Colored Carbon Fiber Fabric for Composites

-

Table of Contents

“Unleash the power of vibrant strength with Colored Carbon Fiber Fabric for your composite projects.”

Introduction

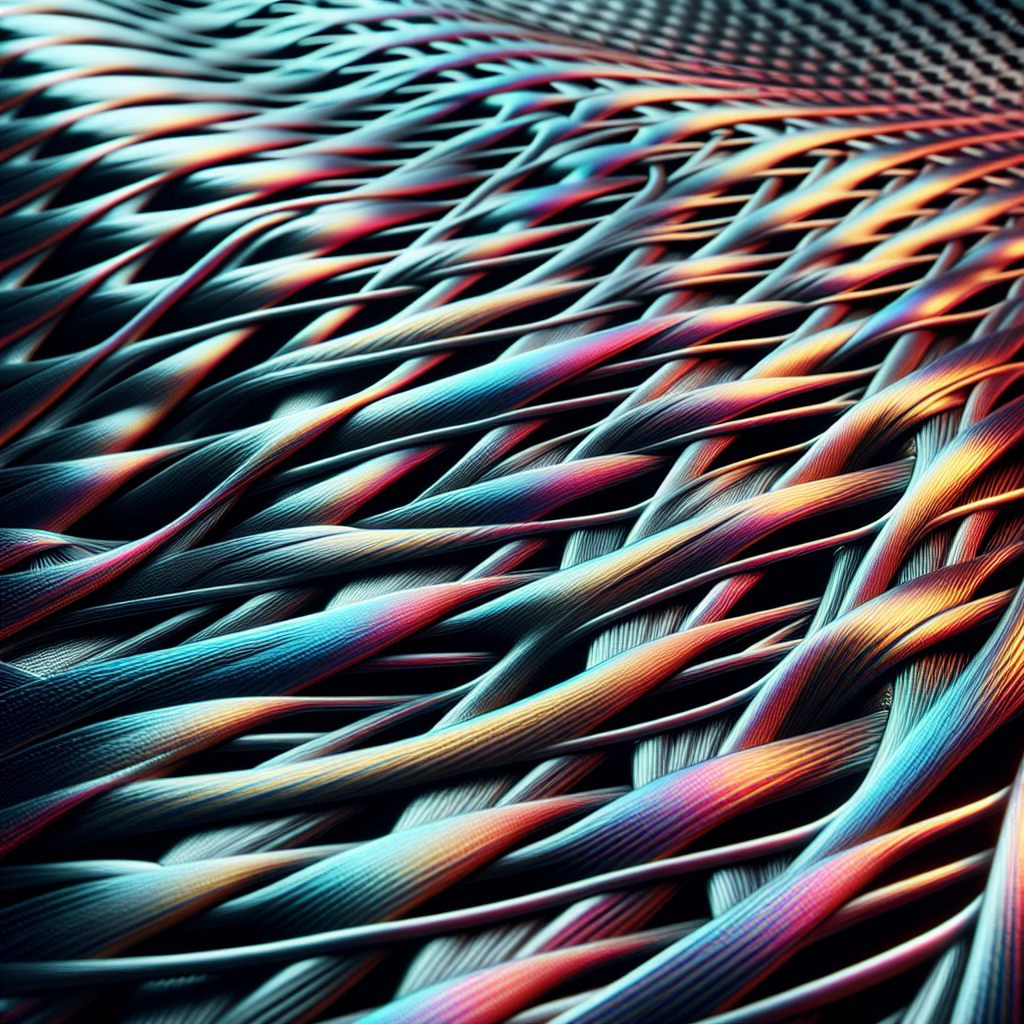

Colored carbon fiber fabric is a type of composite material that is made up of carbon fibers that have been dyed with various colors. This fabric is commonly used in the manufacturing of composites, which are materials that are made up of two or more different components. The addition of color to the carbon fibers not only adds aesthetic appeal, but also provides additional properties such as UV resistance and improved visibility. Colored carbon fiber fabric is becoming increasingly popular in various industries, including automotive, aerospace, and sporting goods, due to its unique combination of strength, light weight, and customizable appearance. In this article, we will explore the properties and applications of colored carbon fiber fabric for composites.

Benefits of Using Colored Carbon Fiber Fabric in Composite Manufacturing

Carbon fiber has long been a popular material in the manufacturing industry, known for its strength, durability, and lightweight properties. However, with advancements in technology, carbon fiber is now available in a variety of colors, making it an even more attractive option for composite manufacturing. In this article, we will explore the benefits of using colored carbon fiber fabric in composite manufacturing.

