Kevlar Fiber Now Available in Ultra-Thin Weaves

-

Table of Contents

“Kevlar Fiber: Unmatched Strength in Ultra-Thin Weaves.”

Kevlar fiber, renowned for its exceptional strength and durability, has now been developed in ultra-thin weaves, revolutionizing its applications across various industries. This innovative advancement maintains the material’s high tensile strength while significantly reducing its weight and thickness. The ultra-thin Kevlar weaves offer enhanced flexibility and comfort, making them ideal for use in protective clothing, aerospace components, and advanced sporting goods. As a result, this new iteration of Kevlar not only improves performance but also opens up new possibilities for design and functionality in high-performance applications.

Kevlar Fiber: Revolutionizing Ultra-Thin Weave Technology

Kevlar fiber, renowned for its exceptional strength and durability, has recently undergone significant advancements, leading to the introduction of ultra-thin weaves that promise to revolutionize various industries. Traditionally associated with bulletproof vests and protective gear, Kevlar’s unique properties have made it a staple in applications requiring high tensile strength and resistance to abrasion. However, the development of ultra-thin weaves opens up new possibilities, expanding the material’s utility beyond conventional uses.

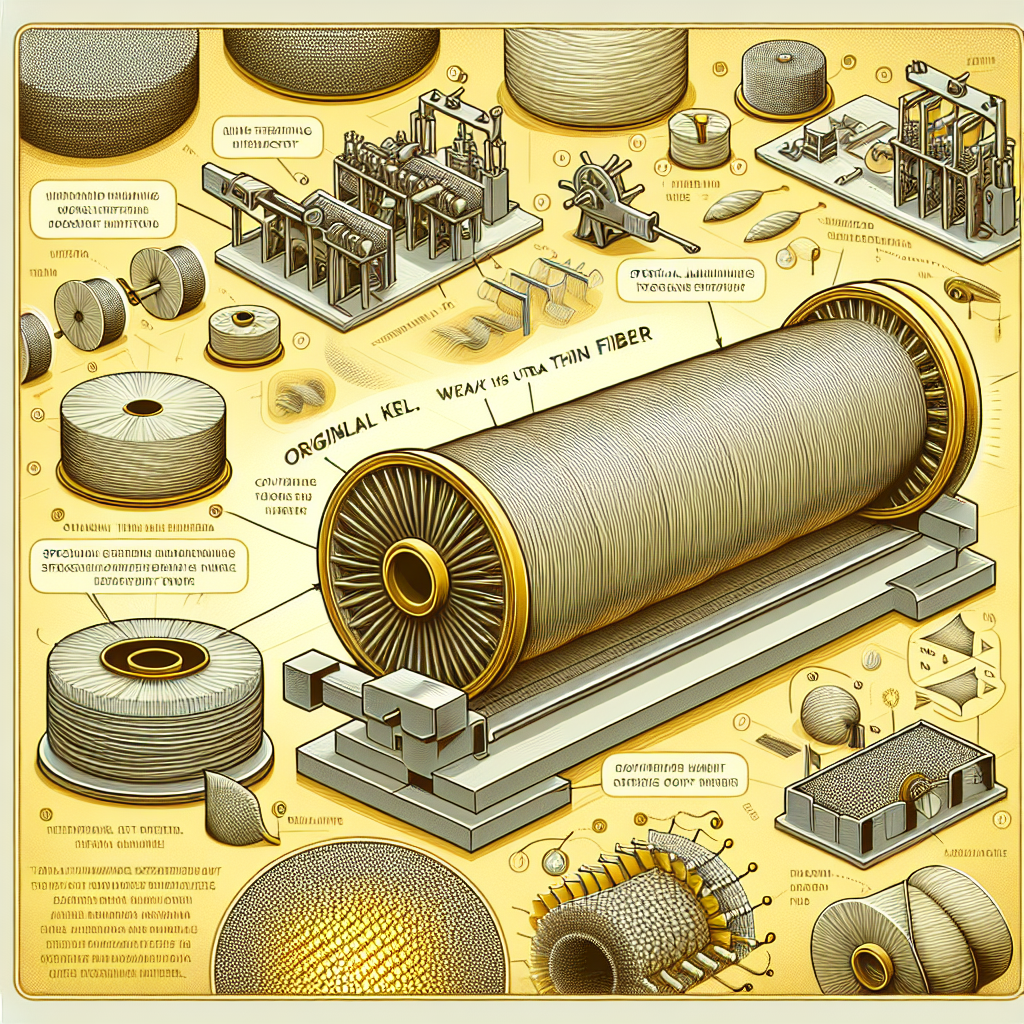

The innovation in ultra-thin Kevlar weaves is primarily driven by advancements in manufacturing techniques and material science. By refining the weaving process, manufacturers can produce Kevlar fibers that are not only thinner but also lighter, without compromising their inherent strength. This breakthrough allows for the creation of fabrics that maintain the protective qualities of traditional Kevlar while offering enhanced flexibility and comfort. As a result, industries such as fashion, automotive, and aerospace are beginning to explore the potential of these ultra-thin weaves.

