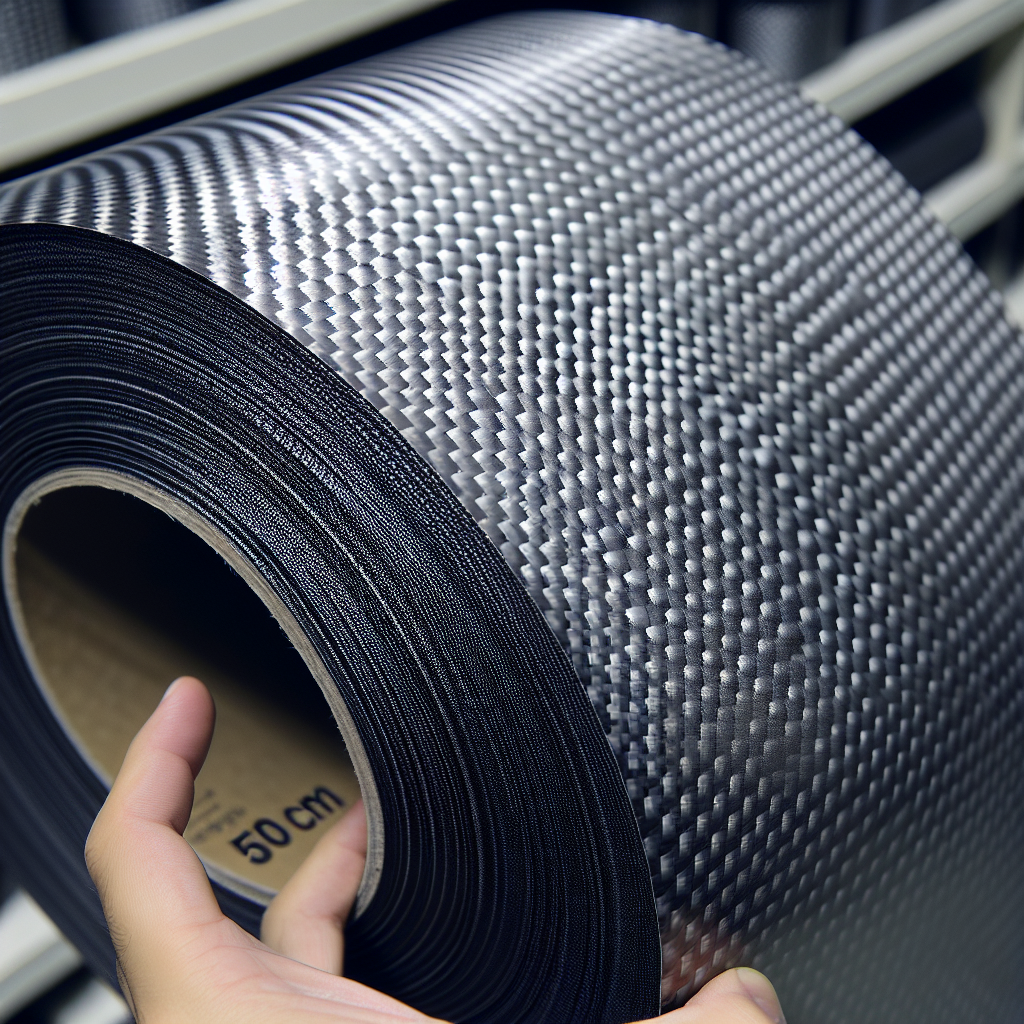

Carbon Fiber Fabric 50CM Width 12K 300G Carbon Cloth for Enforcement Carbon Fiber Fabric 12k Roll

-

Table of Contents

“Strong, lightweight, and versatile – elevate your projects with our 12K 300G carbon fiber fabric roll.”

Introduction

Carbon fiber fabric is a type of reinforced material that is made from carbon fibers. It is known for its high strength, low weight, and durability, making it a popular choice in various industries such as aerospace, automotive, and sports equipment. The Carbon Fiber Fabric 50CM Width 12K 300G Carbon Cloth for Enforcement Carbon Fiber Fabric 12k Roll is a specific type of carbon fiber fabric that is 50cm in width and has a 12K weave pattern with a weight of 300 grams per square meter. This particular fabric is commonly used in the production of enforcement equipment, providing a strong and lightweight solution for various applications. In this article, we will explore the features and benefits of this carbon fiber fabric and its uses in enforcement equipment.

Benefits of Using Carbon Fiber Fabric for Enforcement Purposes

Carbon fiber fabric has become increasingly popular in recent years, especially in the field of enforcement. This high-performance material is known for its strength, durability, and lightweight properties, making it an ideal choice for various enforcement purposes. In this article, we will explore the benefits of using carbon fiber fabric for enforcement purposes.

