Kevlar vs fibra de carbono: resistencia, costo y usos

Did you know that Kevlar is five times stronger than steel, while Carbon Fiber is six times lighter but still provides exceptional strength? In the world of advanced materials, these two powerhouses often go head-to-head, revolutionizing industries across the globe. If you're curious to discover which material reigns supreme in terms of strength, cost, and wide-ranging applications, you've come to the right place. Join us as we dive into the battle of Kevlar versus Carbon Fiber, unlocking their potential and helping you make informed decisions for your next project.

Understanding Kevlar

In this section, we will explore the properties and characteristics of Kevlar, a remarkable material renowned for its exceptional strength, durability, and lightweight nature. Kevlar is a synthetic fiber that offers outstanding resistance to impact and a wide range of external forces.

Fortaleza: Kevlar possesses incredible strength, making it five times stronger than steel on an equal weight basis. This property allows it to withstand heavy loads and resist tearing, making it an ideal choice for applications that require high tensile strength.

Durabilidad: Kevlar is known for its exceptional durability and resistance to external factors such as heat, chemicals, and abrasion. It can maintain its structural integrity even in extreme conditions, making it highly reliable for various industrial applications.

Ligero: One of the key advantages of Kevlar is its lightweight nature. Despite its impressive strength, Kevlar is incredibly lightweight, offering a significant advantage in weight-sensitive applications such as aerospace and sports equipment.

When comparing Kevlar to other materials, such as Carbon Fiber, several differences arise. While Carbon Fiber also offers excellent strength and lightweight properties, Kevlar provides superior impact resistance and has better resistance to abrasion. Additionally, Kevlar's temperature resistance is higher than that of Carbon Fiber, making it suitable for applications that involve high temperatures.

Overall, Kevlar's unique combination of strength, durability, and lightweight nature makes it a highly versatile material with applications in various industries, including aerospace, automotive, defense, and sporting goods.

"Kevlar's exceptional strength, durability, and lightweight nature make it a revolutionary material with numerous applications across industries."

An example of Kevlar's properties in the aerospace industry:

| Propiedad | Kevlar | Fibra de carbono |

|---|---|---|

| Fortaleza | Exceptional tensile strength | Alta resistencia a la tracción |

| Durabilidad | Resistant to heat, chemicals, and abrasion | Resistant to heat and chemicals |

| Peso | Ligero | Ligero |

| Aplicaciones | Aerospace, automotive, defense | Aerospace, automotive, sporting goods |

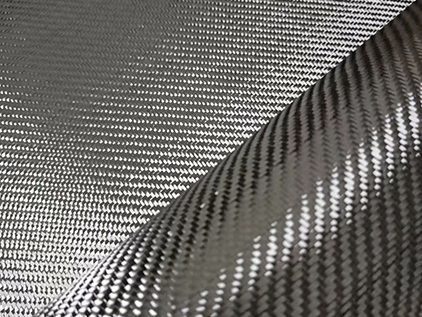

The Versatility of Carbon Fiber

When it comes to advanced materials, few can rival the versatility of Fibra de carbono. This remarkable substance possesses a unique set of properties that make it a preferred choice across various industries. From aerospace to automotive, carbon fiber finds numerous applications, thanks to its exceptional strength-to-weight ratio and distinct characteristics.

Carbon fiber is revolutionizing the way we design and engineer products. Its unparalleled strength and lightweight nature are opening up new possibilities in fields that demand high-performance materials.

The Strength-to-Weight Ratio

One of the most remarkable qualities of carbon fiber is its exceptional strength-to-weight ratio. This means that despite its lightweight nature, carbon fiber exhibits incredible strength, outperforming many traditional materials. Its high tensile strength allows it to endure significant loads and resist deformation, making it a perfect choice for applications where strength and durability are paramount.

Compared to its counterpart, Kevlar, carbon fiber excels in terms of strength. While Kevlar is known for its impressive impact resistance, carbon fiber takes it a step further by providing even greater strength without compromising on weight. This makes carbon fiber an ideal choice for industries that require both strength and lightweight properties.

Applications in Various Industries

The versatility of carbon fiber makes it an invaluable material in a wide range of industries. As mentioned earlier, aerospace and automotive sectors heavily rely on carbon fiber to enhance the performance and efficiency of their products. The exceptional strength and lightweight properties of carbon fiber allow for the construction of stronger, lighter aircraft structures and more fuel-efficient cars.

Additionally, carbon fiber finds applications in sports equipment, such as tennis rackets, golf clubs, and bicycle frames. Its unique properties make it an excellent choice for these applications, providing athletes with enhanced performance and control.

Differences from Kevlar

While carbon fiber and Kevlar are both advanced materials, there are significant differences between the two. Carbon fiber, as discussed, offers exceptional strength and lightweight properties, whereas Kevlar is known for its high impact resistance and durability.

In terms of applications, carbon fiber finds a broader range of uses due to its versatility and strength-to-weight ratio. On the other hand, Kevlar is commonly employed in bulletproof vests, protective gear, and applications where impact resistance is crucial.

Ultimately, the choice between carbon fiber and Kevlar depends on the specific requirements of the project and the desired characteristics of the end product.

Strength: Kevlar vs Carbon Fiber

Kevlar and Carbon Fiber are both renowned for their exceptional strength properties, but they differ in various aspects. In this section, we will explore the differences in their tensile strength, impact resistance, and performance under different conditions.

