Classifications And Applications of Chopped Carbon Fiber

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Carbon fiber is a versatile material with excellent strength and stiffness properties. When chopped into small strands, it becomes chopped carbon fiber, a reinforcement material used widely in various industries. Chopped carbon fiber is used in composites to enhance their strength, durability, and impact resistance.

In this article, we'll explore the different classifications and applications of chopped carbon fiber in the market. We'll discuss its properties and how it is used as a reinforcement material for composites. We'll also delve into the manufacturing process of chopped carbon fiber and its use in various industries, including the automotive, aerospace, and construction sectors.

Key Takeaways

- Chopped carbon fiber is a versatile reinforcement material.

- It enhances the strength, stiffness, and impact resistance of composites.

- The manufacturing process of chopped carbon fiber involves several key steps.

- Chopped carbon fiber is used in various industries, including automotive, aerospace, and construction.

- Carbon fiber chopped strands are a type of chopped carbon fiber.

Understanding Chopped Carbon Fiber

Chopped carbon fiber is a popular reinforcement material that is widely used in various industries, such as automotive, aerospace, and construction. It is a form of carbon fiber that has been chopped into small pieces, typically ranging from 1/8” to 1” in length. These chopped fibers are then mixed into a matrix material, such as plastic or resin, to create a composite material with enhanced properties.

The main reason why chopped carbon fiber is used as a reinforcement material is due to its unique properties. It has high strength, stiffness, and impact resistance, making it ideal for improving the performance of composite materials. In addition, it has a low weight-to-strength ratio, meaning that it adds strength to the final product without adding significant weight.

Chopped carbon fiber also has other advantageous properties, such as its exceptional chemical resistance and thermal stability. These properties make it an ideal reinforcement material that can maintain its structural integrity even in harsh environments and extreme temperatures.

Another factor that makes chopped carbon fiber a preferred reinforcement material for composites is its ease of use. It can be easily incorporated into different matrix materials, including thermoplastics and thermosets, to create a wide range of composite materials. This flexibility adds to its broad range of applications across industries.

In summary, chopped carbon fiber is a versatile and essential component in many composite materials. Its unique properties, ease of use, and broad range of applications make it a popular choice for enhancing the strength and durability of various industries' products.

