شرح أنماط نسيج ألياف الكربون: السادة مقابل المائل مقابل الساتان

Understanding the different carbon fiber weave patterns is crucial for selecting the right material for various applications. The weave pattern significantly affects the material’s strength, flexibility, and appearance.

The most common weave patterns are نسج عادي, نسج مائل، و نسج الساتان. Each has its unique characteristics and advantages, making them suitable for different uses.

ال نسج عادي is the most basic pattern, offering a balanced and stable structure. In contrast, نسج مائل provides a softer and more flexible material, while نسج الساتان is known for its smooth surface and drape.

النقاط الرئيسية

- Different carbon fiber weave patterns affect the material’s properties.

- Plain, twill, and satin weaves are the most common patterns.

- Each weave pattern has its unique advantages and applications.

- The choice of weave pattern depends on the intended use.

- Understanding weave patterns is crucial for material selection.

ما هي ألياف الكربون؟

Carbon fiber is a versatile material that has revolutionized industries with its remarkable properties. It is known for its high strength-to-weight ratio, making it an ideal choice for applications where both strength and lightness are crucial.

Composition and Basic Properties

Carbon fiber is composed of long chains of carbon atoms, typically arranged in a crystalline structure. This composition gives carbon fiber its exceptional قوة الشد و صلابة. The basic properties of carbon fiber include high resistance to fatigue, high temperature tolerance, and a low coefficient of thermal expansion.

نظرة عامة على عملية التصنيع

The manufacturing process of carbon fiber involves several complex steps, starting with the production of a precursor material, typically polyacrylonitrile (PAN). The PAN is then subjected to a series of processes including الاستقرار, الكربنة، و graphitization at high temperatures. The resulting carbon fibers are then processed into various forms, such as yarn, fabric, or prepreg, ready for use in composite materials.

By understanding the composition, properties, and manufacturing process of carbon fiber, we can appreciate its value in modern technology and industry.

The Importance of Weave Patterns in Carbon Fiber

Understanding the importance of weave patterns in carbon fiber is essential for optimizing its performance in various applications. The weave pattern significantly influences both the functional and aesthetic qualities of carbon fiber products.

Performance Impact

The weave pattern of carbon fiber affects its mechanical properties, such as strength, flexibility, and durability. Different weave patterns, including plain, twill, and satin weaves, offer varying levels of performance. For instance, a نسج عادي provides excellent stability and resistance to distortion, making it suitable for applications requiring high strength and minimal stretch.

| Weave Pattern | قوة | المرونة |

|---|---|---|

| نسج عادي | عالي | قليل |

| نسج الساتان | واسطة | واسطة |

| نسج الساتان | قليل | عالي |

Aesthetic Considerations

The aesthetic appeal of carbon fiber is significantly influenced by its weave pattern. نسج مائل, for example, offers a more subtle, diagonal pattern that can provide a sophisticated look, while نسج الساتان gives a smooth, lustrous finish ideal for applications where visual appeal is paramount.

“The choice of weave pattern can dramatically alter the appearance of carbon fiber, making it a critical consideration for designers and engineers alike.”

The selection of an appropriate weave pattern is thus a balance between achieving the desired performance characteristics and the visual appeal of the final product.

Understanding Carbon Fiber Weave Fabric

Understanding the intricacies of carbon fiber weave fabric is vital for selecting the right material for specific projects. Carbon fiber weave fabric’s characteristics are determined by its construction and the terminology used in the industry.

Fabric Construction Basics

The construction of carbon fiber weave fabric involves interlacing carbon fibers in specific patterns. Plain weave, twill weave, and satin weave are common patterns that affect the fabric’s strength, flexibility, and drapeability. The choice of weave pattern depends on the intended application and the desired properties of the final product.

Terminology and Industry Standards

The carbon fiber industry uses specialized terminology to describe fabric characteristics. Terms like yarn count, tow size, and weave density are crucial for understanding the fabric’s properties. Familiarity with these terms enables professionals to communicate effectively and make informed decisions when selecting carbon fiber materials.

Industry standards also play a significant role in ensuring consistency and quality in carbon fiber products. Understanding these standards is essential for manufacturers and consumers alike.

