هل تمنع صفائح الكربون المركبة التداخل الكهرومغناطيسي؟

-

جدول المحتويات

"ألواح الكربون المركبة: حماية المساحة الخاصة بك من التداخل الكهرومغناطيسي."

مقدمة

اكتسبت صفائح الكربون المركبة اهتمامًا واسعًا في مختلف الصناعات بفضل خفة وزنها ومتانتها العالية. ومن الاعتبارات المهمة في تطبيقاتها قدرتها على حجب أو تخفيف التداخل الكهرومغناطيسي (EMI). يمكن أن يُؤثر هذا التداخل سلبًا على أداء الأجهزة والأنظمة الإلكترونية، مما يجعل من الضروري استكشاف مواد قادرة على الحماية من هذا التداخل بفعالية. تتناول هذه المقدمة خصائص صفائح الكربون المركبة وفعاليتها في حجب التداخل الكهرومغناطيسي، مُسلّطةً الضوء على تطبيقاتها المُحتملة في قطاعات الطيران والسيارات والإلكترونيات، حيث تُعد الحماية من التداخل الكهرومغناطيسي أمرًا بالغ الأهمية.

صفائح الكربون المركبة: نظرة عامة على خصائص حجب التداخل الكهرومغناطيسي

حظيت صفائح الكربون المركبة باهتمام كبير في مختلف الصناعات نظرًا لخصائصها الفريدة، لا سيما في مجال حجب التداخل الكهرومغناطيسي (EMI). ومع تقدم التكنولوجيا وانتشار الأجهزة الإلكترونية، أصبحت الحاجة إلى حجب فعال للتداخل الكهرومغناطيسي ملحة بشكل متزايد. يمكن أن يُعطّل التداخل الكهرومغناطيسي أداء المعدات الإلكترونية الحساسة، مما يؤدي إلى أعطال وانخفاض الكفاءة. لذا، يُعدّ فهم قدرات صفائح الكربون المركبة في هذا السياق أمرًا بالغ الأهمية للمهندسين والمصنّعين على حد سواء.

