¿Son las láminas de fibra de carbono compatibles con los sistemas de sensores ADAS?

-

Tabla de contenido

“Seamless Integration: Carbon Fiber Car Sheets and ADAS Sensor Systems Unite for Enhanced Safety.”

Introducción

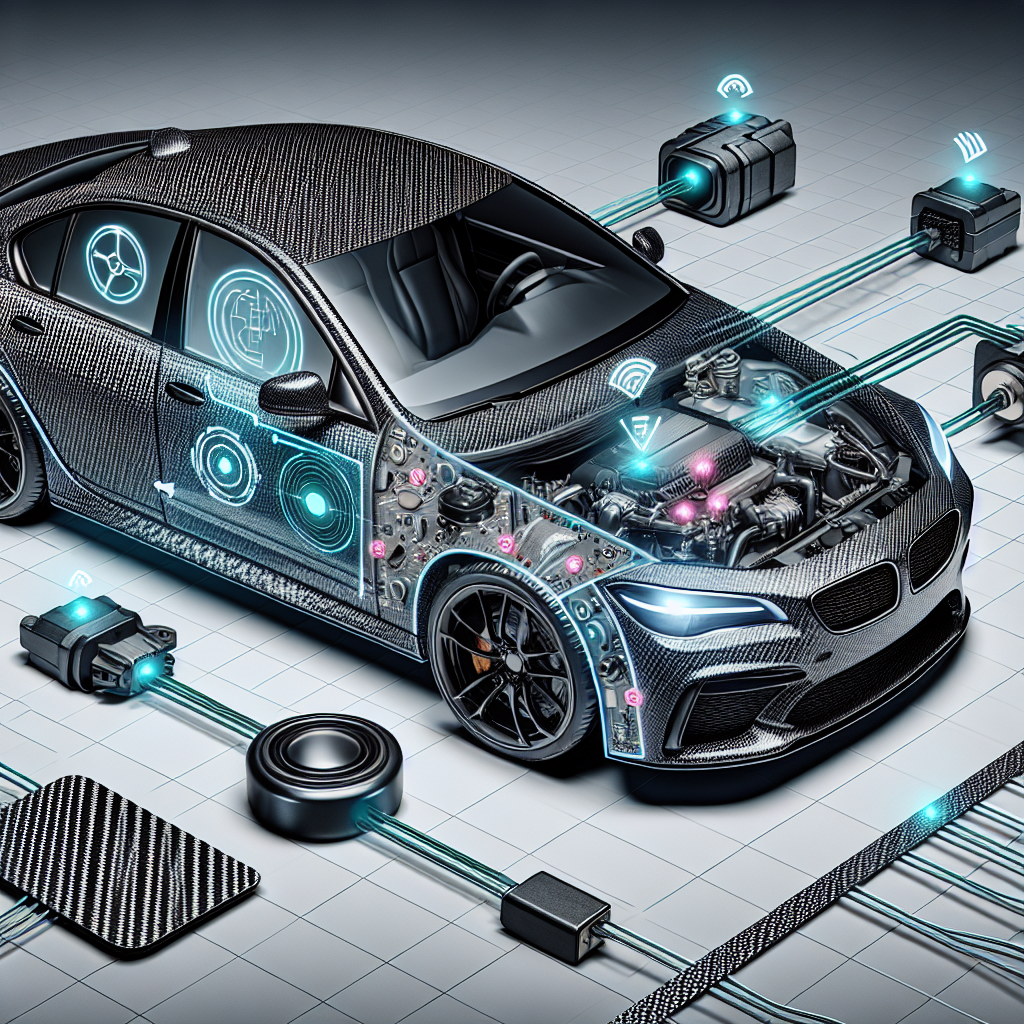

The integration of Advanced Driver Assistance Systems (ADAS) in modern vehicles has revolutionized automotive safety and performance. As manufacturers seek to enhance vehicle design and reduce weight, carbon fiber car sheets have emerged as a popular material choice. However, the compatibility of carbon fiber with ADAS sensor systems raises important considerations. This introduction explores the implications of using carbon fiber in vehicle construction, particularly regarding its impact on the functionality and effectiveness of ADAS technologies, such as radar, lidar, and camera systems. Understanding this compatibility is crucial for manufacturers and consumers alike, as it influences both vehicle safety and performance.

Carbon Fiber Car Sheets: Impact on ADAS Sensor Functionality

The integration of Advanced Driver Assistance Systems (ADAS) in modern vehicles has revolutionized automotive safety and performance. As manufacturers strive to enhance vehicle design and functionality, the use of innovative materials such as carbon fiber has gained prominence. However, a pertinent question arises: are carbon fiber car sheets compatible with ADAS sensor systems? To address this, it is essential to understand both the properties of carbon fiber and the operational requirements of ADAS technologies.