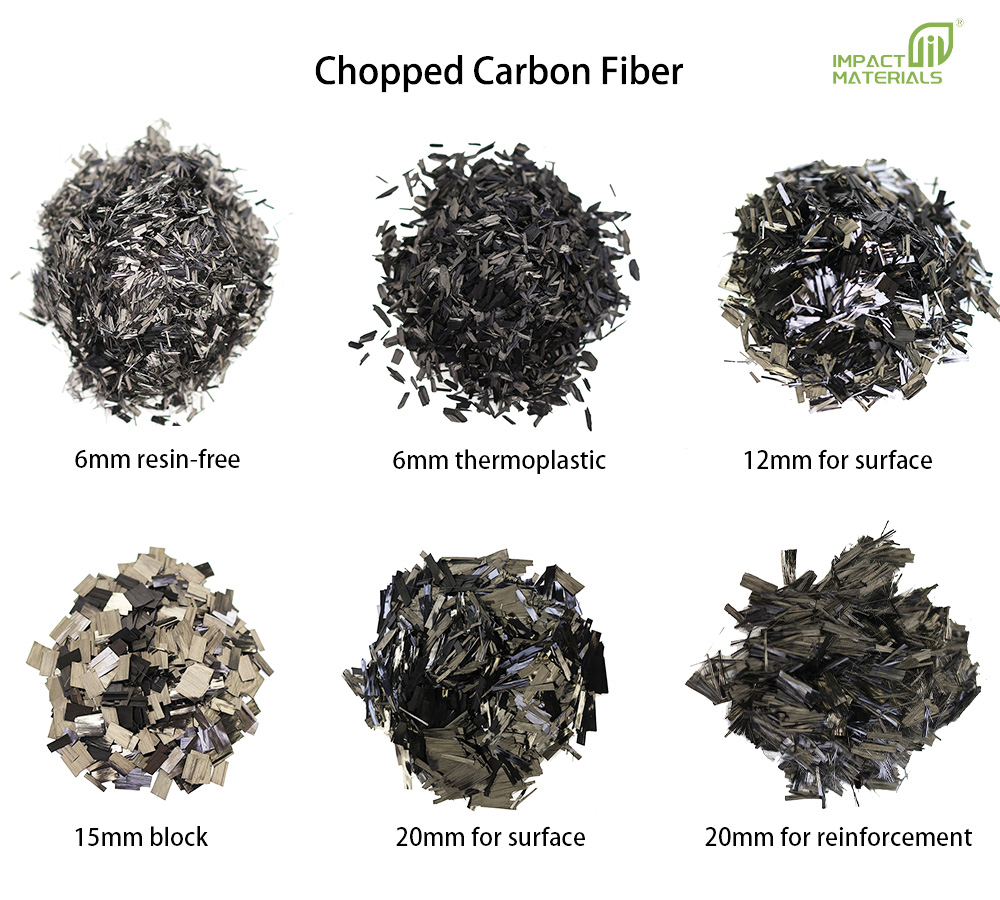

Types of Chopped Carbon Fiber

Chopped carbon fiber is available in different forms, including carbon fiber chopped strands or milled fibers. These forms are designed to meet specific application requirements.

The most common type of chopped carbon fiber is carbon fiber chopped strands. These strands are cut to specific lengths, typically ranging from 3mm to 150mm. The length of the strands is dependent on the application, with longer strands providing higher strength and stiffness.

| Properties | Chopped Strands |

|---|---|

| Length | 3mm to 200mm |

| Diameter | 7μm to 20μm |

| Aspect Ratio | 50 to 500 |

In addition to chopped strands, there are other forms of chopped carbon fiber, including milled fibers. Milled fibers are produced by cutting continuous carbon fibers into small pieces, which range from 30μm to 120μm in diameter. Milled fibers offer unique properties, making them ideal for specific applications, such as electrical conductivity, wear resistance, and improved impact resistance.

Chopped carbon fiber is widely used in composites, where it is added to a polymer matrix to enhance its strength and stiffness. A chopped carbon fiber can significantly increase the mechanical properties of composites, including tensile strength, bending strength, and impact resistance.

Overall, the various forms of chopped carbon fiber offer unique properties that make them ideal for a range of applications in composites.

Applications of Chopped Carbon Fiber in Composites

Chopped carbon fiber is widely used as a reinforcement material in carbon fiber composite materials. It enhances the strength, stiffness, and impact resistance of composites, making them ideal for various applications in different industries.

The use of chopped carbon fiber in composites improves their mechanical properties, making them stronger and stiffer. Carbon fiber reinforced composites have a higher tensile strength, which means they can withstand more tension than non-reinforced materials. Additionally, carbon fiber composites are more lightweight, which makes them an ideal choice for applications that require lightweight materials, such as in the automotive and aerospace industries.

Chopped carbon fiber is commonly used in the production of carbon fiber composite materials because of its high strength, flexibility, and durability. A typical carbon fiber composite consists of several layers of chopped carbon fiber and epoxy.

| Industry | Application |

|---|---|

| Automotive | Interior and exterior parts, body panels, engine components, and suspension systems |

| Aerospace | Aircraft structures, including wings, fuselage, and tail sections |

| Sporting Goods | Tennis rackets, snowboards, surfboards, bicycles, and golf clubs |

| Construction | Concrete reinforcement, strengthening of structural elements, and seismic retrofitting |

Chopped carbon fiber is also commonly used in the production of carbon fiber chopped strand mat, which has the added benefit of providing improved tear resistance and impact strength to composite materials. This makes it ideal for applications in the marine and wind energy industries.

