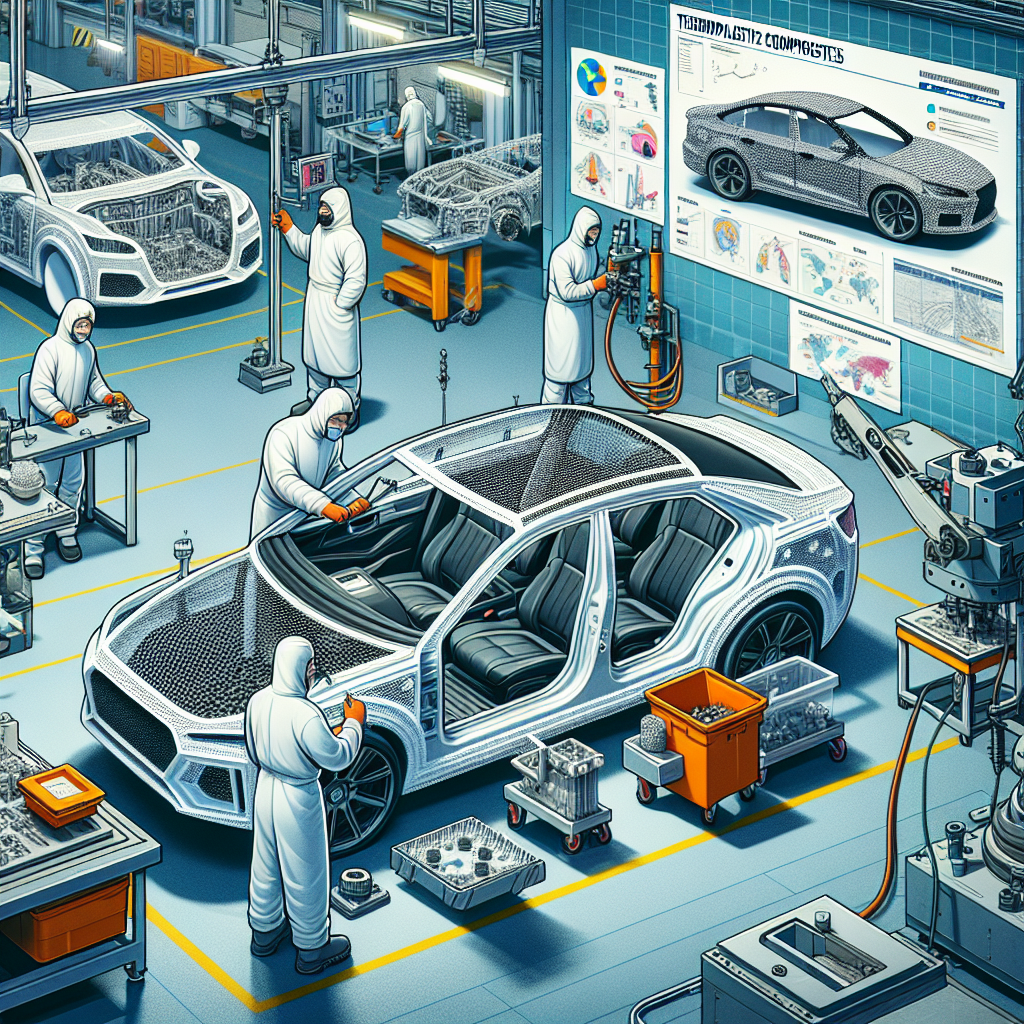

Thermoplastic Composites Gain Ground in the Auto Industry

-

Table of Contents

“Driving Innovation: Thermoplastic Composites Revolutionize the Auto Industry.”

Thermoplastic composites are increasingly gaining traction in the automotive industry due to their lightweight properties, enhanced durability, and recyclability. As manufacturers seek to improve fuel efficiency and reduce emissions, these materials offer a compelling alternative to traditional metal and thermoset composites. The ability to process thermoplastic composites at lower temperatures and their compatibility with automated manufacturing techniques further contribute to their appeal. With advancements in material science and growing environmental concerns, the adoption of thermoplastic composites is poised to transform vehicle design and production, leading to more sustainable and efficient automotive solutions.

Advancements in Thermoplastic Composite Materials for Automotive Applications

The automotive industry is undergoing a significant transformation, driven by the need for lighter, more efficient, and environmentally friendly materials. Among the various innovations, thermoplastic composites have emerged as a promising solution, gaining traction due to their unique properties and advantages over traditional materials. These composites, which combine thermoplastic resins with reinforcing fibers, offer a blend of strength, flexibility, and ease of processing that is particularly appealing for automotive applications.