Resistencia a la tracción

When it comes to tensile strength, Kevlar is known for its remarkable performance. It is five times stronger than steel on an equal weight basis, making it one of the strongest materials available. Its high tensile strength allows it to withstand extreme forces without breaking or deforming.

On the other hand, Carbon Fiber also exhibits impressive tensile strength. Although not as strong as Kevlar, it still surpasses the strength of many traditional materials. Carbon Fiber's strength lies in its unique fiber orientation and composition, contributing to its excellent load-bearing capabilities.

Resistencia al impacto

Both Kevlar and Carbon Fiber excel in impact resistance, albeit in different ways. Kevlar's flexibility and energy absorption properties enable it to dissipate impact forces, minimizing damage and preventing penetration. This makes it an ideal choice for protective applications such as body armor or bulletproof vests.

Carbon Fiber, on the other hand, is known for its exceptional resistance to impact damage. It possesses a higher stiffness-to-weight ratio, enabling it to absorb and distribute impact energy efficiently. This characteristic makes Carbon Fiber suitable for applications that require high strength and impact resistance, such as aerospace components.

Performance Under Different Conditions

When it comes to performance under different conditions, Kevlar and Carbon Fiber also have notable differences. Kevlar has excellent resistance to heat, making it suitable for high-temperature applications. It also maintains its strength and integrity even in humid or wet environments, making it ideal for outdoor applications.

Carbon Fiber, on the other hand, demonstrates outstanding performance in environments where corrosion or chemical exposure is a concern. It is highly resistant to chemicals, including acids and alkalis, making it suitable for applications in the chemical and marine industries.

In summary, while both Kevlar and Carbon Fiber possess impressive strength characteristics, they differ in terms of tensile strength, impact resistance, and performance under different conditions. Table 4 below provides a detailed comparison of their strength properties.

| Kevlar | Fibra de carbono | |

|---|---|---|

| Resistencia a la tracción | Five times stronger than steel on an equal weight basis | Impressive strength surpassing many traditional materials |

| Resistencia al impacto | Flexible with excellent energy absorption properties | Exceptional resistance to impact damage |

| Performance Under Different Conditions | Excellent heat resistance and maintains strength in humid/wet environments | High resistance to corrosion and chemicals |

Cost Considerations: Kevlar vs Carbon Fiber

When considering the use of advanced materials like Kevlar and Carbon Fiber, cost is an important factor to assess. In this section, we will delve into the cost aspects of these materials, exploring their production process, availability, and market prices to help you determine the cost-effectiveness of each.

Production Process:

Both Kevlar and Carbon Fiber require complex manufacturing processes, which contribute to their higher cost compared to traditional materials. Kevlar is produced by polymerizing para-phenylenediamine and terephthaloyl chloride, while Carbon Fiber is made by heating synthetic fibers derived from organic polymers.

Availability:

When it comes to availability, Carbon Fiber is more widely accessible compared to Kevlar. Carbon Fiber is produced in larger quantities due to its extensive use in industries like aviation and automotive, resulting in more competitive pricing and availability. On the other hand, Kevlar is often used in specialized applications and may have limited availability, leading to higher costs.

Market Prices:

The cost of Kevlar and Carbon Fiber can vary significantly depending on factors such as the supplier, quantity purchased, and desired specifications. Generally, Carbon Fiber tends to have a lower market price compared to Kevlar, making it a more cost-effective option for certain applications.

Quote: "While Kevlar offers exceptional strength and durability, the higher production costs and limited availability can make it a more expensive choice. Carbon Fiber, on the other hand, provides a good balance between performance and cost, making it a popular option in industries where cost-effectiveness is crucial."

It's important to note that the cost difference between Kevlar and Carbon Fiber may influence the decision-making process in choosing the right material for your project. Consider weighing the benefits and costs, as well as evaluating the specific requirements and budget constraints of your application.

| Aspecto | Kevlar | Fibra de carbono |

|---|---|---|

| Proceso de producción | Complex and specialized | Complex and specialized |

| Availability | Limitado | Widely accessible |

| Market Prices | Más alto | Más bajo |

Applications of Kevlar

Kevlar, with its exceptional strength and lightweight properties, finds extensive applications in various industries. Let's explore some key fields where Kevlar excels:

- Aeroespacial: Kevlar's high strength-to-weight ratio makes it a crucial material in the aerospace industry. It is used in aircraft components, such as the fuselage, wings, and rotor blades, to enhance structural integrity, increase fuel efficiency, and reduce overall weight.

- Automotor: Kevlar is widely used in the automotive sector for its durability and impact resistance. It is used in manufacturing components such as brake pads, gaskets, and reinforced tires, providing enhanced safety and performance.

- Sporting Goods: The sporting goods industry benefits greatly from Kevlar's strength and lightweight nature. It is used in manufacturing sports equipment like helmets, body armor, gloves, and footwear, ensuring superior protection without compromising flexibility and comfort.

- Marina: Kevlar's resistance to water, UV rays, and abrasion makes it an ideal choice for marine applications. It is used in boat hulls, sails, ropes, and mooring lines, providing excellent durability, strength, and buoyancy.

- Defense and Security: Kevlar's high impact resistance and protective qualities make it a vital material in the defense and security sectors. It is used in bulletproof vests, helmets, and armored vehicles, safeguarding personnel from ballistic threats.