Carbon fiber is renowned for its lightweight and high-strength characteristics, making it an attractive alternative to traditional materials like steel and aluminum. This material not only contributes to improved fuel efficiency and performance but also allows for more flexible design options. Nevertheless, the unique properties of carbon fiber can pose challenges when it comes to the integration of ADAS sensors, which rely on precise data collection and transmission to function effectively.

ADAS systems typically utilize a variety of sensors, including cameras, radar, and lidar, to monitor the vehicle’s surroundings and assist the driver in making informed decisions. These sensors depend on clear lines of sight and unobstructed signals to operate optimally. While carbon fiber is generally transparent to radar waves, its interaction with other sensor technologies can vary. For instance, certain carbon fiber composites may interfere with the performance of cameras and lidar systems, potentially leading to reduced accuracy in object detection and distance measurement.

Moreover, the installation of carbon fiber sheets in areas where ADAS sensors are located must be approached with caution. The thickness and orientation of the carbon fiber can influence the sensor’s ability to receive and interpret signals. Therefore, manufacturers must conduct thorough testing to ensure that the placement of carbon fiber components does not hinder the functionality of these critical systems. This testing often involves evaluating the electromagnetic compatibility of the materials used, as well as assessing the overall impact on sensor performance.

In addition to the physical properties of carbon fiber, the design and engineering of the vehicle play a significant role in determining compatibility with ADAS systems. For instance, the integration of carbon fiber panels must be carefully considered in relation to the vehicle’s aerodynamic profile and structural integrity. A well-designed vehicle that incorporates carbon fiber can enhance the effectiveness of ADAS technologies by providing a lightweight structure that does not compromise safety or performance.

Furthermore, as the automotive industry continues to evolve, manufacturers are increasingly focused on developing composite materials that can seamlessly integrate with ADAS systems. Research and innovation in this area are ongoing, with the aim of creating carbon fiber composites that not only maintain the desirable properties of traditional carbon fiber but also enhance sensor functionality. This could involve the development of hybrid materials that combine carbon fiber with other substances to optimize performance across various sensor types.

In conclusion, while carbon fiber car sheets offer numerous advantages in terms of weight reduction and design flexibility, their compatibility with ADAS sensor systems is a complex issue that requires careful consideration. The interaction between carbon fiber and various sensor technologies can impact the overall effectiveness of ADAS, necessitating thorough testing and innovative engineering solutions. As the industry progresses, it is likely that advancements in material science will lead to improved compatibility, ensuring that the benefits of carbon fiber can be fully realized without compromising the functionality of essential safety systems.

Evaluating the Compatibility of Carbon Fiber with ADAS Technologies

As the automotive industry continues to evolve, the integration of advanced driver-assistance systems (ADAS) has become increasingly prevalent. These systems, which enhance vehicle safety and facilitate autonomous driving features, rely heavily on a network of sensors, cameras, and radar systems. Consequently, the materials used in vehicle construction, particularly those that comprise the body and structural components, must be evaluated for their compatibility with these sophisticated technologies. One material that has garnered significant attention in recent years is carbon fiber, known for its lightweight properties and high strength-to-weight ratio. However, the question arises: are carbon fiber car sheets compatible with ADAS sensor systems?

To begin with, it is essential to understand the fundamental characteristics of carbon fiber. This composite material is composed of thin strands of carbon atoms woven together, resulting in a structure that is not only lightweight but also exceptionally strong and rigid. These properties make carbon fiber an attractive option for automotive manufacturers seeking to improve fuel efficiency and performance. However, the integration of carbon fiber into vehicle design necessitates a thorough examination of its interaction with ADAS technologies.

One of the primary concerns regarding the use of carbon fiber in vehicles equipped with ADAS is its electromagnetic properties. Many ADAS systems rely on radar and other electromagnetic sensors to function effectively. Traditional materials, such as steel and aluminum, have well-understood interactions with these sensors, allowing for reliable performance. In contrast, carbon fiber can exhibit varying degrees of electromagnetic interference, depending on its composition and the presence of conductive materials within the composite. This variability raises questions about the reliability of sensor readings when carbon fiber is used extensively in vehicle construction.

Moreover, the structural integrity of carbon fiber must be considered in relation to ADAS systems. For instance, the placement of sensors is critical for optimal performance. If carbon fiber panels are used in areas where sensors are mounted, the material’s thickness and orientation could potentially obstruct or distort the signals emitted and received by these devices. Consequently, automotive engineers must carefully design the vehicle’s architecture to ensure that carbon fiber components do not hinder the functionality of ADAS technologies.

In addition to these technical considerations, the manufacturing processes associated with carbon fiber also play a significant role in its compatibility with ADAS systems. The production of carbon fiber components often involves complex layering and curing processes, which can introduce variability in the material’s properties. This variability can affect how well the sensors perform, particularly if the carbon fiber is not uniformly applied or if there are inconsistencies in the bonding with other materials. Therefore, rigorous testing and quality control measures are essential to ensure that carbon fiber components meet the necessary standards for ADAS integration.