In conclusion, chopped carbon fiber is an essential component in carbon fiber composite materials. Its unique properties make it an ideal reinforcement material that enhances the strength, stiffness, and impact resistance of composites, making them suitable for use in various industries.

Chopped Carbon Fiber Manufacturing Process

The manufacturing of chopped carbon fiber involves several steps that should be executed precisely to yield high-quality fibers. These steps include:

- Polymerization: This is the first stage of the process, where a high-quality precursor fiber, usually PAN, is formed, and then polymerized at high temperatures to yield the carbon fiber.

- Stabilization: The second stage of the process involves stabilizing the precursor fiber further by heating it at a precise temperature in an oxygen-free environment. The stabilization process prevents the fiber from shrinking during the carbonization process.

- Carbonization: The third stage of the process is carbonization, where the stabilized precursor fiber is heated up to temperatures above 1000°C, causing it to lose its non-carbon atoms and transform into carbon fiber. The carbonized fiber is then oxidized to get rid of any residual impurities, creating a pure carbon fiber.

- Chopping: Once the manufacturing process of carbon fiber is complete, it is then cut into small pieces using a mechanical chopper. The length of the chopped fiber strands depends on the intended application.

Several manufacturers specialize in the production of high-quality chopped carbon fiber. The market offers various grades of chopped carbon fiber, so it is essential to select the right manufacturer to ensure top-quality products.

Chopped Carbon Fiber Reinforced Plastics

Chopped carbon fiber is widely used in reinforced plastics due to its exceptional properties. When added to plastic materials, it enhances their strength, stiffness, and impact resistance. The properties of chopped carbon fiber are determined by its length, diameter, and content.

The length of chopped carbon fiber typically ranges from 0.25 inches to 2 inches, while the diameter can be as small as 5 microns. The content of chopped carbon fiber in reinforced plastics varies, depending on the desired properties of the material.

The advantages of using chopped carbon fiber in reinforced plastics are numerous. It increases the strength and stiffness of the material, making it more durable and resistant to deformation. Additionally, it improves the impact resistance of the material, reducing the likelihood of cracking or breaking under stress.

Fun Fact: Chopped carbon fiber can be added to a wide range of plastic materials to create high-performance composites. These composites are used in many industries, including aerospace, automotive, and sporting goods.

One example of chopped carbon fiber reinforced plastics is carbon fiber reinforced polymer (CFRP). CFRP is lightweight and has high strength and stiffness, making it an ideal material for aerospace and automotive applications. It is used in the construction of aircraft and Formula One racing cars, among other things.

| Properties of CFRP Compared to Steel | CFRP | Steel |

|---|---|---|

| Density (lbs/in^3) | 0.057-0.064 | 0.283 |

| Tensile Strength (ksi) | 300-700 | 58-79 |

| Young's Modulus (Msi) | 15-50 | 29 |

| Flexural Modulus (Msi) | 10-45 | 29 |

As shown in the table above, CFRP has a lower density and higher tensile and flexural strength compared to steel. These properties make it an ideal material for lightweight, high-strength applications.

The use of chopped carbon fiber in reinforced plastics is also prevalent in the sporting goods industry. Manufacturers of tennis rackets, bicycles, and golf clubs use reinforced plastics to achieve greater strength and stiffness while maintaining a lightweight design. The enhanced performance of the final product is a significant advantage for athletes and enthusiasts alike.

Chopped Carbon Fiber in Automotive Industry

The automotive industry is continuously improving vehicle performance, fuel efficiency, and safety. One of the ways this is achieved is through the use of chopped carbon fiber as a reinforcement material. The high strength and stiffness of the fiber make it an ideal material to achieve lightweight car components without compromising on rigidity.

The chopped carbon fiber is used for a wide range of car components, including bonnets, roofs, and spoilers. These components are more resilient to impact and less likely to deform in the event of a collision because of the carbon fiber reinforcement.