These are just a few examples of the diverse applications of Kevlar. Its unique combination of strength, durability, and lightweight properties makes it a sought-after material in various industries, catering to a wide range of needs and requirements.

Aplicaciones de la fibra de carbono

Carbon Fiber is a remarkable material that finds its applications in a wide range of industries, thanks to its exceptional properties. Let's explore some of the key applications of carbon fiber:

1. Aviation Industry

Carbon Fiber is extensively used in the aviation industry for its high strength-to-weight ratio. It is employed in the manufacturing of aircraft components, including wings, fuselages, and landing gear, to reduce weight without compromising structural integrity.

2. Renewable Energy Sector

Carbon Fiber plays a significant role in the renewable energy sector. It is used in the production of wind turbine blades due to its lightweight nature and excellent fatigue resistance. Carbon Fiber enhances the efficiency and performance of wind turbines, contributing to the production of clean and sustainable energy.

3. Sports Equipment

Carbon Fiber has revolutionized the sports industry by introducing advanced and lightweight equipment. From tennis rackets to bicycles, golf clubs to helmets, Carbon Fiber is utilized to create stronger, durable, and more maneuverable sporting goods. Athletes benefit from improved performance and reduced fatigue, giving them a competitive edge.

4. Automotive Sector

In the automotive industry, Carbon Fiber is used to manufacture high-end vehicles, especially in the luxury and sports car segment. The material's strength and lightweight characteristics contribute to enhanced fuel efficiency, improved handling, and increased overall performance of the vehicles.

5. Aerospace Industry

Carbon Fiber is widely employed in the aerospace industry for its exceptional properties. It is utilized to construct aircraft parts such as wings, tailplanes, and fuselages, as well as space-related applications. The use of Carbon Fiber in aerospace ensures robustness while significantly reducing weight, resulting in greater fuel efficiency and improved flight performance.

6. Marine Industry

The marine industry harnesses the benefits of Carbon Fiber for various applications. It is utilized in boat building, where its lightweight and high strength properties make it an ideal choice for hulls, masts, and other structural components. Carbon Fiber offers increased speed, improved handling, and fuel efficiency in marine vessels.

7. Medical Field

In the medical field, Carbon Fiber is used to manufacture lightweight and durable medical equipment and devices. It finds applications in prosthetics and orthotics, providing individuals with enhanced mobility and comfort. Carbon Fiber's biocompatible nature and strength make it an excellent choice for medical applications.

| Industria | Aplicaciones |

|---|---|

| Aviation | Aircraft components, wings, fuselages, landing gear |

| Energía renovable | Palas de turbinas eólicas |

| Equipo deportivo | Tennis rackets, bicycles, golf clubs, helmets |

| Automotor | High-end vehicles |

| Aeroespacial | Aircraft parts, space applications |

| Marina | Boat building |

| Médico | Prosthetics, orthotics, medical equipment |

Durability: Kevlar vs Carbon Fiber

When it comes to durability, both Kevlar and Carbon Fiber are renowned for their exceptional strength and resilience. These advanced materials have distinct properties that make them resistant to various environmental factors, ensuring longevity in demanding applications.

Kevlar: Withstanding the Elements

Kevlar, a synthetic fiber developed by DuPont, exhibits remarkable durability in extreme conditions. It is known for its excellent resistance to heat, making it ideal for high-temperature environments. Additionally, Kevlar demonstrates exceptional stability in the face of corrosive substances, protecting it from chemical damage and enhancing its lifespan.

Kevlar's ability to withstand impacts without losing its structural integrity further solidifies its durability. Whether it's protecting personnel in bulletproof vests or reinforcing critical components in aerospace engineering, Kevlar's durability ensures reliable performance in the harshest conditions.

Carbon Fiber: Unmatched Strength and Endurance

Carbon Fiber, a composite material consisting of carbon atoms tightly bonded together, possesses formidable durability. One of its notable features is its resistance to corrosion, including the effects of moisture and chemicals, which extends its lifespan.

Carbon Fiber's exceptional strength-to-weight ratio also contributes to its durability. Its high tensile strength allows it to withstand heavy loads without compromising its structure, making it an excellent choice for various applications where durability is essential.

Quote: "The extraordinary durability of Carbon Fiber enables it to excel in industries ranging from automotive and aerospace to construction and sports." - [Author]

Comparing Durability

While both Kevlar and Carbon Fiber possess impressive durability, their strengths lie in different areas. Kevlar's resistance to heat and corrosion makes it an optimal choice for applications exposed to extreme temperatures or corrosive environments.

On the other hand, Carbon Fiber's resistance to corrosion, combined with its exceptional strength, provides unmatched durability in scenarios where high loads and structural integrity are crucial.

| Material | Durabilidad | Resistance to Heat | Resistencia a la corrosión | Resistencia al impacto |

|---|---|---|---|---|

| Kevlar | Alto | Excelente | Excelente | Excepcional |

| Fibra de carbono | Alto | Bien | Excelente | Excelente |

As seen in the comparison table, both materials offer notable durability, with Kevlar demonstrating exceptional performance in heat resistance and impact resistance. Carbon Fiber, on the other hand, excels in corrosion resistance while maintaining its strength and endurance.

