Market Forecast of Aramid Fiber in The Next Decade

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

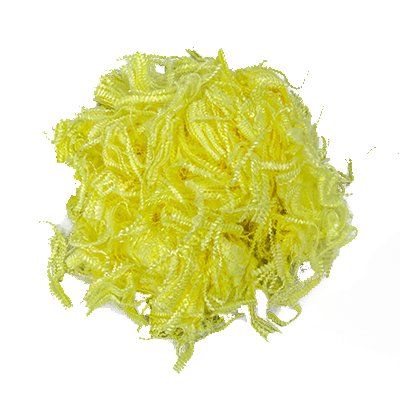

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Aramid fiber, also known as Kevlar, is a powerful synthetic material that has become an essential component of modern industries, from aerospace to automotive and construction. The demand for aramid fiber is expected to increase in the next decade due to its unique properties, versatility, and superior performance.

In this article, we will provide an overview of the aramid fiber market forecast for the next decade, exploring the potential opportunities and growth prospects in the industry. We will dive into the properties and applications of aramid fiber, the top manufacturers and suppliers, its uses and benefits, and the different types available in the market.

Furthermore, we will analyze the current market trends and future prospects for aramid fiber, identifying the key factors that affect the market dynamics. Whether you are an industry player or an investor, this article will provide valuable insights into aramid fiber, enabling you to make informed decisions.

Key Takeaways:

- Aramid fiber is a powerful synthetic material that is widely used in modern industries.

- The demand for aramid fiber is expected to increase in the next decade due to its unique properties and versatility.

- Understanding the market forecast, properties, applications, and types of aramid fiber is crucial for industry players and investors.

- Analyzing the market trends and key factors that affect the aramid fiber market can help to identify potential growth opportunities.

- The future of the aramid fiber market looks promising, with emerging trends, technological advancements, and market demands shaping the industry.

Understanding Aramid Fiber: Properties and Applications

When it comes to high-performance fibers, aramid is a favorite in many industries. Aramid fiber is renowned for its exceptional mechanical properties, high strength, and ability to withstand high temperatures. Its inherent properties make it ideal for use in various applications that need reliable and durable materials.

Aramid Fiber Properties

Aramid fibers are synthetic fibers composed of long-chain polyamide molecules linked by strong hydrogen bonds. These hydrogen bonds create a stiff and rigid structure that gives aramid fiber its strength. The most commonly used types of aramid fiber are para-aramid and meta-aramid.

Para-aramid fibers are incredibly strong and have a higher tensile strength than steel. They are resistant to abrasions, cuts, and heat, making them an excellent choice for bulletproof vests, helmets, and other ballistic applications.

Meta-aramid fibers, on the other hand, are prized for their flame resistance. They do not melt or support combustion, which makes them ideal for protective clothing worn by firefighters and industrial workers.

Aramid Fiber Applications

Due to its exceptional mechanical properties, aramid fiber finds use in various applications across several industries. Here are some common uses:

| Industry | Applications |

|---|---|

| Defense | Bulletproof vests, helmets, gloves, ballistic fabrics, and ropes |

| Automotive | Tire reinforcement, power transmission belts, hoses, and gaskets |

| Aerospace | Structural components, fuel tanks, and engine parts |

| Construction | Reinforcement in concrete structures and cables |

| Electronics | Circuit boards, insulation materials, and electromagnetic shielding |

The exceptional properties of aramid fiber make it an indispensable material in many industries. Its resistance to wear, heat, and flames makes it an ideal choice in many demanding applications. Moreover, aramid fiber offers excellent insulation qualities, making it useful in electrical applications as well.

In the words of an aramid fiber expert, "Aramid fiber is the perfect blend of strength, durability, and resistance to a wide range of environmental factors; it is the go-to material for professionals looking for a reliable and cost-effective solution."

Given its unique properties, it is no wonder that aramid fiber is a preferred choice in many industries, and its demand shows no sign of slowing down in the coming years.

