Por qué la fibra de vidrio sigue siendo el material predilecto en las reparaciones marinas

-

Tabla de contenido

“Fiberglass: The Durable, Lightweight Solution for Lasting Marine Repairs.”

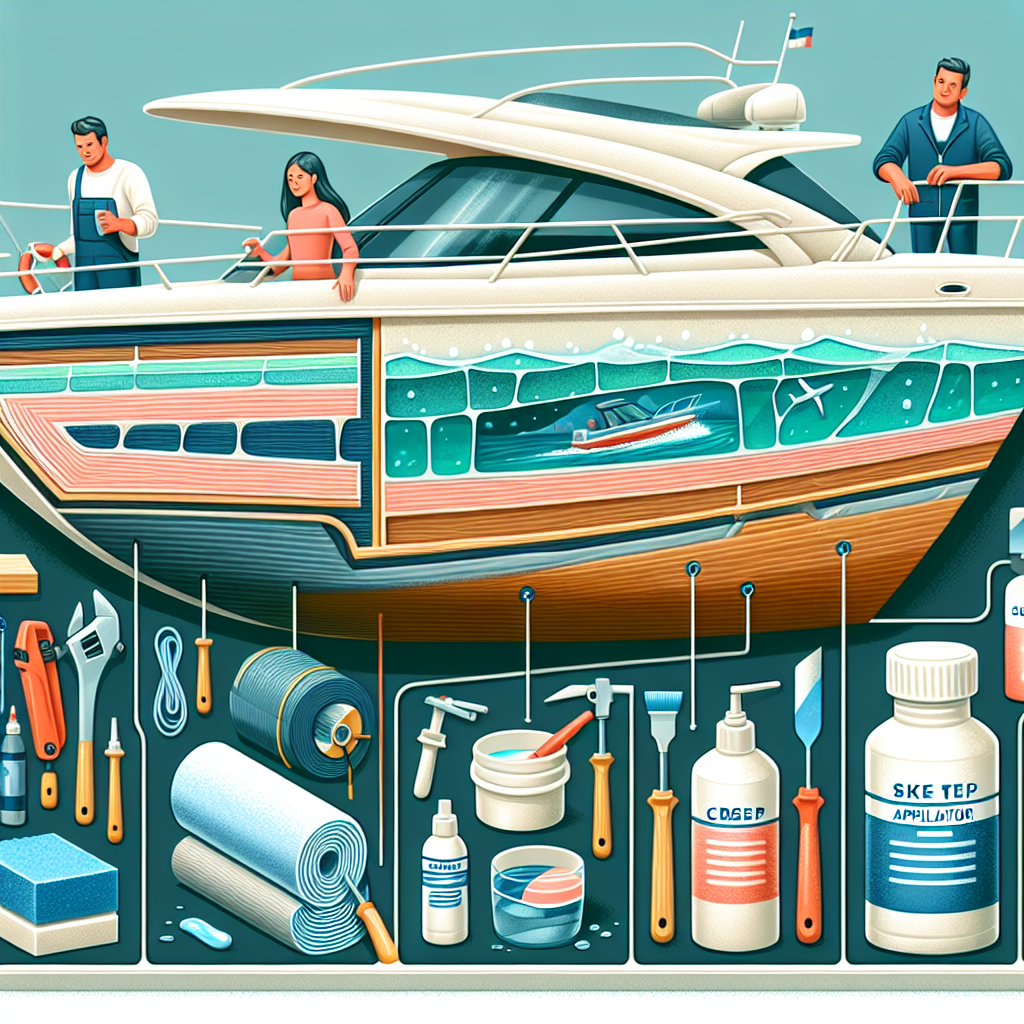

Fiberglass has established itself as a preferred material in marine repair due to its unique combination of strength, durability, and resistance to corrosion. Its lightweight nature allows for easy handling and application, while its ability to withstand harsh marine environments makes it ideal for boat repairs. Additionally, fiberglass can be molded into various shapes, providing versatility in restoring damaged vessels. The material’s excellent bonding properties and compatibility with various resins further enhance its effectiveness in repairs, ensuring long-lasting results. As a result, fiberglass continues to be a go-to choice for both amateur and professional marine repair specialists.

Durability and Strength of Fiberglass in Marine Environments

Fiberglass has long been recognized as a premier material in the marine industry, particularly for its durability and strength in challenging marine environments. This composite material, which consists of glass fibers embedded in a resin matrix, offers a unique combination of properties that make it exceptionally well-suited for use in boats and other marine applications. One of the primary reasons fiberglass remains a go-to material in marine repair is its remarkable resistance to corrosion. Unlike metals, which can succumb to rust and degradation when exposed to saltwater, fiberglass is inherently resistant to the corrosive effects of seawater. This characteristic not only extends the lifespan of marine vessels but also reduces the frequency and cost of repairs, making fiberglass an economically advantageous choice for boat owners.