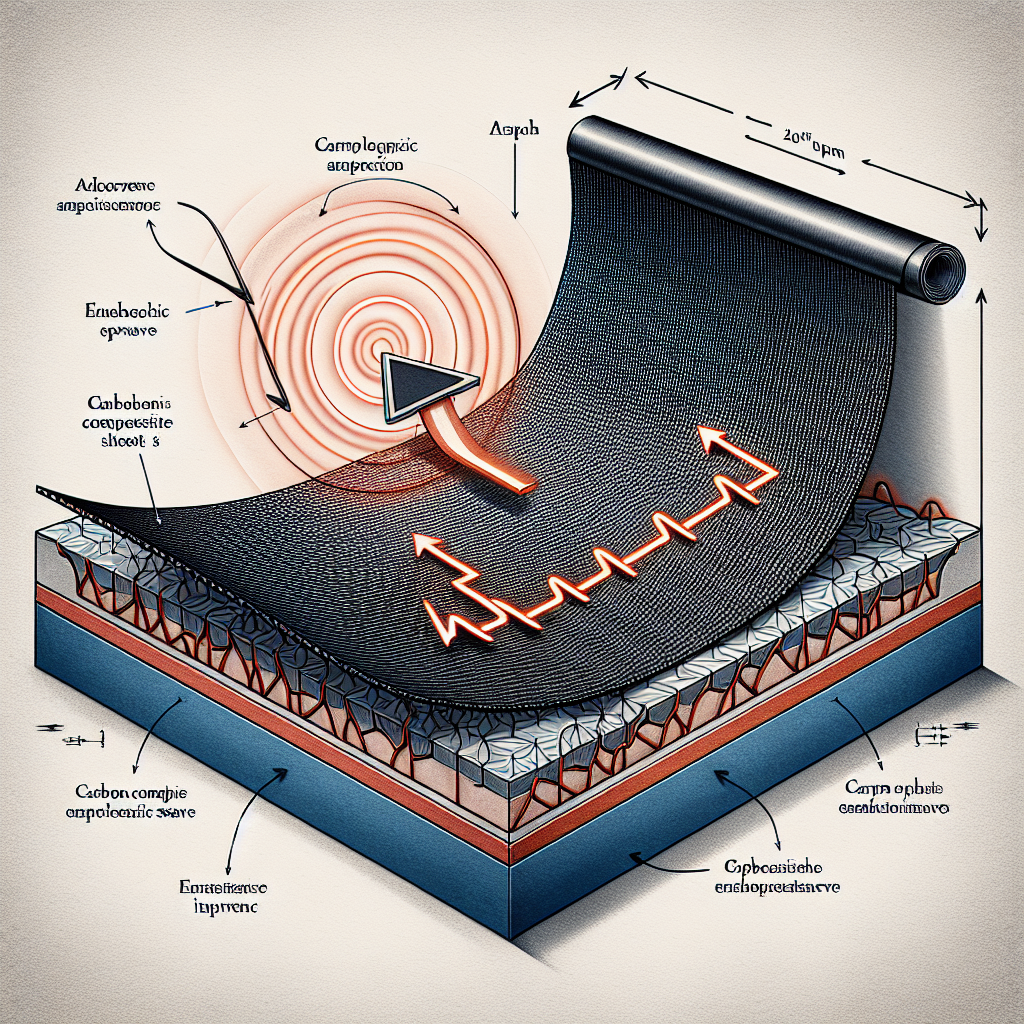

بدايةً، تُصنع مركبات الكربون من مزيج من ألياف الكربون ومصفوفة بوليمر. ينتج عن هذا المزيج مادة خفيفة الوزن ومتينة، تتميز بخصائص ميكانيكية ممتازة. بالإضافة إلى مزاياها الهيكلية، تتميز مركبات الكربون أيضًا بموصلية كهربائية طبيعية، وهو عامل أساسي في قدرتها على منع التداخل الكهرومغناطيسي. تسمح الطبيعة الموصلة لألياف الكربون لهذه المواد بامتصاص وعكس الموجات الكهرومغناطيسية، مما يقلل من كمية التداخل التي تخترق المكونات الإلكترونية الحساسة.

علاوة على ذلك، تتأثر فعالية صفائح الكربون المركبة في حجب التداخل الكهرومغناطيسي بعدة عوامل، منها سُمك المادة، واتجاه ألياف الكربون، وتردد الموجات الكهرومغناطيسية. توفر الصفائح السميكة عمومًا فعالية حماية أفضل، إذ توفر حاجزًا أكبر لاختراق الموجات. إضافةً إلى ذلك، يمكن أن يؤثر اتجاه ألياف الكربون على موصلية المادة؛ فالألياف المتراصة قد تُعزز خصائص الحماية في اتجاهات محددة، مما يجعل من الضروري مراعاة متطلبات التطبيق عند تصميم الصفائح المركبة للحماية من التداخل الكهرومغناطيسي.

بالإضافة إلى خصائصها الهيكلية والتوصيلية، يمكن تصميم صفائح الكربون المركبة لتعزيز قدرتها على حماية التداخل الكهرومغناطيسي. على سبيل المثال، يُمكن أن يُحسّن دمج مواد موصلة إضافية، مثل الجسيمات المعدنية أو الطلاءات، الأداء العام للمادة المركبة بشكل ملحوظ. يتيح هذا النهج الهجين حلولاً مُصممة خصيصاً لتلبية متطلبات حماية التداخل الكهرومغناطيسي المحددة في مختلف التطبيقات، من الفضاء إلى الإلكترونيات الاستهلاكية.

علاوة على ذلك، يمتد تنوع استخدامات صفائح الكربون المركبة إلى إمكانية تشكيلها بأشكال معقدة، وهو أمر مفيد بشكل خاص في التطبيقات ذات المساحة المحدودة. تُمكّن هذه القدرة على التكيف المصنّعين من ابتكار حلول مخصصة لا توفر حماية فعّالة من التداخل الكهرومغناطيسي فحسب، بل تحافظ أيضًا على السلامة الجمالية والوظيفية للأجهزة التي تحميها. ونتيجةً لذلك، يزداد استخدام مركبات الكربون في التطبيقات عالية الأداء حيث يُعدّ الوزن وحماية التداخل الكهرومغناطيسي من الاعتبارات الحاسمة.