Top Aramid Fiber Manufacturers and Suppliers

When it comes to sourcing aramid fiber, it's essential to partner with reliable and reputable manufacturers and suppliers. Here are some of the top players in the market:

| Company | Location | Product Offerings |

|---|---|---|

| DuPont de Nemours, Inc. | Wilmington, Delaware, USA | KEVLAR®, Nomex®, Teijin Conex® |

| Teijin Limited | Tokyo, Japan | Twaron®, Technora® |

| Kolon Industries, Inc. | Gwacheon, Gyeonggi-do, South Korea | Heracron® |

| Hyosung Corporation | Seoul, South Korea | Creora®, regen® |

DuPont de Nemours, Inc. remains one of the biggest manufacturers of aramid fiber in the world. Their flagship products, KEVLAR® and Nomex®, have established themselves as go-to options in different sectors. Meanwhile, Teijin Limited's Twaron® and Technora® continue to gain traction due to their varying strength levels and excellent heat resistance.

Kolon Industries, Inc.'s Heracron® is widely used in reinforcing concrete and construction materials, while Hyosung Corporation's Creora® excels in textile applications such as clothing, swimwear, and sportswear thanks to its superior stretch and recovery properties.

Lastly, Yantai Tayho Advanced Materials Co., Ltd.'s TAYHOX® and TAYHONA® showcase exceptional sound insulation and fire retardant capabilities, making them perfect for automotive and construction applications.

When choosing a supplier or manufacturer, it's essential to keep in mind factors such as product range, quality, pricing, and service delivery. Doing so ensures you get the best value for your investment and access to high-quality aramid fiber that meets your specific needs.

The Versatility of Aramid Fiber: Uses and Benefits

Aramid fiber has become a preferred choice across different industries due to its exceptional properties. Its uses are widespread, ranging from protective gear to aerospace applications, where its strength and durability come into play. Let's delve into some of the most popular uses and benefits of aramid fiber.

Protective Gear

The use of aramid fiber in protective gear is perhaps the most common application of this material. It provides excellent resistance to tear, wear, and abrasion, making it indispensable in law enforcement body armor, firefighting suits, and industrial safety gear. Additionally, aramid fiber's thermal stability allows it to withstand high temperatures, indicating its effectiveness in the production of firefighting suits and filters.

Aerospace Applications

Aramid fiber has found use in the aerospace industry due to its lightweight and high-strength-to-weight ratio. As a result, it is used in the manufacturing of components of aircraft and spaceships, such as motor housings, support structures, and manifold seals, among others. Additionally, aramid fiber's resistance to heat and flame makes it an ideal material for spacecraft re-entry shields to protect astronauts from the high temperatures associated with atmospheric re-entry.

| Uses | Benefits |

|---|---|

| Protective Gear | Excellent resistance to wear, tear, and abrasion, as well as thermal stability. |

| Aerospace Applications | Lightweight with high strength-to-weight ratio and resistance to heat and flame. |

| Automotive Industry | Enhanced fuel efficiency and reduced emissions due to lightweight materials. |

Automotive Industry

Aramid fiber is now being used in the automotive industry to improve fuel efficiency and reduce emissions by incorporating lightweight materials into vehicles. The use of aramid fiber in tire reinforcement and transmission belts results in reduced weight and improved performance of the car while maintaining high safety standards. Furthermore, the integration of composites containing aramid fiber in body structures improves the car's rigidity and crashworthiness.

Aramid fiber has many more uses and applications, including protective gloves, electrical insulation, and filtration, among others. Its benefits range from improving efficiency to providing excellent resistance to wear, tear, and abrasion at high temperatures, making this material a top choice across different industries.

Exploring Different Types of Aramid Fiber

There are several types of aramid fibers available in the market. Each type has unique properties that make it suitable for specific applications. Understanding these differences can help you choose the right aramid fiber for your needs.

Aromatic Polyamide

Aromatic polyamide, also known as PARA-aramid, is the most common type of aramid fiber. It is known for its high strength, heat resistance, and durability. It is commonly used in protective clothing, such as body armor and firefighter gear, as well as in ropes, cables, and tires.

Meta-Aramid

Meta-aramid is another type of aramid fiber that is well-known for its heat resistance. It does not possess the same level of strength as PARA-aramid, but it can withstand temperatures of up to 400°C. This makes it ideal for use in aerospace applications, such as insulation and thermal protection.