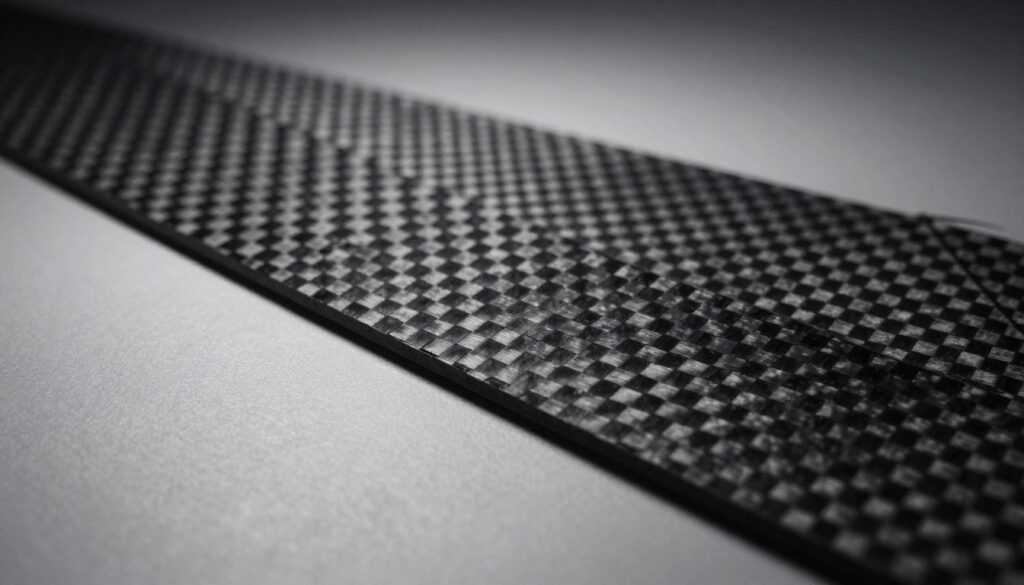

Plain Weave Carbon Fiber

ال نسج عادي pattern is a fundamental weave type used in تصنيع ألياف الكربون, known for its straightforward over-under pattern. This weave is characterized by its simplicity and the way it interlaces carbon fibers, creating a fabric that is both strong and versatile.

Structure and Characteristics

Plain weave carbon fiber fabric is woven by interlacing warp and weft fibers over and under each other. This creates a grid-like pattern that is highly stable and resistant to deformation. The نسج عادي pattern is highly regarded for its balance between strength and flexibility, making it suitable for a wide range of applications.

Strength Properties and Performance

ال strength properties of plain weave carbon fiber are influenced by the tight interlacing of the fibers, which provides excellent resistance to stress and strain. This weave pattern is particularly effective in distributing loads evenly, thereby enhancing the overall durability of the material. The table below summarizes some key strength properties of plain weave carbon fiber.

| ملكية | قيمة | Unit |

|---|---|---|

| قوة الشد | 400 | MPa |

| Compressive Strength | 200 | MPa |

| قوة الانحناء | 300 | MPa |

Visual Appearance and Finishing Options

المظهر المرئي لـ plain weave carbon fiber is distinct, with a clear grid pattern that is often considered aesthetically pleasing. The finish of plain weave carbon fiber products can vary, with options including glossy, matte, or satin finishes.

Plain weave carbon fiber can be finished with various coatings to enhance its appearance and performance. These coatings can provide additional benefits such as UV resistance or improved durability.

Twill Weave Carbon Fiber

Twill weave carbon fiber is a popular choice among manufacturers due to its unique balance of strength and aesthetic appeal. This weave pattern is characterized by its diagonal rib pattern, which is both visually appealing and indicative of its robust mechanical properties.

Structure and Characteristics

ال نسج مائل structure is achieved by passing the weft yarn over one or more warp yarns, then under two or more warp yarns, and so on, with a step or offset between rows. This results in a fabric that has a soft, pliable drape and is less prone to distortion than plain weave fabrics. The twill weave carbon fiber is known for its flexibility and resistance to cracking.