One of the main benefits of carbon fiber fabric is its strength. This material is five times stronger than steel, yet much lighter in weight. This makes it an excellent choice for applications where strength and weight are crucial factors. In enforcement, where equipment and gear need to withstand rigorous use and potential impacts, carbon fiber fabric provides the necessary strength without adding unnecessary weight.

Moreover, carbon fiber fabric is highly durable. It is resistant to corrosion, chemicals, and extreme temperatures, making it suitable for use in various environments. This durability is especially important in enforcement, where equipment and gear are subjected to harsh conditions. With carbon fiber fabric, enforcement personnel can have peace of mind knowing that their equipment will withstand the demands of their job.

Another significant benefit of carbon fiber fabric is its lightweight nature. This material is significantly lighter than traditional materials such as steel or aluminum. This weight reduction can make a significant difference in enforcement operations, where personnel may have to carry their gear for extended periods. The lightweight nature of carbon fiber fabric also allows for faster and more agile movements, which can be crucial in certain enforcement situations.

In addition to its strength, durability, and lightweight properties, carbon fiber fabric also offers excellent impact resistance. This is due to its high stiffness-to-weight ratio, which means it can absorb and distribute impact forces effectively. In enforcement, where personnel may encounter potential impacts from various sources, such as projectiles or collisions, carbon fiber fabric can provide the necessary protection.

Furthermore, carbon fiber fabric is highly customizable. It can be molded into various shapes and sizes, making it suitable for a wide range of enforcement equipment and gear. This versatility allows for the creation of specialized and tailored equipment that meets the specific needs of enforcement personnel. From bulletproof vests to batons and shields, carbon fiber fabric can be used to create a variety of enforcement tools.

Another advantage of carbon fiber fabric is its resistance to fatigue. This material can withstand repeated stress and loading without weakening or breaking. This is especially important in enforcement, where equipment and gear may be subjected to constant use and abuse. With carbon fiber fabric, enforcement personnel can rely on their equipment to perform consistently without the risk of failure due to fatigue.

Moreover, carbon fiber fabric is also resistant to UV radiation, making it suitable for outdoor use. This is particularly beneficial for enforcement personnel who often work in the field, exposed to the sun’s harmful rays. With carbon fiber fabric, equipment and gear can maintain their strength and durability even when exposed to prolonged sunlight.

In conclusion, carbon fiber fabric offers numerous benefits for enforcement purposes. Its strength, durability, lightweight nature, impact resistance, customization options, fatigue resistance, and UV resistance make it an ideal choice for various enforcement equipment and gear. As technology continues to advance, we can expect to see even more applications of carbon fiber fabric in the field of enforcement.

How to Choose the Right Width and Weight for Carbon Fiber Fabric

Carbon fiber fabric has become increasingly popular in various industries due to its high strength-to-weight ratio and durability. It is commonly used in the aerospace, automotive, and sporting goods industries, among others. However, with the wide range of options available, it can be overwhelming to choose the right width and weight for your specific project. In this article, we will discuss the factors to consider when selecting the appropriate carbon fiber fabric width and weight.

Firstly, let’s understand what the width and weight of carbon fiber fabric mean. The width refers to the measurement of the fabric from one edge to the other, usually in centimeters or inches. The weight, on the other hand, is the amount of carbon fiber present in a square meter of the fabric, measured in grams or ounces. These two factors play a crucial role in determining the strength and stiffness of the fabric.

The most common widths for carbon fiber fabric are 50cm and 100cm, with 50cm being the standard width. However, some manufacturers offer wider options, such as 150cm or 200cm. The wider the fabric, the fewer seams will be required when using it for larger projects. This can result in a more aesthetically pleasing finish and reduce the chances of weak spots in the fabric. However, wider fabric also tends to be more expensive and may not be necessary for smaller projects.

When it comes to weight, carbon fiber fabric is available in various options, ranging from 100g to 600g per square meter. The weight of the fabric directly affects its strength and stiffness. A higher weight fabric will have more carbon fiber per square meter, making it stronger and stiffer. However, it will also be thicker and heavier, which may not be suitable for all projects. On the other hand, a lower weight fabric will be thinner and lighter, but it may not have the same strength and stiffness as a higher weight fabric.

So, how do you determine the right width and weight for your project? The first step is to consider the intended use of the carbon fiber fabric. If you are using it for structural purposes, such as in the construction of a car or aircraft, a higher weight fabric would be more suitable. This will provide the necessary strength and stiffness to support the structure. On the other hand, if you are using the fabric for cosmetic purposes, such as in the production of sports equipment, a lower weight fabric may be sufficient.

