Kevlar Carbon Fiber VS. Carbon Fiber

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

Carbon Fiber and Kevlar Carbon Fiber are two of the most sought-after materials in various industries. Both possess exceptional qualities and unique advantages, but they also have their fair share of drawbacks. In this article, we will delve into the differences between Carbon Fiber and Kevlar Carbon Fiber, examine their respective pros and cons, and explore the industries where they are ideal for use.

Key Takeaways

- Carbon Fiber and Aromatic are two of the most popular materials used in various industries.

- Carbon Fiber is renowned for its strength, stiffness, and low weight, while Kevlar Carbon Fiber offers better impact resistance and durability.

- Carbon Fiber is suitable for industries such as aerospace, automotive, and sports equipment manufacturing, while Kevlar Carbon Fiber is ideal for protective gear and high-performance racing components.

- Carbon Fiber can be brittle and prone to damage from impacts, while Aromatic is not as stiff as pure carbon fiber and can be more expensive.

- The choice between Carbon Fiber and Kevlar Carbon Fiber depends on the specific requirements of your project or application.

What is Carbon Fiber?

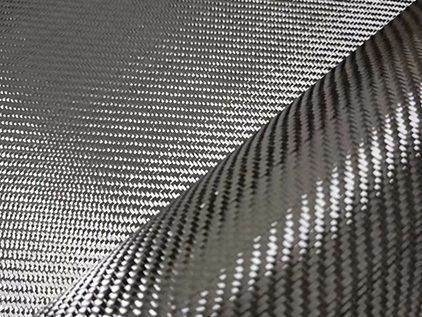

Carbon Fiber is a material made from thin carbon strands that are woven together to form a strong and lightweight fabric. The material is composed of long, thin fibers of carbon that are bound together with resin and heat. Carbon Fiber is known for its exceptional strength-to-weight ratio, making it a popular choice in industries where strength and lightness are crucial.

The composition of Carbon Fiber gives it unique properties that make it ideal for a range of applications. The material is incredibly strong, with a tensile strength that is higher than that of steel. It is also exceptionally stiff, meaning it can resist deformation under stress. Additionally, Carbon Fiber is lightweight, with a density that is significantly lower than that of steel or aluminum.

The combination of strength, stiffness, and lightweight properties make Carbon Fiber a popular choice across a broad range of industries. The material is widely used in aerospace, automotive, and sports equipment manufacturing, among others.

What is Aromatic?

Aromatic, also known as Kevlar Aramid Carbon Fiber, is a hybrid material made by combining carbon fiber and Kevlar aramid fibers. The result is a material that retains the lightweight properties of carbon fiber while also providing enhanced impact resistance and durability. This combination makes Kevlar Carbon Fiber an excellent choice for applications that require toughness and protection against impacts.

The composition of Aromatic consists of around 55% carbon fiber and 45% Kevlar aramid fiber, resulting in a material that possesses the best properties of both materials. Carbon fiber provides the stiffness, strength, and lightweight properties, while Kevlar aramid fiber provides the impact resistance and durability.

Aromatic Composition Table

| Material | Percentage |

|---|---|

| Carbon Fiber | 55% |

| Kevlar Aramid Fiber | 45% |

The properties of Kevlar Carbon Fiber make it an ideal material for a variety of industries. Its durability and impact resistance make it a popular choice for protective gear and armor. It is also commonly used in high-performance racing components that require both strength and lightweight properties.

The impact resistance of Aromatic is so impressive that it is even used in the construction of some buildings to reinforce concrete. Its durability makes it resistant to abrasions, cuts, and punctures, making it an ideal material for applications where toughness is essential.

"Aromatic offers the perfect combination of strength and durability, making it an excellent choice for protective gear and high-performance racing components."

Overall, Aromatic is a hybrid material that offers unique properties that cannot be achieved with one material alone. Its exceptional durability and impact resistance make it an attractive option for applications where toughness and protection are essential.