Polyphenylene Benzobisoxazole (PBO)

Polyphenylene Benzobisoxazole, also known as Zylon, is a high-strength aramid fiber that is even stronger than PARA-aramid. It is commonly used in ballistic armor for military and law enforcement applications, as well as in ropes and cables used in extreme conditions.

Carbonized PAN

Carbonized PAN, or carbon fiber, is a high-performance aramid fiber that is known for its strength, stiffness, and low weight. It is commonly used in aerospace and automotive applications, such as in aircraft wings and racing car bodies.

By understanding the different types of aramid fiber available, you can select the best one for your specific needs. Whether you require heat resistance, high strength, or low weight, there is an aramid fiber that can meet your requirements.

Aramid Fiber: Strength in Performance

When it comes to strength, aramid fiber stands out from other materials. With a superior tensile strength and resistance to abrasion, it is a top choice in demanding industries that require durability and reliability.

One of the primary reasons why aramid fiber is so resistant to wear and tear is its unique molecular structure, which includes strong hydrogen bonds. These bonds provide exceptional stiffness, strength, and dimensional stability even in extreme environments, making aramid fiber ideal for strenuous applications.

| Properties of Aramid Fiber | Benefits |

|---|---|

| High tensile strength | Can withstand heavy loads and stress |

| Heat resistance | Can withstand high temperatures without losing strength or shape |

| Abrasion resistance | Can withstand wear and tear from repeated use or contact |

| Chemical resistance | Can withstand exposure to harsh chemicals without degrading |

The outstanding strength of aramid fiber also makes it invaluable in protective gear for military, law enforcement, and industrial workers. For example, Kevlar, a well-known brand of aramid fiber, is widely used in body armor and helmets because it can effectively stop bullets and resist impact.

Moreover, aramid fiber is also being embraced by the aviation, automotive, and sports industries due to its lightweight and high-strength properties. The material can help reduce the weight of the vehicle or equipment, improve fuel efficiency, and enhance overall performance.

Overall, the strength of aramid fiber makes it a valuable material in many applications where other materials might fail. Its unique properties and impressive performance continue to drive demand in various industries around the world.

Aramid Fiber: Properties and Applications in Various Industries

Aramid fiber is a unique class of synthetic polymer fibers known for their exceptional strength, durability, and heat resistance. These fibers are created through a spinning process that produces long chain-like molecules. The resulting fibers are highly crystalline, with a smooth and slippery surface that provides outstanding abrasion resistance.

The properties of aramid fiber make it ideal for a range of applications in various industries, including:

- Protective gear and apparel – such as bulletproof vests, gloves, and helmets

- Aerospace – for aircraft structures, engines, and interiors

- Automotive – for tire reinforcement, brake pads, and fuel hoses

- E&E – for cables, capacitors, and semiconductors

- Civil engineering – for reinforcing concrete structures and bridges

For protective gear and apparel, the strength and durability of aramid fiber make it a popular choice for law enforcement and military personnel. It offers a high level of protection against ballistic and stab threats, while also being lightweight and comfortable to wear.

In aerospace applications, aramid fiber's resistance to heat and flame makes it ideal for use in the engine compartment. It is also incredibly lightweight and strong, which can help reduce the weight of aircraft and improve fuel efficiency.

In the automotive industry, aramid fiber has numerous uses, including tire reinforcement, brake pads, and fuel hoses. As a reinforcing material, it can help reduce weight and improve the strength of tires, while its heat resistance makes it ideal for use in brake pads.

In the E&E industry, aramid fiber's excellent dielectric properties and resistance to heat make it ideal for use in cables and capacitors. It is also used in semiconductors and other electronic components to improve performance and durability.

In civil engineering applications, aramid fiber reinforcement can help improve the strength and durability of concrete structures and bridges. It is also resistant to corrosion and chemical damage, making it ideal for use in harsh environments.

Market Analysis of Aramid Fiber

After analyzing the current market trends and growth factors, the aramid fiber market is expected to witness significant growth in the next decade. The market size was valued at USD 3.1 billion in 2020, and it is projected to reach USD 4.7 billion by 2028, with a CAGR of 5.3% during the forecast period.

Market Drivers

- Increasing demand for aramid fiber in defense and security applications due to its high strength and resistance to heat and flames.

- Surging demand for lightweight materials in the automotive industry due to fuel efficiency regulations and the need for more sustainable transportation solutions.