Stay tuned for the next section, where we will delve into the lightweight advantages of Kevlar and Carbon Fiber, exploring how their weight plays a crucial role in various applications.

Lightweight Advantages: Kevlar vs Carbon Fiber

When it comes to lightweight materials, both Kevlar and Carbon Fiber are at the forefront of innovation. Their exceptional strength-to-weight ratios make them ideal choices for applications where reducing weight is crucial. Let's explore the differences in their lightweight properties and understand how they impact performance, fuel efficiency, and overall usability in different industries.

Performance Boost with Kevlar

Kevlar is a synthetic fiber renowned for its strength and lightweight nature. With its unique molecular structure, Kevlar offers outstanding resistance to impact, making it highly suitable for protective gear, such as bulletproof vests and safety helmets. In the automotive industry, Kevlar is used to manufacture lightweight components that enhance performance and maneuverability.

Kevlar's lightweight nature empowers athletes and adventurers by providing them with flexibility, agility, and confidence in their pursuits.

Additionally, Kevlar exhibits excellent heat resistance, making it an ideal choice for high-temperature applications such as aerospace components and heat shields.

Unparalleled Strength with Carbon Fiber

On the other hand, Fibra de carbono is renowned for its incredible strength combined with astonishing lightness. This unique combination makes it a preferred material for industries seeking maximum performance with minimal weight. Carbon Fiber is extensively used in the aviation industry to construct aircraft, including wings and fuselages, contributing to improved fuel efficiency and range.

Carbon Fiber's feather-light weight revolutionizes the performance of sports cars, offering unparalleled acceleration, handling, and braking capabilities.

Moreover, the excellent vibration-damping properties of Carbon Fiber make it an excellent choice for sporting goods, like bicycles and tennis rackets, providing athletes with optimized control and comfort during intense activities.

Choosing the Right Material

When deciding between Kevlar and Carbon Fiber for a specific application, it is vital to consider the specific requirements and performance objectives. Kevlar's renowned impact resistance and heat resistance make it ideal for protective gear and high-temperature environments. Carbon Fiber, with its unmatched strength-to-weight ratio, is often preferred in industries where performance and fuel efficiency are paramount.

Whatever your project may be, understanding the differences in the lightweight properties of Kevlar and Carbon Fiber will empower you to make an informed choice that aligns with your goals and aspirations.

By assessing your needs and considering the unique advantages of each material, you can harness the lightweight properties of Kevlar or Carbon Fiber to achieve remarkable results in your next venture.

Conclusión

After extensively comparing Kevlar and Carbon Fiber, it is clear that both materials have their unique strengths and advantages. When it comes to strength, Kevlar excels in tensile strength and impact resistance, making it an excellent choice for applications that require superior durability. On the other hand, Carbon Fiber offers a remarkable strength-to-weight ratio, making it ideal for industries where lightweight yet robust materials are needed.

In terms of cost, Kevlar tends to be more expensive due to its production process and limited availability. Carbon Fiber, although still relatively costly, offers a slightly more cost-effective option. When considering the affordability and feasibility of a project, the cost differences between the two materials should be carefully evaluated.

When it comes to applications, Kevlar finds its place in industries such as aerospace, automotive, and sporting goods. Its remarkable strength and lightweight nature make it invaluable for building durable and high-performance structures. On the other hand, Carbon Fiber's versatility shines in aviation, renewable energy, and sports equipment industries, where its lightweight properties and strength are highly valued.

In summary, the choice between Kevlar and Carbon Fiber ultimately depends on the specific requirements of your project. If strength and impact resistance are crucial, Kevlar is an excellent option. However, if your project demands a lightweight yet robust material, Carbon Fiber is the way to go. Consider the cost implications, application needs, and long-term durability to make an informed decision and select the material that best fits your project objectives.

Preguntas frecuentes

What is the difference between Kevlar and Carbon Fiber?

Kevlar is a synthetic fiber known for its high strength and durability, while Carbon Fiber is a composite material made of carbon fibers. Both materials have different properties and applications.

Which material is stronger, Kevlar or Carbon Fiber?

Carbon Fiber is generally stronger than Kevlar in terms of tensile strength and stiffness. It also has a higher strength-to-weight ratio, making it a popular choice for high-performance applications.

What are the main applications of Kevlar?

Kevlar is widely used in industries such as aerospace, automotive, sporting goods, and personal protective equipment. It is commonly found in bulletproof vests, aircraft components, and lightweight structural reinforcements.

Where is Carbon Fiber commonly used?

Carbon Fiber has a diverse range of applications, including aerospace, automotive, renewable energy, and sports equipment. It is found in aircraft parts, automobile components, wind turbine blades, and high-end bicycles, among others.

Is Kevlar more durable than Carbon Fiber?

Kevlar has excellent resistance to impact, abrasion, and fatigue, making it highly durable. However, Carbon Fiber exhibits higher durability against harsh environmental conditions, heat, and corrosion.

Which material is more cost-effective, Kevlar or Carbon Fiber?

In general, Kevlar is more affordable than Carbon Fiber. However, the cost of both materials can vary depending on factors such as production volume, market demand, and specific application requirements.

Are Kevlar and Carbon Fiber lightweight materials?

Yes, both Kevlar and Carbon Fiber are known for their lightweight properties. They offer high strength-to-weight ratios, resulting in improved performance, fuel efficiency, and ease of handling.

