-

Feb 06

Aramid vs. UHMWPE Plates: The Science Behind Ballistic Test Results

,When it comes to ballistic protection, the materials used in body armor are crucial. Two prominent materials used in ballistic plates are Aramid and UHMWPE. Understanding the differences between them is essential for evaluating their effectiveness in various scenarios. The science behind ballistic test results reveals that the protective capabilities of these materials depend on […]

View Details -

Feb 06

UHMWPE: The Ultimate High-Performance Plastic

,Ultra-high molecular weight polyethylene, commonly referred to as a high-performance plastic, is revolutionizing various industries with its exceptional properties. This advanced material is known for its outstanding wear resistance and impact strength, making it an ideal choice for applications where durability is paramount. With its unique characteristics, UHMWPE is being utilized in a wide range […]

View Details -

Feb 06

Carbon Fiber vs. Aramid vs. UHMWPE: Which High-Performance Fiber Fits Your Project?

,When it comes to selecting the right material for your project, understanding the characteristics of high-performance fibers is crucial. Advanced materials like carbon fiber, aramid, and UHMWPE are revolutionizing various industries due to their exceptional strength, durability, and resistance to extreme conditions. The choice between these fibers depends on the specific requirements of your project. […]

View Details -

Jan 22

UHMWPE Fabric: The Ultimate in Protective Textiles

,When it comes to protective textiles, Ultra-High-Molecular-Weight Polyethylene stands out for its exceptional strength and durability. UHMWPE fabric is engineered to provide superior protection against various threats, making it a critical component in numerous applications. This advanced material is used in a wide range of industries, from military and law enforcement to sports and outdoor […]

View Details -

Jan 09

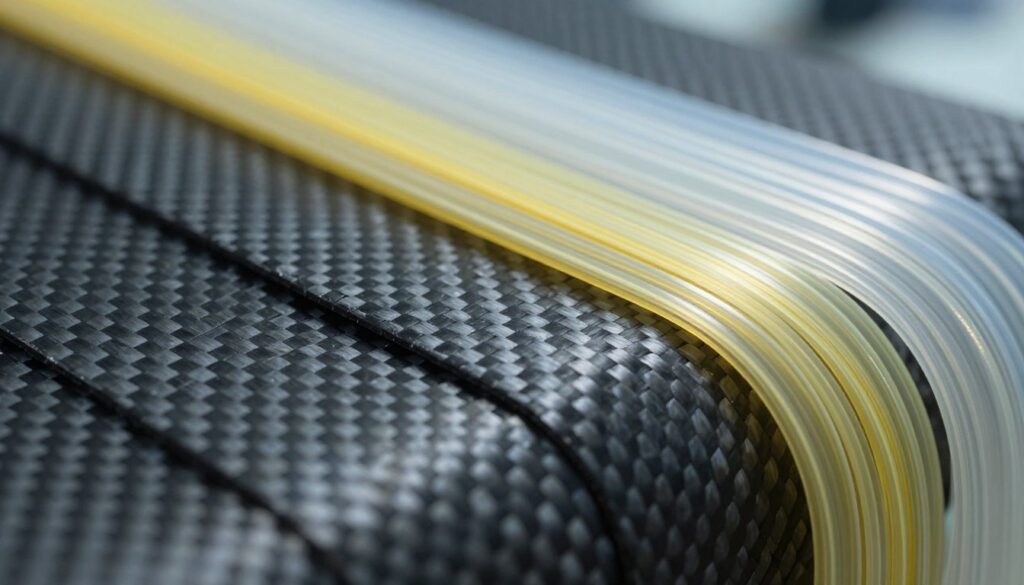

Carbon Fiber Weave Patterns Explained: Plain vs. Twill vs. Satin

,Understanding the different carbon fiber weave patterns is crucial for selecting the right material for various applications. The weave pattern significantly affects the material’s strength, flexibility, and appearance. The most common weave patterns are plain weave, twill weave, and satin weave. Each has its unique characteristics and advantages, making them suitable for different uses. The […]

