UHMW: Ultimate Guide to Ultra-High Molecular Weight

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Ultra-high molecular weight polyethylene, or UHMW, is a remarkable plastic material. It's changing industries worldwide. This guide will explore its amazing properties, uses, and future advancements.

UHMW is known for its strength and durability. It's used in many fields, including industry, transportation, and medicine. This material is set to change how we solve engineering problems.

Key Takeaways

- UHMW is an ultra-strong and durable plastic material with exceptional properties

- UHMW offers a wide range of applications across industries, from manufacturing to aerospace

- UHMW's unique characteristics make it a valuable asset in enhancing performance and safety in various products

- The environmental benefits and sustainability of UHMW make it a forward-thinking choice for modern engineering

- Innovative processing and manufacturing techniques are constantly evolving to unlock the full potential of UHMW

Introduction to Ultra-High Molecular Weight Polymers

UHMW, or ultra-high molecular weight polyethylene, is a special plastic. It has a very long molecular chain. This makes UHMW stand out with its amazing properties.

It's known for being very tough, having low friction, and being strong against impact. These traits make UHMW very useful in many fields.

What is UHMW?

UHMW is a type of polyethylene plastic. It has a very high molecular weight, between 2 to 6 million grams per mole. This high weight means its polymer molecules are very long.

This long chain is what gives UHMW its special benefits and advantages.

Properties and Advantages of UHMW Materials

The amazing qualities of UHMW include:

- Exceptional abrasion resistance

- Low friction and wear

- High impact strength and toughness

- Chemical and corrosion resistance

- Excellent thermal and cryogenic properties

- Self-lubricating and non-stick characteristics

These UHMW features make it perfect for many uses. It's great for industrial tools, sports gear, and even medical devices.

"The unique properties of UHMW make it a versatile and valuable material across many industries."

UHMW: A Versatile and Durable Material

UHMW, or ultra-high molecular weight polyethylene, is a standout material. It's known for its versatility and durability. It has high impact resistance, low coefficient of friction, and great wear resistance. This makes it perfect for many uses, from industrial machines to sports equipment.

UHMW is incredibly strong and tough. It's up to 15 times more resistant to impacts than regular plastics. This makes it great for places where you need something reliable and strong. It also works well in smooth operations, like conveyor belts and gears, because of its low friction and self-lubricating qualities.

"UHMW's remarkable properties have made it an indispensable material in numerous industries, where both strength and longevity are critical factors."

UHMW can handle extreme temperatures, from -40°F to 180°F, without losing its shape. It's also resistant to chemicals and doesn't corrode. This makes UHMW a top choice for tough environments, from industrial areas to outdoor uses.

In short, UHMW is a key material in many fields because of its versatility, durability, strength, toughness, reliability, and performance. Its special qualities keep driving innovation and opening up new uses for this amazing material.

Applications of UHMW Across Industries

Ultra-High Molecular Weight (UHMW) polymer is a versatile and durable material. It is used in many industries. UHMW improves performance, safety, and sustainability in various ways.

Industrial and Manufacturing Applications

In the industrial sector, UHMW is prized for its toughness. It can handle harsh environments well. Its low friction and self-lubricating properties are perfect for high-use areas.

UHMW is often used in conveyor systems and material handling equipment. It helps extend the life of parts and cuts down on maintenance.

Transportation and Automotive Uses

The transportation and automotive industries also benefit from UHMW. It enhances performance, safety, and durability. For instance, UHMW is used in truck bed liners and wheel chocks.

In cars, UHMW is in bearing surfaces and gears. Its low friction and wear resistance are key benefits.

As industries look for materials that can handle modern challenges, UHMW stands out. Its versatility and resilience make it a valuable choice.

