ما هو نمط النسيج الأفضل لنسيج الكربون: عادي أم مائل؟

-

جدول المحتويات

“Choose Twill for Strength and Flexibility: The Superior Weave for Carbon Cloth Fabric.”

مقدمة

When selecting the optimal weave pattern for carbon cloth fabric, two primary options emerge: plain and twill. Each weave pattern offers distinct characteristics that influence the fabric’s performance, appearance, and suitability for various applications. The plain weave, known for its simplicity and durability, provides a tight structure that enhances strength and stability. In contrast, the twill weave, recognized for its diagonal pattern, offers improved drape and flexibility, making it ideal for applications requiring enhanced conformability. Understanding the advantages and limitations of each weave pattern is essential for making informed decisions in industries such as aerospace, automotive, and sports equipment, where the properties of carbon cloth can significantly impact overall performance.

Comparison of Plain and Twill Weave Patterns in Carbon Cloth Fabric

When considering the optimal weave pattern for carbon cloth fabric, the two primary contenders are plain and twill weaves. Each of these patterns offers distinct characteristics that can significantly influence the performance and application of the fabric. Understanding the differences between these weaves is essential for selecting the most suitable option for specific uses in industries such as aerospace, automotive, and sporting goods.

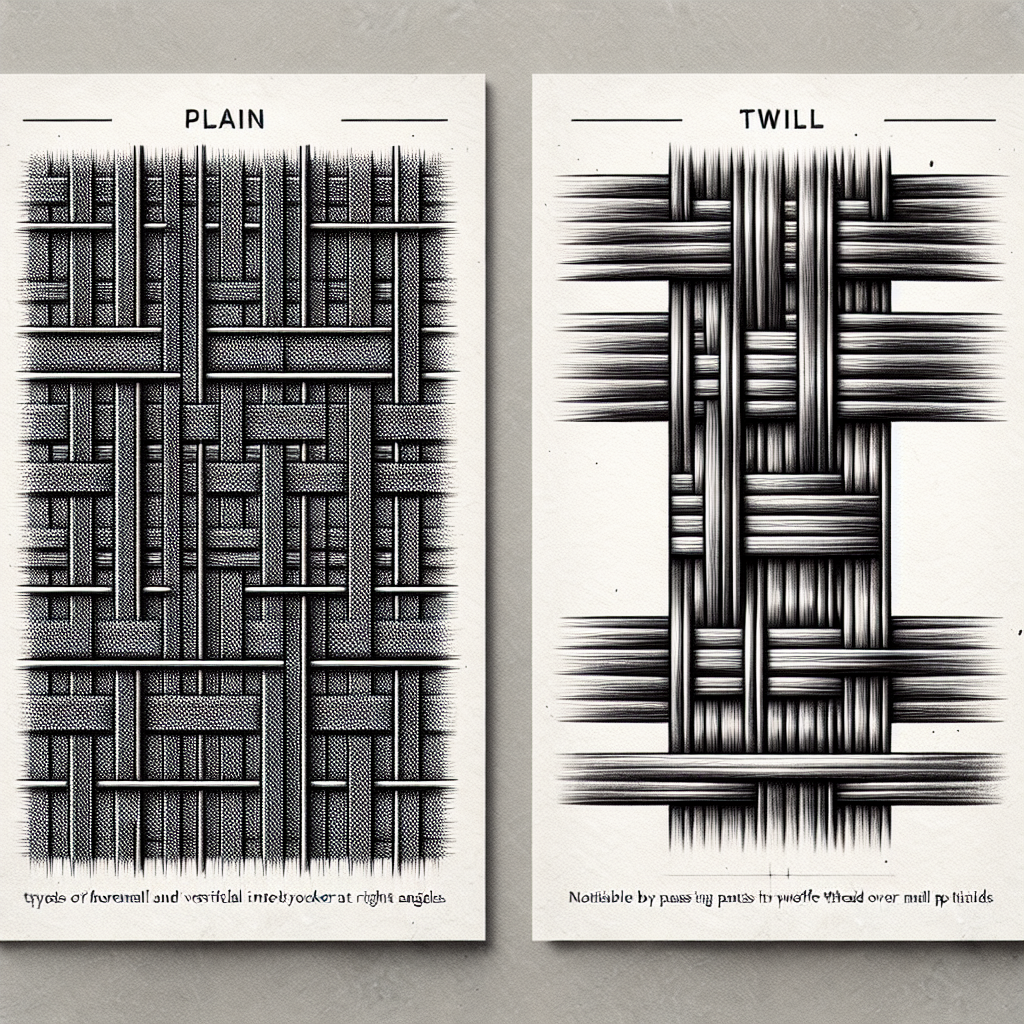

The plain weave pattern is the simplest and most traditional form of weaving. In this structure, the warp and weft threads cross each other at right angles, creating a straightforward, grid-like appearance. This simplicity translates into several advantages, including ease of production and a high degree of stability. The uniformity of the plain weave allows for a consistent thickness and density throughout the fabric, which can be particularly beneficial in applications requiring precise dimensional control. Furthermore, the plain weave exhibits excellent resistance to fraying and unraveling, making it a durable choice for various environments.

On the other hand, the twill weave pattern introduces a more complex structure, characterized by a diagonal ribbing effect. This is achieved by interlacing the warp and weft threads in a staggered manner, which not only enhances the aesthetic appeal of the fabric but also contributes to its functional properties. One of the most notable advantages of twill weave is its increased flexibility and drape compared to plain weave. This flexibility can be particularly advantageous in applications where the fabric needs to conform to complex shapes or surfaces, such as in composite materials used in aerospace components.

Moreover, the twill weave pattern typically offers improved strength and durability. The diagonal interlacing allows for a greater number of threads to be packed into the same area, resulting in a denser fabric that can withstand higher levels of stress and strain. This characteristic makes twill-weave carbon cloth particularly suitable for high-performance applications where mechanical properties are critical. Additionally, the increased surface area of the twill weave can enhance the bonding capabilities with resins in composite applications, leading to stronger and more reliable end products.