In the fashion industry, the introduction of ultra-thin Kevlar weaves is particularly exciting. Designers are now able to incorporate this high-performance material into everyday clothing, creating garments that are both stylish and protective. For instance, jackets and pants made from ultra-thin Kevlar can provide wearers with a level of safety previously reserved for specialized gear. This fusion of fashion and function not only appeals to consumers seeking stylish options but also addresses the growing demand for protective clothing in urban environments where safety is a concern.

Moreover, the automotive sector stands to benefit significantly from the integration of ultra-thin Kevlar weaves. As manufacturers strive to enhance vehicle safety while reducing weight for improved fuel efficiency, the lightweight nature of these new fabrics presents an ideal solution. Ultra-thin Kevlar can be utilized in various components, such as seat covers, interior panels, and even body armor for vehicles, providing enhanced protection without adding substantial weight. This innovation aligns with the industry’s ongoing efforts to develop safer and more efficient vehicles, ultimately contributing to a reduction in road accidents and fatalities.

In addition to fashion and automotive applications, the aerospace industry is also exploring the potential of ultra-thin Kevlar weaves. The need for lightweight yet durable materials is paramount in aviation, where every ounce counts. By incorporating ultra-thin Kevlar into aircraft components, manufacturers can achieve significant weight savings, leading to improved fuel efficiency and reduced operational costs. Furthermore, the enhanced strength of these materials can contribute to the overall safety and longevity of aircraft, making them an attractive option for aerospace engineers.

As the demand for versatile and high-performance materials continues to grow, the introduction of ultra-thin Kevlar weaves represents a significant milestone in material innovation. The ability to combine strength, flexibility, and lightweight properties opens up a myriad of possibilities across various sectors. While the traditional applications of Kevlar remain vital, the emergence of ultra-thin weaves signals a new era where this remarkable fiber can be seamlessly integrated into everyday products, enhancing both safety and style. As industries continue to explore and adopt these advancements, it is clear that Kevlar fiber is not only revolutionizing ultra-thin weave technology but also reshaping the landscape of modern materials. The future holds exciting prospects for this remarkable fiber, promising to enhance our lives in ways previously unimagined.

Applications of Ultra-Thin Kevlar Fiber in Modern Industries

The introduction of ultra-thin Kevlar fiber has marked a significant advancement in various modern industries, showcasing its versatility and effectiveness in applications that require both strength and lightweight properties. Traditionally known for its use in bulletproof vests and protective gear, Kevlar has now evolved to meet the demands of contemporary technological advancements. This evolution has opened new avenues for its application, particularly in sectors such as aerospace, automotive, and electronics.

In the aerospace industry, the need for materials that can withstand extreme conditions while minimizing weight is paramount. Ultra-thin Kevlar fiber, with its remarkable tensile strength and resistance to heat, has become an essential component in the construction of aircraft components. By integrating this advanced material into structural elements, manufacturers can enhance the durability and safety of aircraft while simultaneously improving fuel efficiency. The lightweight nature of ultra-thin Kevlar allows for a reduction in overall aircraft weight, which translates to lower fuel consumption and reduced emissions, aligning with the industry’s push towards sustainability.

Similarly, the automotive sector has recognized the potential of ultra-thin Kevlar fiber in enhancing vehicle performance and safety. As manufacturers strive to produce lighter vehicles that do not compromise on safety, the incorporation of Kevlar into various components, such as body panels and tires, has proven beneficial. The fiber’s ability to absorb impact energy makes it an ideal choice for reinforcing critical areas of vehicles, thereby improving crashworthiness. Furthermore, the use of ultra-thin Kevlar can lead to innovations in electric vehicle design, where weight reduction is crucial for maximizing battery efficiency and range.

In the realm of electronics, ultra-thin Kevlar fiber is making waves as a protective material for devices that require both durability and flexibility. The rise of wearable technology has necessitated the development of materials that can withstand daily wear and tear while remaining lightweight and comfortable. Kevlar’s unique properties allow it to be woven into flexible circuits and protective casings, providing a robust solution for smartphones, smartwatches, and other portable devices. This integration not only enhances the longevity of electronic products but also contributes to the overall user experience by ensuring that devices can endure the rigors of everyday life.

Moreover, the textile industry is experiencing a transformation with the introduction of ultra-thin Kevlar fiber. Fashion designers and manufacturers are beginning to explore its potential in creating high-performance apparel that combines style with safety. For instance, the development of Kevlar-infused fabrics for outdoor gear and sportswear offers consumers protection against abrasions and cuts without sacrificing comfort or aesthetics. This trend reflects a growing consumer demand for multifunctional clothing that meets both practical needs and fashion sensibilities.

