Carbon Fiber Resin – A Complete Guide

Carbon fiber resin is a critical component in the manufacturing of high-strength composite materials. Its unique properties make it a preferred choice for various applications across industries such as aerospace, automotive, and sports equipment manufacturing. By understanding the properties, manufacturing process, and applications of carbon fiber resin, you can make informed decisions about its usage in manufacturing processes.

Key Takeaways

- Resin is essential in creating high-strength composite materials.

- Understanding the properties and manufacturing process of resin is crucial.

- Resin has a wide range of applications, including aerospace, automotive, and sports equipment manufacturing.

- Manufacturing techniques, such as resin infusion, enhance the performance of resin composites.

- Compatibility between carbon fiber and resin is crucial for optimal performance in composite materials.

Understanding Carbon Fiber&Resin

Carbon fiber&resin is a composite material made of two main components: the carbon fibers and the resin matrix. It is the resin matrix that bonds the fibers together, creating a strong and durable composite material. Understanding the properties and characteristics of resin is essential to grasping its applications and benefits.

It has numerous properties that contribute to its strength and flexibility. Firstly, it has a high strength-to-weight ratio, which makes it five times stronger than steel, yet lighter in weight. Additionally, it is highly resistant to corrosion, chemicals, and UV radiation. Carbon fiber resin is also known for its excellent fatigue resistance, which is crucial in applications where repeated stress is expected, such as in aerospace.

Another critical characteristic of resin is its composition. It consists of a thermosetting polymer matrix, most commonly epoxy resin, infused with carbon fibers. This combination provides the composite material's strength, stiffness, and durability.

Comparing Carbon Fiber Resin with Other Resin Systems

| Resin Type | Properties | Applications |

|---|---|---|

| Epoxy Resin | High strength, stiffness, and fatigue resistance | Aerospace, automotive, sports equipment |

| Polyester Resin | Low cost and ease of use | Marine, automotive (less critical applications) |

| Phenolic Resin | High heat resistance and chemical stability | Aerospace, military, automotive |

Epoxy resin is the most commonly used resin system in carbon fiber composites due to its exceptional strength, stiffness, and fatigue resistance. Compared to other resin systems, epoxy resin offers higher performance, making it popular in applications where performance is critical, such as aerospace and sports equipment. Polyester resin, on the other hand, is less expensive and easier to use, making it a popular choice in less critical applications, such as marine and automotive. Phenolic resin is another option for high-performance applications that require high heat resistance and chemical stability, such as in aerospace, military, and automotive industries.

In conclusion, carbon fiber resin is a unique composite material with exceptional properties that make it ideal for high-performance applications. Its composition, strength, and flexibility make it an increasingly popular choice in industries such as aerospace, automotive, and sports equipment manufacturing.

Applications

Carbon fiber resin finds its applications across different industries, thanks to its strength, durability, and lightweight properties. Below are some of the areas where resin is widely used:

Aerospace

The aerospace industry is known for its stringent requirements of high-performance materials. Carbon fiber resin composites are used for the manufacturing of aircraft and spacecraft due to their high strength-to-weight ratio, which helps reduce the weight of the aircraft and enhance fuel efficiency.

Automotive

The automotive industry uses resin for manufacturing various components due to its high strength and stiffness. It is used in the production of race cars, luxury sports cars, and supercars, where lightweight properties and high strength are critical factors in determining the vehicle's performance.

Sports equipment

Resin finds applications in various sports equipment, including tennis rackets, golf clubs, and bicycles. It offers high strength and stiffness while reducing the overall weight of the equipment, ensuring high performance and easy handling.

With the increasing technological advancements, carbon fiber resin is expected to find more applications across different industries, including wind energy, marine, and medical industries, among others.

Manufacturing Carbon Fiber Resin

Resin composites offer exceptional strength and durability, making them a preferred material in many industries, including aerospace, automotive, and sports equipment manufacturing. Understanding the manufacturing process of resin is crucial to achieving optimal performance and ensuring the highest quality in composite materials.

The resin manufacturing process involves several crucial steps that dictate the properties and compatibility of the final product. One of the initial steps in the process is selecting a suitable resin. Manufacturers can select from a variety of resins, depending on the intended application and composite materials.