تجدر الإشارة أيضًا إلى أن التأثير البيئي للمواد المركبة الكربونية يُمثل مصدر قلق متزايد. فبينما قد تكون الدروع المعدنية التقليدية ثقيلة الوزن وأقل ملاءمة للبيئة، تُقدم المواد المركبة الكربونية بديلاً أخف وزنًا يُسهم في ممارسات تصميم أكثر استدامة. ومع استمرار الصناعات في إعطاء الأولوية للحلول الصديقة للبيئة، من المرجح أن يزداد الطلب على صفائح الكربون المركبة ذات خصائص حجب التداخل الكهرومغناطيسي.

في الختام، تُقدم صفائح الكربون المُركبة حلاً واعداً لحجب التداخل الكهرومغناطيسي، بفضل مزيجها الفريد من القوة وخفة الوزن والتوصيل الكهربائي. كما أن إمكانية تخصيصها لتطبيقات مُحددة تُعزز جاذبيتها في مختلف الصناعات. ومع استمرار تطور التكنولوجيا وتزايد الحاجة إلى حجب فعال للتداخل الكهرومغناطيسي، من المُتوقع أن تلعب مواد الكربون المُركبة دوراً محورياً في ضمان موثوقية وأداء الأجهزة الإلكترونية. لذا، يُعد فهم خصائصها وتطبيقاتها المُحتملة أمراً بالغ الأهمية للعاملين في تصميم وتصنيع الأنظمة الإلكترونية الحديثة.

اختبار فعالية صفائح الكربون المركبة ضد التداخل الكهرومغناطيسي

أدى الاعتماد المتزايد على الأجهزة الإلكترونية في مختلف القطاعات إلى تزايد الحاجة إلى حلول فعّالة للحد من التداخل الكهرومغناطيسي (EMI). ونتيجةً لذلك، يستكشف الباحثون والمهندسون مواد مبتكرة توفر حمايةً من التداخل الكهرومغناطيسي، وتبرز صفائح الكربون المركبة كمرشح واعد. لفهم فعالية هذه المواد، من الضروري إجراء اختبارات دقيقة لتقييم قدرتها على حجب أو تخفيف الموجات الكهرومغناطيسية.

يتضمن اختبار فعالية صفائح الكربون المركبة ضد التداخل الكهرومغناطيسي (EMI) نهجًا منهجيًا يشمل التجارب المعملية والاختبارات الميدانية. في البداية، صُممت الاختبارات المعملية لقياس فعالية حجب الصفائح المركبة عبر نطاق ترددات مختلفة. يُعد هذا أمرًا بالغ الأهمية نظرًا لإمكانية حدوث التداخل الكهرومغناطيسي عند ترددات مختلفة، وقد يختلف أداء المادة تبعًا لذلك. باستخدام أساليب اختبار موحدة، كتلك الموضحة في معايير ASTM، يمكن للباحثين ضمان موثوقية نتائجهم وقابليتها للمقارنة مع المواد الأخرى.

من الطرق الشائعة لتقييم فعالية التدريع استخدام مُحلِّل شبكة المتجهات (VNA)، الذي يقيس معاملات انعكاس وانتقال الموجات الكهرومغناطيسية أثناء مرورها عبر صفائح الكربون المُركَّبة. بتحليل هذه المعاملات، يُمكن للباحثين حساب كمية التداخل الكهرومغناطيسي التي تحجبها المادة. تُعد هذه البيانات الكمية بالغة الأهمية، إذ تُوفِّر صورة واضحة عن أداء صفائح الكربون المُركَّبة في التطبيقات العملية.

بالإضافة إلى الاختبارات المعملية، تُعدّ الاختبارات الميدانية بنفس القدر من الأهمية لتقييم الفعالية العملية لصفائح الكربون المركبة في البيئات العملية. غالبًا ما تتضمن هذه الاختبارات وضع الصفائح المركبة بالقرب من الأجهزة الإلكترونية المعروفة بإصدارها تداخلًا كهرومغناطيسيًا، مثل المحركات، ومصادر الطاقة، ومعدات الاتصالات. من خلال قياس مستويات التداخل الكهرومغناطيسي بالقرب من هذه الأجهزة، مع وجود صفائح الكربون المركبة أو بدونها، يمكن للباحثين تقييم أداء المادة في ظل ظروف التشغيل الفعلية. يضمن هذا النهج المزدوج - الذي يجمع بين الاختبارات المعملية المُراقبة والتقييمات الميدانية العملية - فهمًا شاملًا لقدرات المادة.