One of the primary advancements in thermoplastic composite materials is the development of new resin formulations that enhance performance characteristics. For instance, advancements in polyamide and polypropylene matrices have led to composites that exhibit improved thermal stability and impact resistance. These properties are crucial in automotive applications, where materials must withstand harsh environmental conditions and mechanical stresses. Furthermore, the ability to tailor the resin properties allows manufacturers to optimize the composites for specific applications, such as structural components or interior parts, thereby expanding their usability across various vehicle models.

In addition to improved resin formulations, the integration of advanced fiber technologies has significantly contributed to the performance of thermoplastic composites. Innovations in carbon and glass fiber reinforcements have resulted in materials that not only provide superior strength-to-weight ratios but also enhance the overall durability of automotive components. The lightweight nature of these composites is particularly beneficial in the context of fuel efficiency and emissions reduction, as lighter vehicles require less energy to operate. Consequently, automakers are increasingly turning to thermoplastic composites to meet stringent regulatory standards while also appealing to environmentally conscious consumers.

Moreover, the processing techniques for thermoplastic composites have evolved, allowing for more efficient manufacturing processes. Traditional thermoset composites often require lengthy curing times and complex molding techniques, which can hinder production efficiency. In contrast, thermoplastic composites can be processed using methods such as injection molding and thermoforming, which are faster and more cost-effective. This shift not only reduces production times but also enables greater design flexibility, allowing manufacturers to create complex geometries that were previously challenging to achieve with conventional materials.

As the automotive industry continues to embrace sustainability, thermoplastic composites align well with this trend. The recyclability of thermoplastic materials is a significant advantage, as they can be reprocessed and reused without losing their inherent properties. This characteristic is particularly appealing in an era where manufacturers are seeking to minimize waste and reduce their carbon footprint. By incorporating thermoplastic composites into their vehicles, automakers can contribute to a circular economy, where materials are continuously repurposed rather than discarded.

Furthermore, the collaboration between automotive manufacturers and material scientists has accelerated the development of thermoplastic composites tailored for specific automotive applications. Research initiatives and partnerships are focusing on optimizing the performance of these materials under real-world conditions, ensuring that they meet the rigorous demands of the automotive sector. As a result, we are witnessing a growing number of vehicles equipped with components made from thermoplastic composites, ranging from body panels to structural reinforcements.

In conclusion, the advancements in thermoplastic composite materials are reshaping the landscape of the automotive industry. With their superior performance characteristics, efficient processing methods, and sustainability benefits, these materials are becoming increasingly integral to modern vehicle design and manufacturing. As the industry continues to evolve, it is clear that thermoplastic composites will play a pivotal role in driving innovation and meeting the challenges of the future.

The Role of Thermoplastic Composites in Lightweight Vehicle Design

In recent years, the automotive industry has increasingly focused on lightweight vehicle design as a means to enhance fuel efficiency and reduce emissions. Among the various materials being explored, thermoplastic composites have emerged as a significant player, offering a unique combination of properties that align well with the industry’s evolving needs. These materials, which consist of a polymer matrix reinforced with fibers, provide not only the lightweight characteristics essential for modern vehicles but also the durability and versatility required for various automotive applications.

One of the primary advantages of thermoplastic composites is their low density, which contributes to overall vehicle weight reduction. This reduction is crucial, as lighter vehicles require less energy to operate, thereby improving fuel efficiency and lowering greenhouse gas emissions. As automakers strive to meet stringent regulatory standards and consumer demand for more sustainable options, the integration of thermoplastic composites into vehicle design has become increasingly attractive. By replacing traditional materials such as metals and thermoset composites, manufacturers can achieve significant weight savings without compromising structural integrity.

Moreover, thermoplastic composites exhibit excellent impact resistance and fatigue performance, making them suitable for critical components in vehicles. For instance, they can be utilized in the production of exterior panels, structural elements, and interior components, all of which benefit from the material’s strength-to-weight ratio. This capability not only enhances the safety of the vehicle but also contributes to the longevity of its components, reducing the need for frequent repairs or replacements. As a result, automakers are finding that the use of thermoplastic composites can lead to lower lifecycle costs, further incentivizing their adoption.

In addition to their mechanical properties, thermoplastic composites offer processing advantages that are particularly appealing to the automotive industry. Unlike thermoset composites, which require curing and can be time-consuming to manufacture, thermoplastic composites can be processed using various techniques such as injection molding and thermoforming. These methods allow for faster production cycles and greater design flexibility, enabling manufacturers to produce complex shapes and integrate multiple functions into a single component. This efficiency not only streamlines the manufacturing process but also supports the industry’s shift towards more agile production systems.

Furthermore, the recyclability of thermoplastic composites aligns with the automotive industry’s growing emphasis on sustainability. As environmental concerns continue to shape consumer preferences and regulatory frameworks, the ability to recycle materials at the end of a vehicle’s life cycle becomes increasingly important. Thermoplastic composites can be reprocessed and reused, reducing waste and promoting a circular economy. This characteristic not only enhances the environmental profile of vehicles but also positions thermoplastic composites as a forward-thinking choice for manufacturers committed to sustainable practices.