One of the main benefits of using colored carbon fiber fabric in composite manufacturing is the aesthetic appeal it adds to the final product. Traditionally, carbon fiber has been limited to its signature black color, which can be monotonous and unappealing to some consumers. With the introduction of colored carbon fiber, manufacturers now have the option to create visually striking and unique products. This is especially beneficial for industries such as automotive and sports equipment, where aesthetics play a significant role in consumer purchasing decisions.

In addition to its aesthetic appeal, colored carbon fiber also offers practical benefits in composite manufacturing. The color of the fabric can be used to differentiate between different layers or sections of a composite product, making it easier for manufacturers to identify and assemble the components correctly. This is particularly useful in complex and intricate designs, where precision and accuracy are crucial.

Moreover, colored carbon fiber fabric can also be used as a visual indicator for quality control. By incorporating different colors into the fabric, manufacturers can easily identify any defects or inconsistencies in the material during the manufacturing process. This allows for quick and efficient detection of any issues, ensuring that only high-quality products are delivered to consumers.

Another significant advantage of using colored carbon fiber fabric in composite manufacturing is its impact on the environment. Traditional carbon fiber production involves the use of harsh chemicals and high energy consumption, resulting in a significant carbon footprint. However, with the introduction of colored carbon fiber, manufacturers can now use more environmentally friendly dyes and pigments to achieve the desired color. This not only reduces the environmental impact of production but also makes the final product more sustainable.

Furthermore, colored carbon fiber fabric offers improved safety in composite manufacturing. The color of the fabric can be used to indicate the direction of the fibers, making it easier for manufacturers to ensure that the fibers are aligned correctly. This is crucial in creating strong and durable composite products, as misaligned fibers can weaken the overall structure. Additionally, the color of the fabric can also be used to indicate the type of resin used, which is essential in ensuring the correct curing process and avoiding any potential hazards.

Lastly, the use of colored carbon fiber fabric in composite manufacturing can also lead to cost savings. While the initial cost of colored carbon fiber may be slightly higher than traditional black carbon fiber, the benefits it offers can result in long-term cost savings. For instance, the improved efficiency in quality control and production processes can lead to reduced waste and lower production costs. Additionally, the aesthetic appeal of colored carbon fiber can also increase the value and demand for the final product, resulting in higher profits for manufacturers.

In conclusion, the benefits of using colored carbon fiber fabric in composite manufacturing are numerous. From its aesthetic appeal and practical benefits to its positive impact on the environment and cost savings, colored carbon fiber is revolutionizing the composite industry. As technology continues to advance, we can expect to see even more innovative uses for colored carbon fiber in the future.

Innovative Applications of Colored Carbon Fiber Fabric in the Aerospace Industry

Carbon fiber has long been known for its strength, durability, and lightweight properties, making it a popular material in various industries, especially in the aerospace industry. However, with advancements in technology, carbon fiber is now available in a variety of colors, opening up a whole new world of possibilities for its use in composites. In this article, we will explore the innovative applications of colored carbon fiber fabric in the aerospace industry.

Traditionally, carbon fiber has been available only in its natural black color, which is a result of the carbon fibers being woven together. However, with the development of colored carbon fiber fabric, manufacturers can now produce carbon fiber in a range of colors, including red, blue, green, and even metallic shades. This breakthrough has sparked the interest of aerospace engineers and designers, who are now incorporating colored carbon fiber into their projects.

One of the most significant applications of colored carbon fiber fabric in the aerospace industry is in the production of aircraft interiors. The use of colored carbon fiber in place of traditional materials such as aluminum or plastic has not only reduced the weight of the aircraft but has also added a touch of luxury and elegance to the interior design. For instance, the use of red carbon fiber in the cabin of a private jet can give it a sleek and modern look, while blue carbon fiber can create a calming and sophisticated atmosphere.

Moreover, colored carbon fiber fabric is also being used in the production of aircraft components, such as winglets, fuselage panels, and engine covers. These components are not only functional but also play a significant role in the overall aesthetics of the aircraft. By using colored carbon fiber, manufacturers can create visually appealing and unique designs that set their aircraft apart from others in the market.

Another innovative application of colored carbon fiber fabric in the aerospace industry is in the production of satellite components. Satellites are exposed to extreme temperatures and harsh conditions in space, making it crucial for their components to be lightweight, strong, and durable. Colored carbon fiber meets all these requirements, making it an ideal material for satellite components. Additionally, the use of colored carbon fiber can also help with thermal management, as different colors absorb and reflect heat differently.

Furthermore, colored carbon fiber fabric is also being used in the production of rocket components. Rockets require materials that can withstand high temperatures and pressures, and colored carbon fiber has proven to be up to the task. The use of colored carbon fiber in rocket components not only improves their performance but also adds a touch of style to these powerful machines.