However, it is essential to consider the specific requirements of the intended application when choosing between plain and twill weaves. For instance, if a project demands a lightweight fabric with minimal bulk, the plain weave may be the more appropriate choice due to its thinner profile. Conversely, if the application requires enhanced strength and flexibility, the twill weave would likely be the better option. Furthermore, the choice of weave can also affect the fabric’s cost, as twill weaves often require more complex manufacturing processes, which can lead to higher production expenses.

In conclusion, both plain and twill weave patterns have their unique advantages and disadvantages when it comes to carbon cloth fabric. The decision on which weave to use should be guided by the specific performance requirements and application contexts. By carefully evaluating the characteristics of each weave pattern, manufacturers and designers can make informed choices that optimize the functionality and effectiveness of carbon cloth in their respective fields. Ultimately, understanding the nuances of these weave patterns is crucial for harnessing the full potential of carbon cloth fabric in advanced engineering applications.

Advantages of Twill Weave for Carbon Cloth Applications

When considering the optimal weave pattern for carbon cloth fabric, the twill weave emerges as a compelling choice, particularly for applications that demand enhanced performance characteristics. The twill weave, characterized by its diagonal pattern, offers several advantages that make it suitable for various industrial and commercial uses. One of the primary benefits of the twill weave is its superior strength and durability. The interlacing of fibers in a diagonal pattern allows for a more robust structure, which can withstand greater stress and strain compared to the plain weave. This increased strength is particularly advantageous in applications such as aerospace and automotive industries, where materials must endure high levels of mechanical stress.

Moreover, the twill weave provides improved flexibility and drape compared to its plain counterpart. This flexibility is essential in applications where the fabric needs to conform to complex shapes or surfaces. For instance, in the production of composite materials, the ability of the carbon cloth to easily mold around curves and contours can significantly enhance the performance of the final product. Additionally, the drape of twill-woven carbon cloth allows for easier handling and manipulation during the manufacturing process, facilitating more efficient production techniques.

Another notable advantage of the twill weave is its enhanced resistance to fraying and wear. The diagonal structure of the weave helps to lock the fibers in place, reducing the likelihood of unraveling at the edges. This characteristic is particularly important in high-performance applications where the integrity of the fabric is critical. Furthermore, the durability of twill-woven carbon cloth contributes to its longevity, making it a cost-effective option in the long run, as it requires less frequent replacement compared to fabrics that may wear out more quickly.

In addition to its mechanical properties, the twill weave also offers aesthetic benefits. The distinctive diagonal pattern creates a visually appealing texture that can enhance the overall appearance of the finished product. This aesthetic quality can be particularly valuable in consumer-facing applications, such as fashion or sports equipment, where the visual appeal of the material can influence purchasing decisions. The versatility of the twill weave allows it to be used in a variety of contexts, from high-performance gear to luxury items, thereby broadening its market appeal.