Differences Between Carbon Fiber and Aromatic

Carbon Fiber and aromatic are two popular materials in the manufacturing industry, known for their strength, durability, and lightweight properties. While both have their unique advantages, there are also notable differences between the two.

| Material | Strength | Stiffness | Impact Resistance | Weight | Cost |

|---|---|---|---|---|---|

| Carbon Fiber | High | High | Low | Lightweight | Relatively High |

| Aromatic | Moderate to High | Moderate | High | Lightweight | Higher than Carbon Fiber |

Carbon Fiber excels in terms of strength and stiffness, making it an ideal choice for applications that require high structural integrity. Its lightweight properties also make it a popular choice in industries where weight reduction is critical, such as aerospace and sports equipment manufacturing.

However, Carbon Fiber can be brittle and vulnerable to impact damage, requiring careful handling and maintenance. It is also relatively expensive, making it less suitable for cost-sensitive projects.

Kevlar Carbon Fiber, on the other hand, provides improved impact resistance and durability while still maintaining the lightweight properties of carbon fiber. This makes it an excellent choice for applications that require superior toughness and protection against impacts, such as body armor and high-performance racing components.

However, Kevlar Carbon Fiber is not as stiff as pure carbon fiber, limiting its use in applications where high stiffness is critical. It is also more expensive than traditional carbon fiber, making it less suitable for cost-sensitive projects.

In conclusion, the choice between Carbon Fiber and Kevlar Carbon Fiber depends on the specific requirements of your project or application. Consider the pros and cons carefully to determine the best fit for your needs.

Pros of Carbon Fiber

Carbon Fiber offers a range of advantages over other materials, making it an excellent choice for a variety of industries. Here are some of the pros of carbon fiber:

- High strength: Carbon fiber is known for its exceptional strength-to-weight ratio, making it stronger than many other materials in the same weight class.

- Low weight: Carbon fiber is incredibly lightweight, which is especially useful in industries where weight is a critical factor.

- Excellent stiffness: Carbon fiber is very stiff, which makes it an ideal choice in applications where rigidity is essential.

- Resistance to corrosion: Carbon fiber is highly resistant to corrosion, making it an ideal choice for outdoor and marine applications.

- Extreme temperature resistance: Carbon fiber can withstand high and low temperatures, making it ideal for use in high-temperature environments such as motorsports and aerospace.

In addition to these advantages, carbon fiber is also a highly customizable material. It can be molded into complex shapes, allowing for the creation of unique and innovative designs.

Pros of Aromatic

Aromaticoffers a unique set of advantages that make it an ideal choice for a range of applications, including:

- Enhanced impact resistance: Kevlar aramid fibers provide excellent protection against impacts, making Aromatic a popular choice for body armor, protective gear, and high-performance racing components.

- Improved durability: Aromatic is designed to withstand prolonged exposure to harsh conditions, including high temperatures and corrosive substances.

- Reduced weight: While Aromatic is not as lightweight as pure carbon fiber, it is still significantly lighter than many other materials commonly used in industrial applications.

- Easy to work with: Aromatic can be easily cut, shaped, and molded to fit a wide range of applications.

- Great aesthetic appeal: Aromatic has a unique look and texture that makes it a popular choice for high-end automotive and sports equipment manufacturing.

Overall, Kevlar Carbon Fiber is an excellent choice for applications that require superior toughness, durability, and impact resistance. If you need a material that can hold up to harsh conditions, Kevlar Carbon Fiber is the way to go.

Cons of Carbon Fiber

Although Carbon Fiber offers many advantages, it is not without its drawbacks. One of the main disadvantages is its relatively high cost compared to other materials. It is also brittle and prone to damage from impacts, requiring careful handling and maintenance to prevent cracking, delamination, or other damage.

Another disadvantage of Carbon Fiber is its susceptibility to damage from UV radiation, which can degrade the resin matrix and weaken the overall structure. This can be mitigated through the use of UV-resistant coatings, but it adds an additional cost and maintenance requirement.

"Carbon Fiber is a great material, but it requires a lot of care and attention to maintain its performance and longevity. It's not something you can just set and forget." - John Smith, carbon fiber manufacturing expert.