- Growing emphasis on worker safety in the industrial sector, with aramid fiber being used to manufacture protective clothing and gear.

- Emerging applications in the construction industry, including reinforcement of concrete structures and earthquake-resistant buildings.

Market Restraints

- High production costs due to the complex manufacturing process and the high cost of raw materials.

- Increasing competition from substitute materials such as carbon fiber and fiberglass in some applications.

- Stringent regulations regarding the production and use of aramid fiber in various industries.

Market Segmentation

The global aramid fiber market can be segmented based on type, application, end-use industry, and region.

Type

| Type | Properties | Applications |

|---|---|---|

| Meta-Aramid Fiber | High strength and flexibility, excellent heat and flame resistance | Protective clothing, heat shields |

| Para-Aramid Fiber | Exceptionally high tensile strength, resistance to impact, abrasion, and fatigue | Ballistic armor, tires, ropes and cables, cut-resistant gloves |

Application

- Security and Protection

- Aerospace and Defense

- E&E (Electrical and Electronics)

- Sports and Leisure

- Others (Construction, Friction Materials, etc.)

End-use Industry

- Aerospace and Defense

- Automotive

- Sports and Leisure

- Electrical and Electronics

- Oil and Gas

- Others (Industrial, Marine, etc.)

Region

The market can be divided into the following regions:

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East and Africa

Key Factors Affecting the Aramid Fiber Market

The aramid fiber market is influenced by a variety of factors, both internal and external. As demand for the product continues to rise, key players in the industry must stay informed about these factors to remain competitive and meet the evolving needs of their customers.

Industry Regulations

One major factor that affects the aramid fiber market is industry regulations. Regulations can impact the production process and supply chain, influencing the availability and cost of raw materials and products. As regulations become more stringent, companies may need to invest in new technologies or adjust their manufacturing processes to maintain compliance.

Raw Material Prices

The cost of raw materials is another significant factor that affects the aramid fiber market. As the demand for aramid fiber increases, so does the demand for the raw materials used in production. Fluctuations in the price of raw materials, such as petroleum, can impact the production costs and pricing of aramid fiber products. This can affect the purchasing decisions of customers and ultimately, the profitability of companies.

Competition

Competition from other materials, such as carbon fiber and fiberglass, can also impact the aramid fiber market. Companies must remain innovative and responsive to the needs of their customers to maintain a competitive edge in the market. This may include developing new products or applications for aramid fiber or improving production efficiency to offer competitive pricing.

Market Demand

Market demand is another crucial factor that affects the aramid fiber market. As various industries continue to adopt aramid fiber for its unique properties and strength, the demand for aramid fiber products is expected to increase. This presents new growth opportunities for companies in the industry. However, fluctuations in market demand can also impact the profitability and growth potential of companies.

Technological Advancements

Technological advancements in the production and application of aramid fiber can also influence the market. Innovations in manufacturing processes and new applications for the material can open up new markets and opportunities for growth. Companies in the industry must stay informed about emerging technologies and adapt to remain relevant and competitive.

Future Outlook and Opportunities in the Aramid Fiber Market

The aramid fiber market is expected to see significant growth in the coming years. The market forecast predicts that the demand for aramid fiber will continue to rise over the next decade. This is due to increasing applications in various industries such as automotive, aerospace, and defense.

One of the key drivers of growth in the aramid fiber market is the rise of smart fabrics and wearable technology. These innovations require high-performance materials with exceptional strength and durability, making aramid fiber an ideal choice.

In addition, the demand for lightweight materials that can withstand extreme heat and pressure is also driving growth in the market. Aramid fiber's unique properties make it an attractive option for industries such as oil and gas, where high-performance materials are essential.

Future Opportunities

The future holds great potential for aramid fiber. Technological advancements and increasing demand for sustainable materials are expected to drive growth in the market even further. It is anticipated that aramid fiber will play a critical role in the development of new technologies such as 5G networks and electric vehicles.

The current trend towards lightweight and fuel-efficient vehicles also presents a significant opportunity for aramid fiber. OEMs are exploring the use of aramid fiber to reduce vehicle weight without compromising on strength and durability.

