Carbon Fiber vs Fiberglass: Key Differences

-

Your Composites Expert Carbon Fiber Materials&Products

Your Composites Expert Carbon Fiber Materials&Products -

-1.png?width=686&height=617) Your Composites Expert Aramid Fiber Materials&Products

Your Composites Expert Aramid Fiber Materials&Products -

Your Composites Expert UHMWPE Materials&Products

Your Composites Expert UHMWPE Materials&Products -

Your Composites Expert Fiberglass Materials&Products

Your Composites Expert Fiberglass Materials&Products -

Your Composites ExpertPBO Materials&Products

Your Composites ExpertPBO Materials&Products -

Your Composites Expert Basalt Materials&Products

Your Composites Expert Basalt Materials&Products

When it comes to materials commonly used in construction, manufacturing, and various other industries, two popular options are carbon fiber and fiberglass. While both materials are lightweight and sturdy, they have unique properties that differentiate one from the other.

Understanding these differences is crucial in choosing the right material for your project needs. In this article, we will explore the main differences between carbon fiber and fiberglass, their properties, and the industries where each is commonly utilized. We will also discuss the considerations that can help you determine which material is best suited for your project.

Key Takeaways:

- Carbon fiber and fiberglass are both lightweight and sturdy materials.

- Carbon fiber is stronger and more durable than fiberglass, making it more suitable for high-performance applications.

- Fiberglass is versatile and relatively cost-effective, making it an excellent choice for a wide range of applications.

- When choosing between carbon fiber and fiberglass, consider your project needs, budget, and performance requirements.

- Ultimately, the choice between carbon fiber and fiberglass will depend on the specific project requirements and industry standards.

Understanding Carbon Fiber

Carbon Fiber Cloth

Carbon fiber is a lightweight, high-strength composite material that is made up of carbon fibers and a polymer matrix. Compared to fiberglass, carbon fiber has a higher strength-to-weight ratio, meaning it can withstand greater loads while still being lightweight.

One of the many advantages of carbon fiber over fiberglass is its exceptional stiffness, which makes it ideal for high-performance applications such as aerospace, automotive, and sports equipment. Its excellent durability and resistance to temperatures, chemicals, and UV rays also make it a popular choice for construction purposes.

The table below outlines the differences in properties between carbon fiber and fiberglass:

As shown in the table, carbon fiber exhibits higher strength, stiffness, and fatigue resistance than fiberglass, while also being more lightweight and corrosion-resistant. However, on the other hand, fiberglass is more affordable and flexible, making it a popular choice for less demanding applications.

The advantages of carbon fiber over fiberglass are significant, and as technology continues to advance, we can expect to see an increasing number of products incorporating this miracle material.

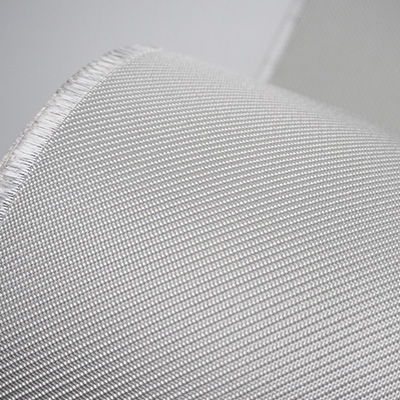

Unveiling Fiberglass

Fiberglass Cloth

Fiberglass is a widely used composite material that consists of glass fibers and a polymer resin. It is a popular alternative to carbon fiber due to its versatility and cost-effectiveness. While not as strong as carbon fiber, fiberglass is still a highly durable material that can withstand a range of environmental factors.

Fiberglass shares several similarities with carbon fiber but also has some critical differences. Both materials are composites that combine a reinforcement material with a resin to increase strength and durability. However, carbon fiber has much greater strength and is lighter than fiberglass, making it more suitable for high-performance applications like aerospace.

Properties of Fiberglass

| Property | Fiberglass |

|---|---|

| Tensile Strength | 4,600 - 6,200 MPa |

| Density | 1.5 - 2.0 g/cm3 |

| Flexural Strength | 100 - 400 MPa |

| Impact Strength | 1.0 - 16 J/m |

Fiberglass is well-suited for applications in industries like automotive, marine, and construction. It is commonly used in the construction of boat hulls, as well as for water tanks and pipes. Fiberglass is also popular for streetlights and traffic signals due to its high durability and resistance to weathering.