Strength Properties and Performance

Twill weave carbon fiber exhibits excellent strength properties, making it suitable for high-performance applications. Its diagonal weave pattern provides good resistance to shear and impact, enhancing its overall durability. The twill weave strength properties are particularly beneficial in situations where the material is subjected to complex stress patterns.

Visual Appearance and Finishing Options

ال twill weave appearance is distinct and often preferred for its aesthetic value. The diagonal pattern creates a unique visual texture that can be further enhanced with various finishing options, such as clear coating or painting. This versatility in appearance makes twill weave carbon fiber a popular choice for visible components in automotive and aerospace applications.

Satin Weave Carbon Fiber

In the realm of advanced composites, satin weave carbon fiber stands out due to its distinctive weave pattern. This weave is characterized by a smooth, glossy finish that is not only aesthetically pleasing but also offers specific performance advantages.

Structure and Characteristics

Satin weave carbon fiber is woven in a way that the weft yarns float over multiple warp yarns, creating a fabric with a soft, pliable nature. This structure allows for better drapeability and formability compared to tighter weaves like plain or twill weaves.

Strength Properties and Performance

ال نسج الساتان pattern provides excellent mechanical properties, including high tensile strength and resistance to deformation. The weave’s characteristics make it suitable for applications where both performance and appearance are critical.

| ملكية | نسيج ساتان | نسيج سادة | نسيج قطني مائل |

|---|---|---|---|

| قوة الشد | عالي | واسطة | عالي |

| Drapeability | ممتاز | فقير | جيد |

| الجاذبية الجمالية | عالي | قليل | واسطة |

Visual Appearance and Finishing Options

ال satin weave carbon fiber has a distinctive, luxurious appearance that is often used in high-end applications. Various finishing options, including clear coating and tinted finishes, can enhance its visual appeal.

Comparative Analysis: Plain vs. Twill vs. Satin

Understanding the differences between plain, twill, and satin weaves is crucial for selecting the right carbon fiber for a specific application. Each weave type has its unique characteristics that influence the final product’s performance, aesthetic appeal, and manufacturing process.

Mechanical Properties Comparison

The mechanical properties of carbon fiber weaves vary significantly. نسج عادي offers balanced properties due to its simple over-under pattern, making it suitable for applications requiring equal strength in both directions. نسج مائل, with its diagonal pattern, provides better drapeability and is often used in complex shapes. نسج الساتان, known for its smooth surface and high flexibility, is ideal for applications where surface finish is critical.

| نوع النسيج | Tensile Strength | Flexural Strength | Drapeability |

|---|---|---|---|

| نسج عادي | عالي | معتدل | قليل |

| نسج الساتان | عالي | عالي | معتدل |

| نسج الساتان | معتدل | عالي | عالي |

Drapeability and Formability

Drapeability refers to how well a fabric can conform to a complex shape without wrinkling. Twill and satin weaves generally offer better drapeability compared to plain weave due to their more flexible nature. This makes them suitable for applications involving intricate designs or curved surfaces.

Cost and Manufacturing Considerations

The cost of carbon fiber weaves can vary based on the complexity of the weave pattern and the manufacturing process. Generally, نسج عادي is less expensive to produce than twill or satin weaves. However, the choice of weave ultimately depends on the specific requirements of the application, including performance, aesthetics, and budget.

In conclusion, the selection of carbon fiber weave should be based on a thorough analysis of the application’s requirements, considering factors such as mechanical properties, drapeability, and cost.

Applications by Weave Pattern

The unique properties of different carbon fiber weaves make them ideal for specific industries and uses. The choice of weave pattern significantly influences the performance, durability, and aesthetic appeal of the final product.

Automotive and Aerospace Uses

In the automotive and aerospace industries, carbon fiber is prized for its high strength-to-weight ratio. Plain weave carbon fiber is often used in applications where high stability and minimal stretch are required, such as in car body panels and aircraft components. For instance, the بي ام دبليو اي8 utilizes carbon fiber reinforced polymer (CFRP) for its chassis, significantly reducing weight while maintaining structural integrity.