Furthermore, as the automotive industry moves towards greater sustainability, the potential for recycling carbon fiber materials presents both challenges and opportunities. The recyclability of carbon fiber composites can influence their long-term viability in vehicle design, particularly as manufacturers seek to balance performance with environmental considerations. However, the recycling process must also account for the preservation of the material’s properties to maintain compatibility with ADAS technologies.

In conclusion, while carbon fiber car sheets offer numerous advantages in terms of weight reduction and structural performance, their compatibility with ADAS sensor systems is a multifaceted issue that requires careful evaluation. Factors such as electromagnetic properties, structural integrity, manufacturing processes, and recyclability all play critical roles in determining how effectively carbon fiber can be integrated into vehicles equipped with advanced driver-assistance technologies. As research and development in this area continue to advance, it is likely that solutions will emerge to enhance the compatibility of carbon fiber with ADAS, paving the way for a new era of automotive innovation.

The Future of Carbon Fiber in Vehicles Equipped with ADAS Systems

As the automotive industry continues to evolve, the integration of advanced driver-assistance systems (ADAS) has become increasingly prevalent. These systems, designed to enhance vehicle safety and improve the driving experience, rely heavily on a variety of sensors and cameras strategically placed around the vehicle. Consequently, the materials used in vehicle construction, particularly carbon fiber, are coming under scrutiny regarding their compatibility with these sophisticated technologies. The future of carbon fiber in vehicles equipped with ADAS systems is a topic of significant interest, as manufacturers seek to balance performance, safety, and technological advancement.

Carbon fiber, known for its lightweight and high-strength properties, offers numerous advantages over traditional materials such as steel and aluminum. Its use in automotive applications can lead to improved fuel efficiency and enhanced performance, making it an attractive option for manufacturers aiming to meet stringent environmental regulations. However, the introduction of carbon fiber into vehicles equipped with ADAS systems raises questions about the interaction between the material and the sensors that are critical for the functionality of these systems. For instance, many ADAS technologies, including radar and lidar, depend on the accurate transmission of signals to detect obstacles and assess the vehicle’s surroundings. Therefore, understanding how carbon fiber affects these signals is essential for ensuring the reliability of ADAS features.

Research indicates that carbon fiber can indeed be compatible with ADAS sensor systems, but certain considerations must be taken into account. The electromagnetic properties of carbon fiber can influence the performance of radar and lidar sensors, potentially leading to signal attenuation or distortion. This phenomenon occurs because carbon fiber, while lightweight and strong, can also be conductive, which may interfere with the electromagnetic waves used by these sensors. To mitigate these issues, manufacturers are exploring various solutions, such as optimizing the placement of sensors and utilizing hybrid materials that combine carbon fiber with non-conductive substances. By carefully engineering the vehicle’s design, it is possible to maintain the structural benefits of carbon fiber while ensuring that ADAS systems function effectively.

Moreover, as technology advances, the development of new carbon fiber composites may further enhance compatibility with ADAS systems. Innovations in material science are paving the way for carbon fiber that exhibits improved electromagnetic transparency, thereby reducing interference with sensor signals. This progress not only supports the integration of carbon fiber in vehicles equipped with ADAS but also aligns with the industry’s broader goals of enhancing safety and performance. As manufacturers continue to invest in research and development, the potential for carbon fiber to coexist harmoniously with advanced sensor technologies becomes increasingly viable.

In conclusion, the future of carbon fiber in vehicles equipped with ADAS systems appears promising, provided that manufacturers address the challenges associated with sensor compatibility. By leveraging advancements in material science and engineering, it is possible to harness the benefits of carbon fiber while ensuring the reliability of critical safety features. As the automotive landscape evolves, the successful integration of carbon fiber and ADAS technologies will likely play a pivotal role in shaping the next generation of vehicles, ultimately leading to safer and more efficient transportation solutions. The ongoing dialogue between material innovation and technological advancement will be crucial in determining how these two elements can work together to enhance the driving experience.

Preguntas y respuestas

1. **Question:** Are carbon fiber car sheets compatible with ADAS sensor systems?

**Answer:** Yes, carbon fiber car sheets can be compatible with ADAS sensor systems, provided they are designed to allow for proper sensor functionality and signal transmission.

2. **Question:** Do carbon fiber materials interfere with ADAS sensor performance?

**Answer:** Carbon fiber can potentially interfere with certain types of sensors, such as radar and some types of cameras, if not properly integrated; however, many manufacturers design carbon fiber components to minimize such interference.

3. **Question:** What considerations should be made when using carbon fiber sheets in vehicles with ADAS?

**Answer:** Considerations include ensuring that the carbon fiber does not obstruct sensor lines of sight, maintaining the integrity of sensor calibration, and verifying that the material meets OEM specifications for ADAS compatibility.