Furthermore, the twill weave facilitates better moisture management compared to plain weaves. The gaps created by the diagonal interlacing allow for improved airflow and moisture wicking, which can be beneficial in applications where breathability is essential. This characteristic is particularly relevant in sportswear and outdoor gear, where moisture management can significantly impact comfort and performance.

In conclusion, the advantages of the twill weave for carbon cloth applications are manifold. Its superior strength, flexibility, and resistance to fraying make it an ideal choice for high-performance environments. Additionally, the aesthetic appeal and moisture management capabilities further enhance its suitability for a wide range of applications. As industries continue to seek materials that combine performance with versatility, the twill weave stands out as a leading option in the realm of carbon cloth fabric. By leveraging the unique properties of the twill weave, manufacturers can create products that not only meet but exceed the demands of modern applications, ensuring that they remain competitive in an ever-evolving market.

When to Choose Plain Weave for Carbon Cloth Fabric

When considering the optimal weave pattern for carbon cloth fabric, the choice between plain weave and twill weave is crucial, particularly when evaluating the specific applications and performance characteristics required. Plain weave, characterized by its simple over-and-under pattern, offers distinct advantages that make it a preferred option in various scenarios. One of the primary reasons to choose plain weave for carbon cloth fabric is its inherent strength and durability. The straightforward interlacing of fibers in a plain weave creates a robust structure that can withstand significant stress and strain, making it ideal for applications where mechanical strength is paramount.

Moreover, the uniformity of the plain weave contributes to its versatility. This weave pattern allows for a consistent surface texture, which is particularly beneficial in applications requiring a smooth finish. For instance, in the aerospace and automotive industries, where carbon cloth is often used for components that demand both lightweight properties and high strength, the smooth surface of plain weave can facilitate better adhesion when combined with resins or other materials. This characteristic not only enhances the performance of the final product but also ensures a more aesthetically pleasing appearance, which can be critical in consumer-facing applications.

In addition to its strength and surface qualities, plain weave carbon cloth fabric is also easier to manufacture. The simplicity of the weave pattern allows for more efficient production processes, which can lead to cost savings. This efficiency is particularly advantageous in large-scale manufacturing settings, where the demand for carbon cloth is high. By opting for plain weave, manufacturers can streamline their operations while still delivering a high-quality product that meets the rigorous standards of various industries.

Furthermore, the plain weave pattern provides excellent dimensional stability. This stability is essential in applications where precise measurements and tolerances are required, such as in the production of sporting goods or high-performance equipment. The lack of bias stretch in plain weave ensures that the fabric maintains its shape and size under varying conditions, which is a critical factor in ensuring the reliability and performance of the end product.

Another important consideration when choosing plain weave for carbon cloth fabric is its compatibility with various resin systems. The open structure of the weave allows for better resin penetration during the composite manufacturing process, which can enhance the overall mechanical properties of the final composite material. This compatibility is particularly beneficial in applications where the composite will be subjected to high loads or extreme conditions, as it ensures that the resin effectively bonds with the carbon fibers, maximizing strength and durability.

In conclusion, the decision to choose plain weave for carbon cloth fabric is influenced by several key factors, including strength, surface finish, manufacturing efficiency, dimensional stability, and resin compatibility. Each of these attributes plays a significant role in determining the suitability of plain weave for specific applications. As industries continue to evolve and demand higher performance materials, understanding the advantages of plain weave will enable manufacturers and engineers to make informed decisions that align with their project requirements. Ultimately, the choice of weave pattern can significantly impact the performance and longevity of carbon cloth fabric in various applications, making it essential to carefully consider the benefits of plain weave in the context of specific use cases.

الأسئلة والأجوبة

1. **Question:** Which weave pattern offers better strength for carbon cloth fabric, plain or twill?

**Answer:** Twill weave generally offers better strength due to its diagonal pattern, which distributes stress more evenly.

2. **Question:** How does the drape of carbon cloth fabric differ between plain and twill weaves?

**Answer:** Twill weave typically provides better drape and flexibility compared to plain weave, making it more suitable for complex shapes.

3. **Question:** Which weave pattern is more suitable for applications requiring high stiffness in carbon cloth fabric?

**Answer:** Plain weave is more suitable for applications requiring high stiffness, as it has a tighter structure that enhances rigidity.