"Fiberglass has been a game-changer for numerous industries, offering a durable, versatile, and cost-effective alternative to traditional materials."

While carbon fiber is more often used in high-performance applications due to its superior strength and lightweight nature, fiberglass remains a popular material across various industries. The choice between carbon fiber and fiberglass will depend on the specific needs of a project and the priorities of the individual or business.

In the next section, we will explore the various applications of carbon fiber and compare them to those of fiberglass.

Uses of Carbon Fiber

Carbon fiber and fiberglass are widely used in various industries due to their unique properties. However, carbon fiber is preferred over fiberglass for its exceptional strength, lightweight nature, and durability. The following are some of the key industries that utilize carbon fiber:

- Aerospace: Carbon fiber is used extensively in aerospace applications due to its high strength-to-weight ratio, making it an ideal material for parts such as wings, fuselage, and tail sections.

- Automotive: Carbon fiber's lightweight nature makes it an attractive option for automotive parts, such as body panels, wheels, and interior trim. It also offers improved fuel efficiency.

- Sports Equipment: Carbon fiber is used in sports equipment, such as racing bikes, tennis rackets, and golf clubs, due to its strength, flexibility, and lightweight nature.

- Construction: Carbon fiber is used in construction to reinforce concrete and steel structures, providing increased strength and durability.

While fiberglass is not as strong or as lightweight as carbon fiber, it is a versatile material that is widely used in various industries:

- Construction: Fiberglass is commonly used in construction for insulation, roofing, and as a strengthening material for concrete.

- Marine: Fiberglass is used in boat hulls, decks, and interiors due to its durability and resistance to moisture.

- Automotive: Fiberglass is used in automotive parts, such as body panels, due to its affordability and ease of manufacturing.

- Household Products: Fiberglass is used in various household products, such as insulation, furniture, and appliances.

In the comparison of carbon fiber vs. fiberglass, it is clear that both materials have different advantages and weaknesses that are specific to different applications. However, carbon fiber is preferred in industries that require a high level of strength, lightness, and durability, while fiberglass is often used in applications that require versatility and cost-effectiveness.

A Comparison of Carbon Fiber and Fiberglass Uses

| Industry | Carbon Fiber Uses | Fiberglass Uses |

|---|---|---|

| Aerospace | Wings, fuselage, tail sections | Aircraft interiors, insulation |

| Automotive | Body panels, wheels, interior trim | Body panels |

| Sports Equipment | Racing bikes, tennis rackets, golf clubs | Bicycles, helmets, paddles |

| Construction | Rebar, bridges, structural beams | Insulation, roofing, concrete reinforcement, pipes |

| Marine | Boat hulls, masts, sails | Shower stalls, tanks, decks |

| Household Products | Vacuum cleaner poles, lamps, appliances | Tubs, shower stalls, insulation |

Applications of Fiberglass

While fiberglass may not be as strong or lightweight as carbon fiber, it is still a versatile material with a wide range of uses. One of its major advantages is its cost-effectiveness, making it a popular choice in industries where budgets are a concern.

In the construction industry, fiberglass is used for insulation, roofing, and siding. Its durability and resistance to moisture make it an ideal material for outdoor applications. In marine applications, fiberglass is used for boat hulls, decks, and furniture due to its resistance to water and salt corrosion.

Fiberglass is also commonly found in automotive parts, such as body panels and bumpers, due to its ability to be easily molded into complex shapes. Additionally, fiberglass is used in household products like bathtubs, shower stalls, and even furniture.

While fiberglass may not have the same strength-to-weight ratio as carbon fiber, its versatility makes it a valuable material in many industries.

Performance Comparison

When comparing carbon fiber to fiberglass, it's essential to understand the differences in their properties and performance.

Strength: Carbon fiber is known for its exceptional strength and stiffness, making it an ideal material for high-performance applications. Fiberglass, on the other hand, is not as strong but is more flexible, making it suitable for applications that require a certain degree of flexibility.

Weight: Carbon fiber is lighter than fiberglass, which is why it is widely used in industries like aerospace and automotive, where weight is a crucial factor for performance.

Environmental factors: Both materials have their limitations when it comes to exposure to environmental factors. Carbon fiber is susceptible to UV radiation, and prolonged exposure can impact its performance. In contrast, fiberglass is not as prone to damage from UV rays but can be affected by moisture and heat over time.