As industries continue to innovate, the applications of ultra-thin Kevlar fiber are likely to expand further. Research and development efforts are ongoing, focusing on enhancing the material’s properties and exploring new uses across various fields. The adaptability of Kevlar, combined with its proven performance, positions it as a key player in the future of material science. In conclusion, the emergence of ultra-thin Kevlar fiber is not merely a technological advancement; it represents a paradigm shift in how industries approach design, safety, and sustainability. As these applications continue to evolve, they will undoubtedly shape the landscape of modern manufacturing and consumer products for years to come.

The Benefits of Using Ultra-Thin Kevlar Fiber in Protective Gear

The introduction of ultra-thin Kevlar fiber into the realm of protective gear marks a significant advancement in materials science, offering a multitude of benefits that enhance both safety and comfort for users. Traditionally known for its robust strength and durability, Kevlar has long been a staple in protective clothing, particularly in applications such as law enforcement, military, and industrial safety. However, the development of ultra-thin weaves has revolutionized the way this material can be utilized, providing a new dimension of functionality that was previously unattainable.

One of the most notable advantages of ultra-thin Kevlar fiber is its lightweight nature. This reduction in weight allows for greater mobility and flexibility, which is crucial in high-stakes environments where agility can be a matter of life and death. For instance, law enforcement officers and military personnel often require protective gear that does not hinder their movement. The incorporation of ultra-thin Kevlar enables the creation of vests and uniforms that offer substantial protection without the cumbersome bulk associated with traditional materials. As a result, users can perform their duties more effectively, maintaining a high level of performance while remaining shielded from potential threats.

In addition to its lightweight properties, ultra-thin Kevlar fiber also enhances breathability. Traditional protective gear can often trap heat and moisture, leading to discomfort and fatigue during prolonged use. The innovative weaving techniques employed in ultra-thin Kevlar allow for improved air circulation, which helps regulate body temperature and wick away sweat. This feature is particularly beneficial in hot and humid environments, where overheating can impair an individual’s ability to function optimally. By prioritizing comfort alongside protection, ultra-thin Kevlar gear encourages longer wear times, ultimately increasing the safety and effectiveness of the wearer.

Moreover, the ultra-thin nature of Kevlar does not compromise its protective capabilities. In fact, advancements in technology have allowed for the development of weaves that maintain the material’s inherent strength while reducing thickness. This means that users can enjoy the same level of ballistic and cut resistance that Kevlar is renowned for, but in a more streamlined form. The ability to create thinner layers of protection without sacrificing performance is a game-changer for industries that rely on personal protective equipment. For example, firefighters can benefit from ultra-thin Kevlar in their gear, which provides essential heat resistance while allowing for greater ease of movement during rescue operations.

Furthermore, the versatility of ultra-thin Kevlar fiber extends beyond traditional applications. Its lightweight and durable characteristics make it an ideal candidate for integration into various consumer products, such as sports gear and outdoor apparel. Athletes and outdoor enthusiasts can now access protective clothing that not only safeguards against injuries but also enhances performance through improved comfort and flexibility. This crossover into everyday use signifies a broader acceptance of advanced materials in mainstream markets, paving the way for innovative designs that prioritize safety without compromising style.

In conclusion, the advent of ultra-thin Kevlar fiber represents a remarkable evolution in protective gear technology. By combining lightweight construction, enhanced breathability, and uncompromised strength, this innovative material offers a multitude of benefits that cater to the needs of users across various fields. As industries continue to embrace these advancements, the future of protective gear looks promising, with the potential for even greater innovations on the horizon. The integration of ultra-thin Kevlar fiber not only enhances safety but also redefines the standards of comfort and performance in protective apparel.

Q&A

1. **What is Kevlar fiber?**

Kevlar fiber is a high-strength synthetic fiber known for its exceptional tensile strength and resistance to heat and abrasion, commonly used in protective gear and industrial applications.

2. **What are the benefits of ultra-thin Kevlar weaves?**

Ultra-thin Kevlar weaves offer enhanced flexibility, lightweight protection, and improved comfort, making them suitable for applications in clothing, armor, and advanced composite materials.

3. **In what industries can ultra-thin Kevlar weaves be utilized?**

Ultra-thin Kevlar weaves can be utilized in various industries, including personal protective equipment (PPE), automotive, aerospace, and sports equipment, where lightweight and durable materials are essential.The introduction of Kevlar fiber in ultra-thin weaves represents a significant advancement in materials technology, offering enhanced flexibility and comfort while maintaining the exceptional strength and durability for which Kevlar is known. This innovation opens new possibilities for applications in various industries, including personal protective equipment, automotive, and aerospace, where lightweight and high-performance materials are essential. The ultra-thin weaves not only improve the wearability of Kevlar products but also expand its potential uses, making it a versatile choice for modern engineering and design challenges.