Moreover, the strength-to-weight ratio of fiberglass is another compelling factor in its continued use in marine repair. Fiberglass is significantly lighter than traditional materials such as wood or metal, yet it maintains a high level of structural integrity. This lightweight nature allows for improved fuel efficiency and better performance on the water, as vessels can achieve higher speeds with less energy expenditure. Additionally, the flexibility of fiberglass enables it to absorb impacts without cracking or breaking, which is particularly beneficial in the unpredictable conditions of marine environments. This resilience is crucial for vessels that encounter rough seas, as it minimizes the risk of structural failure during turbulent conditions.

In addition to its physical properties, fiberglass is also relatively easy to work with, which enhances its appeal in marine repair applications. The material can be molded into various shapes and sizes, allowing for customized repairs that can seamlessly integrate with existing structures. This adaptability is particularly advantageous when addressing damage, as technicians can create patches or reinforcements that match the original design of the vessel. Furthermore, the curing process of fiberglass is straightforward, enabling quick repairs that can be completed in a timely manner, thus minimizing downtime for boat owners.

Another significant advantage of fiberglass is its low maintenance requirements. Once properly cured and finished, fiberglass surfaces are smooth and non-porous, which helps to prevent the accumulation of marine growth such as barnacles and algae. This characteristic not only enhances the aesthetic appeal of the vessel but also contributes to improved performance by reducing drag in the water. Consequently, boat owners can enjoy longer periods between maintenance cycles, further solidifying fiberglass’s reputation as a practical choice for marine applications.

As environmental considerations become increasingly important, fiberglass also offers advantages in terms of sustainability. Many manufacturers are now producing fiberglass using recycled materials, which helps to reduce waste and promote eco-friendly practices within the marine industry. This shift towards sustainability aligns with the growing demand for environmentally responsible products, making fiberglass an even more attractive option for modern boat repair.

In conclusion, the durability and strength of fiberglass in marine environments are key factors that contribute to its status as a preferred material for marine repair. Its resistance to corrosion, impressive strength-to-weight ratio, ease of use, low maintenance requirements, and potential for sustainable production all combine to make fiberglass an ideal choice for boat owners and repair professionals alike. As the marine industry continues to evolve, fiberglass is likely to remain a cornerstone material, ensuring that vessels can withstand the rigors of the sea while providing reliable performance for years to come.

Cost-Effectiveness of Fiberglass for Boat Repairs

When it comes to marine repair, the choice of materials can significantly impact both the cost and longevity of the repairs. Among the various options available, fiberglass has emerged as a preferred choice for many boat owners and repair professionals alike. One of the primary reasons for this preference is the cost-effectiveness of fiberglass, which offers a compelling combination of affordability, durability, and ease of use.

To begin with, fiberglass is relatively inexpensive compared to other materials commonly used in boat repairs, such as wood or metal. The raw materials required for fiberglass construction, including resin and glass fibers, are generally more affordable and widely available. This accessibility translates into lower material costs for boat repairs, making fiberglass an attractive option for those looking to maintain their vessels without breaking the bank. Furthermore, the initial investment in fiberglass can yield significant savings over time, as the material’s durability often results in fewer repairs and replacements in the long run.

In addition to its lower material costs, fiberglass is also lightweight, which contributes to reduced shipping and handling expenses. When transporting materials for repairs, the weight of the materials can significantly affect overall costs. Fiberglass’s lightweight nature not only makes it easier to handle but also reduces fuel costs associated with transportation. This aspect is particularly beneficial for boat repair businesses that need to manage their operational expenses effectively.

Moreover, the ease of application associated with fiberglass further enhances its cost-effectiveness. Unlike traditional materials that may require extensive labor and specialized skills for installation, fiberglass can often be applied with relative simplicity. This ease of use allows for quicker repair times, which translates into lower labor costs. Boat owners can save money by opting for DIY repairs, as many find that they can successfully work with fiberglass after a bit of guidance. Consequently, the combination of lower material costs and reduced labor expenses makes fiberglass an economically viable option for boat repairs.

Another factor contributing to the cost-effectiveness of fiberglass is its resistance to environmental factors. Fiberglass is inherently resistant to water, rot, and corrosion, which are common issues that plague boats made from other materials. This resistance means that repairs made with fiberglass are less likely to require frequent maintenance or replacement, ultimately saving boat owners money over time. In contrast, materials like wood may require regular treatment and upkeep to prevent deterioration, leading to higher long-term costs.

