Как избежать расслоения при укладке углеродной ткани?

-

Оглавление

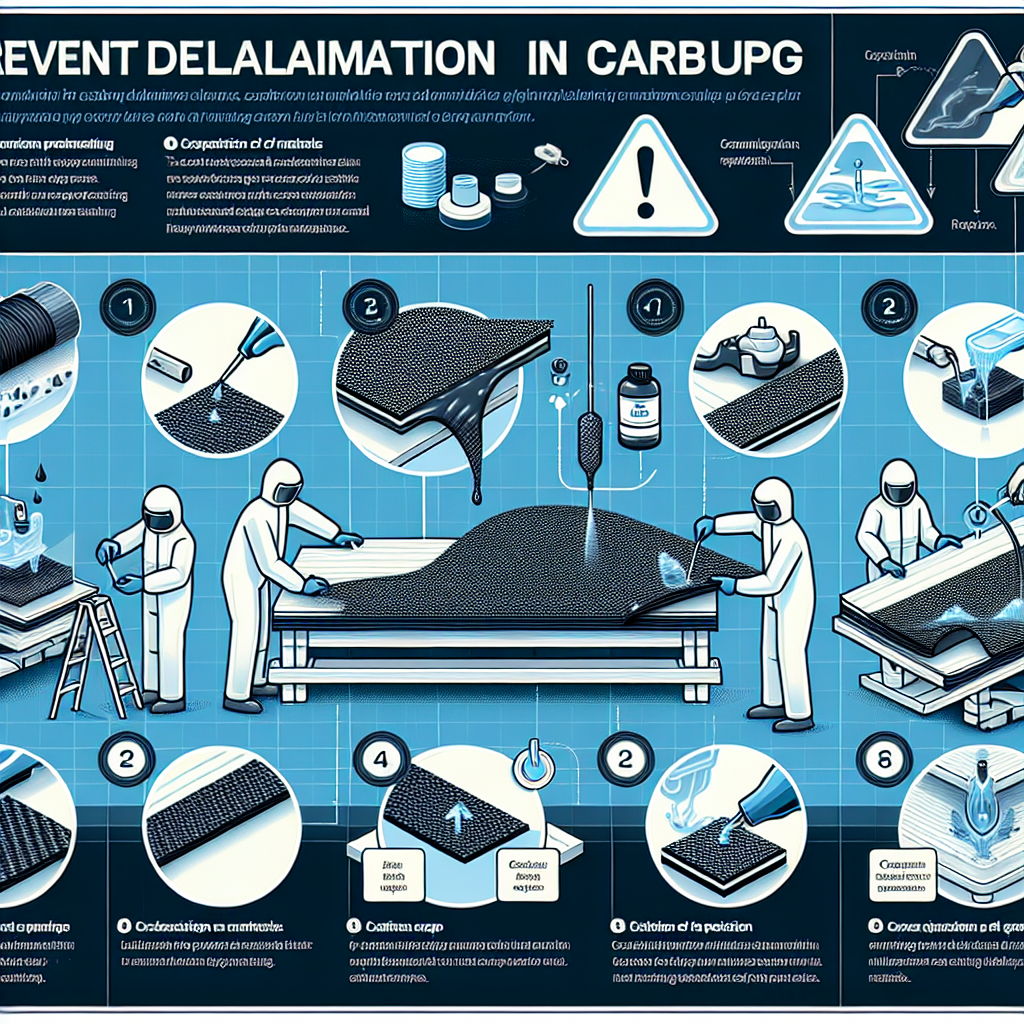

“Master the Layers: Prevent Delamination in Carbon Fabric Layups with Precision and Care.”

Введение

Delamination in carbon fabric layups is a critical issue that can compromise the structural integrity and performance of composite materials. To prevent this phenomenon, it is essential to understand the factors that contribute to delamination, such as improper handling, inadequate bonding, and environmental influences. This guide outlines effective strategies to avoid delamination, including proper surface preparation, optimal resin application techniques, careful layering, and the use of appropriate curing methods. By implementing these practices, manufacturers and engineers can enhance the durability and reliability of carbon fiber composites, ensuring their successful application in various industries.

Proper Surface Preparation Techniques

Proper surface preparation is a critical step in ensuring the integrity and performance of carbon fabric layups, particularly in preventing delamination. Delamination, which refers to the separation of layers within a composite material, can significantly compromise the mechanical properties and overall durability of the finished product. Therefore, understanding and implementing effective surface preparation techniques is essential for achieving optimal adhesion and structural integrity.