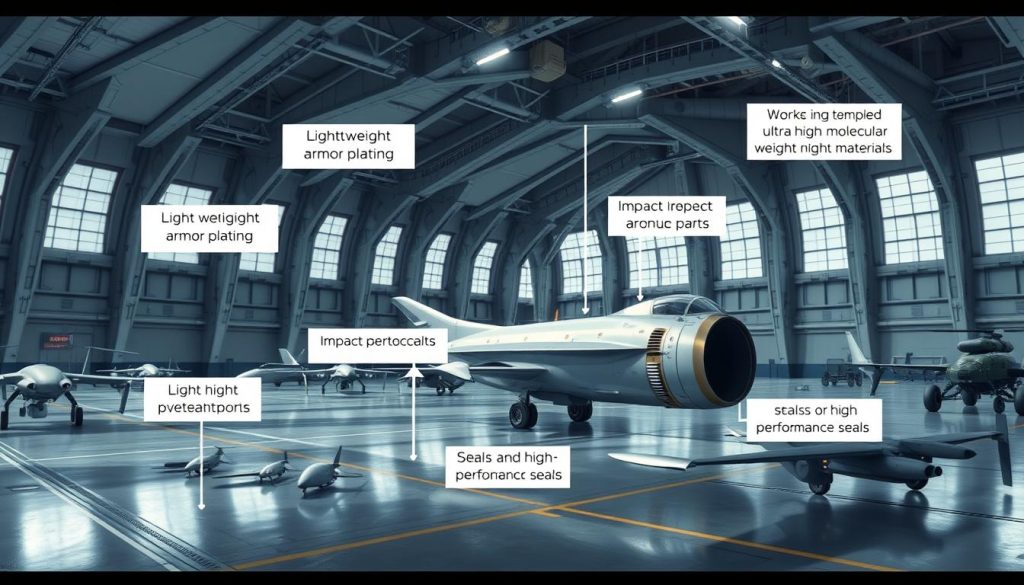

UHMW in Aerospace and Defense

Ultra-High Molecular Weight (UHMW) polymers are key in aerospace and defense. They are light, strong, and resist chemicals well. This makes them perfect for aircraft, spacecraft, and military gear.

In UHMW aerospace applications, it's used everywhere, from inside planes to critical parts. It withstands wear, corrosion, and heat, keeping systems like landing gear and brakes working well. For UHMW defense uses, it's tough and impacts well. This makes it great for military vehicles, body armor, and protective gear, keeping soldiers safe.

UHMW is also used in UHMW military applications for many things, like weapons and gear. Its UHMW engineering for aerospace and UHMW engineering for defense helps these fields grow. It keeps them leading in technology.

| UHMW Aerospace Applications | UHMW Defense Uses |

|---|---|

| Aircraft interiors Landing gear components Aircraft brakes Satellite components | Military vehicle components Body armor Protective equipment Weapon components |

"UHMW's unparalleled strength and durability make it a game-changer in the aerospace and defense industries, pushing the boundaries of what's possible."

As we need better materials, UHMW will keep leading in aerospace and defense. It ensures safety and reliability in critical systems and equipment.

UHMW in Sporting Goods and Recreational Equipment

Ultra-High Molecular Weight Polyethylene (UHMW) has changed the game in sports and outdoor gear. It's strong, has low friction, and can withstand impacts. UHMW boosts the performance and safety of many athletic and outdoor items.

Enhancing Performance and Safety

UHMW is perfect for sports and outdoor gear because of its special properties. Its toughness and abrasion resistance make it great for:

- Ski and snowboard bases for better glide and durability

- Bike and skateboard parts like bearings and bushings for smoother rides

- Protective gear like helmets, knee pads, and elbow guards for better safety

Also, UHMW's low coefficient of friction means better sliding and gliding. This makes sports and outdoor activities more fun and exciting.

| UHMW Sporting Goods Applications | Benefits |

|---|---|

| Ski and Snowboard Bases | Superior glide, durability, and abrasion resistance |

| Bike and Skateboard Components | Improved responsiveness, smooth operation, and reduced friction |

| Protective Equipment | Enhanced impact resistance and safety |

Using UHMW helps make sports and outdoor gear better. It ensures top-notch performance and safety. This makes outdoor fun and safe for everyone.

Medical and Pharmaceutical Applications of UHMW

UHMW, or Ultra-High Molecular Weight Polyethylene, is a versatile and biocompatible material. It has many uses in the medical and pharmaceutical industries. Its excellent biocompatibility, chemical resistance, and low friction make it perfect for healthcare products and implants.

UHMW is mainly used for making prosthetic implants. Its durability and wear resistance make it great for joint replacements like hips and knees. It also ensures smooth movement, reducing wear and tear over time.

UHMW is also used in surgical instruments like scalpels and forceps. Its strength and chemical resistance help it withstand sterilization and repeated use. This makes these medical tools safe and reliable.