The next step involves combining the resin with carbon fibers - this is where the magic happens. Carbon fibers are a critical component in the manufacturing process, and they contribute to the composite's overall strength and durability. Once mixed, manufacturers use specialized processes to ensure that the resin completely saturates the fibers, creating a homogeneous mixture.

The curing process then follows infusion or coating, where the resin is allowed to cure, which solidifies its shape and hardens the composite. The curing process may involve heating the material to activate the curing agent or allowing it to cure at room temperature.

Manufacturers may also utilize additives during the manufacturing process to enhance the overall properties of the composite material. These additives can include flame retardants, colorants, or fillers.

Resin Manufacturing Techniques

Manufacturers use various techniques to produce resin, and the choice of the technique depends on the intended application and the desired composite properties. These techniques include:

- Fabrication: A technique where carbon fibers and resins are combined and molded into the desired shape and size.

- Resin Transfer Molding (RTM): A method that involves the use of a closed mold system where a dry preform is inserted into the mold, and the resin is injected while under pressure, creating a complete and uniform saturation of the carbon fibers.

- Prepreg: A technique that involves combining a resin and carbon fiber to create a pre-impregnated material that can be cured at a later time.

By understanding the resin manufacturing process, manufacturers can optimize their production techniques, resulting in high-quality, high-performance composite materials. As technology advancements continue to impact this field, we can expect even more innovative and efficient processes to emerge.

Resin Composites

Resin is a popular choice for creating high-strength composites as it is compatible with a variety of reinforcement materials. As a matrix in composite materials, resin provides exceptional strength, durability, and stiffness.

Reinforcement Materials

The addition of reinforcement materials such as fibers, fabrics, or particles to carbon fiber resin enhances its properties and capabilities. These materials are chosen based on their compatibility with the resin and their desired function in the composite material. Common reinforcement materials include:

- Carbon fiber: The addition of carbon fibers to the resin creates carbon fiber reinforced composites, which offer high strength, stiffness, and low weight.

- Aramid fibers: Aramid fibers are added to achieve high impact resistance and abrasion resistance.

- Glass fibers: The addition of glass fibers enhances the strength and toughness of the composite material.

- Nanoparticles: With advancements in technology, the addition of nanoparticles such as carbon nanotubes offers improved strength and stiffness in the composite material.

Benefits of Resin Composites

Carbon fiber resin composites offer a range of benefits, including:

- Strength and stiffness: Composites reinforced with resin offer impressive strength and stiffness properties, making them ideal for high-performance applications.

- Low weight: The combination of carbon fiber and the resin matrix results in a lightweight material, which makes it suitable for aerospace or automotive applications where weight savings are crucial.

- Durability: Carbon fiber resin composites have excellent fatigue resistance, making them ideal for applications subjected to cyclic loading.

- Corrosion resistance: Unlike metals, composites made from resin system do not corrode, making them suitable for harsh environments.

Overall, the versatility and compatibility of resin make it an attractive choice for composite materials in various industries.

Resin Infusion Techniques

Resin infusion is a highly effective technique used in the manufacturing of composites. The process involves impregnating carbon fiber layers with resin, which binds them together and enhances strength and durability. The infusion process can be accomplished using several techniques, including the vacuum infusion process.

The Carbon Fiber Resin Infusion Process

The process of resin infusion starts with laying out the carbon fiber layers that will form the composite. The layers are then placed in a mold, and the resin is introduced. The resin penetrates the carbon fiber layers, creating a bond and forming a solid, high-strength composite.

There are several key benefits associated with resin infusion. The process allows for consistent fiber impregnation, which means the composite has a more even and predictable strength. Infusion is also a cleaner process than traditional layup techniques, which can lead to manufacturing defects such as air pockets and variations in fiber content.