To begin with, the surface of the substrate must be meticulously cleaned to remove any contaminants that could interfere with bonding. This includes oils, dust, and other residues that may have accumulated during handling or storage. A common practice is to use solvents such as acetone or isopropyl alcohol, which effectively dissolve and remove unwanted substances. It is crucial to ensure that the surface is completely dry after cleaning, as any residual moisture can lead to poor adhesion and increase the risk of delamination.

Once the surface is clean, the next step involves mechanical preparation, which can significantly enhance the bonding surface. Techniques such as sanding or grinding can be employed to create a roughened texture on the substrate. This roughness increases the surface area available for adhesion and provides mechanical interlocking between the carbon fabric and the substrate. However, it is important to control the degree of roughness; excessive sanding can lead to the introduction of micro-cracks, which may also contribute to delamination. Therefore, a balanced approach is necessary to achieve an optimal surface profile.

In addition to cleaning and mechanical preparation, the application of a suitable primer can further improve adhesion. Primers are specially formulated to enhance the bonding characteristics of the surface, providing a chemical interface that promotes better adhesion between the carbon fabric and the substrate. When selecting a primer, it is essential to consider compatibility with both the substrate material and the resin system that will be used in the layup. Applying the primer according to the manufacturer’s instructions, including recommended curing times, is vital to ensure its effectiveness.

Furthermore, environmental conditions during the preparation and layup process play a significant role in preventing delamination. Temperature and humidity levels should be monitored closely, as extreme conditions can adversely affect the curing process of the resin and the overall adhesion of the carbon fabric. Ideally, the layup should be performed in a controlled environment where temperature and humidity are maintained within specified ranges. This not only ensures optimal curing but also minimizes the risk of moisture ingress, which can lead to delamination over time.

Moreover, it is essential to handle the carbon fabric with care during the layup process. Avoiding excessive tension or stretching of the fabric can prevent micro-tears that may compromise the integrity of the layup. Additionally, ensuring that the fabric is properly aligned and free of wrinkles or folds will contribute to a uniform distribution of resin, further enhancing adhesion and reducing the likelihood of delamination.

In conclusion, proper surface preparation techniques are fundamental in preventing delamination in carbon fabric layups. By meticulously cleaning the surface, employing mechanical preparation methods, applying suitable primers, controlling environmental conditions, and handling the fabric with care, manufacturers can significantly enhance the adhesion and performance of composite materials. Ultimately, these practices not only improve the structural integrity of the final product but also extend its lifespan, making them indispensable in the field of composite manufacturing.

Optimal Resin Application Methods

In the realm of composite manufacturing, particularly when working with carbon fabric layups, the application of resin plays a pivotal role in ensuring the integrity and performance of the final product. Delamination, a common issue that can compromise the structural integrity of composite materials, often arises from improper resin application. Therefore, understanding optimal resin application methods is essential for manufacturers aiming to enhance the durability and reliability of their carbon fabric layups.

To begin with, the choice of resin is fundamental. Different resins possess varying properties, such as viscosity, curing time, and adhesion capabilities. Selecting a resin that is compatible with the specific carbon fabric being used is crucial. For instance, epoxy resins are often favored for their superior bonding strength and resistance to environmental factors. Once the appropriate resin is chosen, the method of application becomes the next critical consideration.

One effective technique is the vacuum infusion method, which not only ensures a uniform distribution of resin but also minimizes the risk of air entrapment. In this process, the carbon fabric is placed in a mold, and a vacuum is applied to draw the resin into the fabric. This method allows for a controlled application, ensuring that the resin saturates the fibers thoroughly without creating voids that could lead to delamination. Moreover, the vacuum infusion technique can enhance the mechanical properties of the composite by promoting a more consistent fiber-to-resin ratio.

In addition to vacuum infusion, hand layup remains a popular method for resin application, particularly in smaller-scale operations or when dealing with complex geometries. However, it requires a skilled operator to ensure that the resin is applied evenly and adequately penetrates the fabric layers. To optimize this method, it is advisable to use a brush or roller to spread the resin, ensuring that it saturates the fibers completely. Care must be taken to avoid excessive resin application, as this can lead to an imbalance in the fiber-to-resin ratio, ultimately increasing the likelihood of delamination.

