Are Threaded Carbon Fiber Tubes Available for Modular Designs?

-

Table of Contents

“Unlock Modular Innovation with Threaded Carbon Fiber Tubes!”

Introduction

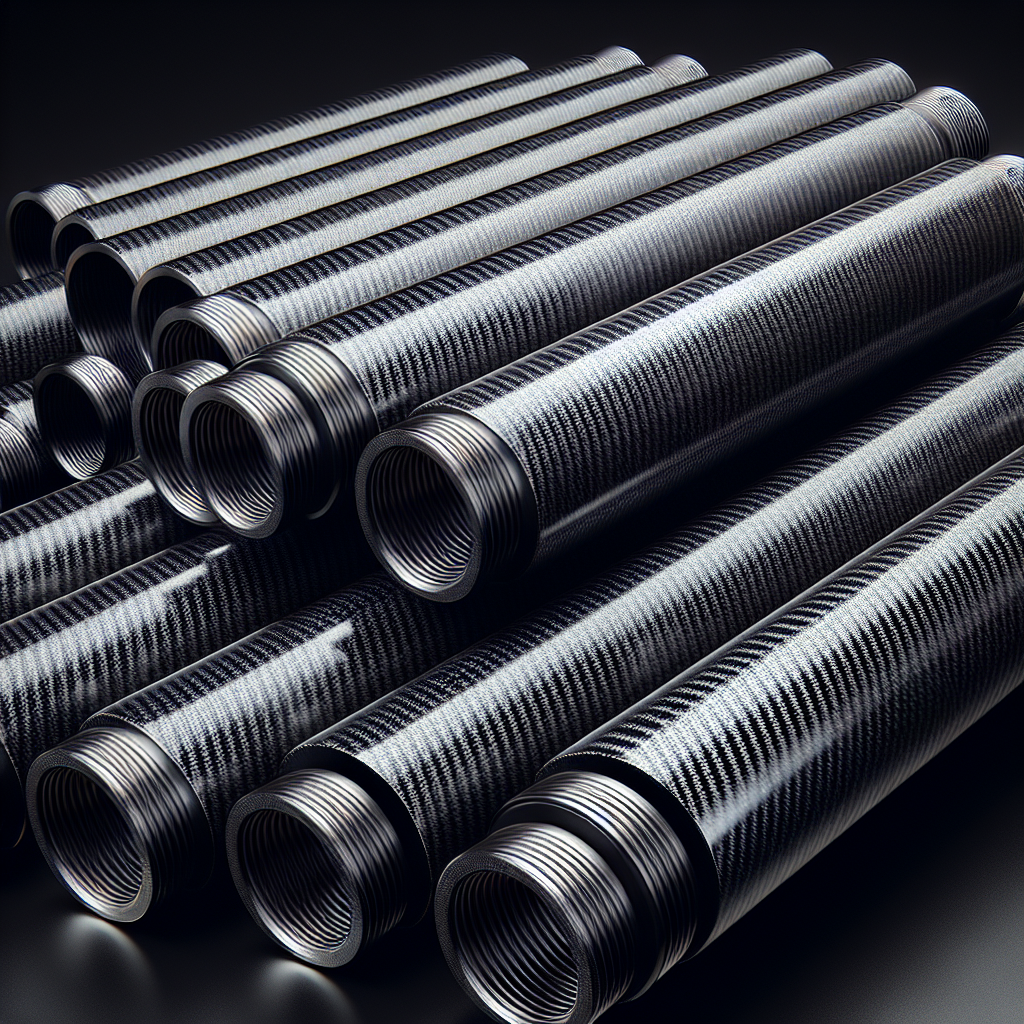

Threaded carbon fiber tubes are increasingly being recognized for their potential in modular design applications. These lightweight yet strong components offer significant advantages in various industries, including aerospace, automotive, and sports equipment. The incorporation of threaded features allows for easy assembly and disassembly, enhancing the versatility and adaptability of modular systems. As demand for innovative materials grows, manufacturers are exploring the feasibility of producing threaded carbon fiber tubes, making them a viable option for designers seeking to optimize performance while maintaining structural integrity.

Advantages of Using Threaded Carbon Fiber Tubes in Modular Designs

The integration of threaded carbon fiber tubes into modular designs presents a multitude of advantages that enhance both functionality and performance. As industries increasingly seek lightweight yet robust materials, carbon fiber has emerged as a leading choice due to its exceptional strength-to-weight ratio. When these tubes are threaded, they offer additional benefits that are particularly advantageous for modular applications, where adaptability and ease of assembly are paramount.

