Carbon Fiber vs Titanium: Strength & Weight Battle

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

When it comes to high-performance applications, two materials that regularly make headlines are carbon fiber and titanium. While both are known for their strength and durability, they also have their unique properties that set them apart. In this article, we will compare the strength and weight of carbon fiber and titanium and evaluate how they perform in various applications.

Key Takeaways

- Carbon fiber and titanium are two high-performance materials known for their strength and durability.

- Both materials have advantages and drawbacks, and choosing between them depends on specific requirements.

- Strength and weight are critical aspects to consider in selecting the right material for various applications.

- Durability and price also play a significant role in determining the suitability of carbon fiber or titanium for a particular use case.

- Understanding the applications where each material excels is essential in making an informed decision.

Understanding Carbon Fiber

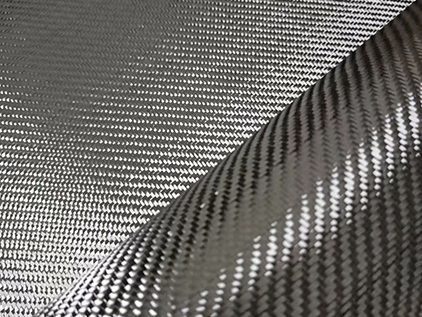

Carbon fiber is a material that has gained enormous popularity in recent years due to its remarkable strength, stiffness, and lightweight characteristics. It is made up of thin strands of carbon woven together to create a fabric-like material that can be formed into various shapes and sizes.

One of the main advantages of carbon fiber is its strength-to-weight ratio. Carbon fiber is much stronger than steel, yet is significantly lighter. This makes it an ideal material for high-performance applications, such as aerospace and motorsports.

However, carbon fiber also has its drawbacks. It is more brittle than metals like steel and aluminum, making it susceptible to cracking and breaking under stress. Additionally, carbon fiber can be expensive and time-consuming to produce compared to other materials.

Despite these limitations, carbon fiber is used extensively in various industries such as aviation, automotive, and sporting equipment. It is commonly found in applications such as aircraft wings, race car bodies, and high-end bicycles. Due to its unique properties, carbon fiber offers designers and engineers a range of possibilities that are not achievable with traditional materials.

Titanium: An Overview

Titanium is a lightweight yet robust metal known for its high strength-to-weight ratio. It is corrosion-resistant and biocompatible, making it ideal for medical implants. Titanium is also extensively used in the aerospace and automotive industries, where the need for light and sturdy materials is critical.

One of the main benefits of titanium is its exceptional strength. It has a higher tensile strength than steel, making it highly resistant to deformation. Additionally, titanium is around 40% lighter than steel and more than twice as strong as aluminum, making it an ideal material for high-performance applications.

However, there are also some drawbacks to using titanium. For instance, it is more expensive than most metals due to the complex extraction process and limited availability. Furthermore, titanium is challenging to weld because it reacts strongly with air, nitrogen, and other gases at high temperatures.

Applications of Titanium

Titanium has a diverse range of applications, thanks to its unique properties. Here are some of the areas where titanium finds its use:

- Aerospace industry - used for making engine parts, frames, and structural components in airplanes and spacecraft.

- Medical implants - due to its biocompatibility, titanium is used for making hip replacements, dental implants, and other medical implants.

- Sports equipment - titanium alloys are used to make golf club heads, bicycle frames, and tennis rackets.

- Automotive parts - titanium is used for making valves, connecting rods, and exhaust systems due to its temperature and corrosion resistance.

It is also used in various other industries, including architecture, marine engineering, and chemical processing.

Strength Comparison: Carbon Fiber vs Titanium

When it comes to high-performance applications, strength is a crucial metric that can make all the difference. Carbon fiber and titanium are both known for their impressive strength properties, but how do they compare?

| Material | Strength (MPa) |

|---|---|

| Carbon Fiber | 1,000 - 3,000 |

| Titanium | 880 - 1,200 |

As seen from the table, carbon fiber outperforms titanium in terms of strength, with a maximum strength nearly triple that of titanium. However, it's important to note that strength is not the only factor in play when it comes to material performance.

Carbon fiber's superior strength-to-weight ratio makes it an ideal choice for applications where weight is a significant concern, such as aerospace and automotive industries. Meanwhile, titanium's unique properties make it a preferred option for medical implants and other applications where biocompatibility is necessary.