Overall, carbon fiber offers several advantages over fiberglass, such as higher strength to weight ratio, better fatigue resistance, and more extensive design flexibility. However, it is also a more expensive material than fiberglass, which can be a significant factor in certain projects.

Considerations for Choosing

When deciding between carbon fiber and fiberglass, several factors need to be considered to make an informed decision.

Project requirements

The first consideration should be the specific requirements of the project at hand. Consider factors such as strength, weight, durability, and flexibility. If the project requires high strength and low weight, carbon fiber may be a better option. On the other hand, if a more cost-effective solution is needed, fiberglass may be a better choice.

Budget

Another important factor is budget. Carbon fiber is generally more expensive than fiberglass due to its superior properties. If cost is a significant concern, fiberglass may be the more practical option.

Performance needs

Performance needs should also be taken into account. Carbon fiber may be the preferred option if a high-performance solution is required, but this should be weighed against the cost implications. Specifically, consider the performance requirements of the project and whether carbon fiber's advantages justify its higher cost.

Industry standards

Industry standards should also be considered when choosing between the two materials. Depending on the type of project, there may be established protocols for the use of certain materials. Always check industry standards before making a decision.

Overall, the choice between carbon fiber and fiberglass depends on the specific project requirements, performance needs, budget, and industry standards. Both materials have their pros and cons, and it's essential to weigh these carefully before making a final decision.

Which Is Best for Your Project Needs

After examining the properties and differences between carbon fiber and fiberglass, you may be wondering which material is best suited for your project needs. The decision ultimately depends on the specific requirements and goals of your project.

If the priority is strength, lightweight, and durability, carbon fiber is often the preferred choice. It's ideal for applications in aerospace, construction, and sports equipment where high performance is critical. On the other hand, fiberglass is an excellent alternative for applications in marine, automotive, and household products where cost-effectiveness and versatility are more important.

Consider the cost, performance requirements, and industry standards when choosing between carbon fiber and fiberglass. Be sure to consult with experts to determine the best option for your specific project needs.

Some key questions to ask when choosing between carbon fiber and fiberglass: Which application is your project for? What are the performance needs of your project? What is your project's budget? What are the industry standards for your project's application? Once you have considered these factors, you will have a clearer idea of which material is best suited for your project needs.

About Impact Materials

Impact Materials is a prominent carbon fiber factory based in China. With years of experience and expertise in the industry, we have earned a leading reputation for providing top-quality carbon fiber products at affordable prices.

As a company committed to sustainability, we strive to reduce our carbon footprint by using eco-friendly materials and implementing environmentally conscious practices in our manufacturing processes. Our commitment to sustainability extends to our customers as we work to reduce the environmental impact of their products as well.

At Impact Materials, we value our customers and aim to provide exceptional customer service from start to finish. We strive to develop long-term partnerships with our clients, understanding their needs and offering customized solutions that fit their individual requirements.

Our team of highly skilled professionals uses state-of-the-art technology to produce carbon fiber products of the highest quality that meet or exceed industry standards. From aerospace and automotive to sports and recreation, we provide carbon fiber solutions for a variety of industries and applications.

If you need carbon fiber solution, please contact us at info@ictfibers.com or click here.

Conclusion

When it comes to selecting between carbon fiber vs fiberglass, several factors come into play. Each material has its unique strengths and weaknesses, making them suitable for different project needs.

Carbon fiber offers superior strength, lightweight, and durability, making it an ideal choice for high-performance products in aerospace, automotive, and sporting goods industries. On the other hand, fiberglass is more cost-effective, versatile and is commonly used in construction, marine, and household products industries.

Choosing between carbon fiber and fiberglass requires a careful analysis of your project's requirements, budget, and performance needs. At the end of the day, the material you choose can significantly affect the outcome of your project.

We hope this article has shed some light on carbon fiber vs fiberglass, highlighting the similarities, differences, applications, and factors to consider when choosing between these two materials.

Keep in mind that both carbon fiber and fiberglass have unique properties that make them stand out. By analyzing the project specifications and comparing the benefits each material has to offer, you can make an informed decision on which one is best suited for your needs.

Whether you choose carbon fiber or fiberglass, make sure to follow industry standards and guidelines to ensure optimal performance and safety.