علاوة على ذلك، من الضروري مراعاة تركيب وبنية صفائح الكربون المركبة نفسها، إذ تؤثر هذه العوامل بشكل كبير على خصائصها في حماية التداخل الكهرومغناطيسي. كما أن اختلاف نوع ألياف الكربون المستخدمة، ومادة المصفوفة، والسمك الكلي للصفائح، كلها عوامل تؤثر على فعاليتها. لذلك، غالبًا ما يجرب الباحثون تركيبات وتكوينات مختلفة لتحسين أداء الحماية. ولا تقتصر هذه العملية التكرارية على تحسين خصائص المادة فحسب، بل تُسهم أيضًا في تطوير حلول مُصممة خصيصًا لتطبيقات مُحددة.

مع تقدم الاختبارات، يتضح أن صفائح الكربون المركبة توفر قدرات حجب EMI ممتازة، خاصةً عند تصميمها لتطبيقات محددة. على سبيل المثال، في صناعات مثل الفضاء والسيارات، حيث يُعدّ الوزن والمساحة عاملين حاسمين، تُوفّر صفائح الكربون المركبة خفيفة الوزن حلاً فعالاً دون إضافة حجم كبير. علاوة على ذلك، فإن متانة هذه المواد ومقاومتها للتآكل تجعلها مناسبة للاستخدام طويل الأمد في البيئات الصعبة.

في الختام، يكشف اختبار صفائح الكربون المركبة ضد التداخل الكهرومغناطيسي عن إمكاناتها كمواد حجب فعالة. ومن خلال الجمع بين الاختبارات المعملية والميدانية، يمكن للباحثين اكتساب رؤى قيّمة حول أدائها في مختلف الترددات والظروف. ومع استمرار تزايد الطلب على حجب موثوق للتداخل الكهرومغناطيسي، من المرجح أن يؤدي البحث المستمر في مواد الكربون المركبة إلى حلول مبتكرة تُحسّن وظائف الأجهزة الإلكترونية وموثوقيتها في مختلف الصناعات.

تطبيقات صفائح الكربون المركبة في حلول حماية EMI

برزت صفائح الكربون المركبة كمواد أساسية في مختلف الصناعات، لا سيما في مجال حلول حماية التداخل الكهرومغناطيسي (EMI). ومع التطور التكنولوجي المتواصل، ازدادت الحاجة إلى حماية فعّالة من التداخل الكهرومغناطيسي، لا سيما في قطاعات مثل الاتصالات والفضاء والسيارات. وتجعلها خصائصها الفريدة، بما في ذلك خفة وزنها ومتانتها الميكانيكية وموصليتها الكهربائية، خيارًا مثاليًا لمواجهة تحديات التداخل الكهرومغناطيسي.

من التطبيقات الرئيسية لصفائح الكربون المركبة في مجال حجب التداخل الكهرومغناطيسي تصميم علب الأجهزة الإلكترونية. تُعد هذه العلب أساسية لحماية المكونات الحساسة من المجالات الكهرومغناطيسية الخارجية التي قد تُعطل وظائفها. ومن خلال دمج صفائح الكربون المركبة في تصميم هذه العلب، يُمكن للمصنعين تحقيق توازن بين تقليل الوزن وفعالية الحجب. تسمح الموصلية المتأصلة لمواد الكربون بتبديد الموجات الكهرومغناطيسية، مما يُقلل التداخل ويُحسّن أداء الأجهزة الإلكترونية.

علاوة على ذلك، يمتد تنوع استخدامات صفائح الكربون المركبة ليشمل تطبيقات السيارات. فمع تزايد تجهيز المركبات بأنظمة إلكترونية متطورة، يزداد احتمال حدوث مشاكل تتعلق بالتداخل الكهرومغناطيسي. يمكن دمج صفائح الكربون المركبة في أجزاء مختلفة من المركبة، مثل لوحات القيادة ولوحات التحكم، لتوفير الحماية اللازمة دون زيادة وزنها بشكل كبير. ويكتسب هذا أهمية خاصة في صناعة السيارات، حيث تُعدّ كفاءة استهلاك الوقود والأداء أمرًا بالغ الأهمية. وباستخدام صفائح الكربون المركبة، يمكن للمصنعين ضمان عمل الأنظمة الإلكترونية بكفاءة مع الحفاظ على الكفاءة الإجمالية للمركبة.