Aerospace applications, such as in the بوينج 787 دريملاينر, also benefit from the use of carbon fiber. The use of carbon fiber weave patterns in these industries not only reduces weight but also enhances fuel efficiency and performance.

| صناعة | Common Weave Pattern | طلب |

|---|---|---|

| السيارات | نسج عادي | Car body panels |

| الفضاء الجوي | Plain Weave, Twill Weave | Aircraft components, interior parts |

Sporting Goods Applications

Sporting goods manufacturers favor carbon fiber for its lightweight and high stiffness properties. Twill weave carbon fiber is commonly used in the production of bicycle frames, golf clubs, and tennis rackets due to its balanced properties and aesthetic appeal.

“The use of twill weave carbon fiber in our golf clubs has significantly improved their performance and durability,” said a representative from a leading golf equipment manufacturer.

The flexibility and strength of twill weave carbon fiber make it an ideal choice for applications that require both performance and visual appeal.

Industrial and Specialized Applications

Beyond the aforementioned industries, carbon fiber weave patterns find applications in various specialized fields. Satin weave carbon fiber, with its smooth surface and high drapeability, is used in the production of complex shapes and components, such as in the marine industry for boat hulls and in the energy sector for wind turbine blades.

The versatility of carbon fiber weaves allows for their use in a wide range of applications, from industrial machinery to medical equipment, where high precision and reliability are paramount.

Common Myths and Misconceptions About Carbon Fiber Weaves

There’s a significant gap between the perceived and actual performance of carbon fiber weaves, often due to prevalent myths. Carbon fiber, known for its strength and lightweight properties, is used in various industries, from aerospace to sports equipment. However, misconceptions about its weave patterns can lead to incorrect assumptions about its performance and quality.

Performance Myths Debunked

One common myth is that a specific weave pattern, such as plain or twill, is always superior in terms of performance. In reality, the choice of weave depends on the application. For instance, نسج عادي is often used where stability and balance are crucial, while نسج مائل offers better drapeability and is used in applications requiring complex shapes.

The table below summarizes the key differences in performance characteristics among plain, twill, and satin weaves:

| Weave Pattern | Stability | Drapeability | قوة |

|---|---|---|---|

| نسج عادي | عالي | قليل | عالي |

| نسج الساتان | واسطة | عالي | عالي |

| نسج الساتان | قليل | عالية جداً | واسطة |

Quality Assessment Realities

Assessing the quality of carbon fiber involves looking beyond the weave pattern. Factors such as resin quality, عملية التصنيع، و finish play critical roles. A high-quality carbon fiber product may not always have the most visually appealing weave but will have been manufactured with precise control over these factors to ensure optimal performance.

By understanding the realities behind carbon fiber weaves, consumers can make more informed decisions based on their specific needs, rather than being swayed by common myths.

Selecting the Right Carbon Fiber Weave for Your Project

Project success often hinges on the careful selection of carbon fiber weave patterns. The choice of weave can significantly affect both the performance and aesthetic appeal of the final product.

Requirements Assessment Framework

To select the appropriate carbon fiber weave, it’s essential to first assess your project’s specific requirements. Consider factors such as the intended application, necessary mechanical properties, and desired visual appearance. Create a checklist of your project’s needs to guide your decision-making process.

Performance vs. Aesthetics Decision Matrix

When choosing a carbon fiber weave, there’s often a trade-off between performance and aesthetics. Plain weave offers excellent stability and is often used in high-performance applications. Twill weave provides a more traditional look and is drapeable, making it suitable for complex shapes. Satin weave, with its smooth surface, is ideal for applications where appearance is critical. Use the following decision matrix to help balance your needs:

| نوع النسيج | Performance Characteristics | Aesthetic Appeal |

|---|---|---|

| نسج عادي | High stability, balanced properties | Grid-like pattern, less smooth |

| نسج الساتان | Good drapeability, diagonal pattern | More traditional look, visually appealing |

| نسج الساتان | Smooth surface, good for visual applications | High-gloss finish, visually attractive |

Budget and Availability Considerations

Finally, consider your budget and the availability of different carbon fiber weaves. Certain weaves may be more expensive or harder to source than others. Factor these considerations into your decision to ensure that your project remains feasible and cost-effective.