Ultimately, the choice between carbon fiber and titanium will depend on the specifics of the given application and the design priorities and constraints at play. However, when assessing strength as a primary consideration for material selection, carbon fiber is the clear winner.

Weight Comparison: Carbon Fiber vs Titanium

When it comes to weight, carbon fiber and titanium are both known for their lightweight properties. However, which material is lighter?

Carbon fiber is the lighter of the two materials. It has a specific weight of 1.6 g/cm³, while titanium has a specific weight of 4.5 g/cm³. This means that for applications that prioritize weight reduction, carbon fiber may be the better option.

However, it's important to note that weight isn't the only factor to consider when it comes to performance. Titanium may not be as light as carbon fiber, but it is still significantly lighter than many other metals commonly used in high-performance applications.

Carbon Fiber vs Titanium Weight Comparison Table

| Material | Specific Weight (g/cm³) |

|---|---|

| Carbon Fiber | 1.6 |

| Titanium | 4.5 |

Overall, when it comes to weight, carbon fiber has the upper hand. However, the choice between the two materials will ultimately depend on the specific application and its performance requirements.

Price Considerations: Carbon Fiber vs Titanium

When it comes to choosing between carbon fiber and titanium, price is a significant factor to consider. While both materials offer high performance and durability, one might exceed the other in terms of affordability.

Carbon fiber is generally more expensive than titanium due to the manufacturing process and the raw materials used. It requires specific machinery for production, which adds to the overall cost. In addition, carbon fiber composites require an epoxy resin to hold the fibers together, further increasing the cost.

In contrast, titanium is relatively cheaper than carbon fiber, but still expensive when compared to other metals. The complex manufacturing process and high melting point of titanium contribute to its price. However, it offers excellent value for money, considering its strength, durability, and corrosion resistance.

| Material | Average Price Range ($ per pound) |

|---|---|

| Carbon Fiber | $10-$30 |

| Titanium | $5-$20 |

As seen in the table above, titanium is available at a lower price range than carbon fiber, making it a more affordable option for many buyers. However, it's important to note that prices can vary depending on factors such as quality, quantity, and supplier.

Ultimately, the price difference between carbon fiber and titanium varies depending on the specific application and requirements. It's important to research and consider all factors before making a purchase decision.

Durability: Carbon Fiber vs Titanium

When it comes to high-performance applications, durability is key. Both carbon fiber and titanium are known for their exceptional strength, but which material is more durable?

Carbon fiber is renowned for its resistance to corrosion and fatigue, which makes it an excellent choice for aerospace and automotive applications. However, it is more prone to scratches and impact damage than titanium, which can compromise its structural integrity over time.

Titanium, on the other hand, is highly resistant to wear and tear, making it the preferred choice for medical implants and high-stress industrial applications. It is also more ductile than carbon fiber, allowing it to withstand severe impacts without cracking or breaking.

In terms of overall durability, titanium may have the upper hand over carbon fiber due to its superior resistance to impact and wear. However, carbon fiber's resistance to corrosion and fatigue makes it a more suitable choice for certain applications that require exceptional corrosion resistance.

Impact Resistance

Impact resistance is a crucial factor in determining a material's durability. Carbon fiber has a high tensile strength, which means it can withstand a significant amount of force without breaking. However, it is also brittle, which means it may crack or break under severe impacts.

Titanium, on the other hand, is highly ductile and has a better ability to absorb impact energy without breaking or cracking. This makes it a more reliable choice for applications that require impact resistance, such as aircraft components and sports equipment.

Wear Resistance

Wear resistance is another important factor in determining a material's durability. Carbon fiber has a smooth surface that reduces friction, making it resistant to everyday wear and tear. However, it can get scratched more easily than titanium, which can compromise its structural integrity over time.

Titanium, on the other hand, has a strong surface layer that makes it highly resistant to scratching and wear. This makes it a more suitable choice for applications that require exceptional wear resistance, such as medical implants and high-stress industrial components.

Application Comparison: Carbon Fiber vs Titanium

Carbon fiber and titanium are both high-performance materials that have found their way into various fields. While there are always multiple factors that dictate the choice of material, understanding where each of them shines and where it can be limited can be crucial in determining the most suitable one for your needs.

Automotive Industry

Carbon fiber massively benefits the automotive sector, as it is lightweight and strong, enhancing fuel efficiency, and overall, the car's performance. In contrast, titanium is more commonly used in parts requiring high strength and durability, such as exhaust system components.