What factors should I consider when choosing between Kevlar and Carbon Fiber?

When choosing between Kevlar and Carbon Fiber, consider factors such as the required strength, cost constraints, specific application needs, and environmental considerations. It is important to assess the benefits and limitations of each material for your project.

Did you know that Kevlar is five times stronger than steel, while Carbon Fiber is six times lighter but still provides exceptional strength? In the world of advanced materials, these two powerhouses often go head-to-head, revolutionizing industries across the globe. If you're curious to discover which material reigns supreme in terms of strength, cost, and wide-ranging applications, you've come to the right place. Join us as we dive into the battle of Kevlar versus Carbon Fiber, unlocking their potential and helping you make informed decisions for your next project.

Understanding Kevlar

In this section, we will explore the properties and characteristics of Kevlar, a remarkable material renowned for its exceptional strength, durability, and lightweight nature. Kevlar is a synthetic fiber that offers outstanding resistance to impact and a wide range of external forces.

Fortaleza: Kevlar possesses incredible strength, making it five times stronger than steel on an equal weight basis. This property allows it to withstand heavy loads and resist tearing, making it an ideal choice for applications that require high tensile strength.

Durabilidad: Kevlar is known for its exceptional durability and resistance to external factors such as heat, chemicals, and abrasion. It can maintain its structural integrity even in extreme conditions, making it highly reliable for various industrial applications.

Ligero: One of the key advantages of Kevlar is its lightweight nature. Despite its impressive strength, Kevlar is incredibly lightweight, offering a significant advantage in weight-sensitive applications such as aerospace and sports equipment.

When comparing Kevlar to other materials, such as Carbon Fiber, several differences arise. While Carbon Fiber also offers excellent strength and lightweight properties, Kevlar provides superior impact resistance and has better resistance to abrasion. Additionally, Kevlar's temperature resistance is higher than that of Carbon Fiber, making it suitable for applications that involve high temperatures.

Overall, Kevlar's unique combination of strength, durability, and lightweight nature makes it a highly versatile material with applications in various industries, including aerospace, automotive, defense, and sporting goods.

"Kevlar's exceptional strength, durability, and lightweight nature make it a revolutionary material with numerous applications across industries."

An example of Kevlar's properties in the aerospace industry:

| Propiedad | Kevlar | Fibra de carbono |

|---|---|---|

| Fortaleza | Exceptional tensile strength | Alta resistencia a la tracción |

| Durabilidad | Resistant to heat, chemicals, and abrasion | Resistant to heat and chemicals |

| Peso | Ligero | Ligero |

| Aplicaciones | Aerospace, automotive, defense | Aerospace, automotive, sporting goods |

The Versatility of Carbon Fiber

When it comes to advanced materials, few can rival the versatility of carbon fiber. This remarkable substance possesses a unique set of properties that make it a preferred choice across various industries. From aerospace to automotive, carbon fiber finds numerous applications, thanks to its exceptional strength-to-weight ratio and distinct characteristics.

Carbon fiber is revolutionizing the way we design and engineer products. Its unparalleled strength and lightweight nature are opening up new possibilities in fields that demand high-performance materials.

The Strength-to-Weight Ratio

One of the most remarkable qualities of carbon fiber is its exceptional strength-to-weight ratio. This means that despite its lightweight nature, carbon fiber exhibits incredible strength, outperforming many traditional materials. Its high tensile strength allows it to endure significant loads and resist deformation, making it a perfect choice for applications where strength and durability are paramount.

Compared to its counterpart, Kevlar, carbon fiber excels in terms of strength. While Kevlar is known for its impressive impact resistance, carbon fiber takes it a step further by providing even greater strength without compromising on weight. This makes carbon fiber an ideal choice for industries that require both strength and lightweight properties.

Applications in Various Industries

The versatility of carbon fiber makes it an invaluable material in a wide range of industries. As mentioned earlier, aerospace and automotive sectors heavily rely on carbon fiber to enhance the performance and efficiency of their products. The exceptional strength and lightweight properties of carbon fiber allow for the construction of stronger, lighter aircraft structures and more fuel-efficient cars.

Additionally, carbon fiber finds applications in sports equipment, such as tennis rackets, golf clubs, and bicycle frames. Its unique properties make it an excellent choice for these applications, providing athletes with enhanced performance and control.

Differences from Kevlar

While carbon fiber and Kevlar are both advanced materials, there are significant differences between the two. Carbon fiber, as discussed, offers exceptional strength and lightweight properties, whereas Kevlar is known for its high impact resistance and durability.

In terms of applications, carbon fiber finds a broader range of uses due to its versatility and strength-to-weight ratio. On the other hand, Kevlar is commonly employed in bulletproof vests, protective gear, and applications where impact resistance is crucial.

Ultimately, the choice between carbon fiber and Kevlar depends on the specific requirements of the project and the desired characteristics of the end product.

Strength: Kevlar vs Carbon Fiber

Kevlar and Carbon Fiber are both renowned for their exceptional strength properties, but they differ in various aspects. In this section, we will explore the differences in their tensile strength, impact resistance, and performance under different conditions.

Resistencia a la tracción

When it comes to tensile strength, Kevlar is known for its remarkable performance. It is five times stronger than steel on an equal weight basis, making it one of the strongest materials available. Its high tensile strength allows it to withstand extreme forces without breaking or deforming.