View Details -

Dec 30

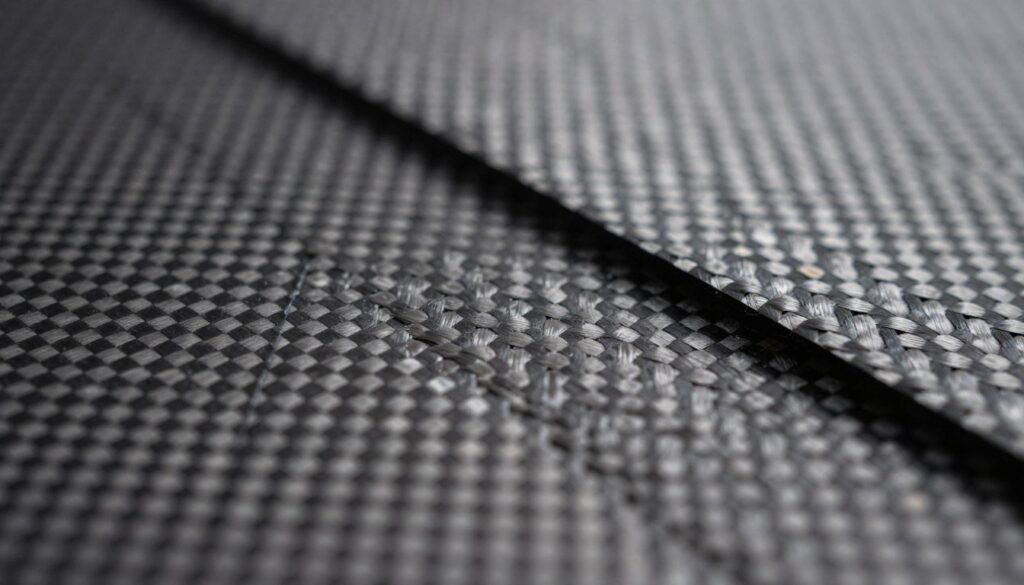

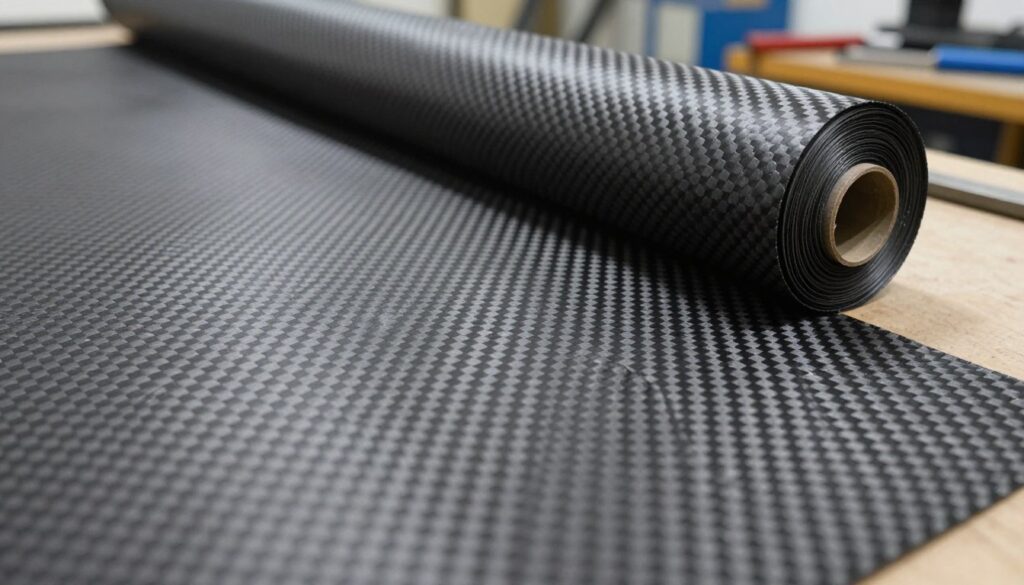

The Ultimate Guide to Carbon Fiber Fabric

,Welcome to the comprehensive guide on carbon fiber fabric, a material that’s revolutionizing various industries with its unique properties. Known for its exceptional strength, lightweight, and resistance to fatigue, carbon fiber fabric is becoming a preferred choice in aerospace, sports equipment, and automotive applications. This guide is designed to walk you through the fundamentals of carbon fiber fabric, its manufacturing process, and its applications. Whether you’re a manufacturer, engineer, or simply a enthusiast, this guide aims to provide you with a thorough understanding of this advanced material. Key Takeaways Understanding the properties of carbon fiber fabric Exploring the manufacturing process of carbon fiber fabric Identifying the applications of carbon fiber fabric in various industries Learning about the advantages and limitations of using carbon fiber fabric Discovering the future prospects of carbon fiber fabric in emerging technologies What Is Carbon Fiber Fabric? Carbon fiber fabric is a revolutionary material known for its exceptional strength and lightweight properties. It is made from thin, strong carbon fibers that are woven together to form a fabric-like material. This unique composition gives carbon fiber fabric its remarkable characteristics, making it a highly sought-after material in various industries. The Science Behind Carbon Fiber Carbon fiber is produced through a process involving the alignment and bonding of carbon atoms. The resulting fibers have a high strength-to-weight ratio, making them ideal for applications where weight reduction is crucial. The science behind carbon fiber involves the pyrolysis of precursor materials, typically polyacrylonitrile (PAN), to create the carbon fibers. Different Types of Carbon Fiber Weaves Carbon fiber fabric comes in various weave patterns, each with its own advantages. The choice of weave depends on the intended application and the desired properties of the final product. Plain Weave Plain weave is the most basic and common type of weave. It offers a balanced and stable structure, making it suitable for a wide range of applications. Twill Weave Twill weave provides a softer and more flexible fabric compared to plain weave. It is known for its diagonal pattern and is often used in applications where drape and conformability are important. Satin Weave Satin weave is characterized by its smooth surface and high flexibility. It