designers, knowing that their projects that incorporate UHMWPE are built to last and resist in the face of chemical adversity.

The Physical Properties of UHMWPE

When it comes to high-performance polymers, Ultra-High Molecular Weight Polyethylene (UHMWPE) boasts an array of physical properties that engineers and designers rely on. Known for its exceptional strength and durability, UHMWPE is also acclaimed for specific attributes that make it indispensable in challenging environments. Among those attributes are UHMWPE thermal properties and UHMWPE abrasion resistance, which we will explore in this section.

Thermal Properties and Performance

The thermal properties of UHMWPE allow it to excel in a variety of temperature conditions, making it a versatile material in diverse industries. From cryogenic components in the aerospace industry to high-heat applications in industrial machinery, the capacity of UHMWPE to withstand extreme temperatures is a testament to its robust performance. Offering an impressive operational temperature range, UHMWPE retains its stability and integrity even when exposed to thermal variations. Its heat deflection temperature is another pivotal characteristic, indicative of the material's ability to maintain form when subjected to high temperatures.

Wear and Abrasion Resistance

The abrasion resistance of UHMWPE is yet another cornerstone of its physical prowess. This property significantly prolongs the life of components made from UHMWPE, as they are less likely to succumb to the wear and tear of everyday use. It's not only about lasting longer; UHMWPE's resistance to abrasive forces means it can help maintain the efficiency of machinery and reduce the frequency of maintenance and replacement. In applications where product longevity and reliability are crucial, such as lining chutes or conveyor belts, the superior abrasion resistance of UHMWPE is not just preferred—it's essential.

Comparing UHMWPE Properties With Other Plastics

To showcase the exceptional qualities of Ultra-High Molecular Weight Polyethylene (UHMWPE), we must put it side by side with closely related polymers and various other material choices in the industry. This comparison not only highlights the UHMWPE properties but also provides a tangible backdrop to appreciate the material's competitive advantages. UHMWPE's notable traits include an unparalleled resistance to wear and abrasiveness and an intrinsic toughness that outperforms many conventional materials.

UHMWPE vs. HDPE

When analyzing UHMWPE properties comparison, particularly against High-Density Polyethylene (HDPE), it's clear that UHMWPE reigns superior in several domains. The exceptional molecular weight of UHMWPE translates into advanced performance metrics.

| Property | UHMWPE | HDPE |

|---|---|---|

| Tensile Strength | Higher | Lower |

| Abrasion Resistance | Extremely high | Moderate |

| Impact Strength | Outstanding | Good |

| Chemical Resistance | Excellent | Very good |

| Friction Coefficient | Very low | Low |

Performance Against Metals and Other Plastics

Considering UHMWPE advantages beyond the realm of polyethylene, we find its properties to be commendably competitive against metals and various engineering plastics. Its inherent characteristics yield impressive results in challenging environments where traditional materials fall short.

| Material | UHMWPE | Metals | Other Plastics |

|---|---|---|---|

| Weight | Lightweight | Heavy | Variable |

| Corrosion Resistance | Inherent | Variable; may require treatment | Good to excellent |

| Wear Resistance | Superior | Dependent on material/type | Good to high |

| Energy Absorption | High | Low to moderate | Variable |

| Operational Temperature Range | Wide | Narrow | Variable |

UHMWPE, with its special amalgamation of advantages, challenges traditional material choices in a myriad of applications. Its comparison with HDPE and other materials illustrates its superior strength and multifunctional capabilities, clearly indicating why UHMWPE is often the go-to material for engineers and designers alike.

UHMWPE Advantages in Engineering and Design

In the realm of engineering and design, material selection is paramount to the success of a product or system. Ultra-High Molecular Weight Polyethylene (UHMWPE) stands out for its exceptional contribution to these fields. Let's delve into the cost-effectiveness and the design versatility that UHMWPE offers, undoubtedly marking it as a material of choice among industry professionals.

Cost-Benefit Analysis

The utilization of UHMWPE in engineering projects provides substantial economic advantages. The material’s durability and resistance to various forms of wear and tear means a longer product lifecycle, reducing the need for frequent replacements. Moreover, UHMWPE's lightweight nature leads to cost savings in transportation and ease of installation. Let's breakdown the economic worth of employing UHMWPE:

- Lower maintenance costs due to high abrasion resistance

- Reduced transportation expenses as a result of its lightweight

- Minimized energy consumption given UHMWPE's low friction coefficient

- Cost savings on protective coatings, thanks to chemical inertness

Design Flexibility with UHMWPE

When it comes to pushing the boundaries of innovation, UHMWPE design advantages are a catalyst for creativity. The material's adaptability allows for a diverse range of applications, from medical devices to cutting-edge aerospace components. Design flexibility is manifested in:

- The ability to mold and extrude UHMWPE into complex shapes

- Excellent material choice for custom applications due to its machinability

- Compatibility with various fabrication processes, including welding and bonding

- Inherent coloration options for aesthetic design without compromising performance

Thus, UHMWPE provides a plethora of benefits that significantly enhance engineering outcomes. Its economic and functional supremacy, paired with unparalleled design opportunities, establishes UHMWPE as a frontrunner in material innovation.