On the other hand, Carbon Fiber also exhibits impressive tensile strength. Although not as strong as Kevlar, it still surpasses the strength of many traditional materials. Carbon Fiber's strength lies in its unique fiber orientation and composition, contributing to its excellent load-bearing capabilities.

Resistencia al impacto

Both Kevlar and Carbon Fiber excel in impact resistance, albeit in different ways. Kevlar's flexibility and energy absorption properties enable it to dissipate impact forces, minimizing damage and preventing penetration. This makes it an ideal choice for protective applications such as body armor or bulletproof vests.

Carbon Fiber, on the other hand, is known for its exceptional resistance to impact damage. It possesses a higher stiffness-to-weight ratio, enabling it to absorb and distribute impact energy efficiently. This characteristic makes Carbon Fiber suitable for applications that require high strength and impact resistance, such as aerospace components.

Performance Under Different Conditions

When it comes to performance under different conditions, Kevlar and Carbon Fiber also have notable differences. Kevlar has excellent resistance to heat, making it suitable for high-temperature applications. It also maintains its strength and integrity even in humid or wet environments, making it ideal for outdoor applications.

Carbon Fiber, on the other hand, demonstrates outstanding performance in environments where corrosion or chemical exposure is a concern. It is highly resistant to chemicals, including acids and alkalis, making it suitable for applications in the chemical and marine industries.

In summary, while both Kevlar and Carbon Fiber possess impressive strength characteristics, they differ in terms of tensile strength, impact resistance, and performance under different conditions. Table 4 below provides a detailed comparison of their strength properties.

| Kevlar | Fibra de carbono | |

|---|---|---|

| Resistencia a la tracción | Five times stronger than steel on an equal weight basis | Impressive strength surpassing many traditional materials |

| Resistencia al impacto | Flexible with excellent energy absorption properties | Exceptional resistance to impact damage |

| Performance Under Different Conditions | Excellent heat resistance and maintains strength in humid/wet environments | High resistance to corrosion and chemicals |

Cost Considerations: Kevlar vs Carbon Fiber

When considering the use of advanced materials like Kevlar and Carbon Fiber, cost is an important factor to assess. In this section, we will delve into the cost aspects of these materials, exploring their production process, availability, and market prices to help you determine the cost-effectiveness of each.

Production Process:

Both Kevlar and Carbon Fiber require complex manufacturing processes, which contribute to their higher cost compared to traditional materials. Kevlar is produced by polymerizing para-phenylenediamine and terephthaloyl chloride, while Carbon Fiber is made by heating synthetic fibers derived from organic polymers.

Availability:

When it comes to availability, Carbon Fiber is more widely accessible compared to Kevlar. Carbon Fiber is produced in larger quantities due to its extensive use in industries like aviation and automotive, resulting in more competitive pricing and availability. On the other hand, Kevlar is often used in specialized applications and may have limited availability, leading to higher costs.

Market Prices:

The cost of Kevlar and Carbon Fiber can vary significantly depending on factors such as the supplier, quantity purchased, and desired specifications. Generally, Carbon Fiber tends to have a lower market price compared to Kevlar, making it a more cost-effective option for certain applications.

Quote: "While Kevlar offers exceptional strength and durability, the higher production costs and limited availability can make it a more expensive choice. Carbon Fiber, on the other hand, provides a good balance between performance and cost, making it a popular option in industries where cost-effectiveness is crucial."

It's important to note that the cost difference between Kevlar and Carbon Fiber may influence the decision-making process in choosing the right material for your project. Consider weighing the benefits and costs, as well as evaluating the specific requirements and budget constraints of your application.

| Aspecto | Kevlar | Fibra de carbono |

|---|---|---|

| Proceso de producción | Complex and specialized | Complex and specialized |

| Availability | Limitado | Widely accessible |

| Market Prices | Más alto | Más bajo |

Applications of Kevlar

Kevlar, with its exceptional strength and lightweight properties, finds extensive applications in various industries. Let's explore some key fields where Kevlar excels:

- Aeroespacial: Kevlar's high strength-to-weight ratio makes it a crucial material in the aerospace industry. It is used in aircraft components, such as the fuselage, wings, and rotor blades, to enhance structural integrity, increase fuel efficiency, and reduce overall weight.

- Automotor: Kevlar is widely used in the automotive sector for its durability and impact resistance. It is used in manufacturing components such as brake pads, gaskets, and reinforced tires, providing enhanced safety and performance.

- Sporting Goods: The sporting goods industry benefits greatly from Kevlar's strength and lightweight nature. It is used in manufacturing sports equipment like helmets, body armor, gloves, and footwear, ensuring superior protection without compromising flexibility and comfort.

- Marina: Kevlar's resistance to water, UV rays, and abrasion makes it an ideal choice for marine applications. It is used in boat hulls, sails, ropes, and mooring lines, providing excellent durability, strength, and buoyancy.

- Defense and Security: Kevlar's high impact resistance and protective qualities make it a vital material in the defense and security sectors. It is used in bulletproof vests, helmets, and armored vehicles, safeguarding personnel from ballistic threats.

These are just a few examples of the diverse applications of Kevlar. Its unique combination of strength, durability, and lightweight properties makes it a sought-after material in various industries, catering to a wide range of needs and requirements.