Aviation Industry

Both carbon fiber and titanium are popular in aerospace engineering thanks to their properties, though not equally distributed between the various components. Titanium can withstand high temperatures and stresses, making it suitable for parts exposed to high heat. Carbon fiber, on the other hand, is light but strong, ideal for exterior panels and structural support.

Construction Industry

Carbon fiber is often used in construction to reinforce concrete structures, providing much-needed strength compared to traditional concrete reinforcements. In comparison, titanium's high cost might limit its usage in construction, but it is commonly used in specialized structural applications, such as underground piping.

Medical Industry

Titanium's unique biocompatibility with the human body makes it the go-to choice for medical implants, including heart valves, artificial hips, and dental implants. Carbon fiber has also found its applications in the medical field, particularly in orthopedic external support devices, like braces and back supports.

Sports Equipment

Carbon fiber's combination of strength and lightness made it popular in various forms of sports equipment, from skis and bicycles to fishing rods and baseball bats. Titanium is less commonly used in sports equipment but can be found in high-performance golf clubs and watches.

Marine Industry

Carbon fiber's low weight and high strength have made it a popular choice for boat building. However, titanium's high corrosion resistance and durability make it ideal for critical components like propellers, shafts, and valves that are heavily exposed to the corrosive sea environment.

Strength-to-Weight Ratio: Carbon Fiber vs Titanium

When it comes to high-performance applications, a material's strength-to-weight ratio is a critical consideration. Carbon fiber and titanium are two materials that excel in this aspect. Carbon fiber is known for its high strength-to-weight ratio, making it a popular choice in industries such as aerospace, automotive, and sports equipment. Titanium, on the other hand, is also renowned for its strength and lightness, and is widely used in applications such as medical implants and aerospace components.

But how do these materials compare when it comes to the strength-to-weight ratio?

| Material | Strength-to-Weight Ratio |

|---|---|

| Carbon Fiber | Stronger than steel, yet lighter than aluminum |

| Titanium | Comparable to steel, yet about 40% lighter |

From the table above, we can see that both carbon fiber and titanium offer excellent strength-to-weight ratios. Carbon fiber is stronger than steel but lighter than aluminum, which makes it an ideal choice in weight-sensitive applications that require high strength. On the other hand, titanium has a strength-to-weight ratio comparable to steel but is significantly lighter in weight, providing an optimal balance between strength and weight.

Conclusion

When it comes to choosing between carbon fiber and titanium, there is no clear winner. Both materials have unique properties that make them suitable for high-performance applications.

Carbon fiber has a high strength-to-weight ratio, making it perfect for industries that require lightweight yet robust materials, such as aerospace and automotive. It also has excellent corrosion resistance and can withstand exposure to harsh chemicals, making it popular in sporting goods and consumer electronics.

Titanium, on the other hand, is renowned for its superior strength and durability, making it ideal for industries that demand rugged materials, such as medical implants, military equipment, and industrial machinery. It also boasts exceptional heat resistance and can withstand extreme temperatures, making it a favorite in the aerospace and marine industries.

Price is another factor to consider. Carbon fiber is generally more expensive than titanium, but it offers more design flexibility and can produce complex shapes and structures. Titanium, on the other hand, is more affordable and readily available, making it an attractive option for many industries.

To summarize, the decision between carbon fiber and titanium comes down to specific requirements, such as strength, weight, durability, and budget. Understanding the advantages and disadvantages of each material is critical in making an informed decision.

Conclusion

After weighing the strengths and weaknesses of carbon fiber and titanium, it's clear that both materials have their advantages and disadvantages. Carbon fiber is lighter and more affordable, making it an excellent choice for applications where weight is a significant factor, like the aerospace industry. On the other hand, titanium is stronger and more durable, making it an ideal material for applications where strength is crucial, such as medical implants.

It's essential to consider the specific requirements of your project carefully. If you need a lightweight material that is relatively affordable and easy to work with, then carbon fiber is an excellent choice. However, if you require a material that has exceptional strength and durability, then titanium is the way to go. Ultimately, the choice between carbon fiber and titanium depends on the application.

We hope that this article has provided you with the information you need to make an informed decision when choosing between carbon fiber and titanium. While both materials have their strengths and weaknesses, understanding their unique properties will help you select the right material for your project.