As the automotive industry continues to evolve, the role of thermoplastic composites in lightweight vehicle design is likely to expand further. With ongoing advancements in material science and processing technologies, these composites are poised to play a pivotal role in the development of next-generation vehicles. By embracing the benefits of thermoplastic composites, automakers can not only meet regulatory requirements and consumer expectations but also contribute to a more sustainable future. In conclusion, the integration of thermoplastic composites into vehicle design represents a significant step forward in the pursuit of lightweight, efficient, and environmentally friendly automobiles, marking a transformative shift in the industry landscape.

Sustainability Benefits of Using Thermoplastic Composites in Auto Manufacturing

The automotive industry is undergoing a significant transformation as manufacturers increasingly prioritize sustainability in their production processes. One of the most promising developments in this regard is the growing adoption of thermoplastic composites. These materials not only offer enhanced performance characteristics but also contribute to environmental sustainability, making them an attractive option for modern vehicle manufacturing. As the industry grapples with the pressing need to reduce its carbon footprint, thermoplastic composites emerge as a viable solution that aligns with both ecological and economic goals.

To begin with, thermoplastic composites are known for their lightweight properties, which play a crucial role in improving fuel efficiency. By reducing the overall weight of vehicles, manufacturers can enhance performance while simultaneously decreasing fuel consumption. This reduction in weight translates to lower greenhouse gas emissions, thereby addressing one of the most significant challenges facing the automotive sector today. Furthermore, as governments around the world implement stricter emissions regulations, the shift towards lighter materials becomes not just beneficial but essential for compliance.

In addition to their lightweight nature, thermoplastic composites are also characterized by their recyclability. Unlike traditional thermoset composites, which are often difficult to recycle due to their chemical structure, thermoplastic composites can be reprocessed and reused multiple times without significant degradation of their properties. This inherent recyclability aligns with the principles of a circular economy, where materials are kept in use for as long as possible, thus minimizing waste. As automakers seek to implement more sustainable practices, the ability to recycle materials effectively becomes a critical factor in their decision-making processes.

Moreover, the production of thermoplastic composites typically requires less energy compared to traditional materials. The manufacturing processes involved in creating these composites often operate at lower temperatures, which not only reduces energy consumption but also lowers production costs. This energy efficiency is particularly relevant in an era where energy prices are volatile and sustainability is a key concern for both manufacturers and consumers. By adopting thermoplastic composites, automotive companies can achieve significant cost savings while simultaneously contributing to a more sustainable manufacturing environment.

Transitioning to thermoplastic composites also allows for greater design flexibility, which can lead to innovative vehicle designs that further enhance sustainability. The ability to mold these materials into complex shapes enables manufacturers to create components that are not only lightweight but also optimized for performance. This design freedom can result in vehicles that are more aerodynamically efficient, further improving fuel economy and reducing emissions. As the industry continues to evolve, the integration of advanced materials like thermoplastic composites will likely play a pivotal role in shaping the future of automotive design.

In conclusion, the sustainability benefits of using thermoplastic composites in auto manufacturing are manifold. From their lightweight properties that enhance fuel efficiency to their recyclability and energy-efficient production processes, these materials represent a significant step forward in the quest for a more sustainable automotive industry. As manufacturers increasingly recognize the importance of environmental responsibility, the adoption of thermoplastic composites is poised to gain further traction. Ultimately, this shift not only supports the industry’s sustainability goals but also aligns with the growing consumer demand for greener vehicles, paving the way for a more sustainable future in automotive manufacturing.

Q&A

1. **What are thermoplastic composites?**

Thermoplastic composites are materials made from a thermoplastic matrix reinforced with fibers, such as glass or carbon, which provide enhanced strength and lightweight properties.

2. **Why are thermoplastic composites gaining popularity in the auto industry?**

They are gaining popularity due to their lightweight nature, which improves fuel efficiency, as well as their recyclability, cost-effectiveness, and ability to be molded into complex shapes.

3. **What are some applications of thermoplastic composites in vehicles?**

They are used in various automotive components, including body panels, interior parts, and structural elements, contributing to overall vehicle performance and sustainability.Thermoplastic composites are increasingly being adopted in the automotive industry due to their lightweight properties, recyclability, and ability to enhance fuel efficiency while meeting stringent safety standards. Their rapid processing capabilities and potential for cost reduction in manufacturing further contribute to their growing popularity. As automakers seek sustainable and efficient materials to meet evolving consumer demands and regulatory requirements, thermoplastic composites are poised to play a significant role in the future of automotive design and production.