Aplicaciones de la fibra de carbono

Carbon Fiber is a remarkable material that finds its applications in a wide range of industries, thanks to its exceptional properties. Let's explore some of the key areas where Carbon Fiber excels:

1. Aviation Industry

Carbon Fiber is extensively used in the aviation industry for its high strength-to-weight ratio. It is employed in the manufacturing of aircraft components, including wings, fuselages, and landing gear, to reduce weight without compromising structural integrity.

2. Renewable Energy Sector

Carbon Fiber plays a significant role in the renewable energy sector. It is used in the production of wind turbine blades due to its lightweight nature and excellent fatigue resistance. Carbon Fiber enhances the efficiency and performance of wind turbines, contributing to the production of clean and sustainable energy.

3. Sports Equipment

Carbon Fiber has revolutionized the sports industry by introducing advanced and lightweight equipment. From tennis rackets to bicycles, golf clubs to helmets, Carbon Fiber is utilized to create stronger, durable, and more maneuverable sporting goods. Athletes benefit from improved performance and reduced fatigue, giving them a competitive edge.

4. Automotive Sector

In the automotive industry, Carbon Fiber is used to manufacture high-end vehicles, especially in the luxury and sports car segment. The material's strength and lightweight characteristics contribute to enhanced fuel efficiency, improved handling, and increased overall performance of the vehicles.

5. Aerospace Industry

Carbon Fiber is widely employed in the aerospace industry for its exceptional properties. It is utilized to construct aircraft parts such as wings, tailplanes, and fuselages, as well as space-related applications. The use of Carbon Fiber in aerospace ensures robustness while significantly reducing weight, resulting in greater fuel efficiency and improved flight performance.

6. Marine Industry

The marine industry harnesses the benefits of Carbon Fiber for various applications. It is utilized in boat building, where its lightweight and high strength properties make it an ideal choice for hulls, masts, and other structural components. Carbon Fiber offers increased speed, improved handling, and fuel efficiency in marine vessels.

7. Medical Field

In the medical field, Carbon Fiber is used to manufacture lightweight and durable medical equipment and devices. It finds applications in prosthetics and orthotics, providing individuals with enhanced mobility and comfort. Carbon Fiber's biocompatible nature and strength make it an excellent choice for medical applications.

| Industria | Aplicaciones |

|---|---|

| Aviation | Aircraft components, wings, fuselages, landing gear |

| Energía renovable | Palas de turbinas eólicas |

| Equipo deportivo | Tennis rackets, bicycles, golf clubs, helmets |

| Automotor | High-end vehicles |

| Aeroespacial | Aircraft parts, space applications |

| Marina | Boat building |

| Médico | Prosthetics, orthotics, medical equipment |

Durability: Kevlar vs Carbon Fiber

When it comes to durability, both Kevlar and Carbon Fiber are renowned for their exceptional strength and resilience. These advanced materials have distinct properties that make them resistant to various environmental factors, ensuring longevity in demanding applications.

Kevlar: Withstanding the Elements

Kevlar, a synthetic fiber developed by DuPont, exhibits remarkable durability in extreme conditions. It is known for its excellent resistance to heat, making it ideal for high-temperature environments. Additionally, Kevlar demonstrates exceptional stability in the face of corrosive substances, protecting it from chemical damage and enhancing its lifespan.

Kevlar's ability to withstand impacts without losing its structural integrity further solidifies its durability. Whether it's protecting personnel in bulletproof vests or reinforcing critical components in aerospace engineering, Kevlar's durability ensures reliable performance in the harshest conditions.

Carbon Fiber: Unmatched Strength and Endurance

Carbon Fiber, a composite material consisting of carbon atoms tightly bonded together, possesses formidable durability. One of its notable features is its resistance to corrosion, including the effects of moisture and chemicals, which extends its lifespan.

Carbon Fiber's exceptional strength-to-weight ratio also contributes to its durability. Its high tensile strength allows it to withstand heavy loads without compromising its structure, making it an excellent choice for various applications where durability is essential.

Quote: "The extraordinary durability of Carbon Fiber enables it to excel in industries ranging from automotive and aerospace to construction and sports."

Comparing Durability

While both Kevlar and Carbon Fiber possess impressive durability, their strengths lie in different areas. Kevlar's resistance to heat and corrosion makes it an optimal choice for applications exposed to extreme temperatures or corrosive environments.

On the other hand, Carbon Fiber's resistance to corrosion, combined with its exceptional strength, provides unmatched durability in scenarios where high loads and structural integrity are crucial.

| Material | Durabilidad | Resistance to Heat | Resistencia a la corrosión | Resistencia al impacto |

|---|---|---|---|---|

| Kevlar | Alto | Excelente | Excelente | Excepcional |

| Fibra de carbono | Alto | Bien | Excelente | Excelente |

As seen in the comparison table, both materials offer notable durability, with Kevlar demonstrating exceptional performance in heat resistance and impact resistance. Carbon Fiber, on the other hand, excels in corrosion resistance while maintaining its strength and endurance.

Stay tuned for the next section, where we will delve into the lightweight advantages of Kevlar and Carbon Fiber, exploring how their weight plays a crucial role in various applications.