In addition to its functional and aesthetic benefits, colored carbon fiber fabric also has practical advantages in the aerospace industry. For instance, the use of colored carbon fiber can help with identification and differentiation of components, making it easier for engineers and technicians to identify and troubleshoot any issues. This can save time and resources, ultimately leading to more efficient operations.

In conclusion, the development of colored carbon fiber fabric has opened up a world of possibilities for its use in the aerospace industry. From aircraft interiors to satellite and rocket components, colored carbon fiber is proving to be a versatile and valuable material. Its strength, durability, lightweight properties, and now its aesthetic appeal make it a top choice for engineers and designers in the aerospace industry. As technology continues to advance, we can expect to see even more innovative applications of colored carbon fiber fabric in the future.

The Future of Colored Carbon Fiber Fabric in Automotive Composite Design

Carbon fiber has long been a popular material in the automotive industry due to its strength, lightweight properties, and ability to improve fuel efficiency. However, one of the limitations of traditional carbon fiber is its lack of color options. This is where colored carbon fiber fabric comes in, offering a new and exciting future for automotive composite design.

Colored carbon fiber fabric is a type of composite material that combines the strength and durability of traditional carbon fiber with the added benefit of color. This is achieved by incorporating colored pigments into the resin used to create the carbon fiber fabric. The result is a material that not only performs well but also adds a visual appeal to the finished product.

One of the main advantages of using colored carbon fiber fabric in automotive composite design is the ability to create unique and eye-catching designs. Traditional carbon fiber is typically black or dark grey, limiting the options for designers. With colored carbon fiber, the possibilities are endless. Different colors can be used to create patterns, logos, or even custom designs, making each car truly one-of-a-kind.

In addition to its aesthetic appeal, colored carbon fiber fabric also offers practical benefits. The colored pigments used in the resin can help to protect the carbon fiber from UV rays, which can cause the material to degrade over time. This means that not only will the car look great, but the colored carbon fiber will also have a longer lifespan compared to traditional carbon fiber.

Another advantage of using colored carbon fiber fabric in automotive composite design is its weight-saving properties. As mentioned earlier, carbon fiber is known for its lightweight properties, and this is especially important in the automotive industry where every pound counts. By using colored carbon fiber, designers can achieve the same strength and durability while also reducing the weight of the vehicle. This can lead to improved fuel efficiency and overall performance.

Furthermore, colored carbon fiber fabric can also be used to create functional parts for vehicles. For example, colored carbon fiber can be used to create lightweight and durable body panels, reducing the overall weight of the car. It can also be used to create interior components such as dashboards, door panels, and even seats. This not only adds a unique touch to the interior design but also helps to reduce the weight of the vehicle, improving its performance.

The use of colored carbon fiber fabric in automotive composite design is not limited to just cars. It can also be used in other vehicles such as motorcycles, boats, and even airplanes. The lightweight and durable properties of colored carbon fiber make it an ideal material for these applications as well.

However, like any new technology, there are still some challenges that need to be addressed before colored carbon fiber fabric becomes a mainstream material in automotive composite design. One of the main challenges is the cost. Currently, colored carbon fiber is more expensive than traditional carbon fiber, making it less accessible for mass production. However, as technology advances and demand increases, it is expected that the cost will decrease, making it a more viable option for automotive manufacturers.

In conclusion, colored carbon fiber fabric offers a promising future for automotive composite design. Its ability to add color, improve durability, and reduce weight make it a desirable material for designers and manufacturers alike. As technology continues to advance and costs decrease, we can expect to see more and more vehicles incorporating this innovative material, making the roads a more colorful and efficient place.

Q&A

Q: What is colored carbon fiber fabric?

A: Colored carbon fiber fabric is a type of composite material made from carbon fibers that have been dyed or coated with a colored resin. This gives the fabric a unique appearance and allows for more design options in composite applications.

Q: How is colored carbon fiber fabric used in composites?

A: Colored carbon fiber fabric is often used as a decorative or aesthetic element in composite materials. It can be incorporated into the outer layers of a composite structure to add color and visual interest, or used as a design element in products such as sports equipment, automotive parts, and consumer goods.

Q: What are the benefits of using colored carbon fiber fabric in composites?

A: Using colored carbon fiber fabric in composites offers several benefits. It adds visual appeal and allows for more design options, making products stand out in the market. It also maintains the strength and lightweight properties of traditional carbon fiber composites, making it a versatile and durable material for various applications. Additionally, the colored resin used in the fabric can provide UV protection and improve the overall durability of the composite.