Another factor to consider is the complexity of your project. If you are working on a simple design with minimal curves and corners, a standard width fabric may be suitable. However, if your project involves intricate shapes and curves, a wider fabric may be necessary to avoid the need for multiple seams. Similarly, if your project requires a high level of strength and stiffness, a higher weight fabric would be more appropriate.

It is also essential to consider your budget when choosing the width and weight of carbon fiber fabric. Wider and higher weight fabrics tend to be more expensive, so it is crucial to strike a balance between your project’s requirements and your budget.

In conclusion, choosing the right width and weight for carbon fiber fabric depends on various factors, including the intended use, complexity of the project, and budget. It is essential to carefully consider these factors to ensure that you select the most suitable fabric for your specific project. With the right width and weight, you can harness the full potential of carbon fiber fabric and create a strong and durable end product.

The Versatility of Carbon Fiber Fabric in Various Industries

Carbon fiber fabric has become a popular material in various industries due to its unique properties and versatility. This lightweight and strong material is made up of carbon atoms bonded together in a crystal lattice pattern, giving it a high strength-to-weight ratio. It is commonly used in the aerospace, automotive, sports, and construction industries, among others. In this article, we will explore the versatility of carbon fiber fabric and its applications in different fields.

One of the main industries that have greatly benefited from the use of carbon fiber fabric is the aerospace industry. The lightweight and high strength properties of carbon fiber make it an ideal material for aircraft and spacecraft construction. It is used in the production of wings, fuselage, and other structural components, reducing the overall weight of the aircraft and increasing fuel efficiency. Additionally, carbon fiber is resistant to corrosion and has a high fatigue resistance, making it a durable material for long-term use in the harsh conditions of space.

In the automotive industry, carbon fiber fabric is used in the production of high-performance vehicles. The use of carbon fiber in car manufacturing has increased in recent years due to its lightweight nature, which improves the speed and handling of the vehicle. It is also used in the production of body panels, reducing the weight of the car and improving its aerodynamics. This not only enhances the performance of the vehicle but also increases its fuel efficiency.

Sports equipment manufacturers have also embraced the use of carbon fiber fabric in their products. The material is commonly used in the production of bicycles, tennis rackets, golf clubs, and other sports equipment. The lightweight and high strength properties of carbon fiber make it an ideal material for these products, as it allows athletes to perform at their best without being weighed down by heavy equipment. Additionally, the stiffness of carbon fiber provides better control and accuracy in sports such as golf and tennis.

The construction industry has also found various applications for carbon fiber fabric. It is used in the reinforcement of concrete structures, providing additional strength and durability. Carbon fiber reinforced concrete is also resistant to corrosion and has a longer lifespan compared to traditional concrete. This makes it a cost-effective and sustainable solution for building structures such as bridges, tunnels, and high-rise buildings.

Another industry that has benefited from the use of carbon fiber fabric is the medical field. It is used in the production of prosthetics, providing a lightweight and strong alternative to traditional materials. Carbon fiber prosthetics are also more flexible and can be customized to fit the specific needs of the patient. Additionally, carbon fiber is used in the production of medical equipment such as X-ray tables and MRI machines, as it is non-magnetic and does not interfere with the imaging process.

In the world of fashion, carbon fiber fabric has also made its mark. It is used in the production of high-end clothing, shoes, and accessories. The lightweight and durable nature of carbon fiber make it a desirable material for fashion designers, who are constantly pushing the boundaries of innovation and design. Carbon fiber is also used in the production of luxury watches, providing a sleek and modern look to these timepieces.

In conclusion, the versatility of carbon fiber fabric has made it a highly sought-after material in various industries. Its lightweight, high strength, and durability properties have revolutionized the way products are designed and manufactured. From aerospace to fashion, carbon fiber fabric has proven to be a game-changer, and its applications are only expected to grow in the future.

Q&A

1. What is Carbon Fiber Fabric 50CM Width 12K 300G Carbon Cloth?

Carbon Fiber Fabric 50CM Width 12K 300G Carbon Cloth is a type of fabric made from carbon fibers that are woven together to create a strong and lightweight material. It is commonly used in industries such as aerospace, automotive, and sports equipment due to its high strength-to-weight ratio.

2. What is the significance of the 12K and 300G in the fabric’s name?

The 12K in the fabric’s name refers to the number of carbon fibers per tow, or bundle, of fibers. In this case, there are 12,000 carbon fibers per tow. The 300G refers to the weight of the fabric per square meter, with 300 grams being the weight of the fabric in this case.

3. What is the purpose of using Carbon Fiber Fabric 12k Roll?

The purpose of using Carbon Fiber Fabric 12k Roll is to reinforce and strengthen various materials and structures. It is commonly used in the manufacturing of high-performance products such as aircraft, race cars, and sporting equipment. The use of carbon fiber fabric can increase the strength and durability of these products while also reducing their weight.