Additionally, chopped carbon fiber-reinforced plastic materials can be used in the interior of vehicles. They have a smooth finish, and their high dimensional stability means they retain their shape over time. Overall, the use of chopped carbon fiber in the automotive industry has produced safer, lighter, and more fuel-efficient cars.

Chopped Carbon Fiber in Aerospace Industry

The aerospace industry demands high-performance materials that are strong, lightweight, and durable. Chopped carbon fiber is an ideal composite reinforcement material that aligns with these requirements. In this section, we will explore the various applications of chopped carbon fiber in aerospace.

Aerospace Applications

Chopped carbon fiber is widely used in the aerospace industry for numerous applications, including:

| Application | Description |

|---|---|

| Flight Control Surfaces | Chopped carbon fiber is used to strengthen and reinforce flight control surfaces such as rudders, elevators, and ailerons. |

| Aircraft Interiors | Chopped carbon fiber is used to enhance the structural integrity of aircraft interiors, including cabin walls, flooring, and partitions. |

| Landing Gear | The landing gear of an aircraft undergoes significant stress during takeoff and landing. Chopped carbon fiber is utilized to reinforce the strength and durability of landing gear components. |

Chopped carbon fiber is also used for the manufacture of engine components such as fan blades and compressor stators.

Benefits

The benefits of using chopped carbon fiber in aerospace are numerous. These include:

- Reduced weight and increased strength, which improves fuel efficiency and lowers operating costs.

- Enhanced impact resistance, which improves safety and reliability.

- Improved stiffness and dimensional stability, which enhances performance and reduces maintenance costs.

- Resistance to corrosion and extreme temperatures, which enhances durability and longevity.

Chopped Carbon Fiber in Sporting Goods

The use of chopped carbon fiber has revolutionized the sporting goods industry. With its exceptional strength and lightweight, chopped carbon fiber is the perfect material for producing high-performance sporting equipment.

Some of the most common chopped carbon fiber applications in sporting goods include:

- Rackets for tennis, squash, and badminton: Chopped carbon fiber reinforcement in racket frames provides better control, accuracy, and speed during games.

- Bicycles: The use of chopped carbon fiber in bicycle frames helps reduce weight, increase durability, and improve performance.

- Golf clubs: Golf clubs reinforced with chopped carbon fiber shafts and heads offer improved swing speed, better ball control, and greater distance.

Chopped carbon fiber's unique properties make it ideal for the sporting industry. Its high strength-to-weight ratio can improve equipment performance, which can be critical in professional sports.

For example, in tennis, the frame of a racket made with chopped carbon fiber helps to deliver a more stable and focused tennis stroke. During intense gameplay, players can experience more fatigue if they use heavier rackets, meaning playing with a lighter racket will save energy and stamina. Chopped carbon fiber provides the perfect solution.

Andy Murray, a former world No. 1 tennis player, stated in an interview that "the lighter frames of a chopped carbon fiber racket allow him to hit more shots with less effort and give him an edge over his competitors."

The same properties that make chopped carbon fiber ideal for sporting goods also have some limitations. Sporting equipment manufacturers have to balance the desire for improved performance against the need for equipment to remain safe and durable. Extreme applications of chopped carbon fiber could lead to equipment breakage or malfunction.

Despite some of these limitations, chopped carbon fiber continues to offer unparalleled benefits in the sporting goods industry.

Chopped Carbon Fiber in Construction

The use of chopped carbon fiber in the construction industry has gained significant importance due to its unique properties of high strength, stiffness, and durability. It is added to cement and concrete mixtures for reinforcement, enhancing the structural integrity of the concrete.