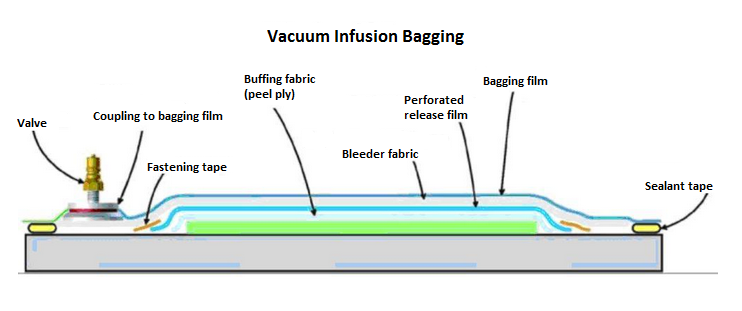

Vacuum Infusion of Carbon Fiber Resin

The vacuum infusion process is an increasingly popular technique for carbon fiber resin infusion. The process involves placing the carbon fiber layers in a vacuum bag and placing the whole assembly in a vacuum. The vacuum removes the air from the mold, creating negative pressure that draws the resin through the carbon fiber layers.

The vacuum infusion process offers several benefits over traditional infusion techniques. The vacuum process ensures the resin is evenly distributed, reducing the likelihood of defects. It is also a highly efficient process, requiring less resin and reducing waste.

| Carbon Fiber Resin Infusion Techniques | Benefits |

|---|---|

| The Resin Infusion Process | Consistent impregnation, cleaner process, reduced defects |

| Vacuum Infusion of Resin | Even distribution, reduced defects, more efficient |

When selecting an infusion technique for your resin application, it is essential to consider the specific needs of your project. The vacuum infusion process is an excellent choice for manufacturers seeking a cleaner, more efficient, and defect-free procedure.

Considerations for Resin Compatibility

When it comes to creating high-performance composites, the compatibility between carbon fiber and resin is crucial. Selecting the right resin is key to achieving the desired functionality, strength, and durability in your composite material.

Resin selection for carbon fiber

Choosing the right resin for your carbon fiber application depends on various factors, such as the desired composite properties, processing methods, and environmental considerations. Epoxy resin is a popular choice for carbon fiber composites due to its excellent adhesion, low shrinkage, and high stiffness properties.

Epoxy resin for carbon fiber

Epoxy resins are ideal for carbon fiber composites due to their exceptional bond strength with fibers, high toughness, and durability. They can be used for wet layup, resin infusion, and prepreg processes, making them highly versatile for a broad range of applications in aerospace, automotive, and sports equipment manufacturing.

When selecting an epoxy resin for your carbon fiber application, consider factors like viscosity, curing time, and compatibility with curing agents. Choose a resin that offers optimal working time and cure time to ensure a successful outcome for your composite material.

Advancements in Resin Technology

The field of resin is constantly evolving, with new innovations and breakthroughs propelling the industry forward. One such area of advancement is in nanocomposite carbon fiber resin technology.

Nanocomposite resin refers to a type of resin that has been infused with nanoparticles to enhance its performance characteristics. These nanoparticles, typically made of materials like graphene or carbon nanotubes, provide increased strength, durability, and thermal stability to the resin.

Through the use of nanocomposite resin, manufacturers can create composites that are stronger, lighter, and more resistant to wear and tear than ever before. This technology has led to exciting new developments in industries like aerospace, where the ability to create stronger and more lightweight components is paramount.

Overall, the advancements in carbon fiber resin technology have opened up new avenues for innovation and growth in the manufacturing industry. As researchers continue to develop new and improved resin formulations, we can expect carbon fiber composites to become even more versatile, capable, and sustainable.

Sustainable Practices in Resin Production

In recent years, there has been a growing concern about the environmental impact of manufacturing processes, including the production of carbon fiber resin. The industry has responded by adopting sustainable practices to minimize its carbon footprint and mitigate any adverse effects on the environment.

Eco-Friendly Resin Options

A popular option is to use eco-friendly resin made from renewable sources, such as bio-based resins. These resins offer comparable mechanical properties to traditional resins while reducing the carbon footprint of the manufacturing process. For instance, using soy-based or palm oil-based resin can decrease GHG emissions by up to 50% compared to petroleum-based resins.