Finally, although Carbon Fiber is a lightweight material, it is not as impact-resistant as some other materials, such as Kevlar Carbon Fiber. This means that it may not be the best choice for applications where impact resistance is critical.

Cons of Kevlar Carbon Fiber

While Kevlar Carbon Fiber offers several advantages, there are also some disadvantages to consider.

One of the main disadvantages is its lack of stiffness compared to pure carbon fiber. This can limit its use in applications where high stiffness is critical.

"The hybrid nature of Kevlar Carbon Fiber means it sacrifices some of the stiffness of carbon fiber for added impact resistance and durability."

Aromatic is also more expensive than traditional carbon fiber, making it less suitable for cost-sensitive projects. However, this cost may be justified in applications that require the enhanced impact resistance and durability that Aromatic can provide.

Another potential drawback of Aromatic is that it can be more challenging to work with than pure carbon fiber. The Kevlar fibers can be more difficult to cut and manipulate, which can increase manufacturing time and costs.

It's worth noting that Aromatic, like pure carbon fiber, can also be prone to damage from impacts. However, its hybrid composition means it may be able to withstand impacts better than pure carbon fiber.

Overall, when deciding between Kevlar Carbon Fiber and pure carbon fiber, it's essential to weigh the pros and cons carefully to determine which material is best suited for your specific needs and requirements.

Conclusion

Deciding between Carbon Fiber and Aromatic depends on the specific needs of your project. If you prioritize strength, stiffness, and low weight, then carbon fiber is the better choice. It's perfect for use in industries such as aerospace, automotive, and sports equipment manufacturing.

On the other hand, if you require enhanced impact resistance and durability, then Kevlar Carbon Fiber is the way to go. It's an excellent choice for applications such as body armor, protective gear, and high-performance racing components.

When considering which material to use, take the pros and cons into account to determine the best fit for your project. Keep in mind that carbon fiber offers exceptional strength and stiffness, while Aromatic provides better impact resistance and durability. Take the time to evaluate the specific needs of your project to make an informed decision.

The choice between Carbon Fiber and Aromatic will ultimately depend on the specific requirements of your project. Consider the pros and cons carefully to determine the best fit for your needs. With the right material, your project will be sure to succeed!

Our Product: https://ictfibers.com/product/aromatic-carbon-fiber-cloth/

FAQ

What are the differences between Carbon Fiber and Kevlar Carbon Fiber?

Carbon Fiber is known for its superior strength and stiffness, while aromatic offers enhanced impact resistance and durability.

What is Carbon Fiber made of?

Carbon Fiber is composed of thin carbon strands that are woven together to create a strong and lightweight fabric.

What is Kevlar Carbon Fiber?

Kevlar Carbon Fiber is a hybrid material that combines carbon fiber with Kevlar aramid fibers, providing improved impact resistance and durability.

What are the advantages of Carbon Fiber?

Carbon Fiber is highly resistant to corrosion, has excellent stiffness, and offers a low weight-to-strength ratio, making it ideal for aerospace, automotive, and sports equipment industries.

What are the advantages of Kevlar Carbon Fiber?

Kevlar Carbon Fiber combines the lightweight properties of carbon fiber with enhanced impact resistance and durability, making it perfect for body armor, protective gear, and high-performance racing components.

What are the disadvantages of Carbon Fiber?

Carbon Fiber can be brittle and prone to damage from impacts. It also tends to be more expensive compared to other materials.

What are the disadvantages of Kevlar Carbon Fiber?

Kevlar Carbon Fiber is not as stiff as pure carbon fiber, limiting its use in applications where high stiffness is critical. It is also generally more expensive than traditional carbon fiber.

Which material is best suited for my project?

The choice between Carbon Fiber and Kevlar Carbon Fiber depends on your project's specific requirements. If you prioritize strength, stiffness, and low weight, carbon fiber is the ideal choice. However, if enhanced impact resistance and durability are crucial, Kevlar Carbon Fiber is the better option. Consider the pros and cons carefully to determine the best fit for your needs.