is commonly used in complex shapes and applications where a high-quality finish is required. Weave Type Characteristics Applications Plain Weave Balanced, stable General-purpose, structural components Twill Weave Soft, flexible, diagonal pattern Aerospace, automotive, sporting goods Satin Weave Smooth surface, high flexibility Complex shapes, high-performance applications The History and Evolution of Carbon Fiber Fabric The development of carbon fiber fabric represents a fascinating journey of scientific discovery and industrial innovation. From its early beginnings to the sophisticated materials used today, carbon fiber fabric has undergone significant transformations. Early Development and Innovations The history of carbon fiber dates back to the late 19th century, but it wasn’t until the 1950s and 1960s that the first viable carbon fibers were produced. Initially, these fibers were used in high-temperature applications and aerospace. The early development was marked by significant challenges, including high production costs and material inconsistencies. Modern Advancements in Carbon Fiber Technology Recent advancements have focused on improving production efficiency and reducing costs. Techniques such as chemical vapor deposition and laser-assisted manufacturing have been developed. These innovations have expanded the applications of carbon fiber fabric beyond aerospace to automotive, sports equipment, and more. Year Event Impact 1950s First carbon fibers produced Initial use in high-temperature applications 1960s Aerospace industry adoption Enhanced material strength and durability 2000s Advancements in manufacturing techniques Reduced production costs and expanded applications The evolution of carbon fiber fabric continues, with ongoing research into new materials and manufacturing processes. As technology advances, we can expect to see even more innovative applications of carbon fiber fabric. Key Properties of Carbon Fiber Fabric With its outstanding strength-to-weight ratio and other notable properties, carbon fiber fabric has revolutionized the way we design and manufacture products. This versatile material is prized for its exceptional characteristics, making it a preferred choice in various high-tech industries. Strength-to-Weight Ratio One of the most significant advantages of carbon fiber fabric is its exceptional strength-to-weight ratio. This property allows for the creation of lightweight yet incredibly strong structures, ideal for applications where weight reduction is critical without compromising on strength. […]

View Details