Chopped carbon fiber is also used in the strengthening of structural elements like beams, columns, and walls. It offers superior performance to steel reinforcement, with its higher tensile strength and corrosion resistance.

| Applications | Benefits |

|---|---|

| Bridge construction | Enhanced durability and load-bearing capacity |

| Building facades | Improved resistance to weather and thermal stresses |

| Repair of damaged concrete | Enhanced bonding strength |

Chopped carbon fiber-reinforced composites provide excellent electrical conductivity and resistance to chemicals, making them ideal for use in coatings and adhesives, especially in harsh environments.

The suitability of chopped carbon fiber for construction applications has resulted in its wider acceptance in the industry. Its contribution to the development of high-performance and sustainable structures is immeasurable.

Conclusion

In conclusion, chopped carbon fiber is a versatile and essential component in many industries, including automotive, aerospace, construction, and sporting goods. Its ability to enhance the strength, stiffness, and impact resistance of composite materials makes it an ideal reinforcement material, and its properties significantly improve the performance of various products. Whether it is used in chopped strand mat or other forms, chopped carbon fiber stands out as a game-changer in the industry.

FAQ

What is chopped carbon fiber?

Chopped carbon fiber refers to short strands of carbon fiber that are generally between 3 to 20mm in length. These fibers are produced by cutting longer continuous carbon fiber strands into smaller pieces. They are widely used as a reinforcement material in the production of composite materials.

What are the properties of chopped carbon fiber?

Chopped carbon fiber possesses several desirable properties that make it a popular choice for reinforcement. These properties include high tensile strength, low weight, excellent stiffness, and resistance to corrosion and fatigue. Its high strength-to-weight ratio makes it ideal for improving the structural integrity and durability of composite materials.

What are the applications of chopped carbon fiber?

Chopped carbon fiber finds a diverse range of applications in various industries. It is commonly used in the production of automotive components, aerospace structures, sporting goods, and construction materials. It enhances the strength, stiffness, and impact resistance of composites, making them suitable for lightweight yet durable products.

What are the types of chopped carbon fiber available?

There are different types of chopped carbon fiber, including chopped carbon fiber strands and chopped carbon fiber mat. Carbon fiber chopped strands are individual fibers that are chopped into short lengths, while chopped carbon fiber mat consists of randomly-oriented carbon fibers held together by a binder. These types offer different reinforcement characteristics for composite materials.

How is chopped carbon fiber manufactured?

The manufacturing process of chopped carbon fiber involves several steps. Firstly, continuous carbon fiber strands are chopped into desired lengths using mechanical cutters. The chopped fibers are then treated with a sizing agent to improve their compatibility with the resin matrix. Finally, the fibers are carefully collected, packaged, and supplied to be used as reinforcement material in various industries.

How does chopped carbon fiber benefit the automotive industry?

Chopped carbon fiber is extensively used in the automotive industry due to its ability to enhance the performance and efficiency of vehicles. It helps in the production of lightweight components, leading to improved fuel economy. Additionally, chopped carbon fiber reinforcement offers increased strength and impact resistance, making vehicles safer and more durable.

How is chopped carbon fiber used in the aerospace industry?

Chopped carbon fiber plays a vital role in the aerospace industry. Its exceptional strength, low weight, and resistance to high temperatures make it suitable for various aerospace applications. It is used in the production of aircraft wings, fuselage structures, engine components, and other critical parts that require superior strength and durability.

What role does chopped carbon fiber play in sporting goods?

Chopped carbon fiber significantly improves the performance and durability of sporting goods. It is commonly used in manufacturing tennis rackets, bicycles, golf clubs, and other sports equipment. The addition of chopped carbon fiber reinforcement enhances the stiffness, strength, and responsiveness of these products, enabling athletes to achieve better results.

In which ways is chopped carbon fiber used in the construction industry?

Chopped carbon fiber is utilized in the construction industry for various purposes. It is employed in the reinforcement of concrete structures, providing increased strength and crack resistance. It is also used in strengthening structural elements such as beams and columns, allowing for improved load-bearing capacity. Chopped carbon fiber offers a reliable and lightweight solution for reinforcing and fortifying construction materials.