One of the primary advantages of using threaded carbon fiber tubes is their ability to facilitate quick and efficient assembly. In modular designs, components often need to be assembled and disassembled frequently. The threaded nature of these tubes allows for straightforward connections, enabling users to easily join or separate parts without the need for complex tools or extensive labor. This ease of assembly not only saves time but also reduces the potential for errors during the construction process, thereby enhancing overall efficiency.

Moreover, the lightweight characteristics of carbon fiber contribute significantly to the overall performance of modular systems. Traditional materials, such as metal, can add considerable weight to a structure, which may limit its portability and ease of use. In contrast, threaded carbon fiber tubes maintain structural integrity while minimizing weight, making them ideal for applications where mobility is essential. This is particularly relevant in industries such as aerospace and automotive, where every gram counts, and reducing weight can lead to improved fuel efficiency and performance.

In addition to their lightweight properties, threaded carbon fiber tubes exhibit remarkable resistance to environmental factors. Unlike metals, which can corrode or degrade over time, carbon fiber is impervious to moisture and chemicals, ensuring longevity and durability in various conditions. This resilience is particularly beneficial in outdoor or industrial applications, where exposure to harsh elements can compromise the integrity of traditional materials. Consequently, the use of threaded carbon fiber tubes can lead to reduced maintenance costs and extended service life for modular designs.

Furthermore, the versatility of threaded carbon fiber tubes allows for a high degree of customization in modular systems. Designers can easily modify the length and diameter of the tubes to suit specific project requirements, enabling the creation of tailored solutions that meet unique needs. This adaptability is crucial in industries that demand rapid innovation and responsiveness to changing market conditions. By incorporating threaded carbon fiber tubes, manufacturers can develop modular designs that are not only functional but also aesthetically pleasing, as the sleek appearance of carbon fiber adds a modern touch to any project.

Another significant advantage lies in the vibration-damping properties of carbon fiber. In applications where vibrations can lead to structural fatigue or performance issues, the inherent characteristics of carbon fiber help mitigate these effects. This is particularly important in modular designs used in high-performance environments, such as robotics or precision machinery, where stability and accuracy are critical.

In conclusion, the advantages of using threaded carbon fiber tubes in modular designs are manifold. Their lightweight nature, ease of assembly, resistance to environmental factors, versatility, and vibration-damping properties make them an ideal choice for a wide range of applications. As industries continue to evolve and demand more efficient and effective solutions, the incorporation of threaded carbon fiber tubes into modular designs will undoubtedly play a pivotal role in shaping the future of engineering and manufacturing. By leveraging these benefits, designers and engineers can create innovative systems that not only meet but exceed the expectations of modern applications.

Applications of Threaded Carbon Fiber Tubes in Various Industries

Threaded carbon fiber tubes have emerged as a versatile solution across various industries, owing to their unique combination of lightweight properties, high strength, and resistance to corrosion. These attributes make them particularly suitable for modular designs, where adaptability and efficiency are paramount. In the aerospace sector, for instance, the demand for lightweight materials is critical for enhancing fuel efficiency and overall performance. Threaded carbon fiber tubes can be utilized in the construction of aircraft components, allowing for modular assembly that facilitates easy maintenance and upgrades. By employing these tubes, manufacturers can create structures that not only reduce weight but also maintain structural integrity under extreme conditions.

In the automotive industry, the trend towards lightweight materials is similarly pronounced. Threaded carbon fiber tubes can be integrated into vehicle frameworks, providing a robust yet lightweight alternative to traditional metal components. This integration supports modular design principles, enabling manufacturers to create vehicles that can be easily modified or upgraded. For example, performance-oriented vehicles can benefit from the use of threaded carbon fiber tubes in their chassis, allowing for enhanced rigidity and reduced weight, which ultimately leads to improved handling and fuel efficiency. Furthermore, the modular nature of these tubes allows for quick replacements or adjustments, catering to the evolving needs of consumers and the market.

The sporting goods industry also stands to gain significantly from the application of threaded carbon fiber tubes. High-performance equipment, such as bicycles, fishing rods, and golf clubs, increasingly incorporates these materials to enhance performance while minimizing weight. The modular design aspect is particularly beneficial in this context, as athletes often seek customizable equipment tailored to their specific needs. By utilizing threaded carbon fiber tubes, manufacturers can create components that are easily interchangeable, allowing users to modify their gear for different conditions or preferences. This adaptability not only improves user experience but also fosters innovation in product design.