بالإضافة إلى تطبيقات السيارات، أدركت صناعة الطيران والفضاء فوائد صفائح الكربون المركبة في حجب التداخل الكهرومغناطيسي. فالطائرات مزودة بأنظمة إلكترونية متعددة تعمل بسلاسة لضمان السلامة والأداء. وتُعد خفة وزن مركبات الكربون ميزةً مميزةً في تطبيقات الطيران والفضاء، حيث يُحدث كل غرام منها فرقًا كبيرًا. ومن خلال استخدام هذه المواد في المجالات الحساسة، يُمكن للمصنعين تعزيز التوافق الكهرومغناطيسي للطائرات، مما يُقلل من خطر التداخل الذي قد يُؤثر سلبًا على عمليات الطيران.

علاوة على ذلك، ازداد استخدام صفائح الكربون المركبة في البنية التحتية للاتصالات. ومع تزايد الطلب على أنظمة اتصالات أسرع وأكثر موثوقية، تزداد الحاجة إلى حجب فعال للتداخل الكهرومغناطيسي. يمكن استخدام صفائح الكربون المركبة في بناء الهوائيات ومحطات القاعدة وأجهزة الاتصالات الأخرى لتخفيف التداخل من المعدات الإلكترونية المحيطة. لا يقتصر هذا الاستخدام على تحسين أداء أنظمة الاتصالات فحسب، بل يساهم أيضًا في إطالة عمر المعدات من خلال حمايتها من التلف المحتمل الناتج عن التعرض الكهرومغناطيسي.

يتماشى التحول من المواد التقليدية إلى صفائح الكربون المركبة لحلول حماية التداخل الكهرومغناطيسي مع التركيز المتزايد على الاستدامة. يمكن إنتاج مركبات الكربون باستخدام مواد مُعاد تدويرها، مما يُقلل من الأثر البيئي لعمليات التصنيع. ويُعد هذا الجانب جذابًا بشكل خاص للصناعات التي تُركز بشكل متزايد على تقليل بصمتها الكربونية وتعزيز الممارسات الصديقة للبيئة.

في الختام، تتعدد استخدامات صفائح الكربون المركبة في حلول حجب التداخل الكهرومغناطيسي، وتغطي قطاعات متعددة مثل السيارات والفضاء والاتصالات. خصائصها الفريدة، بما في ذلك خفة وزنها ومتانتها الميكانيكية وكفاءتها في تبديد الموجات الكهرومغناطيسية، تجعلها خيارًا مثاليًا لمواجهة تحديات التداخل الكهرومغناطيسي. مع التطور التكنولوجي المستمر، سيزداد دور مركبات الكربون في تحسين أداء الأنظمة الإلكترونية وموثوقيتها بلا شك، مما يمهد الطريق لحلول مبتكرة تلبي متطلبات المشهد التكنولوجي سريع التطور.

الأسئلة والأجوبة

1. **السؤال:** هل تعمل صفائح الكربون المركبة على منع التداخل الكهرومغناطيسي (EMI) بشكل فعال؟

**الإجابة:** يمكن لألواح الكربون المركبة أن تخفف من التداخل الكهرومغناطيسي إلى حد ما بسبب خصائصها التوصيلية، ولكنها ليست فعالة مثل مواد الحماية من التداخل الكهرومغناطيسي المخصصة.

2. **السؤال:** ما هي العوامل التي تؤثر على فعالية صفائح الكربون المركبة في منع التداخل الكهرومغناطيسي؟

**الإجابة:** تعتمد الفعالية على عوامل مثل سمك المادة المركبة، وتردد الموجات الكهرومغناطيسية، والتركيبة المحددة للمادة المركبة الكربونية.

3. **السؤال:** هل هناك تطبيقات محددة حيث يتم استخدام صفائح الكربون المركبة للحماية من التداخل الكهرومغناطيسي؟

**الإجابة:** نعم، تُستخدم صفائح الكربون المركبة في تطبيقات مثل صناعات الطيران والسيارات، حيث تكون هناك حاجة إلى مواد خفيفة الوزن إلى جانب مستوى معين من الحماية من التداخل الكهرومغناطيسي.