Market Forecast

The aramid fiber market is expected to see significant growth, with a CAGR of 8.5% from 2020 to 2027. The market is projected to reach USD 6.8 billion by 2027, driven by increasing demand from various industries.

North America and Europe are anticipated to be the largest markets for aramid fiber due to the presence of major manufacturers and high demand from industries such as automotive and defense. The Asia Pacific region is also expected to see significant growth in the market, driven by the growing demand for lightweight materials in the aerospace and automotive industries.

Conclusion

In conclusion, the aramid fiber market is expected to witness steady growth in the next decade, driven by the increasing demand for high-performance materials in various industries. With its exceptional strength, durability, and heat resistance, aramid fiber is a preferred choice for applications that require reliable and long-lasting performance. From protective gear to aerospace components, aramid fiber proves its versatility and effectiveness in diverse fields.

Moreover, the market analysis indicates favorable growth prospects for aramid fiber, supported by emerging trends, technological advancements, and growing demand for sustainable materials. As the market evolves, new opportunities are likely to emerge, providing ample scope for businesses to innovate and expand their offerings.

Overall, aramid fiber is a promising market with significant potential for growth and development. Understanding the properties and applications of aramid fiber is critical to capitalize on the opportunities presented by this dynamic sector. As the industry continues to evolve and expand, businesses that remain agile and responsive to changing market trends are expected to thrive.

SEO keywords: aramid fiber market forecast, aramid fiber properties and applications

For more information: https://ictfibers.com/aramid/

FAQ

What is aramid fiber?

Aramid fiber is a type of synthetic fiber known for its exceptional strength, durability, and heat resistance. It is made from aromatic polyamide compounds and is commonly used in various industries for its unique properties.

What are the properties of aramid fiber?

Aramid fiber possesses several key properties, including high tensile strength, excellent heat resistance, resistance to abrasions, and a low coefficient of thermal expansion. It is also lightweight and offers good chemical resistance.

What are the applications of aramid fiber?

Aramid fiber finds applications in diverse industries such as aerospace, automotive, construction, electronics, and protective gear. It is used for manufacturing bulletproof vests, ropes, cables, tires, reinforced composites, and more.

Who are the top aramid fiber manufacturers and suppliers?

Some of the leading aramid fiber manufacturers and suppliers in the market include DuPont, Teijin Aramid, Kolon Industries, Yantai Tayho Advanced Materials, and Hyosung Advanced Materials.

What are the uses and benefits of aramid fiber?

Aramid fiber is highly versatile and offers numerous benefits. It is used for manufacturing protective clothing, helmets, gloves, and other personal protective equipment. It also provides high-strength reinforcement in composites, enhancing the performance and durability of various products.

What are the different types of aramid fiber?

The different types of aramid fiber available in the market include para-aramid fiber and meta-aramid fiber. Para-aramid fibers, such as Kevlar, are known for their high tensile strength, while meta-aramid fibers, such as Nomex, offer exceptional heat resistance.

What is the strength of aramid fiber?

Aramid fiber is renowned for its strength. It has a high tensile strength, which allows it to withstand heavy loads and impacts. Aramid fiber's strength and durability make it a preferred choice in industries where strength and protection are critical.

What are the specific properties and applications of aramid fiber in different industries?

Aramid fiber exhibits specific properties that make it suitable for different industries. In the automotive industry, it is used for manufacturing tires, belts, and hoses. In the construction industry, it is used for reinforcing concrete and preventing crack propagation. In the electronics industry, it is used for manufacturing flexible printed circuit boards and insulating materials.

What is the market analysis of aramid fiber?

The aramid fiber market is projected to experience significant growth in the next decade. Factors such as increasing demand for high-performance materials, infrastructure development, and the need for lightweight and durable products drive market growth. The market analysis provides insights into current trends, market size, and growth opportunities.

What are the key factors affecting the aramid fiber market?

Several factors influence the aramid fiber market, including raw material prices, government regulations, industry standards, technological advancements, and economic conditions. These external factors can impact the demand, supply, and pricing dynamics of aramid fiber.

What is the future outlook and opportunities in the aramid fiber market?

The future of the aramid fiber market looks promising, with opportunities arising from various industries and applications. The market is expected to witness growth due to advancements in technology, increasing R&D activities, and the demand for sustainable and high-performance materials.