Furthermore, the timing of resin application is another critical factor. It is essential to apply the resin within the specified pot life to ensure optimal curing and bonding. If the resin begins to cure before it is applied to the fabric, it may not adhere properly, leading to weak points in the layup. Therefore, meticulous planning and execution are necessary to align the resin application with the working time of the chosen resin.

Temperature and humidity also play significant roles in the resin application process. High temperatures can accelerate curing times, while excessive humidity can lead to moisture absorption, which may weaken the bond between the resin and the carbon fibers. Maintaining a controlled environment during the layup process can mitigate these risks, ensuring that the resin cures properly and adheres effectively to the fabric.

In conclusion, avoiding delamination in carbon fabric layups hinges significantly on the optimal application of resin. By selecting the right resin, employing effective application methods such as vacuum infusion or hand layup, timing the application correctly, and controlling environmental conditions, manufacturers can significantly enhance the performance and longevity of their composite materials. Ultimately, a thorough understanding of these factors will lead to improved product quality and reduced risk of delamination, ensuring that the final composite structures meet the rigorous demands of their intended applications.

Effective Curing Process Management

The effective management of the curing process is crucial in preventing delamination in carbon fabric layups, a common issue that can compromise the structural integrity and performance of composite materials. To begin with, understanding the curing process itself is essential. Curing refers to the chemical reaction that occurs when resin is applied to carbon fibers, resulting in a hardened composite material. This process is influenced by various factors, including temperature, pressure, and time, all of which must be meticulously controlled to ensure optimal results.

One of the primary considerations in managing the curing process is the selection of the appropriate resin system. Different resin formulations have distinct curing characteristics, and choosing a resin that aligns with the specific requirements of the application can significantly reduce the risk of delamination. For instance, some resins cure at lower temperatures, which can be advantageous in preventing thermal stresses that may lead to separation between layers. Additionally, the viscosity of the resin plays a critical role; a resin that is too thick may not adequately penetrate the fabric layers, leading to voids and weak points that are susceptible to delamination.

Moreover, the curing environment must be carefully controlled. Temperature fluctuations can adversely affect the curing process, leading to incomplete polymerization or uneven curing. Therefore, maintaining a consistent temperature throughout the curing cycle is vital. This can be achieved through the use of temperature-controlled ovens or autoclaves, which provide a stable environment for the curing process. Furthermore, monitoring the temperature with precision instruments ensures that the resin reaches its optimal curing temperature without exceeding it, which could cause degradation.

In addition to temperature, pressure is another critical factor in the curing process. Applying the correct amount of pressure during curing helps to eliminate air pockets and ensures that the resin fully saturates the carbon fabric. This is particularly important in vacuum bagging techniques, where a vacuum is applied to compress the layup and remove any trapped air. The use of vacuum pumps and proper sealing techniques can enhance the effectiveness of this process, thereby reducing the likelihood of delamination.

Time is also a significant element in the curing process. Each resin system has a specific pot life and curing time, which must be adhered to for optimal results. Rushing the curing process by applying heat prematurely or removing the layup from the curing environment too soon can lead to incomplete curing and, consequently, delamination. Therefore, it is essential to follow the manufacturer’s guidelines regarding curing times and to allow sufficient time for the resin to fully harden.

Furthermore, post-curing treatments can enhance the properties of the composite material and further mitigate the risk of delamination. Post-curing involves subjecting the cured layup to additional heat treatment, which can improve the cross-linking of the resin and enhance its mechanical properties. This step is particularly beneficial for high-performance applications where the material will be subjected to extreme conditions.

In conclusion, effective curing process management is integral to avoiding delamination in carbon fabric layups. By carefully selecting the resin system, controlling the curing environment, applying appropriate pressure, adhering to recommended curing times, and considering post-curing treatments, manufacturers can significantly enhance the quality and durability of composite materials. Ultimately, a thorough understanding of these factors will lead to improved performance and reliability in applications where carbon composites are utilized.

Вопросы и ответы

1. **Question:** What is a key factor in preventing delamination in carbon fabric layups?

**Answer:** Ensuring proper surface preparation and cleanliness of the substrate before layup is crucial to prevent delamination.

2. **Question:** How does the curing process affect delamination in carbon fabric layups?

**Answer:** Properly controlling the curing temperature and time is essential, as inadequate curing can lead to weak bonds between layers, increasing the risk of delamination.

3. **Question:** What role does the orientation of carbon fibers play in avoiding delamination?

**Answer:** Correctly orienting the carbon fibers according to the load requirements and ensuring consistent fiber alignment throughout the layup can significantly reduce the likelihood of delamination.