Resin Recycling

Another sustainable practice is carbon fiber resin recycling, which involves the recovery of carbon fibers and resin from composite waste. This waste can be repurposed and used as raw materials for new composite structures. This recycling approach is known as closed-loop recycling and has the potential to reduce waste and ensure the efficient use of natural resources.

Manufacturers' Efforts in Reducing the Environmental Impact

Manufacturers are also striving to reduce the environmental impact of resin production. One approach is to optimize the manufacturing process to minimize waste. For instance, by optimizing the resin infusion technique and curing process, manufacturers can reduce the amount of resin and energy required to produce composite parts.

In addition, manufacturers are reducing the GHG emissions associated with resin production by using renewable energy sources, such as solar power or wind turbines, to power their facilities. Some companies are also utilizing advanced monitoring systems to track and analyze GHG emissions, identify any environmental issues, and take corrective action to minimize their environmental impact.

| Sustainable Practices in Carbon Fiber Resin Production | Benefits |

|---|---|

| Eco-Friendly Resin Options | -Reduced carbon footprint -Comparable mechanical properties to traditional resins -Potential cost savings |

| Carbon Fiber Resin Recycling | -Reduced waste -Efficient use of natural resources -Lower carbon footprint |

| Optimizing Manufacturing Processes | -Reduced energy consumption -Reduced waste -Potential cost savings -Improved product quality |

| Renewable Energy Sources | -Reduced GHG emissions -Potential cost savings -Sustainable power source |

| Advanced Monitoring Systems | -Identification of environmental issues -Corrective action taken to minimize environmental impact -Improved environmental performance |

Sustainable practices in resin production are essential for the industry to continue to grow while minimizing its environmental impact. By adopting eco-friendly resin options, resin recycling, optimizing manufacturing processes, and using renewable energy sources, manufacturers can reduce their carbon footprint and ensure sustainable production.

Conclusion

In conclusion, understanding the essentials of resin is crucial for anyone involved in composite material manufacturing. The unique properties of resin, including its exceptional strength and flexibility, make it a preferred choice across various industries, such as aerospace, automotive, and sports equipment manufacturing.

By comprehending the manufacturing process, applications, and advancements in resin technology, you can make informed decisions when it comes to selecting the right type of resin for your needs. Moreover, sustainable practices and eco-friendly options can help reduce the environmental impact of resin production.

As technology continues to drive improvements in carbon fiber resin, we can expect to see even more significant advancements in this field. These developments will push the boundaries of composite material manufacturing, enhancing the performance and capabilities of resin composites.

Thank you for reading our comprehensive guide to carbon fiber resin. We hope that you have found it informative and helpful in your future endeavors. Keep exploring the exciting world of resin, and stay ahead of the game with the latest trends and innovations in this fascinating field.

FAQ

What are the properties of carbon fiber resin?

is known for its excellent strength-to-weight ratio, high tensile strength, low thermal expansion, and resistance to corrosion and chemicals.

What are the uses of carbon fiber resin?

It is widely used in aerospace, automotive, sports equipment, and construction industries for applications such as aircraft components, car body panels, bicycle frames, and bridge structures.

How is carbon fiber resin manufactured?

The manufacturing process of resin involves selecting the appropriate resin, combining it with carbon fibers, and curing it under controlled conditions to form a composite material.

What are the applications of carbon fiber resin composites?

Resin composites are used in various industries for manufacturing lightweight and high-strength materials such as aircraft wings, automotive parts, wind turbine blades, and sporting goods.

How does carbon fiber resin infusion work?

Resin infusion involves impregnating layers of carbon fiber with resin by applying vacuum pressure, ensuring uniform resin distribution and eliminating air voids in the composite material.

What should be considered for carbon fiber resin compatibility?

When selecting a resin for carbon fiber applications, factors such as resin viscosity, cure temperature, and adhesion properties should be considered to ensure compatibility and optimal performance.

What are the advancements in carbon fiber resin technology?

Advancements in resin technology include the development of nanocomposite resins, which enhance the mechanical and thermal properties of composites, leading to improved performance.

What are sustainable practices in carbon fiber resin production?

Sustainable practices in resin production focus on using eco-friendly resin options, implementing recycling techniques for waste materials, and reducing the environmental impact of the manufacturing process.