In the field of robotics, threaded carbon fiber tubes are gaining traction due to their strength-to-weight ratio and ease of assembly. Modular robotic systems often require components that can be easily reconfigured or replaced, and threaded carbon fiber tubes provide an ideal solution. These tubes can be used to construct lightweight frames for robotic arms or drones, enabling efficient movement and operation. The ability to quickly assemble or disassemble these systems using threaded connections enhances their versatility, making them suitable for a wide range of applications, from industrial automation to research and development.

Moreover, the medical industry is exploring the potential of threaded carbon fiber tubes in the design of prosthetics and orthopedic devices. The lightweight nature of carbon fiber, combined with its strength, allows for the creation of prosthetic limbs that are both functional and comfortable for users. The modular design aspect is particularly advantageous, as it enables healthcare providers to customize devices to meet individual patient needs. By incorporating threaded carbon fiber tubes, manufacturers can produce prosthetics that are easily adjustable, ensuring a better fit and improved mobility for users.

In conclusion, the applications of threaded carbon fiber tubes span a diverse array of industries, each benefiting from the unique properties of this material. Their lightweight, strong, and corrosion-resistant characteristics make them ideal for modular designs, facilitating innovation and adaptability in product development. As industries continue to seek efficient and effective solutions, the role of threaded carbon fiber tubes is likely to expand, paving the way for new advancements and applications in the future.

How to Choose the Right Threaded Carbon Fiber Tube for Your Modular Project

When embarking on a modular design project, selecting the appropriate materials is crucial to achieving both functionality and aesthetic appeal. Among the various options available, threaded carbon fiber tubes have gained popularity due to their unique combination of strength, lightweight properties, and versatility. However, choosing the right threaded carbon fiber tube for your specific modular project requires careful consideration of several factors.

To begin with, it is essential to assess the intended application of the modular design. Different projects may demand varying levels of strength, flexibility, and weight. For instance, if the modular design is intended for structural applications, such as in aerospace or automotive industries, opting for a tube with a higher tensile strength is advisable. Conversely, for applications where weight is a critical factor, such as in drone construction or portable equipment, a lighter tube may be more suitable. Understanding the specific requirements of your project will guide you in selecting a tube that meets those needs effectively.

In addition to strength and weight, the diameter and wall thickness of the threaded carbon fiber tube are also significant considerations. The diameter will influence the overall stability and load-bearing capacity of the modular design. A larger diameter tube may provide greater strength but could also add unnecessary weight, which may not be ideal for all applications. On the other hand, a smaller diameter tube may be lighter but could compromise structural integrity. Therefore, it is essential to strike a balance between these factors based on the design requirements.

Moreover, the threading of the carbon fiber tube plays a pivotal role in ensuring compatibility with other components in the modular system. When selecting a threaded carbon fiber tube, it is crucial to consider the thread type and pitch, as these will determine how well the tube can connect with other parts. Standardized threading can facilitate easier assembly and disassembly, which is particularly beneficial in modular designs that require frequent modifications or upgrades. Therefore, ensuring that the threading aligns with the specifications of other components is vital for achieving a seamless integration.

Furthermore, the quality of the carbon fiber material itself should not be overlooked. Different manufacturers may use varying grades of carbon fiber, which can significantly impact the performance and durability of the tubes. It is advisable to source threaded carbon fiber tubes from reputable suppliers who adhere to industry standards and provide detailed specifications regarding their products. This diligence will help ensure that the tubes you select are not only reliable but also capable of withstanding the demands of your modular project.

Lastly, cost considerations are an inevitable aspect of any project. While it may be tempting to opt for the cheapest option available, it is essential to weigh the long-term benefits of investing in high-quality threaded carbon fiber tubes. Cheaper alternatives may save money upfront but could lead to increased maintenance costs or even project failure down the line. Therefore, a thorough evaluation of both quality and cost will ultimately lead to a more successful and sustainable modular design.

In conclusion, choosing the right threaded carbon fiber tube for your modular project involves a comprehensive assessment of application requirements, dimensions, threading compatibility, material quality, and cost. By carefully considering these factors, you can ensure that your modular design not only meets its intended purpose but also stands the test of time, providing both functionality and aesthetic appeal.

Q&A

1. **Question:** Are threaded carbon fiber tubes available for modular designs?

**Answer:** Yes, threaded carbon fiber tubes are available and can be used in modular designs for various applications.

2. **Question:** What are the benefits of using threaded carbon fiber tubes in modular designs?

**Answer:** The benefits include lightweight construction, high strength-to-weight ratio, corrosion resistance, and the ability to easily connect and disconnect components.

3. **Question:** Where can I find threaded carbon fiber tubes for modular applications?

**Answer:** Threaded carbon fiber tubes can be found at specialized composite material suppliers, online marketplaces, and manufacturers that focus on custom carbon fiber products.