Challenges and Disadvantages of UHMWPE

In contemplating the widespread adoption of Ultra-High Molecular Weight Polyethylene (UHMWPE) across industries, it is crucial to address not only the remarkable advantages but also the UHMWPE disadvantages and the challenges it presents. While UHMWPE boasts a myriad of beneficial properties, certain attributes may reduce its efficacy in specific applications, casting light on its limitations. This analysis aims to provide a thorough and unbiased look at the hurdles associated with this material, ensuring a comprehensive understanding of its role in the world of materials engineering.

Limitations in Certain Applications

Despite its impressive versatility, UHMWPE isn't a one-size-fits-all solution. In applications where rigidity is paramount, UHMWPE may not be the ideal choice due to its relatively lower modulus of elasticity when compared to materials like metals. Moreover, when it comes to environments with extreme temperatures, UHMWPE can encounter performance issues such as a propensity to creep under load over time. These scenarios exemplify the UHMWPE challenges that designers and engineers need to consider when choosing this material for their projects.

Handling and Processing Difficulties

During the manufacturing process, UHMWPE presents distinct challenges related to its handling and processing. Its high viscosity requires specialized equipment and techniques for proper molding and extrusion, potentially elevating production costs. Additionally, bonding and printing on UHMWPE surfaces are tasks that demand specific preparations due to its chemical resistance, which often translates to additional processing steps. These manufacturing nuances can complicate production workflows, suggesting the need for expert oversight when working with UHMWPE.

FAQ

What Is UHMWPE and Why Is It Significant?

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a thermoplastic known for its outstanding combination of strength, durability, and resistance to wear, corrosion, and chemicals. It's significant due to its versatile applications in industries like medical devices, food processing, and aerospace, among others.

Can You Explain the Unique Characteristics of UHMWPE?

UHMWPE exhibits a set of unique characteristics such as a high strength-to-weight ratio, impressive durability, low friction coefficient, and resistance to impact, abrasion, and chemicals. These properties make it suitable for heavy-duty engineering applications and environments with demanding conditions.

What Are the Common Uses of UHMWPE?

UHMWPE is commonly used in orthopedic implants, like joint replacements, bulletproof vests, mechanical parts like gears and bearings, lining materials in bulk material handling, marine applications due to its water resistance, and as cutting boards in the food industry.

How Does UHMWPE Compare to Other Plastics Like HDPE?

UHMWPE has a much higher molecular weight than HDPE, which contributes to its enhanced strength, wear, and abrasion resistance properties. Compared to HDPE, UHMWPE can withstand higher impacts and more abrasive conditions while maintaining a lower friction surface.

Are There Any Disadvantages or Limitations to Using UHMWPE?

Despite its many advantages, UHMWPE does have some limitations. It can be difficult to bond or weld, has a lower resistance to very high temperatures compared to some other plastics, and can experience material creep under persistent mechanical stress or loading.

What Mechanical Properties Make UHMWPE Stand Out?

UHMWPE is known for its exceptional tensile strength, impact resistance, and fatigue endurance. Its mechanical properties enable it to perform well under rigorous conditions without losing its structural integrity, making it a preferred choice for critical applications.

How Does UHMWPE Perform in Different Environmental Conditions?

UHMWPE is chemically inert, which makes it resistant to a vast range of corrosive substances and able to perform in various environmental conditions. Its chemical stability is a key asset in applications where exposure to aggressive substances is common.

Why Is UHMWPE Favored in Engineering and Design?

UHMWPE is favored in engineering and design for its versatility, cost-benefit ratio, and the design flexibility it offers. Its ability to be shaped into complex geometries, coupled with its material properties, allows for innovative product development that can push industry standards forward.

In Terms of Thermal Properties, How Does UHMWPE Perform?

UHMWPE has good insulation properties and can operate within a wide temperature range, although it may not be suitable for long-term use at very high temperatures. It has a low coefficient of thermal expansion and maintains its properties over a wide range of temperatures.

What Are the Challenges Associated With Processing UHMWPE?

Processing UHMWPE can pose challenges due to its high viscosity. It often requires specialized equipment for molding and shaping, and traditional methods like welding or bonding can be difficult. Engineers and designers must account for these factors when working with UHMWPE.