Working with Different Carbon Fiber Weaves

To fully leverage the benefits of carbon fiber, it’s essential to understand the intricacies of handling and fabricating different weave patterns. The unique characteristics of each weave type demand specific techniques to achieve optimal results.

Handling and Fabrication Techniques

Effective handling of carbon fiber weaves requires careful consideration of their drapeability and formability. نسج عادي carbon fiber, for instance, is relatively easy to handle due to its balanced construction. In contrast, نسج الساتان carbon fiber offers superior drapeability, making it ideal for complex shapes.

| نوع النسيج | Drapeability | Formability |

|---|---|---|

| نسج عادي | معتدل | جيد |

| نسج الساتان | جيد | جيد جدًا |

| نسج الساتان | ممتاز | ممتاز |

Resin Systems and Compatibility

The choice of resin system is critical when working with carbon fiber weaves. Ensuring compatibility between the resin and the carbon fiber is vital for achieving the desired mechanical properties.

Different resin systems offer varying levels of performance, including temperature resistance and chemical resistance. Selecting the appropriate resin system depends on the specific application and the required properties of the final composite material.

خاتمة

Understanding the different weave patterns of carbon fiber is crucial for selecting the right material for various applications. This article has explored the characteristics, advantages, and uses of plain, twill, and satin weaves, providing a comprehensive summary of carbon fiber weaves.

The choice of weave pattern significantly affects the performance, aesthetics, and cost of carbon fiber products. By considering factors such as mechanical properties, drapeability, and visual appearance, manufacturers can make informed decisions to optimize their products.

In conclusion, the applications of carbon fiber are diverse, ranging from automotive and aerospace to sporting goods and industrial uses. As the demand for high-performance, lightweight materials continues to grow, understanding the conclusion on carbon fiber applications will be essential for industries looking to leverage these advanced materials.

By summarizing the key aspects of carbon fiber weave patterns, this article aims to provide a valuable resource for those seeking to understand the complexities of carbon fiber technology and its potential applications.

التعليمات

What is the difference between plain, twill, and satin weave carbon fiber?

The main difference lies in their weave patterns, which affect their appearance, strength, and performance. Plain weave has a simple, grid-like pattern, twill weave has a diagonal pattern, and satin weave has a smooth, glossy appearance with a prominent diagonal.

How do I choose the right carbon fiber weave for my project?

To choose the right weave, consider factors such as the desired appearance, required strength and performance, and budget. Assess your project’s specific needs, and balance performance, aesthetics, and cost.

ما هي فوائد استخدام ألياف الكربون؟

Carbon fiber offers exceptional strength-to-weight ratio, corrosion resistance, and durability, making it ideal for various applications, including aerospace, automotive, and sporting goods.

How do different weave patterns affect the drapeability and formability of carbon fiber?

Different weave patterns can significantly impact the drapeability and formability of carbon fiber. For example, satin weave is generally more drapeable than plain weave, while twill weave offers a balance between the two.

What are the common applications of plain, twill, and satin weave carbon fiber?

Plain weave is often used in high-strength applications, twill weave is used in a variety of applications, including aerospace and automotive, and satin weave is commonly used in high-end applications where appearance is critical.

How do I handle and fabricate carbon fiber materials?

Handling and fabrication techniques vary depending on the specific carbon fiber material. Generally, it’s essential to use proper safety equipment, follow manufacturer guidelines, and use compatible resin systems to ensure optimal results.

What are some common myths and misconceptions about carbon fiber weaves?

Common myths include the idea that a specific weave pattern is always superior or that carbon fiber is always the best choice. In reality, the best weave pattern depends on the specific application, and carbon fiber may not be suitable for every project.

What are the cost considerations when working with carbon fiber?

The cost of carbon fiber can vary significantly depending on the weave pattern, quality, and quantity. Generally, satin weave is more expensive than plain or twill weave, and high-quality materials command a premium price.

How do I assess the quality of carbon fiber materials?

To assess quality, look for factors such as fiber count, resin quality, and weave consistency. It’s also essential to work with reputable suppliers and follow industry standards.