Furthermore, the versatility of fiberglass allows it to be used in a wide range of applications, from hull repairs to structural reinforcements. This adaptability means that boat owners can rely on a single material for various repair needs, simplifying the repair process and reducing the need for multiple types of materials. As a result, the overall cost of repairs can be minimized, making fiberglass an even more appealing choice.

In conclusion, the cost-effectiveness of fiberglass as a material for boat repairs is evident in its affordability, lightweight nature, ease of application, and resistance to environmental factors. These attributes not only make fiberglass a practical choice for immediate repairs but also ensure long-term savings for boat owners. As the marine industry continues to evolve, fiberglass remains a go-to material, proving that it is not only a reliable option but also a financially sound investment for those looking to maintain their vessels efficiently.

Versatility of Fiberglass in Various Marine Applications

Fiberglass has long been recognized as a cornerstone material in the marine industry, and its versatility in various applications is a significant reason for its enduring popularity. This composite material, composed of glass fibers embedded in a resin matrix, offers a unique combination of strength, lightweight properties, and resistance to corrosion, making it an ideal choice for a wide range of marine repairs and constructions. As the demands of the marine environment continue to evolve, fiberglass remains a go-to material for both manufacturers and repair professionals alike.

One of the most notable advantages of fiberglass is its adaptability to different forms and structures. Whether it is used in the construction of hulls, decks, or even smaller components such as hatches and fittings, fiberglass can be molded into virtually any shape. This flexibility allows for innovative designs that can enhance the performance and aesthetics of marine vessels. For instance, the ability to create complex curves and contours not only improves the hydrodynamics of a boat but also contributes to its visual appeal. As a result, fiberglass has become synonymous with modern boat design, enabling manufacturers to push the boundaries of creativity while ensuring functionality.

Moreover, the lightweight nature of fiberglass is another critical factor that contributes to its widespread use in marine applications. Compared to traditional materials such as wood or metal, fiberglass offers significant weight savings without compromising structural integrity. This characteristic is particularly advantageous in the marine industry, where weight directly impacts performance, fuel efficiency, and overall handling. By utilizing fiberglass, boat builders can create lighter vessels that are easier to maneuver and more fuel-efficient, ultimately enhancing the user experience on the water.

In addition to its lightweight properties, fiberglass exhibits remarkable resistance to environmental factors that can cause deterioration in other materials. The marine environment is notoriously harsh, with exposure to saltwater, UV radiation, and extreme weather conditions. Fiberglass is inherently resistant to corrosion, which means that it can withstand prolonged exposure to these elements without succumbing to rust or decay. This durability not only extends the lifespan of marine vessels but also reduces maintenance costs, making fiberglass an economically sound choice for boat owners and operators.

Furthermore, the ease of repair associated with fiberglass is another compelling reason for its continued use in marine applications. When damage occurs, whether from impacts, wear and tear, or environmental factors, fiberglass can be repaired relatively quickly and efficiently. The repair process typically involves cleaning the damaged area, applying a resin and fiberglass cloth, and allowing it to cure. This straightforward approach minimizes downtime, allowing vessels to return to service promptly. Additionally, advancements in repair techniques and materials have further streamlined the process, ensuring that repairs are not only effective but also aesthetically pleasing.

As the marine industry continues to innovate, the versatility of fiberglass remains a key asset. Its ability to adapt to various applications, combined with its lightweight nature, resistance to corrosion, and ease of repair, solidifies its status as a preferred material in marine repair and construction. As boat builders and repair professionals seek to meet the demands of modern boating enthusiasts, fiberglass will undoubtedly continue to play a pivotal role in shaping the future of marine design and maintenance. In conclusion, the multifaceted benefits of fiberglass ensure that it will remain a go-to material in the marine industry for years to come, supporting both performance and longevity in a challenging environment.

Preguntas y respuestas

1. **Question:** What are the primary benefits of using fiberglass in marine repair?

**Answer:** Fiberglass is lightweight, strong, resistant to corrosion, and has excellent durability, making it ideal for marine environments.

2. **Question:** How does fiberglass contribute to the longevity of marine vessels?

**Answer:** Fiberglass provides a waterproof barrier and resists damage from saltwater, UV rays, and impacts, which helps extend the lifespan of boats.

3. **Question:** What makes fiberglass repair processes efficient for marine applications?

**Answer:** Fiberglass can be easily molded and shaped to fit various structures, and its curing process allows for quick repairs that can be completed in a relatively short time.Fiberglass remains a go-to material in marine repair due to its exceptional strength-to-weight ratio, resistance to corrosion and water damage, ease of application, and versatility in various repair scenarios. Its ability to bond well with existing materials and provide a durable, long-lasting finish makes it an ideal choice for boat repairs, ensuring longevity and performance in challenging marine environments.