In the pharmaceutical industry, UHMW is used for packaging and storing sensitive drugs and devices. Its chemical resistance and impermeability to gases protect the integrity of these products during storage and transport.

| UHMW Medical Applications | UHMW Pharmaceutical Uses |

|---|---|

| Prosthetic implants (hip, knee, etc.) Surgical instruments Orthopedic devices Bone replacement materials | Pharmaceutical packaging Drug storage containers Medical device components Clean room equipment |

In biomedical engineering, UHMW is used in tissue engineering scaffolds and implantable devices. Its biocompatibility and customization make it valuable for improving patient outcomes.

"UHMW's unique properties, such as its biocompatibility, chemical resistance, and low friction, make it an indispensable material in the medical and pharmaceutical industries."

As healthcare needs grow, UHMW's use in medicine and pharmacy will likely increase. This shows its versatility and importance in enhancing patient care and safety.

Environmental Benefits and Sustainability of UHMW

UHMW (Ultra-High Molecular Weight) is not just durable; it's also great for the environment. It's highly recyclable, which means it can help cut down on waste and save resources. This makes UHMW a top pick for companies looking to lessen their environmental impact.

Recyclability and Eco-Friendliness

UHMW lasts a long time, often longer than the products it's in. This means it uses fewer resources and creates less waste. Plus, UHMW can be recycled, adding to its eco-friendly status.

- Highly recyclable material, reducing waste and resource consumption

- Exceptional durability and long-lasting performance, minimizing product replacement

- Contributes to UHMW environmental benefits and UHMW sustainability

The UHMW recyclability and UHMW eco-friendly traits make it a great choice for green industries. As more focus is put on sustainability, UHMW is a standout material. It helps companies meet their green goals while still delivering top performance.

"UHMW is a game-changer in the pursuit of sustainable materials. Its recyclability and long-lasting durability make it an essential component in the drive towards a more eco-friendly future."

Processing and Manufacturing UHMW

Ultra-high molecular weight (UHMW) polymers need special techniques to use their unique properties. Methods like compression molding, extrusion, machining, and sintering are used. These processes require a deep understanding of UHMW to ensure quality and performance.

Techniques and Methods

Compression molding is a common method. It heats and presses the polymer into the desired shape. This allows for complex shapes and stronger parts with added fibers.

Extrusion is another key technique. It melts the UHMW and pushes it through a die to make continuous profiles and sheets.

Machining and sintering are also used. Machining, like CNC milling, creates precise parts from UHMW stock. Sintering, a powder technique, makes parts with complex shapes and high performance.

FAQ

What is UHMW?

UHMW stands for ultra-high molecular weight polyethylene. It's a type of plastic with a very long molecular chain. This makes UHMW very strong, resistant to wear, and stable against chemicals.

What are the properties and advantages of UHMW materials?

UHMW is known for its high impact resistance and low friction. It's also very durable. These qualities make it great for many uses, from industrial machinery to sports equipment.

What are the key applications of UHMW across industries?

UHMW is used in many industries. It's valued for its toughness and ability to reduce wear in industrial settings. In transportation, it improves safety and performance.

How is UHMW used in the aerospace and defense industries?

UHMW is crucial in aerospace and defense. Its lightness, strength, and resistance to chemicals are perfect for aircraft and military gear. It ensures durability and performance.

What are the benefits of using UHMW in sporting goods and recreational equipment?

UHMW is a top choice for sports and outdoor gear. It's strong, has low friction, and resists impact. This makes it better for skis, snowboards, and bike parts, improving safety and performance.

How is UHMW used in medical and pharmaceutical applications?

UHMW is great for medical uses because it's biocompatible and resistant to chemicals. It's used in implants, surgical tools, and other healthcare items. Its properties ensure safety and comfort for patients.

What are the environmental benefits and sustainability aspects of UHMW?

UHMW is not just durable; it's also good for the environment. It's recyclable and lasts a long time, reducing waste. This makes it a green choice for industries looking to cut their environmental footprint.

How is UHMW processed and manufactured?

Making UHMW requires special techniques. It's molded, extruded, machined, and sintered to bring out its best qualities. This process needs a deep understanding of UHMW to ensure quality and performance.