Lightweight Advantages: Kevlar vs Carbon Fiber

When it comes to lightweight materials, both Kevlar and Carbon Fiber are at the forefront of innovation. Their exceptional strength-to-weight ratios make them ideal choices for applications where reducing weight is crucial. Let's explore the differences in their lightweight properties and understand how they impact performance, fuel efficiency, and overall usability in different industries.

Performance Boost with Kevlar

Kevlar is a synthetic fiber renowned for its strength and lightweight nature. With its unique molecular structure, Kevlar offers outstanding resistance to impact, making it highly suitable for protective gear, such as bulletproof vests and safety helmets. In the automotive industry, Kevlar is used to manufacture lightweight components that enhance performance and maneuverability.

Kevlar's lightweight nature empowers athletes and adventurers by providing them with flexibility, agility, and confidence in their pursuits.

Additionally, Kevlar exhibits excellent heat resistance, making it an ideal choice for high-temperature applications such as aerospace components and heat shields.

Unparalleled Strength with Carbon Fiber

On the other hand, Fibra de carbono is renowned for its incredible strength combined with astonishing lightness. This unique combination makes it a preferred material for industries seeking maximum performance with minimal weight. Carbon Fiber is extensively used in the aviation industry to construct aircraft, including wings and fuselages, contributing to improved fuel efficiency and range.

Carbon Fiber's feather-light weight revolutionizes the performance of sports cars, offering unparalleled acceleration, handling, and braking capabilities.

Moreover, the excellent vibration-damping properties of Carbon Fiber make it an excellent choice for sporting goods, like bicycles and tennis rackets, providing athletes with optimized control and comfort during intense activities.

Choosing the Right Material

When deciding between Kevlar and Carbon Fiber for a specific application, it is vital to consider the specific requirements and performance objectives. Kevlar's renowned impact resistance and heat resistance make it ideal for protective gear and high-temperature environments. Carbon Fiber, with its unmatched strength-to-weight ratio, is often preferred in industries where performance and fuel efficiency are paramount.

Whatever your project may be, understanding the differences in the lightweight properties of Kevlar and Carbon Fiber will empower you to make an informed choice that aligns with your goals and aspirations.

By assessing your needs and considering the unique advantages of each material, you can harness the lightweight properties of Kevlar or Carbon Fiber to achieve remarkable results in your next venture.

Conclusión

After extensively comparing Kevlar and Carbon Fiber, it is clear that both materials have their unique strengths and advantages. When it comes to strength, Kevlar excels in tensile strength and impact resistance, making it an excellent choice for applications that require superior durability. On the other hand, Carbon Fiber offers a remarkable strength-to-weight ratio, making it ideal for industries where lightweight yet robust materials are needed.

In terms of cost, Kevlar tends to be more expensive due to its production process and limited availability. Carbon Fiber, although still relatively costly, offers a slightly more cost-effective option. When considering the affordability and feasibility of a project, the cost differences between the two materials should be carefully evaluated.

When it comes to applications, Kevlar finds its place in industries such as aerospace, automotive, and sporting goods. Its remarkable strength and lightweight nature make it invaluable for building durable and high-performance structures. On the other hand, Carbon Fiber's versatility shines in aviation, renewable energy, and sports equipment industries, where its lightweight properties and strength are highly valued.

In summary, the choice between Kevlar and Carbon Fiber ultimately depends on the specific requirements of your project. If strength and impact resistance are crucial, Kevlar is an excellent option. However, if your project demands a lightweight yet robust material, Carbon Fiber is the way to go. Consider the cost implications, application needs, and long-term durability to make an informed decision and select the material that best fits your project objectives.

Preguntas frecuentes

What is the difference between Kevlar and Carbon Fiber?

Kevlar is a synthetic fiber known for its high strength and durability, while Carbon Fiber is a composite material made of carbon fibers. Both materials have different properties and applications.

Which material is stronger, Kevlar or Carbon Fiber?

Carbon Fiber is generally stronger than Kevlar in terms of tensile strength and stiffness. It also has a higher strength-to-weight ratio, making it a popular choice for high-performance applications.

What are the main applications of Kevlar?

Kevlar is widely used in industries such as aerospace, automotive, sporting goods, and personal protective equipment. It is commonly found in bulletproof vests, aircraft components, and lightweight structural reinforcements.

Where is Carbon Fiber commonly used?

Carbon Fiber has a diverse range of applications, including aerospace, automotive, renewable energy, and sports equipment. It is found in aircraft parts, automobile components, wind turbine blades, and high-end bicycles, among others.

Is Kevlar more durable than Carbon Fiber?

Kevlar has excellent resistance to impact, abrasion, and fatigue, making it highly durable. However, Carbon Fiber exhibits higher durability against harsh environmental conditions, heat, and corrosion.

Which material is more cost-effective, Kevlar or Carbon Fiber?

In general, Kevlar is more affordable than Carbon Fiber. However, the cost of both materials can vary depending on factors such as production volume, market demand, and specific application requirements.

Are Kevlar and Carbon Fiber lightweight materials?

Yes, both Kevlar and Carbon Fiber are known for their lightweight properties. They offer high strength-to-weight ratios, resulting in improved performance, fuel efficiency, and ease of handling.

What factors should I consider when choosing between Kevlar and Carbon Fiber?

When choosing between Kevlar and Carbon Fiber, consider factors such as the required strength, cost constraints, specific application needs, and environmental considerations. It is important to assess the benefits and limitations of each material for your project.